Professional Documents

Culture Documents

Control Measures

Control Measures

Uploaded by

Charlie Dela Rosa0 ratings0% found this document useful (0 votes)

4 views4 pagesCopyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

4 views4 pagesControl Measures

Control Measures

Uploaded by

Charlie Dela RosaCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 4

Sr

Job Steps Potential Hazards Control Measures / Mitigation Plan Responsibility

No.

Refer to Sadara Safety Policy Supervisor

Conduct Too Box Talk

Non-compliance of Safety

Wear proper PPE as per the Job at all the times (i.e Hard hat, Supervisor/

Policy

Dust mask, safety glasses/goggles, Leather gloves, Face shield, Technician

leather apron etc.)

Barricade the area where pressure-test is to be carried out. Supervisor/

Unauthorized Personnel

Post warning notice. Technician

Check and Ensure the equipment / tool to be used for pressure

testing (such as hose, coupling, pressure gauge, spade, gasket

1 Planning

etc.) are free from defect and suitable for the pressure rating

of the system

Usage of tools shall be based on the recommendations stated

Supervisor/

Defective Tools/Equipment in the manufacturer manual and test shall be based on

Technician

standard.

Handling and storing of tools and equipment shall be based on

the recommendations given by manufacturer.

All tools and equipment needed to be used shall be inspected

by a competent person prior usage.

2 Pressure Testing Check any rupture of Pressure Equipment due to brittle Supervisor/

fracture and ductile fracture. Technician

Unintentional release of Check if attachment of blanking plates and their clamps/

stored energy attachment bolts, screwed plugs, isolation valves, etc.

Check the attachment of temporary welds on plug at pipe ends

and nozzles

Check the quality of the gaskets

Exceeding Maximum Ensure the pressure relieving device is set at maximum

Allowable Pressure allowable pressure for weakest portion of the segment to be

pressure-tested.

Damage to Equipment / Never increase the test pressure more than the

System maximum allowable pressure for the weakest portion in the

segment or pressure rating of the hose & coupling.

Do not leave the pressurized hose unattended when the

Un-attended Pressurized Tool

pressure-test is going on.

/ Equipment

Isolate the equipment from all source of energy when not in

use.

Changing the Duration of Do not change (exceed / decrease) the duration of pressure

Testing test without permission from Inspection Engineer.

Keep away from the pressurized segment of the system being

pressure-tested.

Injury to Workers Monitor the pressure gauge from a safe distance away from

the potential source of high pressure jetting (Such as Flange

Joint, Spade, and Coupling etc.)

Ensure the workers are wearing required PPE

Unsafe Depressurization Ensure the safe depressurization of air

Tools / Instruments Failure All instruments that will be used shall be calibrated and

inspected prior to use.

Calibration shall be based on the manufacturer’s

recommendation. Color coding for the month shall be

complied.

Instruments / Tools maintenance plan shall be adhered to.

Visual inspection of the tools to be used shall be conducted

before using it.

Defective tools and equipment shall be removed from the site.

Continuity testing shall be performed with the use of

calibrated multi meter.

Use appropriate power cable and supply for the specified

voltage current to be tested

and used.

Proper planning to be carried out when conducting

instruments tests.

1.5.1 Training for ergonomics shall be provided around the

work area.

1.5.2 Use proper body mechanics when lifting materials and

tools manually.

1.5.3 Team lifting or sharing of load shall be applied when

manually transferring load which exceeds 25 kg.

Supervisor/

Ergonomic Hazards 1.5.4 Avoid monotonous task and take breaks on regular

Technician

interval.

1.5.5 Only use specific / recommended tools for the job.

1.5.6 When working on tight spaces, Plan properly the

sequence of the job to manage time and exposure of the

worker to awkward and extreme body positions while dealing

with the task.

Ensure proper wind up & housekeeping at worksite. Supervisor/

The accessories (hoses & compressor) not being used must be Technician

Scattered Material

disconnected and the hoses are stored properly

PSV (in case isolated) to be lined up after pressure test

Windup & completion.

