Professional Documents

Culture Documents

Ecostan CG 75

Uploaded by

Dipesh PatelOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ecostan CG 75

Uploaded by

Dipesh PatelCopyright:

Available Formats

ECOSTAN INDIA PRIVATE LIMITED

LUDHIANA-MALERKOTLA ROAD, KM-23, VPO LEHRA, DISTT. LUDHIANA-141118

MANUFACTURERS OF COMPLETE BIOMASS SOLUTIONS

Annexure: 1

ECOSTAN Chipper Grinder Machine Model ECOSTAN® CG 75 Technical Details:

Description:

Chipper Grinder is Pocket Drum Type Chipper. It is fully Automatic Control Machine which

can convert any type of Agri/Forest waste into Chipped form for further uses or

transportation purposes.

Working Parameters:

✓ The machine can operate in both Auto & Manual modes.

✓ In case of over feeding, Chipper in-feed rollers will stop & re-start automatically to

safeguard the Chipper Machine from overfeeding or damage.

✓ Perforated screen can be changed to get the desired output up to some limited size

✓ Foot Switch is used to reverse the in-feed rollers.

Raw Material Parameters:

Sugarcane Leaves, Sugarcane Bagasse, Veneer

In-Feed Raw Material (Type) Waste, Coconut Shells, Cotton & Corn Stalks, Corn

Cobs, Tree Leaves & Shrubs etc.

In-Feed Raw Material (Size) Maximum Diameter of 25mm

Acceptable Moisture in Raw material for 25% Max (Addition in moisture may reduce the

best results production or keep jamming the machine)

Raw Material

www.ecostan.com Email: sales@ecostan.com (V 11.1)

Page 1

ECOSTAN INDIA PRIVATE LIMITED

LUDHIANA-MALERKOTLA ROAD, KM-23, VPO LEHRA, DISTT. LUDHIANA-141118

MANUFACTURERS OF COMPLETE BIOMASS SOLUTIONS

Annexure: 2

Specifications of Chipper Grinder Machine Model ECOSTAN® CG 75

Particulars Description

Up-to: 3,000 KG/HR

Production (Actual production may vary; depends on the combination of raw

material)

Rotter Plate Material MS Made

Body Thickness Plate 25 mm

Blade Material HCHC

Blade Thickness 13 mm

Perforated Screen Type MS Made

Dead Blade Type EN 8

No of Reduction Gears 3

In-feed Chamber Mouth 32 inches Wide

Output Material Size 10 mm – 50 mm Length (Depends on raw material type)

Operator - 1

Manpower Required

Labor – 2

Consumable Parts Detail:

Sr. No. Item Name In Chipper Extra with Chipper

1 Chipper Blades 24 Pcs 2 Pcs

2 Cutting Blade Bolts 48 Pcs 8 Pcs

3 Dead Blade 1 Pcs -

4 Perforated Screen 1 Pc -

www.ecostan.com Email: sales@ecostan.com (V 11.1)

Page 2

ECOSTAN INDIA PRIVATE LIMITED

LUDHIANA-MALERKOTLA ROAD, KM-23, VPO LEHRA, DISTT. LUDHIANA-141118

MANUFACTURERS OF COMPLETE BIOMASS SOLUTIONS

Annexure: 3

Chipper Grinder Machine & Accessories

Particulars Description

Chipper Grinder Machine

ECOSTAN® CG 75

Model

75 HP Electric Main Motor attached with Pulley to drive Grinder

Power Required

3 HP with Speed Reduction Gear on the in-feed conveyor

(Total Power Required:

