Professional Documents

Culture Documents

Traffic Management Plan

Uploaded by

Shailendra SinghCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Traffic Management Plan

Uploaded by

Shailendra SinghCopyright:

Available Formats

Karratha Batch Plant - 3187

Traffic Management Plan (TMP)

Site orientation and safety training for employees, contractors, clients and other site visitors must include

information regarding the site traffic management plan with emphasis on the site-specific traffic safety rules.

Traffic Management Plan | we’ll make it happen

Traffic Management Plan

Table of Contents

1. Endorsement of the TMP 2

2. Scope and Responsibilities 3

2.1. Scope 3

2.2. Responsibilities 3

3. Traffic Control Plan 4

3.1. Traffic Movements 4

3.2. General Arrangement 4

3.3. Potential Hazards 4

3.4. Break Beam Laser Protocol 5

3.5. Communication Plan 6

3.6. Inspection and Review Process 6

3.7. Signage 6

3.8. Busy Periods 7

Appendix A: Batch Plant TMP

Appendix B: Batch Plant Lighting Layout

1 Traffic Management Plan | we’ll make it happen

Traffic Management Plan

1. Endorsement of the TMP

Management in Hanson Construction Materials, as listed below, have reviewed and approved the

Traffic Management Plan:

Chris Bonett – Plant Manager

The Traffic Management Plan (TMP)

The Traffic Management Plan (“TMP”) is designed to control the flow of traffic through the Concrete Batch Plant area

and yard. It will limit the possibility of contact between different types of vehicles and the likelihood of vehicle and

pedestrian related incidents.

This will be achieved by use of an approved Site Traffic Plan, Signage to Australian Standard AS1742.3, onsite training

and Toolbox meetings with all Hanson staff.

Hanson Construction Materials (Hanson) recognizes that other statutory and legislative requirements, specifications

and standards are considered under this plan. This TMP will ensure that procedures will be in place for all staff and

visitors. This has been developed from the following, where applicable:-

• Occupational Health and Safety Act 1984 (WA)

• Occupational Health and Safety Regulations 1996 (WA)

Please note that this TMP is correct and reflects Hanson’s intentions as of this current revision. Some minor aspects of

the TMP may change to reflect final on-site design and should this occur an updated TMP will be issued.

Compliance with Australian Standards, Regulations & Guidelines

Australian Standard AS 1742.3 Manual of uniform traffic control devices

The plant will comply with all relevant local and state legislation.

2 Traffic Management Plan | we’ll make it happen

Traffic Management Plan

2. Scope and Responsibilities

2.1. Scope

The TMP will address the following potential hazard areas:

Light Vehicle movements;

Yellow Machines;

Heavy Vehicles;

Speed Control;

Vehicular Interaction;

Pedestrian Interaction;

Emergency response;

Un-authorised site access; and

Change.

Hazards are addressed in Section 3.3 of this TMP. The flow of traffic will be illustrated on the TMP

once the site has been physically inspected, indicating the direction road trains, agitator trucks and

light vehicles.

2.2. Responsibilities

The Plant Manager will assume overall responsibility for the management of the Hanson TMP during

day to day operations. However, all employees are responsible for ensuring and maintaining the safe

flow of traffic onsite. All employees and contractors entering site will be subject to placarded speed

limits and will be counseled by the plant Manager if infringements are detected.

Site inspections will be carried out on a daily basis to monitor the effectiveness of traffic design flow

and signage, this will form part of the HSE inspections

3 Traffic Management Plan | we’ll make it happen

Traffic Management Plan

3. Traffic Control Plan

3.1. Traffic Movements

Traffic movements in the area include:

Hanson Construction Materials Vehicles

Normal Road Users

Various Construction Work Crews

Site Visitors

Permanent signs on the access road and entry to the Batch Plant Area will provide guidance on mandatory speed limits, entry

requirements and direction of flow of traffic. Delineation will be followed as per designated walkways as per the

interaction, volume of pedestrian and traffic levels of the area.

