Professional Documents

Culture Documents

Mathematical Modeling and Simulation of Permanent Magnet Synchronous Machine

Uploaded by

Faiza OuiddirOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mathematical Modeling and Simulation of Permanent Magnet Synchronous Machine

Uploaded by

Faiza OuiddirCopyright:

Available Formats

International Journal of Electronics and Electrical Engineering Vol. 1, No.

2, June 2013

Mathematical Modeling and Simulation of

Permanent Magnet Synchronous Machine

Mrs. S S Kulkarni

Department of Electrical Engineering, College of Engineering, Jalgaon, Maharashrtra State, India.

sskharkar@gmail.com

A G Thosar

Department of Electrical Engineering, College of Engineering, Aurangabad, Maharashrtra State, India.

aprevenkar@gmail.com

Abstract—Rapid developments are occurring in design of The survey indicates that the stator related faults are

electrical machines and its control. To get optimum major faults around 35-40% and are related to the stator

performance under normal/fault condition needs winding insulation and core. The terminal connector

implementation of fault tolerance. Next decade is of

Permanent Magnet Synchronous Machines. The paper failure may also result in winding faults. Stator winding

presents mathematical modeling of PMSM. A current and related failures can be divided into winding open circuit

speed controller is designed to implement fault tolerance fault, winding short circuit fault and winding turn to turn

and its stability analysis. short circuit fault, winding to ground short circuit fault.

These faults are the consequence of long term or

Index Terms—PMSM, fault tolerance, mathematical model overstressed operation in the motor drive. The second set

of faults is magnetic or mechanical. Among these faults

are partial demagnetization of the rotor magnets, rotor

I. INTRODUCTION

eccentricity.

Performance of motor control systems contribute to a Feature of a fault tolerant system is the ability to detect

great extent to the desirable performance of drive. the fault and then to clear it. Based on this, the optimal

Existing motors in the market are the Direct Current and excitation for the stator winding has to be calculated. This

Alternative Current motors, synchronous and data is stored in the memory and in case of a fault the

asynchronous motors. These motors, when properly optimal currents would be applied to the remaining

controlled and excited produce constant instantaneous healthy phases to get the maximum torque per ampere in

torque the output. This needs deriving a mathematical model in

A. Objective of Problem suitable form [2].

In what respect PMSM are better and whether motor

be designed from few watts to mega watt with stable II. MATHEMATICAL MODEL OF PMSM

operation In PMSM the inductances vary as a function of the

B. Classification of Faults in PMSM rotor angle. The two-phase (d-q) equivalent circuit model

is used for analysis. The space vector form of the stator

Replacing rotor field windings and pole structure with

voltage equation in the stationary reference frame is

permanent magnets makes the motor as brushless motors.

Permanent Magnet Synchronous Machines (PMSM) can given as:

be designed with any even number poles. Greater the vs= rsis + dλs/dt (2.1)

number of poles produces greater torque for the same

level of current [1]. Surface Mounted PMSM and Interior where rs , Vs , is , and λs are the resistance of the stator

PMSM are two types of PMSMs. In SPMSM magnets are winding, complex space vectors of the three phase stator

mounted on the rotor, air gap is large hence armature voltages, currents, and flux linkages, all expressed in the

reaction is negligible. Whereas in IPMSM, magnets are stationary reference frame fixed to the stator, respectively.

buried inside the rotor,rotor is robust and airgap is They are defined as:

uniform hence suitable for high speed operation. Most vs= [vsa (t) + avsb (t) + a2vsc (t)]

frequently occurring faults in PMSM can be classified as: is=[isa (t) + aisb (t) + a2isc (t)] (2.2)

Faults related to electrical structure λs=[λsa (t) + aλsb (t) + a2λsc (t)]

Faults related to mechanical structure

Manuscript received March 1, 2013; revised June 12, 2013.

©2013 Engineering and Technology Publishing 66

doi: 10.12720/ijeee.1.2.66-71

International Journal of Electronics and Electrical Engineering Vol. 1, No. 2, June 2013

Lss=

Lls + L0 – Lms cos 2θ -.5L0- Lms cos 2(θ-π/3) .5L0- Lms cos 2(θ+ π/3)

-.5L0- Lms cos 2(θ-π/3) Lls + L0 – Lms cos 2(θ-2π/3) -.5L0- Lms cos 2(θ-π)

- .5L0- Lms cos2(θ+ π/3)-.5L0- Lms cos 2(θ+π) Lls+ L0 – Lms cos 2(θ+

2π/3)

(2.6)

It is evident from the above equation that the elements

of Lss are a function of the rotor angle which varies with

time at the rate of the speed of rotation of the rotor. Under

a three-phase balanced system with no rotor damping

circuit and knowing the flux linkages, stator currents, and

resistances of the motor, the electrical three-phase

dynamic equation in terms of phase variables can be

Figure 1. Schematic representation of a two-pole, three-phase arranged in matrix form similar to that of (2.1) and

permanent magnet synchronous machine. written as:

[vs]=[rs][is]+d/dt[λs] (2.7)

