Professional Documents

Culture Documents

Responsibility Matrix APQP

Uploaded by

Khushbu IndreshOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Responsibility Matrix APQP

Uploaded by

Khushbu IndreshCopyright:

Available Formats

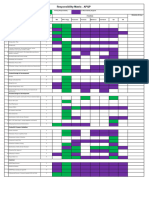

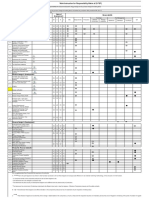

Responsibility Matrix - APQP (DRAFT COPY)

LEGENDS : Primary Responsibility Co-Resonsibility /Support

CFT Required ? Functions

S.NO. Description

(Y/N) Mkt. D&D / Engg. Production Purchase Maintence Tool Room QA HR

Planning programme

1 Receipt of RFQ / self design and development idea Y

2 Formation of CFT Y

3 Listing of customer Requirements Y

4 Feasibility Review Y

5 Submission of quotation and Contract Review N

6 Timing chart / Plan Y

7 Design goals N

9 Customer Expectations/ Past problem History/ review Y

/refelection in new project (TGW & TGR)

10 Reliability and Quality goals ( Develop product specification Y

linked to customer)

11 Develop Product and Process concept Y

12 Preliminary bill of materials Y

13 Preliminary Process Flow N

15 Preliminary listing of special product and process characterstics Y

16 Program Risk Evaluation and approval Y

Product Design & Development

3 DFMEA N

4 Design verification Plan N

5 Design Reviews Y

6 Design Change History /ECN Y

9 Engineering Drawings (Tools drawing, tool materials and

specification)

Process Design & Development

1 Product/Process quality system plan ( Process maturation plan ) Y

2 Process flow chart Y

3 Floor Plan Layout Y

5 Process FMEA Y

7 Pre-Launch Control Plan Y

8 Work instructions Y

9 Identification of skills & train Personnel Y

10 MSA / SPC plan (Gages / testing equipment verification) Y

11 Packaging Specifications Determination Y

Product & Process Validation

3 Product Trial Run Y

4 Preliminary Process Capability Study Y

5 Measurement systems Evaluation Y

6 Production Control Plan Y

7 Production Validation Testing Y

8 Identification of skills & train Personnel Y

9 Production Part Approval Y

10 Packaging Evaluation Y

11 Project Hand over Y

Common

1 APQP Phase Reviews Y

2 Problem Escalation Y

3 APQP Phase clearnace & Sign-Off Y

4 Collection & Review of Lessons Learned (TGW & TGR) Y

Remarks (If Any)

You might also like

- Responsibility Matrix - APQPDocument1 pageResponsibility Matrix - APQPKrunal PandyaNo ratings yet

- 420365400 Responsibility Matrix APQPDocument1 page420365400 Responsibility Matrix APQPcer.qualityNo ratings yet

- Responsibility Rank of Development: D:/APQP Document/ Special Product and Process CharactesticsDocument4 pagesResponsibility Rank of Development: D:/APQP Document/ Special Product and Process CharactesticsAL BARAKAH GRAINS100% (1)

- Responsibility Matrix 1of ApqpDocument4 pagesResponsibility Matrix 1of ApqpanuailddNo ratings yet

- Automotive Core Tools - CompressDocument69 pagesAutomotive Core Tools - CompressNikhil Pandey100% (1)

- Automotive Core Tools GuideDocument69 pagesAutomotive Core Tools GuideRAJESH KV100% (2)

- APQP Checklist: Supplier: Supplier Code: Part Name: Part NumberDocument2 pagesAPQP Checklist: Supplier: Supplier Code: Part Name: Part NumberRAHUL HERANI100% (1)

- Apqp PDFDocument2 pagesApqp PDFMi BuNo ratings yet

- Apqp PDFDocument2 pagesApqp PDFChandru JattiNo ratings yet

- New Product Development ProcedureDocument6 pagesNew Product Development ProcedureOM BhardwajNo ratings yet

- 02-F-02 APQP Timing PlanDocument2 pages02-F-02 APQP Timing Planshobhit2310100% (1)