3 HP with Speed Reduction Gear on the in-feed rollers

83 HP/ 62.25 K.W.)

2 HP with Speed Reduction Gear on the under-belt conveyor

Nylon Belts (V-Belts) 5 Nylon Belts to drive the Grinder Pulley

4 Rotor

Rotors & Rollers

8 Rollers

1 x Belt Conveyor 10 feet long to drift the material into the Chipper Grinder

Belt Conveyors 1 x Belt Conveyor as per the size if chipper base is used to drive out the

chipped material from the Chipper Grinder

Electrical Motors Make: Siemens/ Crompton/ Kirloskar/ ABB/ Bharat Bijlee

Electrical Panel Make: Schneider

Control System Type Ecostan Automatic Control System

Electrical Cable & Wires From Chipper Grinder to Electric Panel 18 feet long

Reduction Gears Make: Motovario/ Regal Marathon/ Rotomotive/ Top Transmission

Bearings Make: SKF/ TIMKEN/ NTN/ DODGE/ NBC

Tool Kit For calibration of main components

✓ We reserve the right to change any specification for the Model ECOSTAN® CG 75 without

any intimation

www.ecostan.com Email: sales@ecostan.com (V 11.1)

Page 3

ECOSTAN INDIA PRIVATE LIMITED

LUDHIANA-MALERKOTLA ROAD, KM-23, VPO LEHRA, DISTT. LUDHIANA-141118

MANUFACTURERS OF COMPLETE BIOMASS SOLUTIONS

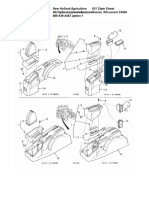

Annexure: 4

Chipper Grinder Machine Model ECOSTAN® CG 75

✓ This drawing is for demonstration purpose only, Drawing is not to scale, Drawing is

Copyright © of ECOSTAN®

www.ecostan.com Email: sales@ecostan.com (V 11.1)

Page 4

You might also like

- Ecostan HM 50Document4 pagesEcostan HM 50Rohan AgarwalNo ratings yet

- Ecostan Esm 150Document4 pagesEcostan Esm 150angdutta2No ratings yet

- ECOSTAN DualFeed™ 90Document5 pagesECOSTAN DualFeed™ 90Dipesh PatelNo ratings yet

- Ecostan 90 HDDocument5 pagesEcostan 90 HDRohan AgarwalNo ratings yet

- Sawdust Making MachineDocument4 pagesSawdust Making MachineSwati YadavNo ratings yet

- ECOSTAN Flash Dryer (Single Pass) FD 25Document4 pagesECOSTAN Flash Dryer (Single Pass) FD 25Rohan AgarwalNo ratings yet

- Ecostan 90Document5 pagesEcostan 90Deepesh GuptaNo ratings yet

- Ecostan India Private Limited: Manufacturers of Complete Briquetting SolutionsDocument4 pagesEcostan India Private Limited: Manufacturers of Complete Briquetting SolutionsSwati YadavNo ratings yet

- Biomass Briquette MachineDocument4 pagesBiomass Briquette Machineramanathan72-1No ratings yet

- Applitrac Manual ImplementsDocument22 pagesApplitrac Manual ImplementsSatish Kumar D VNo ratings yet

- Achinta Pran Sarmah Quotation................................Document8 pagesAchinta Pran Sarmah Quotation................................Agro SolutionNo ratings yet

- Fine Caot 80 AXDocument2 pagesFine Caot 80 AXPrasad JadhavNo ratings yet

- Design of Waste Shredder Machine: Asst. Prof. S.Nithyananth, Libin Samuel, Nithin Mathew, S.SurajDocument5 pagesDesign of Waste Shredder Machine: Asst. Prof. S.Nithyananth, Libin Samuel, Nithin Mathew, S.SurajRohan GadhveNo ratings yet

- Achinta Pran Sarmah QuotationDocument8 pagesAchinta Pran Sarmah QuotationAgro SolutionNo ratings yet

- Briquette Moulding MachineDocument29 pagesBriquette Moulding MachineLife of kalyanNo ratings yet

- S.M.G. Industries: (Structural and Mechanical EngineersDocument3 pagesS.M.G. Industries: (Structural and Mechanical EngineersRamNo ratings yet

- Banana Expert System - Farm ImplementDocument11 pagesBanana Expert System - Farm ImplementbhushanNo ratings yet

- 1000KG - Fully Automatic - Raw Cashew Nut Processing Machine - OSCAR CASHEW TECH - Ahmedabad - Gujarat - IndiaDocument8 pages1000KG - Fully Automatic - Raw Cashew Nut Processing Machine - OSCAR CASHEW TECH - Ahmedabad - Gujarat - IndiaOscar CashewtechNo ratings yet