Cover Sharp Edges of materials with softener in handling and

3 Housekeeping work.

Secure sharp-edged materials and safety store sharp tools

after use

Sharp Edge Tools / Materials Substandard / improvised hand & special tools are strictly

prohibited.

Wear appropriate PPE while performing the task (E.g.: Cut

Resistant Gloves)

Wear proper PPE as per the Job at all the times (i.e Hard hat,

Personal without required Dust mask, safety glasses, Leather gloves, Face shield, leather

PPEs apron etc.)

4 Working in an Working in Extreme Heat Stress campaign and heat stress management program to

Adverse Temperature be applied.

Site safety measures including proper shading, well ventilated

Environment and heated break areas and sufficient cold fluids provided etc.

Pre-job heat stress monitoring checklist.

Adequate information, Training, Instruction and supervision.

Implement flag system to provide guidance to all workers on

site.

Work rotation regular work intervals.

Dust mask shall be provided and worn as needed, to limit

exposure level.

Dust If applicable, apply dust suppression control measure by

spraying water over the area.

Training course for toxic gasses and awareness shall be

provided to all workers on site.

Toxic Gas (release) Gas detector must be provided to key personnel on site, Gas

test shall be conducted regularly.

Smoking shall be done in designated areas.

Personnel shall strictly comply with the smoking policy on site.

All workers must strictly comply with the recommendations

Fire stated in the permit.

Fire Watcher shall be assigned in every hot work / activity

inside the brown field area.

Emergency drills shall be conducted as scheduled to ensure

emergency preparedness

of all personnel on site.

All Personnel shall be informed on the emergency contact

Unawareness of Emergency Supervisor/

5 Emergency number to be used in case

Procedure of emergency. Technician

Personnel must know the procedure of emergency evacuation.

All equipment to be shut down if safe to do so.

Follow emergency muster procedure.

You might also like

- JSA Crack Injection at Scruber Basin Unit 3Document6 pagesJSA Crack Injection at Scruber Basin Unit 3MarhendraNo ratings yet

- AIA Health Declaration FormDocument4 pagesAIA Health Declaration FormkotisanampudiNo ratings yet

- Example Risk Assessment For Outdoor EventsDocument6 pagesExample Risk Assessment For Outdoor EventsAnonymous 5YMOxVQNo ratings yet

- The Top Fiber-Rich Foods ListDocument8 pagesThe Top Fiber-Rich Foods ListSabina Alic100% (1)

- F 05 KDI QHSE 17a Environmental Inspection ChecklistDocument4 pagesF 05 KDI QHSE 17a Environmental Inspection ChecklistArsh AlamNo ratings yet

- Emergency Response Plan - Marafiq Jubail 21Document1 pageEmergency Response Plan - Marafiq Jubail 21jonathan cambaNo ratings yet

- 4 First Aid Box Inventory (White) 2020Document1 page4 First Aid Box Inventory (White) 2020lez2No ratings yet

- Environmental Register: Electrical Power Distribution & Maintenance of 33Kv Transformer A 1Document2 pagesEnvironmental Register: Electrical Power Distribution & Maintenance of 33Kv Transformer A 1Pandu Birumakovela100% (1)

- Rimal Global Technical Services LLC.: HSE Management System ProcedureDocument1 pageRimal Global Technical Services LLC.: HSE Management System ProcedureSreekumarNo ratings yet

- FM-EHS-02 Non-Conformance Report Log Sheet Rev.1Document1 pageFM-EHS-02 Non-Conformance Report Log Sheet Rev.1joanNo ratings yet

- R-06 Monthly Safety Audit ChecklistDocument2 pagesR-06 Monthly Safety Audit ChecklistSandeep Kumar100% (1)

- KPI Submission (October)Document3 pagesKPI Submission (October)Htoo Htoo KyawNo ratings yet