Parking bays has been allocated for light vehicles (ie. Non-trucks), which is sufficient for all site employees and two site visitors.

When agitator trucks and material delivery trucks, Austroad guides have been checked and will ensure that the trucks turn

directly onto their own lane and not impose onto the oncoming lane.

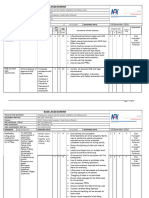

3.2. General Arrangement

Plan A (Appendix 1), which is taken to be the plant layout on site, indicates a scaled and dimensioned general layout of the

batch plant footprint. It indicates the interaction between the paths of the types of vehicles will be limited to only that which is

necessary for the proper operation of the concrete batch plant. The Front End Loader will operate within the designated

exclusion zone and entry thereto will require confirmation via the designated UHF Channel. LV entry to the yard will be limited

to the LV car park where practicable.

Items contained within this plan include but are not limited to

Muster points;

Isolation points;

SDS location;

Traffic flow;

Area specific signage;

Exclusion zones.

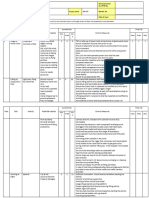

3.3.Potential Hazards

Identified hazards involved in traffic management and the controls implemented to limit or eliminate

risk.

HAZARD TARGET CONTROL

Light Vehicle Movements Limit Interaction between LV’s and FEL; LV have designated parking. Designated

Limit Interaction between LV’s and Pedestrian; pedestrian walkway.

Limit Interaction between LV’s & Heavy Vehicles; TMP indicates traffic flow UHF radio

positive communication upon entering site.

Refuelling LV's, Yellow Limit Interaction between LV’s and Yellow TMP indicates traffic flow UHF radio

Machines and Trucks Machines; positive communication upon entering

Limit Interaction between LV’s and Pedestrians; refuelling area.

Limit Interaction between LV’s & Heavy Vehicles;

Limit Interaction between Yellow Machines and Trucks entering site to gain approval

Pedestrians; via radio before entering site.

Exclusion Zone tape to be extended to

block incoming traffic

Cement Tanker Limit Interaction between LV’s and Yellow Truck entering site to gain approval via

Machines; radio before entering site.

Limit Interaction between LV’s and Pedestrians;

Limit Interaction between LV’s & Heavy Vehicles; Tanker to park in designated area and

Limit Interaction between Yellow Machines and Exclusion Zone tape to be extended to

Pedestrians; block incoming traffic

4 Traffic Management Plan | we’ll make it happen

Traffic Management Plan

HAZARD TARGET CONTROL

Mobile Equipment Limit Interaction between FEL and LV; Allocated visitor parking Allocated

Limit Interaction between FEL and Pedestrian; Limit FEL operating area Allocated

Interaction between FEL and Heavy Vehicles; Suitable pedestrian walkways Clear signage

signage placed in appropriate locations; Correct PPE for (not faded) Positive communication

clear vision of pedestrian movements; Separation of

vehicle types where practicable.

Heavy Vehicle Movements Limit Interaction between Heavy Vehicles and LV; Interaction between HV's and LV

Limit Interaction between Heavy Vehicles and Pedestrian; limited and controlled via positive

Suitable signage placed in appropriate locations; Correct communication with drivers and

PPE for clear vision of pedestrian movements; Separation Batcher/PS. TMP clearly shows

of vehicle types where practicable. vehicle paths around site

Agitator trucks to give way to Road

trains when required

No Radio - No Entry

Speed Control Suitable signage placed in appropriate locations; Speed Speed limit signs placed at entry to

limits with batch plant area limited to 8km/h for all staff & site.

visitors. Included in site induction

Vehicular Interaction Prevent interaction between Agitator Trucks, Heavy vehiclle Parking identified in TMP

and LVs by means of vehicular separation;

Safe distance and positive

Two-Way communications between all vehicle types communication between vehicles of

Dedicated park-up areas for vehicle types. all types

Pedestrian Interaction Dedicated pedestrian only zones; Walkways established between site

Correct PPE for clear identification vision of pedestrian areas to maintain safe working areas.