Fig. 1 illustrates a conceptual cross-sectional view of a

where, [vs] = [vsa, vsb, vsc ]t

three-phase, two-pole surface mounted PMSM along with

the two-phase d-q rotating reference frame. Symbols used [Is] = [isa, Isb, I sc ]t

in (2.2) are explained in detail below:a, and a2 are spatial [rs]=[ra,rb,rc]t (2.8)

operators for orientation of the stator windings, a = e j2π/3 [λs] = [λsa, λsb, λsc ]t

and a2 = e j4π/3. vsa, vsb, vsc. are the values of stator

In (2.7), vs, is, and λs refer to the three-phase stator

instantaneous phase voltages. isa, isb, isc are the values of

voltages, currents, and flux linkages in matrix forms as

stator instantaneous phase currents. λsa, λsb, λsc are the

shown in equation(2.8) respectively. Further all the phase

stator flux linkages and are given by:

resistances are equal and constant, rs= ra = rb= rc

λsa = Laaia + Labib + Lacic + λra

A. Park’s Transformation

λsb=Labia+ Lbbib + Lbcic + λrb (2.3)

λsc = Lacia + Lbcib + Lccic + λrc As Lss presents computational difficulty (in equation,

2.1) when used to solve the phase quantities directly. To

where Laa, Lbb, and Lcc, and are the self-inductances of the obtain the phase currents from the flux linkages, the

stator a,b and c-phase respectively. Lab, Lbc and Lca, are inverse of the time varying inductance matrix will have to

the mutual inductances between the ab, bc and ac phases

be computed at every time step [4]. The computation of

respectively [3]. λra, λrb and λrc are the flux linkages that

the inverse at every time step is time-consuming and

change depending on the rotor angle established in the

could produce numerical stability problems. To remove

stator a, b, and c phase windings respectively due to the

presence of the permanent magnets on the rotor. They are the time-varying quantities in voltages, currents, flux

expressed as: linkages and phase inductances, stator quantities are

transformed to a d-q rotating reference frame using

λra= λr cosθ Park’s transformation. This results in the above equations

λrb= λr cos (θ -120°) (2.4) having time-invariant coefficients. The idealized

λrc= λr cos (θ +120°) machines have the rotor windings along the d- and q-axes.

In equation (2.4), λr represents the peak flux linkage Stator winding quantities need transformation from three-

due to the permanent magnet. It is often referred to as the phase to two-phase d-q rotor rotating reference frame.

back-emf constant. Note that in the flux linkage equations, Park’s transformation is used to transform the stator

inductances are the functions of the rotor angle. Self- quantities to d-q reference frame, the d-axis aligned with

inductance of the stator a-phase winding, Laa including the magnetic axis of the rotor and q-axis is leading the d

leakage inductance and a and b-phase mutual inductance, axis by π/2 as shown in Fig.1. The original d-q Park’s

Transformation [Tdq0 ] is applied to the stator quantities

Lab= Lbc have the form:

Laa= Lls + L0 - Lms cos (2θ) (2.5) n in equation 2.7 is given by:

Lab = Lba = ½ L0 - Lms cos (2θ ) [vdq0] = [Tdq0 (θr)][vs]

where Lls is the leakage inductance of the stator winding [idq0]=[Tdq0(θr)][is] (2.9)

due to the armature leakage flux.L0 is the average

inductance due to the space fundamental air-gap flux; L0 [λdq0] = [Tdq0 (θr)][λs]

= ½ (Lq + Ld), Lms is the inductance fluctuation (saliency); Where

due to the rotor position dependent on flux Lms= ½ (Ld – [vdq0]=[vdvqv0] (2.10)

Lq).Similar to that of Laa but with θ replaced by (θ-2π/3) -1 -1

[vdq0]=[Tdq0(θr)][rs][Tdq0(θr)] [idq0]+[Tdq0r)]p[Tdq0(θr)] [dq0](2.11)

and (θ-4π/3)for b-phase and c-phases self-inductances.

Lbb and Lcc, can also be obtained similarly. All stator [Tdq0 6 磅(θr)][rs][Tdq0(θr)] -1[idq0]=rs[idq0] (2.12)

inductances are represented in matrix form below:

©2013 Engineering and Technology Publishing 67

International Journal of Electronics and Electrical Engineering Vol. 1, No. 2, June 2013

The model of PMSM without damper winding has current is zero. Desirable currents for zero torque ripple

been developed using the following assumptions: operation assuming i1=Im sin θ, i2=Im sin(θ-1200), i3=Im

Saturation is neglected. sin(θ+1200)

The induced EMF is sinusoidal. Here, Im is peak value of phase current [5]. Hence for

Eddy currents and hysteresis losses are negligible. healthy operation the total output torque for single motor

There are no field current dynamics. drive is T0 =(3/2)KeIm0.

Voltage equations are given by: If phase 1 is open circuited and no fault remedial

strategies are adopted, the total output torque is given by

vd = Rs id – ωrλq + Tf0 =KeIm(1+0.5cos2θ)

Here Tf0 is torque under faulty condition

vq=Rsiq–ωrλd+ (2.18)

B. Winding Short Circuit Fault Analysis

λdλ=Ldid+λf

The winding short circuit fault is the most critical fault.