- Health, Safety and Environment Policy ManualDocument3 pagesHealth, Safety and Environment Policy ManualVikas SinghNo ratings yet

- OCP - 13 - Fire SafetyDocument2 pagesOCP - 13 - Fire SafetyNagendra Kumar SinghNo ratings yet

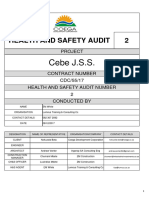

- Cebe JSS Audit 2 Report 08.12.2017Document14 pagesCebe JSS Audit 2 Report 08.12.2017mthokozisishangase6No ratings yet

- 1S 2S ChechsheetDocument5 pages1S 2S ChechsheetMaintenance BawalNo ratings yet

- Safety Training FormatsDocument11 pagesSafety Training FormatsAsan IbrahimNo ratings yet

- Safety Committee Meeting - CircularDocument1 pageSafety Committee Meeting - Circularshamshad ahamedNo ratings yet

- Responsibility, Authority and Accountability of EHS/ERT TeamDocument1 pageResponsibility, Authority and Accountability of EHS/ERT Teamsuraj rawatNo ratings yet

- 1 Site Safety Inspection ReportDocument1 page1 Site Safety Inspection ReportMohammed AbdulmuqeetNo ratings yet

- Fire Risk Assessment - JRG Automotive Industries India Pvt. Ltd. (J253)Document8 pagesFire Risk Assessment - JRG Automotive Industries India Pvt. Ltd. (J253)neerajrdxNo ratings yet

- Concrete WorkDocument3 pagesConcrete WorkAbdul Ghaffar100% (1)

- HIRA Injection MouldingDocument17 pagesHIRA Injection MouldingAnish Kumar PandeyNo ratings yet

- FSMS-stage 02Document15 pagesFSMS-stage 02Arpita TripathiNo ratings yet

- Legal Statutory RequirementsDocument70 pagesLegal Statutory RequirementsDendi Pradeep ReddyNo ratings yet

- 01 WI HSE 001 - Risk Assessment GroutingDocument4 pages01 WI HSE 001 - Risk Assessment GroutingMisbah Ul Haq Labeed100% (1)

- Hardrock Attachments Pvt. LTD.: Preventive Maintenance ChecklistDocument1 pageHardrock Attachments Pvt. LTD.: Preventive Maintenance ChecklistSandeep KumarNo ratings yet

- Rev - Safety DocumentsDocument9 pagesRev - Safety DocumentsCar ThickNo ratings yet

- Fire Drill or Actual Event Report: S. No. Sequence of Events CommentsDocument1 pageFire Drill or Actual Event Report: S. No. Sequence of Events CommentsArun Sharma100% (2)

- BOCW and SafetyDocument31 pagesBOCW and Safetydreamboy87No ratings yet

- EHS ManualDocument78 pagesEHS ManualSagar BahirjeNo ratings yet

- Health, Safety and Environmental: GoalsDocument15 pagesHealth, Safety and Environmental: Goalsprojects sureshNo ratings yet

- Happy Forgings Limited: Mock Drill ReportDocument3 pagesHappy Forgings Limited: Mock Drill Reportmool raj100% (1)

- Punch Ratna Fasteners PVT LTD, Chennai - 5S Audit Plan For 2019 - 20Document1 pagePunch Ratna Fasteners PVT LTD, Chennai - 5S Audit Plan For 2019 - 20R KumarNo ratings yet

- 02 AS-F-HSE 002B - HSE InductionTraining.Document1 page02 AS-F-HSE 002B - HSE InductionTraining.JHUPEL ABARIALNo ratings yet

- QMS-F-PCMR - Pest Control Monitoring RecordDocument4 pagesQMS-F-PCMR - Pest Control Monitoring RecordRajkumar PrajapatiNo ratings yet

- Risk AssessmentDocument2 pagesRisk Assessmentmelkenany654No ratings yet

- Near Miss 02.09.17 SCGDocument3 pagesNear Miss 02.09.17 SCGHolly Smith100% (1)