If not possible, create exclusion zone.

Walkways to be clear and visible for

staff and visitors. Visitors to be

escorted at all times.

Emergency Response Muster points located in TMP; Site induction to include all facets of

Spill kits located in suitable locations & regularly inspected; TMP including Emergency

Eye wash facilities available & regularly inspected; procedures

First Aid stations located suitably & regularly inspected;

Material SDS available for all chemicals on site

Un-Authorised Site Access All visitors to report to site office upon arrival; Appropriate signage which is clearly

All visitors to receive site induction and be required to sign visible and easy to follow for

in to visitor book; contractors and visitors.

Suitable signage placed in appropriate locations directing

visitors to park-up areas and site offices;

3.4. FEL Operating Area Protocol

Break Beam laser & Positive Communication

HAZARD TARGET CONTROL

Person/s Entering FEL Positive communication before entering FEL Zone Appropriate signage which is clearly

Operating Area No employees/contractor entering FEL operating area When visible and easy to follow for

contractors and visitors.

FEL is operating drivers to remain in trucks at all times.

Positive communication upon entering

If truck is is washout area, no movements are to be made and leaving FEL Area. When pedestrian/

vehicle entering FEL zone, bucket its to

until positive communication is held and movement be lowered and FEL to stop moving

permission is granted by operator

Break Beam Laser alerts when entering/

exiting FEL Area bucket its to be

lowered and FEL to stop moving

In the event of a Breach, incident is to

be reported via IRIS

5 Traffic Management Plan | we’ll make it happen

Traffic Management Plan

3.5. Communication Plan

On approval, the TMP will be posted in the crib and batch rooms located next to the LV parking onsite. An employee briefing

will be delivered during the prestart meeting. Changes to this plan will follow the Hanson Change Management Process.

These changes will be rolled out to the workforce via subsequent prestart and toolbox meetings.

3.6. Inspection and Review Process

The TMP will be periodically inspected and audited to ensure compliance and suitability for its purpose. Issues that are

identified will be addressed and, where more significant changes are required, Hanson will consult with the Council

representatives for guidance.

3.7. Signage

The traffic signage will comply with AS1742.3; all other signage will be for information purposes only. Some of the signage

that will be found on site are indicated below.

6 Traffic Management Plan | we’ll make it happen

Traffic Management Plan

3.8. Busy Periods

During busy periods, Hanson intends to hold vehicles at the entrance to the plant, where they will be released as congestion is

reduced. The only time Hanson expects to have a vehicle wait is when a tipper or tanker truck drops off material and needs to

turn around, which will see the supervisor stop the loader (and park up), so that the truck can safely turn around and exit

without any risk. The waiting area is indicated in Appendix A below.

Figure 1: Karratha Site

7 Traffic Management Plan | we’ll make it happen

LEGEND

KARRATHA TRAFFIC MANAGEMENT PLAN Restricted Area

Telephone

First Aid

Fire Extinguisher

Walking Path

Restricted Area

Barrier

ST

Muster Point Visitor

CEMENT TANKE

R LOADING AREA OC

KP

ILE

S

Parking Main

ADMIXTURES Isolation Point

Chemical Storage

MARDIE RD

COLO

PIT

UR SH

Emergency Alarm

ED

GE

WED

BATCH FUEL

WATER BOW

HUT SER

WATER

Blind Spot

AREA ACTS AS WAITING CHILLER

AREA & ADDITIONAL

Agitator Truck Path

WATER

PARKING AT END OF DAY

STORES

FEL PARK UP /

Road Train Path

Exclusion Zone reel

WAITING

AREA

WORK

AREA AGG BINS AGG BINS AGG BINS AGG BINS AGG BINS AGG BINS

STORES

Hand Rail Barrier

VISITOR PARKING

SITE ENTRY

SITE OF

CONVEX

MIRROR F.O.V

LV LV

PARKING PARKING

FEL OPERATING AREA

FICE

TOILET

LV

PARKING CRIB ROOM

AGG BINS

AGG BINS AGG BINS

AGG BINS

WASTE WASTE WATER

PIT PIT PIT

AGITATOR TRUCKS TO FOLLOW BLUE LINES TO EITHER PARKING AREA OR NO PEDESTRIAN ENTRY INTO FEL OPERATING AREA WITHOUT STRICT