λq=Lqiq (2.19)

Equivalent circuit of winding short circuit fault and

Substituting equations 2.19 in 2.18: switch short circuit fault and its waveforms are shown in

Vd = Rsid – ωrLqiq + (Ldid+ λf) Fig. 2 and Fig. 3.

Vq = Rsiq – ωrLqiq + (Lqiq) (2.20)

The developed torque is given by

Te=1.5(P/2)( λdiq- λqid) (2.22)

The mechanical Torque equation is

Tm=TL+Bωm+J(dωm/dt) (2.23)

Solving for the rotor mechanical speed from equation

2.23

ωm= ([(Te - TL - Bωm)/J]dt

ωm= ωr(2/P) (2.24)

Figure 2. Winding short circuit fault waveform.

In the above equations ωr is the rotor electrical speed

where as ωm is the rotor mechanical speed.

III. MATHEMATICAL MODEL OF REFERENCE

CURRENT CALCULATION

The back emf voltages of an n-phase fault tolerant PM

motor drive can be given as

ej = Ke ω ej (θ) ( 3.1)

Here j is an integer representing the phase number of the

motor(j= 1,2,3…n.) The output torque T0 with two phases

Figure 3. Switch short circuit fault waveform.

can be expressed as a function of the phase currents and

corresponding back emf voltages as For a sinusoidal back emf, during short circuit fault

T0=Ke[e1i1+e2i2] (3.2) operation, a short circuit current Isc will be generated in

the winding and the peak steady state current is given by

Here i1 and i2 are instantaneous phase currents. From

equation (1.2) current i2 can be derived as: Iscm = Em/(√(R2+[ωmL] 2

i2=[(T0/ke)-e1i1]/e2 But Em is function of rotor speed and back emf

2 2 constant I sc = Keωm // (√(R2+[ωmL] 2

Pcu=(i1 +i2 )R (3.3) Corresponding copper loss is expressed as

R is resistance of phase winding. For copper loss to be Pcusc= (Iscm2 /√2)2

minimum, Y=(i12+i22) should be minimum Tdrag = I sc Em cos φ /2ωm, cos φ =R/(√(R2+[ωmL] 2

Y=i12+(1/e22)[(T02/ke2)-2*(T0/ke)e1i1+e12] Tdrag = I sc Em cos φ /2ωm = Ke 2 R ωm /2* ((R2+[ωmL] 2)

i1=[e1/(e12+e22)] (T0/ke) (3.4) Assuming base voltage is equal to back emf voltage at

rated rotor speed. Base current is equal to winding short

i2=[e2/(e12+e22)] (T0/ke) circuit current

A. Fault Analysis in Fault Tolerant Motor Drives Isc = ωm /(√Rpu2+(ωpu +Lpu)2

Winding open circuit fault is the most common fault Tavedrag = ωpuRpu / Rpu2+ (ωpu +Lpu)2

and detected by the phase current sensor when the phase Pcuscu = ωpu2Rpu / Rpu2+ (ωpu +Lpu)2

©2013 Engineering and Technology Publishing 68

International Journal of Electronics and Electrical Engineering Vol. 1, No. 2, June 2013

Where Rpu and Lpu represent the per unit resistance and GOL(s)=Gsam(s)*Gc(s)*GCA(s)GPL(s)

the inductance of the short circuited windings. ω pu is the =[1/(0.5Tss+1)]*[kpi(1+Tiis)/Tiis][1/(Tss+1)]*[ K/(

per unit value of the angular speed the motor. This needs 1+sTq)]

reference current controller to be designed [6].

The slowest pole is the one of PMSM transfer function

C. Current Controller Design and is meant to cancel the zero of controller, making the

The error between reference speed and measured speed system more stable. This implies

is send to a PI controller. Since d and q axis controller are (1+Tiis)→ (1+sTq)→ Tii

identical tuning of q axis controller is sufficient. Structure

of q axis current controller is shown in Fig. 4. Tq = Ls/Rs =0.116sec

In order to simplify the transfer function a time

constant is introduced [8]. It represents the approximation

1

Iref

of first order transfer function that introduce delays. Its

1 1

PI

s+1 s+1

1 transfer function will be replaced by a unique transfer

Iq

PI Controller control algorithm plant function of first order having the time constant equal to

sampling

the sum of all the time constants from the system.

1

Tsi = 1.5Ts=0.3msec

.5s+1

With above assumptions the open loop transfer

Figure 4. Q axis current controller. function of second order system has the form

Gom(s)=1/2ζs(ζs+1)

PI controller offers a zero steady state error. Its transfer

function is Gc(s)=U(s)/E(s) Kpi K/Tii =(1/2*Tsi)

= Kpi

= kpi+kii/s

= (Tii Rs )/(2*Tsi)

= kpi (1+Tiis)/ Tiis =3.333

where kpi is proportional gain, Kii is integrator gain Tii Thus Pi transfer function is

integrator time constant. It is a ratio between Kpi and Kii

Gc(s)=3.33+(300/s)

Tii= Kpi/ Kii ,Ts=0.2 ms

The bode diagram of the q axis current controller is

Gpe(s)= iq(s)/Uq(s) shown in Fig. 6.