- FM-NPD-12 (IPP Handover Check List)Document1 pageFM-NPD-12 (IPP Handover Check List)akash.vd.1603No ratings yet

- Sop For New Product Devolopment Process ObjectiveDocument18 pagesSop For New Product Devolopment Process ObjectiveYATHISH BABUNo ratings yet

- Apqp Matrix-Pin Post Side HingeDocument2 pagesApqp Matrix-Pin Post Side Hingeabhishek100% (1)

- 2022-06-15 EIT-Medidee - 03 V&V-TDDocument49 pages2022-06-15 EIT-Medidee - 03 V&V-TDJugurtha BoutlikhetNo ratings yet

- Procedure For ApqpDocument19 pagesProcedure For ApqpRaja RehaNo ratings yet

- PPAP ChecklistDocument1 pagePPAP ChecklistJan PeelsNo ratings yet

- Commissioning Responsibility MatrixDocument1 pageCommissioning Responsibility Matrixvin ssNo ratings yet

- PPAP Supplier TrainingDocument6 pagesPPAP Supplier Training4lexxNo ratings yet

- TQM - TRG - A-06 - Check Sheet - Rev02 - 20180603 PDFDocument17 pagesTQM - TRG - A-06 - Check Sheet - Rev02 - 20180603 PDFpradeep1987coolNo ratings yet

- APQP Chart With Responsibility Matrix: Development Categories Category Details A B C D E F Activity DescriptionDocument6 pagesAPQP Chart With Responsibility Matrix: Development Categories Category Details A B C D E F Activity DescriptionParveen KumarNo ratings yet

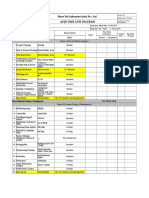

- Shree Ved Industries India Pvt. Ltd. Apqp Time Line DiagramDocument2 pagesShree Ved Industries India Pvt. Ltd. Apqp Time Line DiagramS. R. OvhalNo ratings yet

- Development Procedure 16-08-2021Document6 pagesDevelopment Procedure 16-08-2021CompdevpNo ratings yet

- Landscape of Planning Activity Ver. 04: Core PhaseDocument1 pageLandscape of Planning Activity Ver. 04: Core PhasetrungNo ratings yet

- APQP Gate Check ProgressDocument7 pagesAPQP Gate Check ProgressKamardeen Nazurudeen100% (1)

- APQP ProcedureDocument6 pagesAPQP ProcedureluckydaysNo ratings yet

- Visio-PMPP-DIA-001 - Rev0 - Tank Project Delivery Process - FinalDocument1 pageVisio-PMPP-DIA-001 - Rev0 - Tank Project Delivery Process - Final15142442No ratings yet

- Ford ApqpDocument17 pagesFord ApqpmageroteNo ratings yet

- Iso Qualified Company Standard Procedure BUSINESS Process MapDocument13 pagesIso Qualified Company Standard Procedure BUSINESS Process MapJohn P. BandoquilloNo ratings yet

- Walbro APQP Guidelines and SupportDocument10 pagesWalbro APQP Guidelines and SupportsubbuNo ratings yet

- 7 - P1 - Requirement Engineering - 24112022Document44 pages7 - P1 - Requirement Engineering - 24112022Mạnh QuỳnhNo ratings yet

- Advance Product Quality Planning - MatrixDocument6 pagesAdvance Product Quality Planning - Matrixomm100% (1)

- Value Stream Mapping: SeriesDocument36 pagesValue Stream Mapping: Seriespradeep1987coolNo ratings yet

- Apqp PhaseDocument6 pagesApqp PhaseDisha ShahNo ratings yet

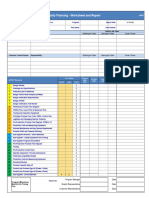

- MTP Micro Turn Proudtcs Apqp Timing Plan: S.No Description Resp. Status W1 W2Document9 pagesMTP Micro Turn Proudtcs Apqp Timing Plan: S.No Description Resp. Status W1 W2Sahil WadhwaNo ratings yet