- MR Sultan Ethiopia Feb 24 Offer For 100 Bales Per Day Cotton Ginning & Pressing PlantDocument11 pagesMR Sultan Ethiopia Feb 24 Offer For 100 Bales Per Day Cotton Ginning & Pressing Plantsultannesru2030No ratings yet

- Enviro Caretech: Tel No.:-9610238442Document9 pagesEnviro Caretech: Tel No.:-9610238442Pawan KhandelwalNo ratings yet

- S.M.G. Industries: (Structural and Mechanical EngineersDocument3 pagesS.M.G. Industries: (Structural and Mechanical EngineersRamNo ratings yet

- LON GK GK523H EngDocument12 pagesLON GK GK523H EngNaveed ShoukatNo ratings yet

- Single Stage Injection Stretch Blow Molding MachineDocument2 pagesSingle Stage Injection Stretch Blow Molding MachineAmit KarNo ratings yet

- 110MM Plastic Reprocess Machine (220KG)Document5 pages110MM Plastic Reprocess Machine (220KG)Vivek MoreNo ratings yet

- PI 3 Machines With 2 Lanes Log Saw & 2 Boxes Packing MachineDocument8 pagesPI 3 Machines With 2 Lanes Log Saw & 2 Boxes Packing MachineMURALITHHARANNo ratings yet

- Comitrol Processor Model 1700: Controlled Particle Size ReductionDocument2 pagesComitrol Processor Model 1700: Controlled Particle Size ReductionNguyễn Lê Anh KhoaNo ratings yet

- Amey Engineers Shredders and Crushers CatalogDocument26 pagesAmey Engineers Shredders and Crushers CatalogNinad LeleNo ratings yet

- 5TPH Mobile Seed Cleaning MachineDocument7 pages5TPH Mobile Seed Cleaning MachinevillegasfrankieNo ratings yet

- Primary00 Processing of Millets01Document69 pagesPrimary00 Processing of Millets01Biz InvestNo ratings yet

- Metod-Offer-Vertex Group - 27.05.2017Document32 pagesMetod-Offer-Vertex Group - 27.05.2017shaiyek taslimNo ratings yet

- Plant Expenses - Mr. Devjeet SinghDocument4 pagesPlant Expenses - Mr. Devjeet SinghofficialdevjeetsinghNo ratings yet

- Eco-Friendly: Ruian Zhenjing Machinery. PVT - LTDDocument8 pagesEco-Friendly: Ruian Zhenjing Machinery. PVT - LTDBikash NayakNo ratings yet

- Acc-1224gx 2.5.24Document8 pagesAcc-1224gx 2.5.24Jerry LoeraNo ratings yet

- Solutions Library Product: Imara Tech Multi-Crop ThresherDocument3 pagesSolutions Library Product: Imara Tech Multi-Crop ThresherGojjam LibayNo ratings yet

- Design and Fabrication of Coconut de HuskingDocument5 pagesDesign and Fabrication of Coconut de HuskingKenneth LorenzoNo ratings yet

- Advance Quality Chara Cutter Without Motor, 600 KG/HR: DescriptionDocument3 pagesAdvance Quality Chara Cutter Without Motor, 600 KG/HR: DescriptionvmuthubharathNo ratings yet

- Quotation - Biogas Plant 20 TonDocument3 pagesQuotation - Biogas Plant 20 TonAnkit Agrawal0% (1)

- Modifikasi Sistem Transmisi Pada Mesin Pencacah Sampah - Limbah Plastik Dengan Sistem Crusher Dan Silinder Pemotong Tipe ReelDocument11 pagesModifikasi Sistem Transmisi Pada Mesin Pencacah Sampah - Limbah Plastik Dengan Sistem Crusher Dan Silinder Pemotong Tipe ReelmyunusanisNo ratings yet

- Dyeing MachineDocument63 pagesDyeing Machineanowartex100% (2)