=1/Rs+sLs=1/ Rs (1+s Ls/Rs) 100

Bode Diagram

= K/(1+sTq) k=1/Rs Rs-stator resistance 50

Magnitude (dB)

System: sys

Frequency (rad/sec): 2.79

Tq= Ls/Rs =0.116sec is the time constant of the motor 0 Magnitude (dB): -18.3

The feedback is the delay introduced by digital to -50

analog conversion. It is a first order transfer function with -100

time constant Ts -90

Gsam(s)= 1/(0.5 Ts s+1)

Phase (deg)

-135

Thus modified q axis controller with unity feedback is

shown in Fig. 5 below [7]. -180

-2 -1 0 1 2

10 10 10 10 10

Frequency (rad/sec)

Figure 6. Bode plot of q axis controller .

1 1 1

1 In1Out1 1 GM=19.1dB, PM=63.6,

s+1 s+1 s+1 Closed loop system stable? yes

iqmea Maximum overshoot Mp= 4.32 %

1/(0.5Ts S+1) sampling PI Control Algorithm Pl a nt (1 / . L s+Rs) Settling time ts=2.53 ms , Rise time tr= 0.912 ms

D. Design of Speed Controller

The speed controller block diagram is shown below

The transfer function of Pi controller is given by

Gc(s)= Kps(1+Tiss)/ Tiss

Figure 5. Modified q axis current controller. Where Kps is the proportional gain of the speed controller

and Tis is the time constant. The delay introduced by the

The open loop transfer function is given by digital calculations is representing the control algorithm

©2013 Engineering and Technology Publishing 69

International Journal of Electronics and Electrical Engineering Vol. 1, No. 2, June 2013

[9]. Transfer function has the form of a first order system

with time constant Ts=0.2ms=1/5k=1/fs, GA(s) =1/1+Tss Step Response

The current control loop can be expressed like a first

order system Tiq=Tii Rs /Kpi

TF= Gc(s)=1/(1+Tiqs)

The mechanical equation of PMSM is given by

Amplitude

Tm=Jdwm/dt +Bwm +TL

TL is the load torque and is considered as disturbance

hence will not be considered. Filter has time constant

Tf=1/wc=1/2πf=0.796 ms

The sampling block introduces delay for digital to

analog conversion and is equal to Ts,

0 5 10 15 20 25 30 35 40 45 50

Time (sec)

Gsam(s)=1/0.5Tss+1

Figure 9. Step response for modified system.

Thus sampling the TF, the disturbances are not taken

into consideration. The closed loop system is modified

Its bode plot and step response is shown in Fig. 8 and

with unity feedback as shown below [10].

Fig. 9.

GM=13(dB) at 689 rad/sec

1 1 1 1 PM=34.89deg) at 300 rad/ sec

1 1 1 1

s+1 0.5s+1 s+1 s+1

wm Closed loop system is stable? yes

(1+s)(0.5s+1) filter sampling PI Mech time Current control gain control

IV. CONCLUSION

The mathematical model helps to design reference

current controller needed to design fault tolerant system.

Figure 7. Modified closed loop current control system. The design of the current and speed controllers are

Its open loop transfer function: necessary for good implementation of control strategy.

GOL(s)=[1/(0.5Tss+1)(Tfss+1)][Kps(1+Tiss)/iss)]*[1/Tss+1][ 1/(1+Tiqs

As shown by bode plot for current and speed controller,

)] the system is second order hence stable. Further use of

permanent magnets helps in reduction of size and gives

In order to simplify the transfer function all the time higher current, torque and speed compared to machine

constants of the delays are approximated with one time

with electromagnets. The only drawback is higher cost of

constant:

magnets.

Tss=1.5Ts +Tf+Tiq = 1.8 ms

So, the open loop transfer function becomes: REFERENCES

2 [1] H. Amano, “Characteristics of a permanent-magnet synchronous

GOL(s)=kc Kps (1+Tiss)/JTiss (1+Tsss)

motor with a dual-molding permanent-magnet rotor,” IEEE

With kc=1.5*λm , Kps=1/k1T1=0.462, Power Engineering Society General Meeting, 2007, pp 1298-

1304.

Tis=4T1 =4Tss [2] M. I. A. El-Sebahy, “PMSM position control with a SUI PID

controller”, IEEE, 2009, pp. 516-526.

200

Bode Diagram [3] N. C. Kar, “A new method to evaluate the q-axis saturation

characteristic of cylindrical-rotor synchronous generator,” IEEE,

100 2000, pp. 269-276.

[4] V. Comnac, “Sensor less speed and direct torque control of

Magnitude (dB)

0

surface permanent magnet synchronous machines using an

-100 extended kalman filter,” IEEE, 2001, pp. 217-226.

[5] Radovan, Jaroslav, “Traction permanent magnet synchronous

-200 motor torque control with flux weakening,” Radio Engg, pp. 601-

-300

610, 2009.

