Professional Documents

Culture Documents

Fluid 5

Uploaded by

mhd slmnOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fluid 5

Uploaded by

mhd slmnCopyright:

Available Formats

97

Example 4

Water at 15C is to be discharged from a reservoir at a rate of 18 L/s using two horizontal cast

iron pipes connected in series and a pump between

them. The first pipe is 20 m long and has a 6-cm

diameter, while the second pipe is 35 m long and has a

4-cm diameter. The water level in the reservoir is 30 m

above the centerline of the pipe. The pipe entrance is

sharp-edged, and losses associated with the connection

of the pump are negligible. Determine the required

pumping head and the minimum pumping power to maintain the indicated flow rate.

Properties The density and dynamic viscosity of water at 15C are = 999.1 kg/m3 and = 1.13810-

3

kg/ms. sharp-edged entrance. cast iron pipes.

D1 = 6 cm, D2 = 4 cm, ηpump =75%

Properties The density and dynamic viscosity of water at 15C are = 999.1 kg/m3 and = 1.13810-

3

kg/ms. The loss coefficient is KL = 0.5 for a sharp-edged entrance. The roughness of cast iron pipes

is = 0.00026 m.

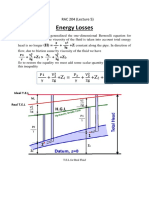

Analysis We take point 1 at the free surface of the tank, and point 2 and the reference level at the

centerline of the pipe (z2 = 0). Noting that the fluid at both points is open to the atmosphere (and thus

P1 = P2 = Patm) and that the fluid velocity at the free surface of the tank is very low (V1 0), the

energy equation for a control volume between these two points (in terms of heads) simplifies to

P1 V12 P V2 V22

+ + z1 + hpump = 2 + 2 + z 2 + hturbine + hL → z1 + hpump = + hL

g 2 g g 2 g 2g

Where

L V

2

hL = hL , total = hL ,major + hL ,minor = f + KL and the summation is over two pipes.

D 2g

Noting that the two pipes are connected in series and thus the flow rate through each of them

is the same, the head loss for each pipe is determined as follows (we designate the first pipe

by 1 and the second one by 2):

Pipe 1:

Q Q 0.018 m 3 /s

V1 = = = = 6.367 m/s

Ac1 D12 / 4 (0.06 m) 2 / 4

Fundamentals of Fluid Dynamics (Dr. Hameed Alawadi) 97

You might also like

- LecturesNotes (MEE122) 88Document1 pageLecturesNotes (MEE122) 88mhd slmnNo ratings yet

- Fluids - IIIDocument9 pagesFluids - IIIPOONAM RANINo ratings yet

- 2013 Fluids Solutions PDFDocument5 pages2013 Fluids Solutions PDFBakheit Layli100% (1)

- Lecture 5 2Document15 pagesLecture 5 2IbrahimDewaliNo ratings yet

- Fluid MachineryDocument34 pagesFluid MachineryEhtisham ZiaNo ratings yet

- Module HydraulicsDocument62 pagesModule HydraulicsTricia Mae CatapangNo ratings yet

- ME 363 - Fluid MechanicsDocument5 pagesME 363 - Fluid MechanicsCristobal MendozaNo ratings yet

- LecturesNotes (MEE122) 89Document1 pageLecturesNotes (MEE122) 89mhd slmnNo ratings yet

- Protok Realnog Fluida-3Document34 pagesProtok Realnog Fluida-3konticvNo ratings yet

- Fluid 2Document1 pageFluid 2mhd slmnNo ratings yet

- Bölüm 8 Çalışma SorularıDocument29 pagesBölüm 8 Çalışma SorularıBuse Nur ÇelikNo ratings yet

- Chapter 4 PipesDocument18 pagesChapter 4 Pipeshamadamjad047No ratings yet

- LecturesNotes (MEE122) 86Document1 pageLecturesNotes (MEE122) 86mhd slmnNo ratings yet

- Fluid MachineryDocument23 pagesFluid Machineryromanbrock991No ratings yet

- Exp 5 Head Loss Due To FrictionDocument17 pagesExp 5 Head Loss Due To FrictionnileshNo ratings yet

- Flow in PipelinesDocument14 pagesFlow in Pipelinesbewake711100% (1)

- DCC30122 - Fluids MechanicsDocument50 pagesDCC30122 - Fluids MechanicsHadif NuqmanNo ratings yet

- Pipe's Minor LossesDocument95 pagesPipe's Minor LossesJosept RevueltaNo ratings yet

- ProblemsDocument83 pagesProblemsShiva SanthojuNo ratings yet

- Student Handout 20 2014Document20 pagesStudent Handout 20 2014kietniNo ratings yet