- Final Krishinery Brochure 1 PDFDocument25 pagesFinal Krishinery Brochure 1 PDFSantosh KunwarNo ratings yet

- User Manual English VersionDocument15 pagesUser Manual English VersionEdwinGtHJNo ratings yet

- Size ReductionDocument28 pagesSize Reductionchurvalooo100% (1)

- Charcoal Briquette Production Line 2-3tonDocument32 pagesCharcoal Briquette Production Line 2-3tonБат-Эрдэнэ ЭрдэнэчулуунNo ratings yet

- Performance Evaluation of Shredder For AgriculturalDocument7 pagesPerformance Evaluation of Shredder For AgriculturalDanica Joyce DayritNo ratings yet

- SaiDocument28 pagesSaiShivaradhan KondaNo ratings yet

- Agromill Reaper Binder PDFDocument1 pageAgromill Reaper Binder PDFSourabh KulkarniNo ratings yet

- Shreeji MahrasatraDocument4 pagesShreeji MahrasatraShivam AcharyaNo ratings yet

- Ginning Investment Machine Lay OutDocument14 pagesGinning Investment Machine Lay OutGizachew ZelekeNo ratings yet

- Design and Fabrication of Organic Portable Shredder Machine IJERTV6IS080181Document4 pagesDesign and Fabrication of Organic Portable Shredder Machine IJERTV6IS080181Alodia JabamiNo ratings yet

- Panchal Plastic Machinery PVT LTDDocument28 pagesPanchal Plastic Machinery PVT LTDsan dipNo ratings yet

- Metatech Polishing QuotDocument13 pagesMetatech Polishing QuotRohitShingadeNo ratings yet

- 29naimi PDFDocument13 pages29naimi PDFX800XLNo ratings yet

- Strzelecki Fiber Recycling 2007Document26 pagesStrzelecki Fiber Recycling 2007Jose Lorenzo ToralNo ratings yet

- Design and Fabrication of An Economical Coconut Dehusking MachineDocument9 pagesDesign and Fabrication of An Economical Coconut Dehusking MachineMohamed SaleemNo ratings yet

- Billet Quality IS13106Document2 pagesBillet Quality IS13106fernando cruzado padillaNo ratings yet

- Rss 120-m Recycling Shredder Screener Sell Sheet Pss-1339-00-EnDocument2 pagesRss 120-m Recycling Shredder Screener Sell Sheet Pss-1339-00-Enamolsinha1No ratings yet

- J-Bubbler PC: The Ultimate OptionDocument2 pagesJ-Bubbler PC: The Ultimate OptionTimothy MartinezNo ratings yet

- CatlogDocument9 pagesCatlogPrashanth VenkataramanaNo ratings yet

- Waste Sorting SolutionDocument8 pagesWaste Sorting SolutionLi GaryNo ratings yet

- Circular Vi To XiiDocument3 pagesCircular Vi To XiiDipesh PatelNo ratings yet

- Health Check Up Booklet 2023 FinalDocument8 pagesHealth Check Up Booklet 2023 FinalDipesh PatelNo ratings yet

- Briquetting Machine (Comp)Document1 pageBriquetting Machine (Comp)Dipesh PatelNo ratings yet

- Quotation - ES - 22-23 - 10371Document3 pagesQuotation - ES - 22-23 - 10371Dipesh Patel100% (1)

- Grove Gmk6450Document100 pagesGrove Gmk6450cristiano.faddaNo ratings yet

- C610 / MPS610C ES6405: Spare Parts Illustration ManualDocument23 pagesC610 / MPS610C ES6405: Spare Parts Illustration ManualWalterNo ratings yet

- A Look at The New MP Transfer CaseDocument4 pagesA Look at The New MP Transfer CaseКостя СеверинNo ratings yet

- CRP900 Benchtop PRO Assembly Instructions v2019Q1 1Document86 pagesCRP900 Benchtop PRO Assembly Instructions v2019Q1 1glamura100% (1)

- PowerPlus-SA-10KVA-3x400V UPS GamatronicDocument107 pagesPowerPlus-SA-10KVA-3x400V UPS GamatronicFernando Alexander SarmientoNo ratings yet