-90 [6] A. Hassanpour, “Design of a permanent magnet synchronous

machine for the hybrid electric vehicle,” WAS, pp. 566-576,

2007

Phase (deg)

[7] Z. Zhang, “Study on novel twelve-phase synchronous generator

-135

rectifier system,” DRPT, 2008, pp. 2270-2274.

[8] S. Bologani, “Experimental fault-tolerant control of a PMSM

drive,” IEEE, 2000, pp. 1134-1141.

-180 [9] F. Morer, “Permanent magnet synchronous machine hybrid

1 2 3 4 5 6

10 10 10 10 10 10 torque control,” IEEE, 2008, pp. 501-511.

Frequency (rad/sec) [10] Y. Jeong, “Fault detection and fault-tolerant control of interior

permanent-magnet motor drive system for electric vehicle,” IEEE,

Figure 8. Bode plot for modified system. 2005, pp. 46-50.

©2013 Engineering and Technology Publishing 70

International Journal of Electronics and Electrical Engineering Vol. 1, No. 2, June 2013

ACKNOWLEDGEMENT Dr. Mrs. A G Thosar, was born in 1971. In 1992

she had completed her graduation in Electrical

The authors wish to thank to Govt. College of Engg from Walchand College of Engineering,

Engineering, Aurangabad (M.S.),India for pursuing Sangli, Shivaji University, Kolhapur (M.S.), India.

She received her Post Graduation degree in Control

research. Systems in 1997 from the same institute. She

gained her PhD from IIT Kharagpur, India in 2010.

Mrs. S S Kulkarni is assistant professor with Now she is working as associate professor, with

Department of Electrical Engineering, Govt. Department of Electrical Engineering, Govt.

College of Engineering, Jalgaon,(M.S.),India and College of Engineering, Aurangabad, (M.S.), India. Her areas of

persuing her research under the guidance of Dr. A G interests are automatic control systems, fault tolerance. She has

Thosar. Her area of interest is fault tolerant control, published many papers in various national, international conferences

control of drives. She has published five papers in and journals.

national and international conferences.

©2013 Engineering and Technology Publishing 71

You might also like

- A Time-Stepping Coupled Finite Element-State Space Model For Im DrivesDocument3 pagesA Time-Stepping Coupled Finite Element-State Space Model For Im Drivessajs201100% (1)

- IJCER (WWW - Ijceronline.com) International Journal of Computational Engineering ResearchDocument5 pagesIJCER (WWW - Ijceronline.com) International Journal of Computational Engineering ResearchInternational Journal of computational Engineering research (IJCER)No ratings yet

- Differential Forms on Electromagnetic NetworksFrom EverandDifferential Forms on Electromagnetic NetworksRating: 4 out of 5 stars4/5 (1)

- Simulation and Analysis of Modified DTC of PMSMDocument10 pagesSimulation and Analysis of Modified DTC of PMSMpreetivermaeeeNo ratings yet

- DQ InductanceDocument11 pagesDQ Inductancegthulasi789193No ratings yet

- Handbook of Power Systems Engineering with Power Electronics ApplicationsFrom EverandHandbook of Power Systems Engineering with Power Electronics ApplicationsNo ratings yet

- Extreme Possibilities of Circuital Models of Electric MachinesDocument10 pagesExtreme Possibilities of Circuital Models of Electric Machinesmherold2No ratings yet

- Characteristic Modes: Theory and Applications in Antenna EngineeringFrom EverandCharacteristic Modes: Theory and Applications in Antenna EngineeringNo ratings yet

- Permanent Magnet Synchronous MachineDocument7 pagesPermanent Magnet Synchronous MachineSantiago DavidNo ratings yet

- Simulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetFrom EverandSimulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetNo ratings yet

- Meng-Jen Chen, Yu-Chi Wu, Jie-Lu Liao, Jin-Yuan Lin, Hsien-Yin Chiang, and Wen-Liang HuangDocument10 pagesMeng-Jen Chen, Yu-Chi Wu, Jie-Lu Liao, Jin-Yuan Lin, Hsien-Yin Chiang, and Wen-Liang HuangGeet DeokateNo ratings yet

- Simulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetFrom EverandSimulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetRating: 2 out of 5 stars2/5 (1)

- Simulation of Six Phase Permanent Magnet Synchronous Generator in MATLABDocument5 pagesSimulation of Six Phase Permanent Magnet Synchronous Generator in MATLABجمال ضيفيNo ratings yet

- Articol 9Document6 pagesArticol 9Constantin DorinelNo ratings yet

- Modeling and Parameter Identification of A Double-Star Induction MachinesDocument7 pagesModeling and Parameter Identification of A Double-Star Induction MachineshaimantiNo ratings yet

- Rotor Flux Estimation Using Voltage Model of Induction MotorDocument5 pagesRotor Flux Estimation Using Voltage Model of Induction MotorBobby RinaldiNo ratings yet

- 87 Kutt Michna PopDocument6 pages87 Kutt Michna PopVally ZazaNo ratings yet

- Understanding Switched Reluctance Motor Analysis Using ANSYS/MaxwellDocument5 pagesUnderstanding Switched Reluctance Motor Analysis Using ANSYS/MaxwellItsMeASNo ratings yet