- Agreement Between Alpha & Disposafe Health and Life CareDocument2 pagesAgreement Between Alpha & Disposafe Health and Life CarePrakash RathodNo ratings yet

- Application To Perform Work - Grass CuttingDocument2 pagesApplication To Perform Work - Grass CuttingRauf HuseynovNo ratings yet

- Draft Site Operating Manual - HUL HO Mumbai (For Joint Discussion With UL Team)Document1 pageDraft Site Operating Manual - HUL HO Mumbai (For Joint Discussion With UL Team)Subhranshu ChakrabortyNo ratings yet

- IMS Objectives Review Report, FY 19-20Document1 pageIMS Objectives Review Report, FY 19-20Chintala YesukiranNo ratings yet

- Health: Key Performance Indicator Month of JANUARYDocument1 pageHealth: Key Performance Indicator Month of JANUARYSaddem Hadfi100% (1)

- Sample Template - Safety-DashboardDocument6 pagesSample Template - Safety-DashboardSivakumar ENo ratings yet

- HIRA - Pier ConstructionDocument8 pagesHIRA - Pier ConstructionMMRDACA07 SAFETYNo ratings yet

- Ppe Training Record: Department Occupation Type of Ppe Make/Model Name InitialsDocument3 pagesPpe Training Record: Department Occupation Type of Ppe Make/Model Name Initialsvlad100% (1)

- 37 Material StorageDocument5 pages37 Material StorageKhuda BukshNo ratings yet

- Emergency Response Plan Sri City Project Rev 00Document23 pagesEmergency Response Plan Sri City Project Rev 00HSE OFFICENo ratings yet

- Ra RegisterDocument2 pagesRa Registerzarni77No ratings yet

- Job Safety Analysis CustodialDocument4 pagesJob Safety Analysis Custodialwahyu nugrohoNo ratings yet

- 03 - SOP On Legal Requirement & Legal RegisterDocument3 pages03 - SOP On Legal Requirement & Legal RegisterPankaj Pandey100% (1)

- Equipment Maintenance and Measuring Equipment ProcedureDocument2 pagesEquipment Maintenance and Measuring Equipment ProcedureRaja Mani100% (1)

- Hazard Identification and Risk Assessment Form: Project ProcessDocument4 pagesHazard Identification and Risk Assessment Form: Project ProcessAli Al-GhamghamNo ratings yet

- Health, Safety & Environmental Program Jsa (Job Safety Analysis)Document3 pagesHealth, Safety & Environmental Program Jsa (Job Safety Analysis)Wealth OSIOBENo ratings yet

- Contractor's EHSS Evaluation by PMT EHSS PK CLC Project FMO Jan 2020Document5 pagesContractor's EHSS Evaluation by PMT EHSS PK CLC Project FMO Jan 2020ManPower RecruitingNo ratings yet

- JSA EmployeesDocument2 pagesJSA EmployeesburhanNo ratings yet

- RA Every ActvityDocument38 pagesRA Every ActvityvijayNo ratings yet

- Audit ComplianceDocument1 pageAudit ComplianceNitin SharmaNo ratings yet

- Rameshwer Lal Gadri - Safety KPIs For FY 2021-22Document7 pagesRameshwer Lal Gadri - Safety KPIs For FY 2021-22Nikhil VaidyaNo ratings yet

- FRM-EHS-PRO-05 Hazard Identification & Risk Assessment (HIRA)Document1 pageFRM-EHS-PRO-05 Hazard Identification & Risk Assessment (HIRA)Venkatesan DNo ratings yet

- Subcontractor H&S QuestionnaireDocument8 pagesSubcontractor H&S QuestionnairejasonhopolNo ratings yet

- Preconditions, PreparationsDocument1 pagePreconditions, PreparationsCharlie Dela RosaNo ratings yet

- Effect of Gravity 'G' On Calibration of BalanceDocument1 pageEffect of Gravity 'G' On Calibration of BalanceCharlie Dela RosaNo ratings yet