- Scheduling Fundamentals: Engr. Mohamed MagedDocument75 pagesScheduling Fundamentals: Engr. Mohamed MagedEhabSufyanNo ratings yet

- APQP Responsibility MatrixDocument3 pagesAPQP Responsibility MatrixSuraj RawatNo ratings yet

- Apqp 20181116Document23 pagesApqp 20181116med amine mnasserNo ratings yet

- DR4 - Flap Pillion Holder-Master 22.12.11Document16 pagesDR4 - Flap Pillion Holder-Master 22.12.11premNo ratings yet

- Training Need IdentificationDocument42 pagesTraining Need IdentificationIshu VohraNo ratings yet

- APQP Format NationalDocument53 pagesAPQP Format NationalqualityNo ratings yet

- APQPWorkbookDocument39 pagesAPQPWorkbookAnjani kumarNo ratings yet

- ANPQP Version 2 1 - ACCOMPAGNATEUR - DAY 2 ON 2 MORNING - 251108Document69 pagesANPQP Version 2 1 - ACCOMPAGNATEUR - DAY 2 ON 2 MORNING - 251108adrianNo ratings yet

- PPAP Check ListDocument1 pagePPAP Check Listhello2er.ajayNo ratings yet

- APQP Sample FormatDocument32 pagesAPQP Sample FormatManigandan RNo ratings yet

- Project Management Hands-on Training Session 2 GuideDocument30 pagesProject Management Hands-on Training Session 2 GuideAnuj KhannaNo ratings yet

- APQP Process Ensures Supplier Quality PlanningDocument4 pagesAPQP Process Ensures Supplier Quality PlanningKristof MCNo ratings yet

- APQP Activities MatrixDocument7 pagesAPQP Activities MatrixPk Nimiwal100% (1)

- Me403.01 - Production and Operations Management - Lab ManualDocument33 pagesMe403.01 - Production and Operations Management - Lab ManualTUSHAR VALANo ratings yet

- 7 Magnificent Tools of QualityDocument31 pages7 Magnificent Tools of Qualityjunaid_256No ratings yet

- The Software Development Life Cycle SDLCDocument23 pagesThe Software Development Life Cycle SDLCsapsdeccNo ratings yet

- ANPQP - 3.0 - in ActionDocument14 pagesANPQP - 3.0 - in Actionjefry sitorus100% (1)

- ASUG QM Session 1 QM 101 Introduction To SAP Quality Management Module PDFDocument41 pagesASUG QM Session 1 QM 101 Introduction To SAP Quality Management Module PDFStorm100% (1)

- Manual 10-Project Communication Management-Book 3Document26 pagesManual 10-Project Communication Management-Book 3ms.aboulfotouhNo ratings yet

- 3-DPA Awareness ProgramDocument27 pages3-DPA Awareness ProgramVishal MaliNo ratings yet

- Anpqp Version 2 1 - Accompagnateur - Day 1 On 2 - 251108Document96 pagesAnpqp Version 2 1 - Accompagnateur - Day 1 On 2 - 251108adrianNo ratings yet

- Renault-Nissan Product Development ProcessDocument27 pagesRenault-Nissan Product Development Processjefry sitorus100% (1)

- APQP Matrix Pedal Yl1 at IsgDocument11 pagesAPQP Matrix Pedal Yl1 at Isgkaran singh100% (2)

- Lecture 2 OM PDFDocument11 pagesLecture 2 OM PDFhkboozNo ratings yet

- Pdvsa: Engineering Design ManualDocument3 pagesPdvsa: Engineering Design ManualGerson ContrerasNo ratings yet

- Model XMT868 PDFDocument111 pagesModel XMT868 PDFJAC 91No ratings yet

- Arduino Code SampleDocument5 pagesArduino Code SampleVon Russel SaringNo ratings yet

- Cisco Anyconnect Posture With Asa, Ise and Amp V1. 2: About This DemonstrationDocument29 pagesCisco Anyconnect Posture With Asa, Ise and Amp V1. 2: About This DemonstrationShady MohamedNo ratings yet

