Professional Documents

Culture Documents

Case Study Dfmea Pfmea

Uploaded by

bhuvaneshOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Case Study Dfmea Pfmea

Uploaded by

bhuvaneshCopyright:

Available Formats

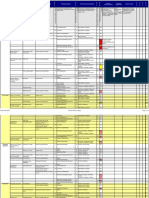

Failure Modes and Effects Analysis (Design FMEA)

SCOPE DEFINTION (STEP 1)

Company Name: Subject:

Borgwarner Power tranmission system(Chain)

Engineering Location: DFMEA Start Date: DFMEA ID Number:

Chennai 21-02-2020 FMEA/NPD021D

Customer Name: DFMEA Revision / Date: Design Responsibility:

M&M 24-07-2020 Karthik(dwsign lead)

Model of Year / Platform: Cross-Functional Team Confidential Level:

2023 D22 Bala(Quality); Ramanan(NPD); Manikandan(Design); Sudhakar(Manufacturing); Jaishankar (Program ma Business level/ Confidential

STRUCTURE ANALYSIS (STEP 2) FUNCTION ANALYSIS (STEP 3) FAILURE ANALYSIS (STEP 4) RISK ANALYSIS (STEP 5) OPTIMIZATION (STEP 6)

Detection (D) of FC/FM

Occurance (O) of FC

Severity (S) of FE

Status:

serial number #

Occurance (O)

Detection (D)

3. Next Lower level or (Untouched,

Severity (s)

DFMEA AP

3. Next Lower Level 1. Failure Effects (FE)

Characteristic Type 1. Next Higher Level 2. Focus Element 3. FAILURE CAUSE (FC) Target under Action Taken

Function and to Next Higher Level 2. FAILURE MODE (FM) of Current Prevention Current Detection Responsibile Completion

AP

1. Next Higher Level 2. Focus Element (Geometry, Material, Function and Function and of the Next Lower Prevention Action Detection Action Completion consideration, with Pointer to Remarks

Requirement or Element and/or the Focus Element Controls Controls Person Date

Surface Finish, Requirement Requirement Element or Characteristic Date in progress, Evidence

Characteristic Vechile End User

Coating, etc.) completed,

discarded)

Power Chain Bush(Size) To transmit To transmit Bush, Which 1.Frequent noise Chain may worn out. Improper seating of Bush OD is Chain wear

transmission power From power from makes the chain and vibration bush in the teeth designed to test, and

system engine to wheels. engine cranshaft to seat on the from the chain. radius(Due to high design (NVH), Noise

to cam shaft(4W) Sprocket 2. Degradation of OD size) requirements as vibration test

completely to primary function per tolerance procedure

1

promote smooth 7 sheet specifed 2 with 2 L NA NA NA NA NA NA NA NA NA NA NA NA

transmission of by Customer. equipment

power. (FRM/NPD/T09 available for

available. testing.

634981402.xlsx: Blank Template - DFMEAForm: AIAG-SAE-VDA 1 of 2 Organization's distribution policy statement.

Failure Modes and Effects Analysis (PROCESS FMEA)

SCOPE DEFINTION (STEP 1)

Borgwarner Assembly of chain

Company Name: Subject:

Chennai 17-01-2020 FRM/12/NPD/FMEA

Engineering Location: PFMEA Start Date: PFMEA ID Number:

M&M 22-05-2020 S.Sudhakar(Manufacturing Lead)

Customer Name: PFMEA Revision Date: Process Responsibility:

2022D15 Ramanan(NPD); Sudhakar(Manufacturing); Ravi (Quality) Business use/ Confidential

Co Model of Year / Platform: Cross-Functional Team Confidential Level:

nti

nu

ou

s

im

STRUCTURE ANALYSIS FUNCTION ANALYSIS FAILURE ANALYSIS RISK ANALYSIS OPTIMIZATION

pro

Detection (D) of FC/FM

ve

Occurance (O) of FC

me

Severity (S) of FE

Status:

Serial numnber #

special feature

Occurance (O)

nt 2. Function of the

Detection (D)

1. Function of Process (Untouched,

Severity (s)

1. Process Item, Process Step and 3. Function of the 1. Failure Effects (FE)

His 2. Process Step, Station Item, System, Current Current Detection Target under Action Taken

System, Subsystem, 3. Process Work Product Process Work to the Next Higher 2. Failure Mode (FM) of the 3. Failure Cause (FC) of Completion

AP

AP

tor No. and Name of the Subsystem, Part Prevention Controls of FC or Prevention Action Detection Action Responsibile Person Completion on consideration, with Pointer to Remarks

Part Element or Name Element - 4M Type Characteristics Element and Process Level Element and/or Focus Element the Next Lower Element Date

y Focus Element Element or Name of Controls of FC FM date in progress, Evidence

of the Process (Quantity value is Characteristics End user or Characteristics

the Process completed,

optional)

discarded)