- Mathematical Driving Model of Three Phase Induction Motors in Stationary Coordinate FrameDocument11 pagesMathematical Driving Model of Three Phase Induction Motors in Stationary Coordinate Framegodspower brunoNo ratings yet

- Modeling &torque Ripple Minimization of Switched Reluctance Motor For High Speed ApplicationsDocument6 pagesModeling &torque Ripple Minimization of Switched Reluctance Motor For High Speed ApplicationsMoon3pellNo ratings yet

- Short Circuit Current Duties of Circuit Breakers and Fuses - Part 1Document6 pagesShort Circuit Current Duties of Circuit Breakers and Fuses - Part 1rajuanthatiNo ratings yet

- Ying 99Document6 pagesYing 99Vladimir GeorgievskiNo ratings yet

- Jaswant Scopus PaperDocument15 pagesJaswant Scopus PaperpreetivermaeeeNo ratings yet

- Comparison Between Foc and DTC Strategies For Permanent Magnet Synchronous MotorsDocument6 pagesComparison Between Foc and DTC Strategies For Permanent Magnet Synchronous MotorsaasfklNo ratings yet

- PMSM ModelDocument6 pagesPMSM ModelAditya SinghNo ratings yet

- Direct Torque Control (DTC) of PMSM Using Space Vector Modulated Inverter: A Simulink ApproachDocument4 pagesDirect Torque Control (DTC) of PMSM Using Space Vector Modulated Inverter: A Simulink ApproachKushagra KhamesraNo ratings yet

- Short Circuit Current Duties of Circuit Breakers and FusesDocument13 pagesShort Circuit Current Duties of Circuit Breakers and Fuseskra_amNo ratings yet

- Modelling of A 3-Phase Induction Motor Under Open-Phase - 2016Document7 pagesModelling of A 3-Phase Induction Motor Under Open-Phase - 2016laith fadhilNo ratings yet

- 12 Nilaykumar PatelDocument7 pages12 Nilaykumar Patelmohammed dawNo ratings yet

- A Modified Sensorless Control of Induction Motor Based On Reactive PowerDocument4 pagesA Modified Sensorless Control of Induction Motor Based On Reactive PowerSherif M. DabourNo ratings yet

- D6 Transmission Model Parameter Draft1-2 - 9!3!2010Document38 pagesD6 Transmission Model Parameter Draft1-2 - 9!3!2010فیضان حنیفNo ratings yet

- Dynamic Model of Induction Motors For Vector ControlDocument10 pagesDynamic Model of Induction Motors For Vector ControlMarica RalucaNo ratings yet

- Modeling and Simulation of Six-Phase Permanent Magnet Synchronous Motor DriveDocument9 pagesModeling and Simulation of Six-Phase Permanent Magnet Synchronous Motor Driveجمال ضيفي100% (1)

- IPMSM Inductances Calculation Using FEADocument5 pagesIPMSM Inductances Calculation Using FEABooNo ratings yet

- Dynamic Simulation of Switched Reluctance Motor Using MatlabDocument5 pagesDynamic Simulation of Switched Reluctance Motor Using MatlabachyuachyuthanNo ratings yet

- 1 s2.0 S0378475418300983 MainDocument15 pages1 s2.0 S0378475418300983 MainFaiza OuiddirNo ratings yet

- 12pulse Lci Synchronous Drive For A 20 MW Compressor Modeling SiDocument7 pages12pulse Lci Synchronous Drive For A 20 MW Compressor Modeling Sijeevan sankarNo ratings yet

- Analytical Investigation On Fundamental Electrical Characteristics of Large Air-Gap Superconducting Synchronous MachineDocument8 pagesAnalytical Investigation On Fundamental Electrical Characteristics of Large Air-Gap Superconducting Synchronous MachineahmadNo ratings yet

- Modeling of Electric Motors For Electromagnetic Compatibility AnalysisDocument5 pagesModeling of Electric Motors For Electromagnetic Compatibility AnalysisRudanekNo ratings yet

- Design and Simulation of Field Oriented Control of VSI Fed Induction Motor DriveDocument10 pagesDesign and Simulation of Field Oriented Control of VSI Fed Induction Motor Drivesuhail ahmadNo ratings yet

- Models of Synchronous Generator and Transformers For Dispatch Training Simulators and Real Time Digital SimulatorsDocument6 pagesModels of Synchronous Generator and Transformers For Dispatch Training Simulators and Real Time Digital Simulatorsiraj_214No ratings yet

- Kumar-Jena2017 Article SolutionToFaultDetectionDuringDocument11 pagesKumar-Jena2017 Article SolutionToFaultDetectionDuringBrooke ClineNo ratings yet

- Research On SVPWM OkDocument6 pagesResearch On SVPWM OkAnonymous 1D3dCWNcNo ratings yet

- IEEE-TOM - Journal ArticleDocument4 pagesIEEE-TOM - Journal ArticleedumacerenNo ratings yet

- Sensorless Vector ControlDocument23 pagesSensorless Vector ControlTien Nguyen DangNo ratings yet