TO WASH PITY AREA AND FOLLOW ALONG TO FUEL BOWSER. SUPERVISION AND ESCORT FROM PRODUCTION SUPERVISOR/BATCHER

ROAD TRAINS TO FOLLOW RED LINES IN BOTH DIRECTIONS ONLY UNDER

PERMISSION FROM BATCHER/MANAGER TO ENSURE PATH IS CLEAR AND

FREE FROM PEDESTRIANS. ENSURE POSITIVE COMMINICATION IS IN USE.

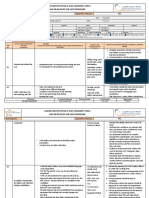

KARRATHA LIGHTING LAYOUT PLAN

ST

OC

KP

ILE

S

ADMIXTURES

MARDIE RD

COLO

PIT

UR SH

ED

GE

WED

BATCH FUEL

WATER BOW

HUT SER

WATER

AREA ACTS AS CHILLER

ADDITIONAL PARKING AT WATER

END OF DAY

STORES

AGG BINS AGG BINS AGG BINS AGG BINS AGG BINS AGG BINS

STORES

VISITOR PARKING

SITE ENTRY

SITE OF

CONVEX

MIRROR F.O.V

ING

PARKING PARK

FEL OPERATING AREA

FICE

TOILET

PARKING

CRIB ROOM

AGG BINS

AGG BINS AGG BINS

AGG BINS

WASTE WASTE WATER

PIT PIT PIT

You might also like

- Jha - Modification Erection Scaffolding Activity and Housekeeping Scaffolding MaterialDocument14 pagesJha - Modification Erection Scaffolding Activity and Housekeeping Scaffolding MaterialAliff ApamNo ratings yet

- Piping Jacing and Erection of Placing BoomDocument3 pagesPiping Jacing and Erection of Placing BoomramsafeNo ratings yet

- Vocabulary For Academic IELTS Writing Task 1Document31 pagesVocabulary For Academic IELTS Writing Task 1Jose Mia94% (18)

- Lifting Fixing of Cross BracingDocument2 pagesLifting Fixing of Cross BracingShahid RazaNo ratings yet

- Structural Fabrication & Erection by Using Hydra or Farana JSA HSE ProfessionalsDocument2 pagesStructural Fabrication & Erection by Using Hydra or Farana JSA HSE ProfessionalsDarseen RNo ratings yet

- Rectification Work Risk AssessmentDocument10 pagesRectification Work Risk Assessmentadeniyi abiolaNo ratings yet

- Concrete ChippingDocument3 pagesConcrete ChippingAbhijit ParasharNo ratings yet

- 12 (1) HIRA - PaintingDocument6 pages12 (1) HIRA - PaintingSk younusNo ratings yet

- 02 RISK ASSESMENT For Constraction Vehicle Movement at SiteDocument1 page02 RISK ASSESMENT For Constraction Vehicle Movement at SiteVIRUPAKSHA KOOLINo ratings yet

- Delivery of ConcreteDocument5 pagesDelivery of Concretesikandar1234No ratings yet

- 6 RA Installation Testing Commissioning of Fire Fighting PumpsDocument7 pages6 RA Installation Testing Commissioning of Fire Fighting PumpsAdel MorsyNo ratings yet

- 47 Cable Glanding and TerminationDocument3 pages47 Cable Glanding and TerminationvasudevanmNo ratings yet

- Al Musairie Trading & Contracting Co. Qatar WLL: Hazard Identification & Risk AssessmentDocument9 pagesAl Musairie Trading & Contracting Co. Qatar WLL: Hazard Identification & Risk AssessmentSujan AugustinNo ratings yet