- M/s 5 - 2 M/S) 10 (M) 16 - 0 (M) (0.08 4 / 4Document4 pagesM/s 5 - 2 M/S) 10 (M) 16 - 0 (M) (0.08 4 / 4Refisa JiruNo ratings yet

- Discharge From VesselsDocument6 pagesDischarge From VesselsMr ChuNo ratings yet

- Chapter 6: Steady Flow in PipesDocument9 pagesChapter 6: Steady Flow in PipesSyahid MuhammadNo ratings yet

- Hydraulics Solution Sheet 9 - Basic Hydraulics of Flow in PipesDocument5 pagesHydraulics Solution Sheet 9 - Basic Hydraulics of Flow in Pipessalem nourNo ratings yet

- Experiment 1 - Friction Losses in Pipes-ReportDocument41 pagesExperiment 1 - Friction Losses in Pipes-ReportKhairil Ikram67% (3)

- Closed Conduit SystemsDocument8 pagesClosed Conduit SystemsPatrick Joseph RoblesNo ratings yet

- Pipes Flow Analysis: CED, CECOS University, PeshawarDocument24 pagesPipes Flow Analysis: CED, CECOS University, PeshawarALIKHAN CU-40-2019BNo ratings yet

- Application of Bernoullis EquationDocument11 pagesApplication of Bernoullis EquationChong Zi HaoNo ratings yet

- Topic 4c Minor Losses Turbulent Flow in Circular Pipes 2021Document23 pagesTopic 4c Minor Losses Turbulent Flow in Circular Pipes 2021Nor SyamimiNo ratings yet

- MA3006 Tutorial 7 SolutionDocument4 pagesMA3006 Tutorial 7 Solutionclarence limNo ratings yet

- Fluid Mechanics Benno 7Document25 pagesFluid Mechanics Benno 7Ella PurnamasariNo ratings yet

- Coursework 2Document2 pagesCoursework 2tanatswaphiri54No ratings yet

- Experiment 1 - Friction Losses in Pipes-ReportDocument41 pagesExperiment 1 - Friction Losses in Pipes-ReportKhairil Ikram68% (53)

- Hydraulics Discussion 6 7Document2 pagesHydraulics Discussion 6 7livade lNo ratings yet

- MODULE#8 - Compressible FlowDocument12 pagesMODULE#8 - Compressible FlowChristianNo ratings yet

- Dimaano, John Michael A. 10-40670 Chapter FiveDocument27 pagesDimaano, John Michael A. 10-40670 Chapter FiveJohn Michael DimaanoNo ratings yet

- Ch.2 PapersDocument4 pagesCh.2 PapersOmed. HNo ratings yet

- Fluid Mechanics 203 Tutorial No.2 Applications of BernoulliDocument37 pagesFluid Mechanics 203 Tutorial No.2 Applications of BernoulliGeorge Opar100% (1)

- TutorialDocument7 pagesTutorialAnik MondalNo ratings yet

- Solved Problems - 6 ExerciseDocument6 pagesSolved Problems - 6 ExerciseRoberto Macias NNo ratings yet

- Chapter 2 - Groundwater Movements - Part 5 PDFDocument53 pagesChapter 2 - Groundwater Movements - Part 5 PDFTrisha Veronica Candelaria AVENGOZANo ratings yet

- Exp#3 Venturi Meter - 2016Document6 pagesExp#3 Venturi Meter - 2016ashwindranNo ratings yet

- Abril-Duhaylongsod-Baluran - Modelling ProjectDocument13 pagesAbril-Duhaylongsod-Baluran - Modelling ProjectKim Rohn AbrilNo ratings yet

- Experiment 1 - Friction Losses in PipesDocument34 pagesExperiment 1 - Friction Losses in PipesKhairil Ikram33% (3)

- Class 20 - Fluid Mechanics: Z G V P Z G V PDocument7 pagesClass 20 - Fluid Mechanics: Z G V P Z G V PMertYakarNo ratings yet

- Week 8 10 Hydraulic Structures Part I WEIRSDocument50 pagesWeek 8 10 Hydraulic Structures Part I WEIRSgeorgedytrasNo ratings yet

- Sample ProblemsDocument8 pagesSample Problemsaj shoppieNo ratings yet

- Sample Problems 7 PDF FreeDocument8 pagesSample Problems 7 PDF FreeEd Lawrence MontalboNo ratings yet

- MEC241 - Chapter 4Document15 pagesMEC241 - Chapter 4Jack SantosNo ratings yet

- Fluid Mechanics Lecture Material - Lesson 1Document25 pagesFluid Mechanics Lecture Material - Lesson 1Douglas Kufre-Abasi GilbertNo ratings yet