- Verification of ComparatorDocument1 pageVerification of ComparatorCharlie Dela RosaNo ratings yet

- UntitledDocument1 pageUntitledCharlie Dela RosaNo ratings yet

- Repeatability TestDocument1 pageRepeatability TestCharlie Dela RosaNo ratings yet

- Furnace Decription and SpecificationDocument1 pageFurnace Decription and SpecificationCharlie Dela RosaNo ratings yet

- Details of Calculations For S. No 5: Standard Deviation S (X) 0.009 °CDocument1 pageDetails of Calculations For S. No 5: Standard Deviation S (X) 0.009 °CCharlie Dela RosaNo ratings yet

- Maximum Capacity of The Balance or The Range To Be CalibratedDocument1 pageMaximum Capacity of The Balance or The Range To Be CalibratedCharlie Dela RosaNo ratings yet

- Pneumatic TestDocument4 pagesPneumatic TestCharlie Dela RosaNo ratings yet

- Equip For ServiceDocument2 pagesEquip For ServiceCharlie Dela RosaNo ratings yet

- Summary of Standard Uncertainty ComponentsDocument1 pageSummary of Standard Uncertainty ComponentsCharlie Dela RosaNo ratings yet

- Standards Such As The AMS 2750 FDocument1 pageStandards Such As The AMS 2750 FCharlie Dela RosaNo ratings yet

- AdjustmentDocument2 pagesAdjustmentCharlie Dela RosaNo ratings yet

- Testing Preparation and ExecutionDocument2 pagesTesting Preparation and ExecutionCharlie Dela RosaNo ratings yet

- Roles and ResponsibilitiesDocument3 pagesRoles and ResponsibilitiesCharlie Dela RosaNo ratings yet

- Audit Findings For SDEDocument2 pagesAudit Findings For SDECharlie Dela RosaNo ratings yet

- Hydrostatic TestDocument2 pagesHydrostatic TestCharlie Dela RosaNo ratings yet

- Engine and LubricantsDocument1 pageEngine and LubricantsCharlie Dela RosaNo ratings yet

- Forklift Inspection ChecksheetDocument1 pageForklift Inspection ChecksheetCharlie Dela RosaNo ratings yet

- Safety RequirementsDocument1 pageSafety RequirementsCharlie Dela RosaNo ratings yet

- Required Personal Protective EquipmentDocument5 pagesRequired Personal Protective EquipmentCharlie Dela RosaNo ratings yet

- Reference Standard ListaDocument4 pagesReference Standard ListaCharlie Dela RosaNo ratings yet

- Resistance Generate 330 M OhmsDocument3 pagesResistance Generate 330 M OhmsCharlie Dela RosaNo ratings yet

- Vacum GaugeDocument1 pageVacum GaugeCharlie Dela RosaNo ratings yet

- Requested Reference Standards (03-Oct-22)Document2 pagesRequested Reference Standards (03-Oct-22)Charlie Dela RosaNo ratings yet

- LIFTING EQUIPMENT REFERENCE STANDARDS LOG SHEET - Rev0Document2 pagesLIFTING EQUIPMENT REFERENCE STANDARDS LOG SHEET - Rev0Charlie Dela RosaNo ratings yet

- Data Sheet For ThermocoupleDocument4 pagesData Sheet For ThermocoupleCharlie Dela RosaNo ratings yet

- Lyrics - Always (Marco Sison)Document1 pageLyrics - Always (Marco Sison)Charlie Dela RosaNo ratings yet

- Furnace 30 To 1200 CDocument3 pagesFurnace 30 To 1200 CCharlie Dela RosaNo ratings yet

- Comparison - ProcedureDocument8 pagesComparison - ProcedureCharlie Dela RosaNo ratings yet

- PP Healthy Growth Nutrition ChildrenDocument50 pagesPP Healthy Growth Nutrition ChildrenSakshi SharmaNo ratings yet