1 B123 Assy line Block Building Machine Plant: Assembly of Assembles the Your plant: Width between inner Press tool Wear(one Tool life Mechanical None. Electrical poke S.Sudhakar 5/1/2021 Under Pending pending pending

(operation no. 30) To assemble the bush and inner Inner plate unable to seat in plates is low. side high and one monitoring is poke yoke at yoke to be (Manufacturing) consideartion

child parts and plates for making through fork the sprocket of side low) available and the end of made available

make a complete a Block as per stick CDM checking 2. Machine loading to be updated chute track is for detecting

chain. design and punches the equipment (Setting tool crack every avaialble to the width

Ship to plant: requirements. bush in to the Customer: Noise formation). month(FRM/N detect. between inner

To support the plates for making and vibration PD/23TL) plates(By using

primary function the Block. issue 2. Operator 2. CDM sensor based

of the vehicle. End user: 8 training and 4 checking 5 M automatic

End user: Degradation of setup sprocket contraol

Smoother primary function approval available at system).

transmission of for(PIR) the final

power and safre avaialble for station.

driving of all product

vehicle. and Process

parameters.

You might also like

- RT ETR-001 Rev D Engineer Test Request FormDocument1 pageRT ETR-001 Rev D Engineer Test Request FormVijay RajaindranNo ratings yet

- Key Product Characteristic Definitions and ControlsDocument2 pagesKey Product Characteristic Definitions and Controls57641100% (2)

- MSR-Columns hidden or deletedDocument2 pagesMSR-Columns hidden or deleted57641100% (1)

- ? What Are The Existing Controls, Ns What Are The Actions ForDocument10 pages? What Are The Existing Controls, Ns What Are The Actions ForPk NimiwalNo ratings yet

- Administering PDMWorks Workgroup PDFDocument138 pagesAdministering PDMWorks Workgroup PDFAlanRoqueGarciaNo ratings yet

- Problemsolving&Quality Tools TrainingDocument45 pagesProblemsolving&Quality Tools TrainingStirbalovaLilianaNo ratings yet

- APQP 3 - 1 Pan Brand Reporter V7c (586) Rev 19Document49 pagesAPQP 3 - 1 Pan Brand Reporter V7c (586) Rev 19Pranjal JangidNo ratings yet

- APQP FormsDocument23 pagesAPQP FormsJOECOOL670% (1)

- PPAP/APQP Requirements Checklist FormDocument17 pagesPPAP/APQP Requirements Checklist FormalexrferreiraNo ratings yet

- PFD, Pfmea & CPDocument482 pagesPFD, Pfmea & CPnadi gobinda0% (1)

- 1 ApqpDocument30 pages1 ApqpVIPIN YADAVNo ratings yet

- Injection Molding Scrap ReductionDocument57 pagesInjection Molding Scrap ReductionkggganiNo ratings yet

- FMEA Latest Format 1st Edition 2019Document2 pagesFMEA Latest Format 1st Edition 2019jineshdmehtaNo ratings yet

- SMT Generic Control PlanDocument3 pagesSMT Generic Control Plantuan mai vanNo ratings yet

- Blank Turtle DiagramDocument1 pageBlank Turtle DiagramnormalNo ratings yet

- VW QualityDocument16 pagesVW Qualityjohnoo7No ratings yet

- Advanced Product Quality Planning (APQP)Document22 pagesAdvanced Product Quality Planning (APQP)mjapmgNo ratings yet

- Oracle Big Data SQL Installation GuideDocument139 pagesOracle Big Data SQL Installation Guidepedro.maldonado.rNo ratings yet

- DRBFM Worksheet AnalysisDocument1 pageDRBFM Worksheet AnalysisHareth MRAIDINo ratings yet

- CorrectSPC PresentationDocument90 pagesCorrectSPC Presentationpkj009No ratings yet

- Repair and Modification of Printed Boards and Electronic AssembliesDocument6 pagesRepair and Modification of Printed Boards and Electronic AssembliesArvind NangareNo ratings yet

- Global 8d WorkbookDocument20 pagesGlobal 8d Workbookapi-556601577No ratings yet

- Meenakshi Molding Private Limited Process FMEA: O C C U RDocument4 pagesMeenakshi Molding Private Limited Process FMEA: O C C U Rilaya raja100% (1)

- Qms (Quality Management System)Document16 pagesQms (Quality Management System)Sundaramoorthy ArumugamNo ratings yet

- Apqp MiniDocument14 pagesApqp MiniSudhagarNo ratings yet

- Process Flow DiagramDocument2 pagesProcess Flow Diagramakav123No ratings yet

- Forever Requirements - ChryslerDocument35 pagesForever Requirements - ChryslerR H100% (1)