- 15 C While Boiling Saturated Water at 1 Atm. What Is The PowerDocument13 pages15 C While Boiling Saturated Water at 1 Atm. What Is The PowerchurvaloooNo ratings yet

- PipesDocument25 pagesPipesSidesway 26No ratings yet

- Solved Problems - 5 ExerciseDocument8 pagesSolved Problems - 5 ExerciseRoberto Macias NNo ratings yet

- O Discharge Measur. Op. CH L 3rd CLDocument16 pagesO Discharge Measur. Op. CH L 3rd CLGerardus PudyastowoNo ratings yet

- Pipe Systems and Networks: DR WCDK FernandoDocument29 pagesPipe Systems and Networks: DR WCDK FernandoSuranga Gayan0% (1)

- Exp#2 Venturi MeterDocument4 pagesExp#2 Venturi MeterasdNo ratings yet

- Tweg 2Document30 pagesTweg 2davpaffNo ratings yet

- Feynman Lectures Simplified 2C: Electromagnetism: in Relativity & in Dense MatterFrom EverandFeynman Lectures Simplified 2C: Electromagnetism: in Relativity & in Dense MatterNo ratings yet

- Test Bank Mid 2Document13 pagesTest Bank Mid 2mhd slmnNo ratings yet

- Advance Manufacturing Processes MCQ S 1 PDFDocument18 pagesAdvance Manufacturing Processes MCQ S 1 PDFmhd slmnNo ratings yet

- Presentation Chapter 04.1 7 PDFDocument1 pagePresentation Chapter 04.1 7 PDFmhd slmnNo ratings yet

- Presentation Chapter 04.1 4Document1 pagePresentation Chapter 04.1 4mhd slmnNo ratings yet

- Unit 4 Ucmp MCQDocument10 pagesUnit 4 Ucmp MCQmhd slmnNo ratings yet

- Module 1 Interoduction 8Document1 pageModule 1 Interoduction 8mhd slmnNo ratings yet

- Module 1 Interoduction 9Document1 pageModule 1 Interoduction 9mhd slmnNo ratings yet

- LecturesNotes (MEE122) 76Document1 pageLecturesNotes (MEE122) 76mhd slmnNo ratings yet

- Advanced Machine ProcessesDocument7 pagesAdvanced Machine Processesmhd slmnNo ratings yet

- Module 1 Interoduction 7Document1 pageModule 1 Interoduction 7mhd slmnNo ratings yet

- Module 1 Interoduction 6Document1 pageModule 1 Interoduction 6mhd slmnNo ratings yet

- Module 1 Interoduction 4Document1 pageModule 1 Interoduction 4mhd slmnNo ratings yet

- Module 1 Interoduction 5Document1 pageModule 1 Interoduction 5mhd slmnNo ratings yet

- LecturesNotes (MEE122) 78Document1 pageLecturesNotes (MEE122) 78mhd slmnNo ratings yet

- Module 1 Interoduction 3Document1 pageModule 1 Interoduction 3mhd slmnNo ratings yet

- LecturesNotes (MEE122) 77Document1 pageLecturesNotes (MEE122) 77mhd slmnNo ratings yet

- LecturesNotes (MEE122) 79Document1 pageLecturesNotes (MEE122) 79mhd slmnNo ratings yet

- LecturesNotes (MEE122) 74Document1 pageLecturesNotes (MEE122) 74mhd slmnNo ratings yet

- LecturesNotes (MEE122) 71Document1 pageLecturesNotes (MEE122) 71mhd slmnNo ratings yet

- LecturesNotes (MEE122) 75Document1 pageLecturesNotes (MEE122) 75mhd slmnNo ratings yet

- LecturesNotes (MEE122) 89Document1 pageLecturesNotes (MEE122) 89mhd slmnNo ratings yet

- LecturesNotes (MEE122) 82Document1 pageLecturesNotes (MEE122) 82mhd slmnNo ratings yet

- LecturesNotes (MEE122) 87Document1 pageLecturesNotes (MEE122) 87mhd slmnNo ratings yet

- LecturesNotes (MEE122) 72Document1 pageLecturesNotes (MEE122) 72mhd slmnNo ratings yet

- LecturesNotes (MEE122) 73Document1 pageLecturesNotes (MEE122) 73mhd slmnNo ratings yet

- LecturesNotes (MEE122) 84Document1 pageLecturesNotes (MEE122) 84mhd slmnNo ratings yet

- LecturesNotes (MEE122) 85Document1 pageLecturesNotes (MEE122) 85mhd slmnNo ratings yet

- LecturesNotes (MEE122) 86Document1 pageLecturesNotes (MEE122) 86mhd slmnNo ratings yet

- Fluid 52Document1 pageFluid 52mhd slmnNo ratings yet