- Cracking Core Java Interviews Sample PDFDocument51 pagesCracking Core Java Interviews Sample PDFAmit MitraNo ratings yet

- Zghulam,+production+editor,+layout MustofahilmiDocument19 pagesZghulam,+production+editor,+layout MustofahilmiTiktok BelanjaNo ratings yet

- Deep Learning OnrampDocument1 pageDeep Learning OnrampwubiedNo ratings yet

- Automata TheoryDocument57 pagesAutomata Theorysir ABDNo ratings yet

- The Dust Bunnies COL FKBDocument36 pagesThe Dust Bunnies COL FKBPradeep ManralNo ratings yet

- Assignment 3 - Software Implementation PDFDocument8 pagesAssignment 3 - Software Implementation PDFSandaru RathnayakeNo ratings yet

- MAA NATIONAL HIGH SCHOOL 2ND SUMMATIVE TEST PROGRAMMING .NETDocument2 pagesMAA NATIONAL HIGH SCHOOL 2ND SUMMATIVE TEST PROGRAMMING .NETVanz MaNo ratings yet

- Introduction of Line BalancingDocument19 pagesIntroduction of Line Balancingwunan07100% (20)

- Spring Boot Reference 2.3.XDocument550 pagesSpring Boot Reference 2.3.XRam ChiyeduNo ratings yet

- Hrss-Xeg Program Command: User ManualDocument31 pagesHrss-Xeg Program Command: User ManualAnh HoàngNo ratings yet

- SSL Offloading Relieves Server CPU LoadDocument2 pagesSSL Offloading Relieves Server CPU Loadsyed_engrNo ratings yet

- CS 345B Homework 3: XML and Databases: Donald Kossmann Daniela Florescu Anish Das SarmaDocument2 pagesCS 345B Homework 3: XML and Databases: Donald Kossmann Daniela Florescu Anish Das SarmaAnfal ChNo ratings yet

- Development of Interactive Media With Contextual Teaching Learning To Enhance Vocational Schools Student Creativity in MalangDocument8 pagesDevelopment of Interactive Media With Contextual Teaching Learning To Enhance Vocational Schools Student Creativity in MalangrissmamNo ratings yet

- PC Express Dealers Pricelist June 25 2022Document2 pagesPC Express Dealers Pricelist June 25 2022Ivan UntalanNo ratings yet

- Manual RHRS 2014Document45 pagesManual RHRS 2014Tom BoeremaNo ratings yet

- Stochastic Sound SynthesisDocument4 pagesStochastic Sound SynthesispomodoroNo ratings yet

- FleXNET ConfiguratorDocument70 pagesFleXNET ConfiguratorRobertoNo ratings yet

- 555 Timer IC - WikipediaDocument20 pages555 Timer IC - WikipediaJuniorNo ratings yet

- Microsoft Office 365: Administrator GuideDocument10 pagesMicrosoft Office 365: Administrator GuideMichaelNo ratings yet

- 4720-0024-01A A8 Service Manual - 100504Document42 pages4720-0024-01A A8 Service Manual - 100504Nikolay Penev100% (1)

- Chapter 1 - Introduction To Embedded SystemsDocument70 pagesChapter 1 - Introduction To Embedded SystemsCU TưNo ratings yet

- MPT Prox Tags Setup GuideDocument4 pagesMPT Prox Tags Setup GuideAndre EinsteinNo ratings yet

- ? Wolf Face EmojiDocument1 page? Wolf Face EmojiXxxɴɪɴᴊᴀɢᴜʀʟxxXNo ratings yet

- Scheme of Work: Cambridge IGCSE Information and Communication Technology 0417Document64 pagesScheme of Work: Cambridge IGCSE Information and Communication Technology 0417Benish RehanNo ratings yet

- OI - HovaCAL® N - V2.0.1Document137 pagesOI - HovaCAL® N - V2.0.1Alexis BerruNo ratings yet

- Product Backlog ManagementDocument8 pagesProduct Backlog ManagementSu-kEm Tech LabNo ratings yet