- Risk Assessments - Materials Offloading-Transportation& Lifting Opereation - ADFI-GFTS-CESDocument7 pagesRisk Assessments - Materials Offloading-Transportation& Lifting Opereation - ADFI-GFTS-CESIbrahim Esmat0% (1)

- Risk Assessment For Installation of Drainage Pipes PDF FreeDocument17 pagesRisk Assessment For Installation of Drainage Pipes PDF FreeMalik RizwanNo ratings yet

- Code of Practice - Construction Work - AUSDocument52 pagesCode of Practice - Construction Work - AUSAnonymous iWaBM6P9V6No ratings yet

- Risk Assessment For Production and ErectionDocument14 pagesRisk Assessment For Production and ErectionFurqan FarrukhNo ratings yet

- Jha Region7 GeoprobeDocument10 pagesJha Region7 Geoprobewasif ahmedNo ratings yet

- Legal Register Evaluation Feb '20Document21 pagesLegal Register Evaluation Feb '20Priyanka JNo ratings yet

- OHS-PR-09-03-F07 JOB SAFE PROCEDURE (08) Concrete Poring and Removal of CasineDocument16 pagesOHS-PR-09-03-F07 JOB SAFE PROCEDURE (08) Concrete Poring and Removal of Casinemohammed tofiqNo ratings yet

- Excavation Working in Trenches Swms 10281-6Document17 pagesExcavation Working in Trenches Swms 10281-6JamesNo ratings yet

- Method of Statement For Dewatering WorkDocument14 pagesMethod of Statement For Dewatering WorkMohd MuksinNo ratings yet

- Sra0008 Brickwork and Concrete RepairsDocument9 pagesSra0008 Brickwork and Concrete RepairsAyu Wanda SaraswatiNo ratings yet

- Job Hazard Analysis: Rohan Builders (I) PVT LTDDocument4 pagesJob Hazard Analysis: Rohan Builders (I) PVT LTDTigor GurningNo ratings yet

- Risk AssesmentDocument3 pagesRisk AssesmentShahd JaberNo ratings yet

- Risk Assessment: Job:Control Blasting For Wagon TipplerDocument1 pageRisk Assessment: Job:Control Blasting For Wagon Tipplerali rezaNo ratings yet

- RA Civil Works T 1006Document12 pagesRA Civil Works T 1006fayaz fayazhotmail.comNo ratings yet

- Legal Register - Federal Law No.8Document4 pagesLegal Register - Federal Law No.8Priyanka JNo ratings yet

- RA Ug Fire Pipe Installation and Hyrant SystemDocument17 pagesRA Ug Fire Pipe Installation and Hyrant SystemvinayNo ratings yet

- Pipelayers CPH v1.1 03.13.14 PDFDocument13 pagesPipelayers CPH v1.1 03.13.14 PDFbugseNo ratings yet

- SWP Excavation Near Overhead Electrical Live LinesDocument2 pagesSWP Excavation Near Overhead Electrical Live LinesSn AhsanNo ratings yet

- JLG 600A Articulating Boom Lift Manual PDFDocument148 pagesJLG 600A Articulating Boom Lift Manual PDFbabaNo ratings yet

- ARL700 UCM Test Instructions For Hydraulic Lifts V1.EnDocument5 pagesARL700 UCM Test Instructions For Hydraulic Lifts V1.EnkizonimeisterNo ratings yet

- Method of StatementDocument33 pagesMethod of StatementEr. TK SahuNo ratings yet

- Ewrc SHP Gen CM MS 00027Document16 pagesEwrc SHP Gen CM MS 00027Rickz Cabalo100% (1)

- Commented HSE-PLAN-MBPL-R0Document53 pagesCommented HSE-PLAN-MBPL-R0PNCPL PLANNINGNo ratings yet

- Safety Audit Checklist - Excavation & FoundationDocument2 pagesSafety Audit Checklist - Excavation & FoundationsAuRaBhNo ratings yet