- Effect of Metal Oxide Surge Arrester On Ferroresonance in Voltage Transformer Including Nonlinear Core LossesDocument5 pagesEffect of Metal Oxide Surge Arrester On Ferroresonance in Voltage Transformer Including Nonlinear Core LossesbpchimeraNo ratings yet

- PMSM Model With Phase-to-Phase Short-Circuit and Diagnosis by ESA and EPVADocument9 pagesPMSM Model With Phase-to-Phase Short-Circuit and Diagnosis by ESA and EPVAJaydi ZambranoNo ratings yet

- Analysis and Comparison of Two Brushless DC Generators With Doubly Salient Structure and Stator Field WindingDocument4 pagesAnalysis and Comparison of Two Brushless DC Generators With Doubly Salient Structure and Stator Field WindingmohammadNo ratings yet

- Class 3Document11 pagesClass 3Manjula sNo ratings yet

- Analysis of Short-Circuit Asymmetrical Currents in Power Distribution SystemsDocument6 pagesAnalysis of Short-Circuit Asymmetrical Currents in Power Distribution SystemscesarNo ratings yet

- Fluxes and Dispersion Reactances Fluxes and Dispersion Reactances of The Asyncronous MachineDocument6 pagesFluxes and Dispersion Reactances Fluxes and Dispersion Reactances of The Asyncronous MachineUrsatii NicolaiNo ratings yet

- Transformer Internal Faults Simulation: Advances in Electrical and Computer Engineering June 2008Document7 pagesTransformer Internal Faults Simulation: Advances in Electrical and Computer Engineering June 2008Ali AldesogeNo ratings yet

- Modeling Induction Motors: Abstract: in This Paper, A Novel Technique For On-Line Estimation of MostDocument10 pagesModeling Induction Motors: Abstract: in This Paper, A Novel Technique For On-Line Estimation of Mostseshubabu_999No ratings yet

- Ga Speed and DQ Currnets Control of PMSM WithDocument9 pagesGa Speed and DQ Currnets Control of PMSM Withhieuhuech1No ratings yet

- Pedstc2020 Farbodsaedi 01510144Document5 pagesPedstc2020 Farbodsaedi 0151014426765144No ratings yet

- Design and Comparison of Multistage Axial Flux Permanent Magnet Machines For Potable Generating ApplicationDocument8 pagesDesign and Comparison of Multistage Axial Flux Permanent Magnet Machines For Potable Generating Applicationray davisNo ratings yet

- A Direct Torque Controller For Permanent Magnet Synchronous Motor DrivesDocument6 pagesA Direct Torque Controller For Permanent Magnet Synchronous Motor DrivesGo GoNo ratings yet

- FEA Model Study of Spectral Signature Patterns of Chapitre1Document6 pagesFEA Model Study of Spectral Signature Patterns of Chapitre1Faiza OuiddirNo ratings yet

- Usman 2017Document6 pagesUsman 2017Faiza OuiddirNo ratings yet

- Stator Faults Modeling and Diagnostics of Line-Start Permanent Magnet Synchronous MotorsDocument10 pagesStator Faults Modeling and Diagnostics of Line-Start Permanent Magnet Synchronous MotorsFaiza OuiddirNo ratings yet

- A 2-D Model of The Induction Machine An Extension of The Modified Winding Function ApproachDocument7 pagesA 2-D Model of The Induction Machine An Extension of The Modified Winding Function ApproachFaiza OuiddirNo ratings yet

- An Extended Model of Induction Machines With Saturation Suitable For Fault AnalysisDocument8 pagesAn Extended Model of Induction Machines With Saturation Suitable For Fault AnalysisFaiza OuiddirNo ratings yet

- Structural Identifiability Analysis of Steady-State Induction Machine ModelsDocument6 pagesStructural Identifiability Analysis of Steady-State Induction Machine ModelsFaiza OuiddirNo ratings yet

- Short Review of Development Approaches of Mathematical Models For Induction Motor Nonsymmetrical Modes ResearchDocument5 pagesShort Review of Development Approaches of Mathematical Models For Induction Motor Nonsymmetrical Modes ResearchFaiza OuiddirNo ratings yet

- 10.1007@s42417 020 00253 y - CurrentDocument32 pages10.1007@s42417 020 00253 y - CurrentPedro OdorizziNo ratings yet

- A Review of Subdomain Modeling Techniques in Electrical Machines Performances and ApplicationsDocument7 pagesA Review of Subdomain Modeling Techniques in Electrical Machines Performances and ApplicationsFaiza OuiddirNo ratings yet

- Modeling For The Design of Fractional Slot PM Machines With Concentrated Windings Protected From Demagnetization During Three-Phase Short CircuitDocument8 pagesModeling For The Design of Fractional Slot PM Machines With Concentrated Windings Protected From Demagnetization During Three-Phase Short CircuitFaiza OuiddirNo ratings yet

- Accurate Torque-Sensorless Control Approach For Interior Permanent-Magnet Synchronous Machine Based On Cascaded Sliding Mode ObserverDocument9 pagesAccurate Torque-Sensorless Control Approach For Interior Permanent-Magnet Synchronous Machine Based On Cascaded Sliding Mode ObserverFaiza OuiddirNo ratings yet