- Self Declaration Form Details For International Arriving PassengersDocument2 pagesSelf Declaration Form Details For International Arriving PassengersKoteswar MandavaNo ratings yet

- Lab Articles As Per Indian Nursing CouncilDocument20 pagesLab Articles As Per Indian Nursing CouncilChaitanya RkNo ratings yet

- Price List Alkes Pt. Carmella Gustavindo Periode April 2021Document26 pagesPrice List Alkes Pt. Carmella Gustavindo Periode April 2021naelarizqiNo ratings yet

- VaccineCertificate VCC13072126154Document2 pagesVaccineCertificate VCC13072126154ABDUL KADERNo ratings yet

- Procedure For Performance Monitoring and MeasurementDocument5 pagesProcedure For Performance Monitoring and MeasurementDaniel Cheng MahsaNo ratings yet

- Ernestine WiedenbachDocument7 pagesErnestine WiedenbachVien WhitlockNo ratings yet

- Lacrivera BrochureDocument3 pagesLacrivera BrochureHaag-Streit UK (HS-UK)No ratings yet

- Presentation 1 - DR Martin RoyleDocument66 pagesPresentation 1 - DR Martin Royleশরীফ উল কবীরNo ratings yet

- NCP For FT, SGADocument7 pagesNCP For FT, SGAJule Santoya80% (5)

- CHCCOM005Document24 pagesCHCCOM005Divya Joshi50% (2)

- Gordon's 11 Functional Health AssessmentDocument4 pagesGordon's 11 Functional Health AssessmentJehn Pauleen Fernandez RollanNo ratings yet

- 2021 Bobcat T590 Skidsteer - Risk Assessment - LJD Civil Pty LTDDocument16 pages2021 Bobcat T590 Skidsteer - Risk Assessment - LJD Civil Pty LTDengrmcabNo ratings yet

- 01 - Fitoterapi - D3 SMT VDocument17 pages01 - Fitoterapi - D3 SMT VMaman SuharmanNo ratings yet

- RAHBAR - NDMA-manualDocument252 pagesRAHBAR - NDMA-manualDanielNo ratings yet

- Module 2 Session 1 Trauma OSAECDocument22 pagesModule 2 Session 1 Trauma OSAECbrian venNo ratings yet

- MSDS Ldpe BB120 EngDocument10 pagesMSDS Ldpe BB120 EngQcNo ratings yet

- Monograph - IntegumentarySystem (1) - For MergeDocument32 pagesMonograph - IntegumentarySystem (1) - For MergeJeralyn CABALIDANo ratings yet

- Thesis Statement About The Value of A College EducationDocument8 pagesThesis Statement About The Value of A College Educationgjgpy3daNo ratings yet

- Bach Brandenburg Concerto, No. 3 CelloDocument2 pagesBach Brandenburg Concerto, No. 3 CelloMartin BurNo ratings yet

- Public Health, Health and LifestyleDocument149 pagesPublic Health, Health and LifestyleBrian MaloneyNo ratings yet

- Safeguarding Level 1 Booklet (2019)Document24 pagesSafeguarding Level 1 Booklet (2019)MubeenRahmanNo ratings yet

- Region X List of Offices and FunctionsDocument2 pagesRegion X List of Offices and FunctionsMARCHELL DENN DIONSONNo ratings yet

- IMNCI2021Document94 pagesIMNCI2021Let BNo ratings yet

- MR Chips Synonyms Chapter 9 TP 18Document1 pageMR Chips Synonyms Chapter 9 TP 18subhani495No ratings yet

- Intellectual Disability - SummaryDocument3 pagesIntellectual Disability - SummaryAlexis Autor SuacilloNo ratings yet

- Applegate1960 - The Rationale of Partial Denture Choice.Document17 pagesApplegate1960 - The Rationale of Partial Denture Choice.Zachary DuongNo ratings yet

- Reflection 6Document1 pageReflection 6Renalyn CaingcoyNo ratings yet