- Camp InspectionDocument76 pagesCamp InspectionshijadNo ratings yet

- Adjustment of Light Pole Frame and Illumination Test For Existing Light Pole (S-FL-26)Document13 pagesAdjustment of Light Pole Frame and Illumination Test For Existing Light Pole (S-FL-26)hse quizNo ratings yet

- 2022 SWMS - Combined SWMSDocument8 pages2022 SWMS - Combined SWMSSteveNo ratings yet

- Installation and Removal of High MastDocument3 pagesInstallation and Removal of High MastMohd Hafiz Muhamed100% (1)

- Temporary Structure Erection Work Risk AssessmentsDocument2 pagesTemporary Structure Erection Work Risk Assessmentshussein aliNo ratings yet

- Risk Assessment: Site Facilities Larsen & Toubro Limited PT&D (I) (Africa)Document4 pagesRisk Assessment: Site Facilities Larsen & Toubro Limited PT&D (I) (Africa)Naveen GladsonNo ratings yet

- Electrical Conduit Check ListDocument5 pagesElectrical Conduit Check ListehteshamNo ratings yet

- Risk Assessment - ExcavationDocument6 pagesRisk Assessment - Excavationganesh gbNo ratings yet

- Discharge Rod 11kv 3phaseDocument1 pageDischarge Rod 11kv 3phasewaytobhushan100% (1)

- Method Statement For Cable Terminaton (CP3)Document20 pagesMethod Statement For Cable Terminaton (CP3)Jacky TamNo ratings yet

- OHS-PR-09-03-F07 JOB SAFE PROCEDURE (20) OPGW Cable Installation and SplicingDocument12 pagesOHS-PR-09-03-F07 JOB SAFE PROCEDURE (20) OPGW Cable Installation and Splicingmohammed tofiqNo ratings yet

- Alec Qa QC AssesmentDocument34 pagesAlec Qa QC AssesmentAbirhamNo ratings yet

- NCR-Corrective & Preventive Action RequestDocument2 pagesNCR-Corrective & Preventive Action RequestRakesh SidhuNo ratings yet

- Risk Assessment / Method Statement Form: (Please)Document5 pagesRisk Assessment / Method Statement Form: (Please)Sham AranNo ratings yet

- OHS-PR-09-03-F07 JOB SAFE PROCEDURE (18) Spacer and Vibration Damper InstallationDocument14 pagesOHS-PR-09-03-F07 JOB SAFE PROCEDURE (18) Spacer and Vibration Damper Installationmohammed tofiqNo ratings yet

- Trakhees Comments ReplyDocument2 pagesTrakhees Comments ReplyGhaffar LaghariNo ratings yet

- HIRA Reference Bearing & StopprtDocument51 pagesHIRA Reference Bearing & StopprtPlanning C7100% (1)

- 8) SWP-08 Working at HeightsDocument3 pages8) SWP-08 Working at HeightsRachel NoraNo ratings yet

- Construction Procedure Concrete Form WorkDocument12 pagesConstruction Procedure Concrete Form WorkDimas DzununNo ratings yet

- Marker Post Installation JSADocument10 pagesMarker Post Installation JSAShahid BhattiNo ratings yet

- RA - Painting Works - Car ParkDocument14 pagesRA - Painting Works - Car ParkDurai KailasamNo ratings yet

- JSA - Smith StructuresDocument10 pagesJSA - Smith Structuresmonu chaudharyNo ratings yet

- HIRA Electrical Works HRC 002Document7 pagesHIRA Electrical Works HRC 002syed khaja misbhuddinNo ratings yet

- Sr. Manager Weekly H&S Walkthrough Report 005Document11 pagesSr. Manager Weekly H&S Walkthrough Report 005abdelaziz.a.zakariaNo ratings yet

- Risk Analysis of BMSDocument4 pagesRisk Analysis of BMSWinnie RaghuNo ratings yet