- Demagnetization Fault Diagnosis of PMSM Based On Analytic Inductance CalculationDocument5 pagesDemagnetization Fault Diagnosis of PMSM Based On Analytic Inductance CalculationFaiza OuiddirNo ratings yet

- Analytical Model For Combined Study of Magnet Demagnetization and Eccentricity Defects in Axial Flux Permanent Magnet Synchronous MachinesDocument12 pagesAnalytical Model For Combined Study of Magnet Demagnetization and Eccentricity Defects in Axial Flux Permanent Magnet Synchronous MachinesFaiza OuiddirNo ratings yet

- 10 1109@upec 2013 6715044Document6 pages10 1109@upec 2013 6715044Faiza OuiddirNo ratings yet

- 1 s2.0 S0378475418300983 MainDocument15 pages1 s2.0 S0378475418300983 MainFaiza OuiddirNo ratings yet

- Appendix 7Document27 pagesAppendix 7Siswand BIn Mohd AliNo ratings yet

- Concept Recap Test Mains 2Document22 pagesConcept Recap Test Mains 2Siddharth GangalNo ratings yet

- Transformer & PumpDocument10 pagesTransformer & PumpGareth LestradeNo ratings yet

- Rocket Water Parachute - KrishnaDocument33 pagesRocket Water Parachute - KrishnaKrishna PreeyaNo ratings yet

- Chem Group 2Document32 pagesChem Group 2Princess AndoNo ratings yet

- Factors Affecting The Motion of A Falling ObjectDocument51 pagesFactors Affecting The Motion of A Falling ObjectJanet VillasanaNo ratings yet

- Caloric RequirementsDocument12 pagesCaloric RequirementsMeow CattoNo ratings yet

- Busbar Size and CalculationDocument8 pagesBusbar Size and Calculationandro max100% (1)

- 1073R PDFDocument10 pages1073R PDFElhindi hatimNo ratings yet

- Oa1-Two MarksDocument28 pagesOa1-Two MarksMEIVELJ 19EE025No ratings yet

- ETO - Interview SyllabusDocument3 pagesETO - Interview SyllabusKarthikeyan GNo ratings yet

- Low Cost, Miniature Isolation Amplifiers AD202/AD204: High AccuracyDocument12 pagesLow Cost, Miniature Isolation Amplifiers AD202/AD204: High AccuracyDiego I. HernándezNo ratings yet

- Chapter 2. Spatially Varied Flow (SVF) PDFDocument14 pagesChapter 2. Spatially Varied Flow (SVF) PDFVỏ Bọc0% (1)

- UR18650A SanyoDocument6 pagesUR18650A SanyobuddymdqNo ratings yet

- Complete Project ReportDocument100 pagesComplete Project ReportSrijith 5004No ratings yet

- Imel Talag Las Technical Drafting G10 Week 3-4Document5 pagesImel Talag Las Technical Drafting G10 Week 3-4Imel Aguado TalagNo ratings yet

- Labphys 6Document4 pagesLabphys 6Edyson CitraNo ratings yet

- Islamic University of Technology (Iut) Organisation of Islamic Cooperation (Oic)Document3 pagesIslamic University of Technology (Iut) Organisation of Islamic Cooperation (Oic)Ashik AhmedNo ratings yet

- 0309 Energy Transition and The Electricity MarketDocument70 pages0309 Energy Transition and The Electricity MarketFenhia RivasNo ratings yet

- Science 8 1st Quarter Exam 2021-2022Document4 pagesScience 8 1st Quarter Exam 2021-2022JingjingAloComendador100% (3)

- Technical ResolutionDocument1 pageTechnical Resolutionsyedabuthahir_mNo ratings yet

- ATV312 Quick Start en S1A10942 03Document4 pagesATV312 Quick Start en S1A10942 03w.priatmadiNo ratings yet

- A30050-X6026-X-4-7618-rectifier GR60Document17 pagesA30050-X6026-X-4-7618-rectifier GR60baothienbinhNo ratings yet

- FluidsDocument55 pagesFluidsdanena88No ratings yet

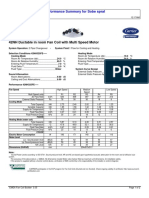

- 42NH Ductable in Room Fan Coil With Multi Speed Motor: Performance Summary For Sobe SpratDocument2 pages42NH Ductable in Room Fan Coil With Multi Speed Motor: Performance Summary For Sobe Spratvelikimag87No ratings yet

- What Is The Difference Between 0 2 and 0 2s Class CTDocument3 pagesWhat Is The Difference Between 0 2 and 0 2s Class CTSatyadeo VyasNo ratings yet

- Boardwork 1Document59 pagesBoardwork 1Tapan BadheiNo ratings yet

- Thermodynamics II Assignment 3: C R I H H I R H HDocument2 pagesThermodynamics II Assignment 3: C R I H H I R H HPriyanshuNo ratings yet

- Panelboard and Switchboard PDFDocument32 pagesPanelboard and Switchboard PDFGerardo M. James BravoNo ratings yet

- Data Sheet 3UG4615-2CR20Document6 pagesData Sheet 3UG4615-2CR20Daniel GomesNo ratings yet