- Pajero Sport GLS 4WD 7 Seats (Diesel) (Automatic) : MechanicalDocument4 pagesPajero Sport GLS 4WD 7 Seats (Diesel) (Automatic) : MechanicalEzequiel Dos SantosNo ratings yet

- Catalogo Quality ElevatorDocument268 pagesCatalogo Quality ElevatorFrancis PinheiroNo ratings yet

- Superlacht280 WrmsDocument5 pagesSuperlacht280 WrmsgustavoNo ratings yet

- FL6051 Maint Kit 358Document3 pagesFL6051 Maint Kit 358rburtonshawNo ratings yet

- Manual de Servicio Montacargas Hyundai DS45S-7Document246 pagesManual de Servicio Montacargas Hyundai DS45S-7Jose A. Basanta H.0% (1)

- Soa TLDMDocument1 pageSoa TLDMAmir AsyrafNo ratings yet

- Take Home Pack Gr. 9 TechnologyDocument8 pagesTake Home Pack Gr. 9 Technologythokoanebokang00No ratings yet

- Dm2x2 ServiceManual - enDocument57 pagesDm2x2 ServiceManual - enAny MinimundoNo ratings yet

- 318-Y (H05VV-F) : Ordinary Duty PVC Insulated and Sheathed Flexible CordsDocument4 pages318-Y (H05VV-F) : Ordinary Duty PVC Insulated and Sheathed Flexible CordsterradyneamgNo ratings yet

- (Power Systems) Wen-Wei Chen, Jiann-Fuh Chen (Auth.) - Control Techniques For Power Converters With Integrated Circuit-Springer Singapore (2018)Document195 pages(Power Systems) Wen-Wei Chen, Jiann-Fuh Chen (Auth.) - Control Techniques For Power Converters With Integrated Circuit-Springer Singapore (2018)archssiNo ratings yet

- Kezelesi Utmutato Q3 RF 2010 AngolDocument12 pagesKezelesi Utmutato Q3 RF 2010 AngolClaudiu AdamNo ratings yet

- Trinity Advanced Pro: Instruction ManualDocument26 pagesTrinity Advanced Pro: Instruction ManualZondaNo ratings yet

- Gearshift Selector, 12 X 12 & 16 X 16 TransmissionDocument4 pagesGearshift Selector, 12 X 12 & 16 X 16 TransmissionrafaNo ratings yet

- Spare Parts NeoliftDocument184 pagesSpare Parts Neoliftthiago candidoNo ratings yet

- Electromagnetic ClutchDocument4 pagesElectromagnetic ClutchKunal PatidarNo ratings yet

- Piezo and Magnetic BuzzersDocument4 pagesPiezo and Magnetic BuzzersM Salman RyanNo ratings yet

- Enlite LED LAMPS Europe EnglishDocument56 pagesEnlite LED LAMPS Europe EnglishMastin SneadNo ratings yet

- Varodry: Dry Screw Vacuum PumpsDocument8 pagesVarodry: Dry Screw Vacuum PumpsDilson Barbosa RamosNo ratings yet

- Cableado IndustrialDocument16 pagesCableado IndustrialzerohuntercodeNo ratings yet

- TEA2025B TEA2025D: Stereo Audio AmplifierDocument9 pagesTEA2025B TEA2025D: Stereo Audio AmplifierSasha PkhidenkoNo ratings yet

- Remote Vehicle Control Through Cell Phone Using DTMFDocument11 pagesRemote Vehicle Control Through Cell Phone Using DTMFIJRASETPublicationsNo ratings yet

- DI78Document1 pageDI78Erln LimaNo ratings yet

- Kioxia SSD XG6-P Product BriefDocument2 pagesKioxia SSD XG6-P Product Brieftanzim ornabNo ratings yet

- 9320 Manual - PDF de AmperimetroDocument37 pages9320 Manual - PDF de AmperimetroluisNo ratings yet

- BE Cat Penn SSElectronicTempControlsDocument15 pagesBE Cat Penn SSElectronicTempControlsjose.patinojllNo ratings yet