- Applied logic assessment: Traffic light colorsDocument70 pagesApplied logic assessment: Traffic light colorsdocsenNo ratings yet

- Advanced Product Quality Planning (APQP) and Production Part Approval Process (PPAP) Training MaterialDocument29 pagesAdvanced Product Quality Planning (APQP) and Production Part Approval Process (PPAP) Training MaterialxiwaxeNo ratings yet

- Benutzerhandbuch QTR Online Englische Version PDFDocument34 pagesBenutzerhandbuch QTR Online Englische Version PDFBrian BoruNo ratings yet

- DfmeaDocument42 pagesDfmeaabhijeet7362No ratings yet

- Shainin AmeliorDocument40 pagesShainin AmeliorOsman Tig100% (1)

- GDT Training PyramidDocument1 pageGDT Training PyramidkhalidcosmosNo ratings yet

- Root Cause Analysis - ShaininapproachDocument6 pagesRoot Cause Analysis - ShaininapproachRaghavendra KalyanNo ratings yet

- EML2322L-Engineering Change NoticeDocument5 pagesEML2322L-Engineering Change NoticeJohn MelvinNo ratings yet

- MSA WorksheetDocument29 pagesMSA Worksheetmohammad wasimNo ratings yet

- NCR Supplier PPAP Training PresentationDocument166 pagesNCR Supplier PPAP Training PresentationAmitava Datta67% (3)

- Woodward GCP-30 LeoPC1 37240 PDFDocument31 pagesWoodward GCP-30 LeoPC1 37240 PDFAbdul Kurniadi100% (1)

- Determining the Right Sample Size for an MSA StudyDocument80 pagesDetermining the Right Sample Size for an MSA StudyVikram BillalNo ratings yet

- Baby Techni ReportDocument25 pagesBaby Techni Reportwww.timzbaba100% (1)

- GM 1927 Supplier Quality ManualDocument109 pagesGM 1927 Supplier Quality ManualCarlos CarranzaNo ratings yet

- GM 1927-16b Injection Molding Process AuditDocument6 pagesGM 1927-16b Injection Molding Process AuditfernandoNo ratings yet

- Lj-Ts Series Horizontal ScreensDocument8 pagesLj-Ts Series Horizontal ScreensLuis Vallecillo100% (1)

- Quality Engineer or Supplier Quality or Failure Analysis EngineeDocument3 pagesQuality Engineer or Supplier Quality or Failure Analysis Engineeapi-121417252No ratings yet

- Advanced Product Quality Planning and Control Plan PDFDocument13 pagesAdvanced Product Quality Planning and Control Plan PDFCesarNo ratings yet

- Pfmea ExampleDocument5 pagesPfmea Exampleesivaks2000No ratings yet

- Global supplier quality 8D processDocument1 pageGlobal supplier quality 8D processAlex NogueiraNo ratings yet

- 8D ReportDocument20 pages8D ReportSuryanarayana Tata100% (1)

- PPAP PriruckaDocument10 pagesPPAP PriruckaKin MattNo ratings yet

- Design Verification Process Project III Samudra Indonesia 20/11/2019 Samudra Indonesia 21/12/2019 See Project III R1 ReportDocument6 pagesDesign Verification Process Project III Samudra Indonesia 20/11/2019 Samudra Indonesia 21/12/2019 See Project III R1 ReportAufa Jaya Perkasa LegalityNo ratings yet

- Q RaciDocument2 pagesQ RacigrandoviNo ratings yet

- Moudling Operation GSIC Process: MouldingDocument13 pagesMoudling Operation GSIC Process: MouldingBalakumaran MurugesanNo ratings yet

- Supplier-QUAL TM 0027-01 PPAP PackageDocument67 pagesSupplier-QUAL TM 0027-01 PPAP PackageMahe RonaldoNo ratings yet

- Surface Texture Measurement Fundamentals For Metrology Center Open HouseDocument54 pagesSurface Texture Measurement Fundamentals For Metrology Center Open HouseSushant VashisthaNo ratings yet

- Standard STD 105-0007: Special CharacteristicsDocument11 pagesStandard STD 105-0007: Special CharacteristicsKrunal PandyaNo ratings yet

- Processsignoffedition5 5 PDFDocument123 pagesProcesssignoffedition5 5 PDFJuan Manuel Martinez SanchezNo ratings yet

- Corrective Action 8d-LeakageDocument1 pageCorrective Action 8d-LeakageManoj JhajhriaNo ratings yet

- APQPDocument2 pagesAPQPjitenderbawalia0% (1)

- APQP Assessment Module GuideDocument44 pagesAPQP Assessment Module Guidea570303No ratings yet