- Risk Assessment For Erection of Steel GirderDocument11 pagesRisk Assessment For Erection of Steel GirderNirajan MarwaitNo ratings yet

- Section 1 Part 16Document3 pagesSection 1 Part 16Kántor ErvinNo ratings yet

- Ey Envisioning The Future of Indian Logistics at 2047Document64 pagesEy Envisioning The Future of Indian Logistics at 2047마형석No ratings yet

- FinalreportzeranogtosteDocument23 pagesFinalreportzeranogtosteLyubomir IvanovNo ratings yet

- MandateDocument3 pagesMandateGabor FarkasNo ratings yet

- Cpad Assignment: Case Study On Fractals in ArchitectureDocument37 pagesCpad Assignment: Case Study On Fractals in ArchitectureSophia Chin100% (1)

- Design of StructuresDocument50 pagesDesign of StructuresAHMAD HASSANNo ratings yet

- IRITS0615079Pullstar Heavy Air FlyerDocument4 pagesIRITS0615079Pullstar Heavy Air FlyerShubham JainNo ratings yet

- 20 - Katy Keene #20 (1987) - TextDocument26 pages20 - Katy Keene #20 (1987) - Textconceicaovasco213No ratings yet

- T Mms 18rav4Document66 pagesT Mms 18rav4Ali AliNo ratings yet

- Assessment Point Essay 2 - R1508D933901Document14 pagesAssessment Point Essay 2 - R1508D933901Rue Spargo ChikwakwataNo ratings yet

- Thomas Joseph DavisDocument3 pagesThomas Joseph Davisapi-547413934No ratings yet

- MSA5T0726A161934 Headlight Beam Leveler System PDFDocument1 pageMSA5T0726A161934 Headlight Beam Leveler System PDFMishu MishuNo ratings yet

- DCM2601 PROJECT 2023 SEMESTER 2 (Due Date - 11 September)Document4 pagesDCM2601 PROJECT 2023 SEMESTER 2 (Due Date - 11 September)Rachel Du PreezNo ratings yet

- Navi112 ReviewerDocument3 pagesNavi112 ReviewerXander Rubia jr100% (1)

- Sor RR 2020-21Document170 pagesSor RR 2020-21riazul islamNo ratings yet

- Bond Statement Guide & in Lieu of Bond AffidavitDocument2 pagesBond Statement Guide & in Lieu of Bond Affidavitlane.moreau29No ratings yet

- 4.aircraft Nationality and Registration MarksDocument12 pages4.aircraft Nationality and Registration MarksNirmal FrancisNo ratings yet

- 0.35 A Comparative Study On Effectiveness of Underpass and Overpass AmongDocument17 pages0.35 A Comparative Study On Effectiveness of Underpass and Overpass AmongrajjaNo ratings yet

- To, To,: National Highwa Hority of IndiaDocument3 pagesTo, To,: National Highwa Hority of IndiaPushNo ratings yet

- Dongyang 1926 Parts Catalog Watermark 150625104921 Lva1 App 6891Document10 pagesDongyang 1926 Parts Catalog Watermark 150625104921 Lva1 App 6891shirley100% (46)

- M05-Automotive Mechanical System FundamentalDocument61 pagesM05-Automotive Mechanical System FundamentalMeseret Sisay50% (2)

- PCM Products GeneralDocument6 pagesPCM Products Generalvenugopalan srinivasanNo ratings yet

- ENG Luka Koper Tariffs 2020Document70 pagesENG Luka Koper Tariffs 2020GeoMarcNo ratings yet

- Pallet Racking Ewrcs22qxcDocument8 pagesPallet Racking Ewrcs22qxcTreeSix SolutionsNo ratings yet

- FB2750 M TMT2750CDocument8 pagesFB2750 M TMT2750Csiyavash seifNo ratings yet

- ShantiesDocument6 pagesShantiesfabiorr75No ratings yet

- Carraro 20.19Document10 pagesCarraro 20.19Mindaugas MonkevičiusNo ratings yet