- Quality Management AnswersDocument42 pagesQuality Management AnswersVrushali Nayak100% (1)

- Strategy Diagram ExamplesDocument8 pagesStrategy Diagram ExamplesmanuelNo ratings yet

- Master Form VDADocument4 pagesMaster Form VDAapi-3856433No ratings yet

- Long Service Award ListDocument1 pageLong Service Award ListbhuvaneshNo ratings yet

- Axles India LimitedDocument1 pageAxles India LimitedbhuvaneshNo ratings yet

- Updated Resume SupremeDocument3 pagesUpdated Resume SupremebhuvaneshNo ratings yet

- Production ReportDocument1 pageProduction ReportbhuvaneshNo ratings yet

- PC assignment data analysisDocument5 pagesPC assignment data analysisbhuvaneshNo ratings yet

- RIDGID A-Frame Fault LocatorDocument2 pagesRIDGID A-Frame Fault LocatorNazeer AhmedNo ratings yet

- GLA45AMG 156 133 Oil ChangeDocument2 pagesGLA45AMG 156 133 Oil ChangeJoan Callau FuentesNo ratings yet

- Star Control: Operating InstructionsDocument14 pagesStar Control: Operating InstructionsMohamed RaeesNo ratings yet

- Framo Service Stations - Contact InfoDocument11 pagesFramo Service Stations - Contact InfoDeliu AlexandruNo ratings yet

- CTX, FTXA15-50AW, AS, AT - 3PEN482320-7H - 2018 - 02 - Installation Manual - EnglishDocument16 pagesCTX, FTXA15-50AW, AS, AT - 3PEN482320-7H - 2018 - 02 - Installation Manual - EnglishHuanNo ratings yet

- TMS320C6000 One-Day WorkshopDocument262 pagesTMS320C6000 One-Day WorkshopkalataNo ratings yet

- 05132015173818KOLDocument250 pages05132015173818KOLAman DubeyNo ratings yet

- Buck Boost ConverterDocument32 pagesBuck Boost ConverterJanmejay MohapatraNo ratings yet

- ResumeDocument3 pagesResumeIsmahan Ochi NoroNo ratings yet

- Accessing Databases Using Amharic Natural LanguageDocument136 pagesAccessing Databases Using Amharic Natural Languageamanuel etafaNo ratings yet

- Fitting Adjustment: Temporary Manual Roadroid Pro Version 2 - BETA TESTINGDocument5 pagesFitting Adjustment: Temporary Manual Roadroid Pro Version 2 - BETA TESTINGPedro Alirio Sandoval JimenezNo ratings yet

- Crio 9951 User ManualDocument123 pagesCrio 9951 User ManualjefersonNo ratings yet

- Electricity Billing SystemDocument81 pagesElectricity Billing SystemAjay Sharma25% (4)

- Ican Export V1.0-GBDocument112 pagesIcan Export V1.0-GBhakim BGNo ratings yet

- Oracle FMW11gR2 Forms and Reports 11.1.2.0.0 With SLES11SP2GM ReportV1Document51 pagesOracle FMW11gR2 Forms and Reports 11.1.2.0.0 With SLES11SP2GM ReportV1medoBedoNo ratings yet

- 2DCrypt Image Scaling and CroppingDocument4 pages2DCrypt Image Scaling and CroppingInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- High Potential Cable TestingDocument1 pageHigh Potential Cable TestingAries dNo ratings yet

- A.d.a.4 Expo ChankevinDocument56 pagesA.d.a.4 Expo ChankevinManuel Alejandro Estrella GutiérrezNo ratings yet

- IMAGEnet I-Base en New CIDocument6 pagesIMAGEnet I-Base en New CISamuel DJOSSOUNo ratings yet

- Lab 1 - Code Conversion.: A. IntroductionDocument22 pagesLab 1 - Code Conversion.: A. IntroductionAishwarya JSNo ratings yet

- Inspeksi Mekanik Bulldozer v1Document1 pageInspeksi Mekanik Bulldozer v1kedapsayaaqNo ratings yet

- Madras Cements CaseStudy FinalDocument6 pagesMadras Cements CaseStudy Finalbhatia_rk100% (1)

- Tsubaki Cam Clutch BoxDocument16 pagesTsubaki Cam Clutch BoxHoàng Long VõNo ratings yet

- Resume NewDocument4 pagesResume NewZeal PavthawalaNo ratings yet

- Oracle Data Dictionary: - Tables, - Columns, - Users, - Data Files Etc. MetadataDocument9 pagesOracle Data Dictionary: - Tables, - Columns, - Users, - Data Files Etc. MetadataredroNo ratings yet

- Res-440 eDocument89 pagesRes-440 ePedro Luiz PráNo ratings yet