Professional Documents

Culture Documents

ITP-Steel Structure New

Uploaded by

Prasanta ParidaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ITP-Steel Structure New

Uploaded by

Prasanta ParidaCopyright:

Available Formats

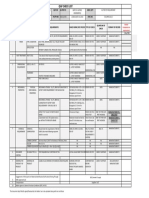

SIMPLEX INFRASTRUCTURES LIMITED

NOAPARA-BARANAGAR-DAKHINESWAR METRO RAILWAY PROJECT, KOLKATA

CONSTRUCTION OF PSC VIADUCT, EMBANKMENTS AND STATIONS INCLUDING E&M WORKS IN CONNECTION WITH EXTENSION OF METRO RAILWAY LINE BETWEEN CH: 2591M TO CH:6373M FOR NOAPARA

(EXCLUDING)-BARANAGAR-DAKHINESWAR OF KOLKATA METRO IN THE STATE OF WEST BENGAL, INDIA

INSPECTION & TEST PLAN - STEEL STRUCTURE WORK FOR STEEL BRIDGE AND METRO STATION

ITP REF: 012/SIL/RVNL/C 3004/VOL.1/05 DATE: 20/02/2015

SCOPE OF

REFERENCE INSPECTION

SL. DESCRIPTION OF FREQUENCY OF

CHARACTERISTICS TYPE OF CHECK ACCEPTANCE CRITERIA DOCUMENTS / REMARKS

NO. MATERIALS CHECK

SPECIFICATION

SIL RVNL

1 Incoming Inspection of Raw Materials and Bought Out Items

Dimension Measurement 100% As per drawing

Physical Appearance Visual Inspection 100% No pitting & heavy rusting.

Structual steel girder conforming to FE

Mechanical Tests - UTS, 410B(O) as per IS:2062- 2011 Grade B

Yield stress, elongation & Verify MTC and for cross frame the steel shall MTC, Challlan, Lab Test

1.1 Steel plates & Rolled Sections W R

bend test & Impact test MTC-100% and Lab Test: confirm IS 226-1975 for steel bridge. Report & Site Register

Built up sections are made from hot

One sample for each

rolled plates confirming to ASTM A 572

Invoice . Gr 50 ( 345 MPA) steel Hot rolled

sections except beams are mill section

complying with IS 2062 for 240 MPA

yield for station structures.

Chemical Properties Verify MTC

UT at site: One sample

As per ASTM 578 level B & Test

UT Visual for each Heat No in >/=

Report

20mm thk.

For GMAW: SFA/AWS A 5.18 ER-

Welding Filler Wire / Electrodes / challan & Batch Test 70S-6 / For SAW: SFA/AWS 5.17 Site Register / Batch Test

1.2 Specification 100% W R

Flux etc. Certificate EM-12-K / For SMAW: SFA/AWS 5.1 Certificate

E-7018.

Dimension Measurement One sample in every lot As per drawing

MTC, Challlan, Lab Test

1.3 HSFG Bolts, Nuts & Washers W R/W

Report & Site Register

TC-100% and Lab Test:

Mechanical Properties Verify MTC IS: 1367 Part-III & Test Report

One sample per Invoice .

Client Specification / Approved Site Register / Batch Test

1.4 Primer & Paints Specification Batch Test Certificate 100% W R

technical literature of manufacturer. Certificate

SCOPE OF

REFERENCE INSPECTION

SL. DESCRIPTION OF FREQUENCY OF

CHARACTERISTICS TYPE OF CHECK ACCEPTANCE CRITERIA DOCUMENTS / REMARKS

NO. MATERIALS CHECK

SPECIFICATION

SIL RVNL

Dimension Measurement Random

Client Specification / Relevant MTC, Challlan, Lab Test

1.5 Stud Shear Connector W R

MTC-100% and Lab Test: Code. Report & Site Register

Mechanical Properties Test Certificate One sample for each

Batch / Lot.

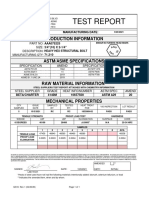

2 Pre-Manufacturing Process

SAW Visual, NDT and DT 100%

Inspection Reports / NDT

Procedure Qualification Record

2.1 SMAW Visual, NDT and DT 100% AWS D1.1 / Technical Specification Reports / Lab Test W W&R

(PQR)

Certificate

GMAW Visual, NDT and DT 100%

SAW Verify Approved PQR 100%

Welding Procedure Specification

2.2 SMAW Verify Approved PQR 100% AWS D1.1 / Technical Specification Approved WPS W W&R

(WPS)

GMAW Verify Approved PQR 100%

Visual Verify Approved WPS 100%

Data Sheet / NDT Reports /

2.3 Welder Qualification Test AWS D1.1 / Technical Specification Welder's Certificate & ID W W&R

Card

NDT Verify Approved WPS 100%

SCOPE OF

REFERENCE INSPECTION

SL. DESCRIPTION OF FREQUENCY OF

CHARACTERISTICS TYPE OF CHECK ACCEPTANCE CRITERIA DOCUMENTS / REMARKS

NO. MATERIALS CHECK

SPECIFICATION

SIL RVNL

3 Manufacturing Process

Dimension Measurement 100%

3.1 Marking As per approved drawing Dimension Report W R

Marking Measurement 100%

3.2 Cutting Dimension Measurement Random As per approved drawing Dimension Report W R

3.3 Layout of Components & Joints Dimension Visual & Measurement 100% As per approved drawing Inspection Report W W&R

3.4 Jigs, Fixtures & Templates Dimension Visual & Measurement 100% As per approved drawing Approved Drawing W R/W

Edge Preparation of

Visual 100%

Joints

3.5 Fit up Dimension Measurement 100% As per approved drawing Fit up inspection Report W W&R

Temporary Support to

Visual 100%

avoid Distortion

Welding Parameters

Approved WPS / As per

(Current, Voltage, Travel Random

job requirement

Speed etc.)

Consumables

(Electrodes, Filler Wire, Specification 100%

Flux etc.)

3.6 Welding As per approved WPS Internal inspection Report W W&R

Approved Welder's

Welder's Identification 100%

Certificate & ID Card

Approved WPS Visual 100%

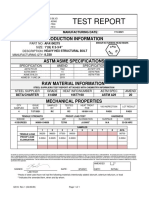

SCOPE OF

REFERENCE INSPECTION

SL. DESCRIPTION OF FREQUENCY OF

CHARACTERISTICS TYPE OF CHECK ACCEPTANCE CRITERIA DOCUMENTS / REMARKS

NO. MATERIALS CHECK

SPECIFICATION

SIL RVNL

Dimension Measurement 100%

Visual Inspection Visual 100%

Distortion Visual & Measurement 100%

Final Inspection Report /

3.7 Final Inspection As per approved drawing W W/R

Approved Drawing

Alignment Measurement 100%

Weld Size Weld Gauge Random

Finishing Visual 100%

100% for Groove Joints &

DPT Visual As per AWS D1.1 Site Register / DPT Report W W&R

20% for Fillet Joints.

100 % for bevel butt joint

3.8 NDT UT Visual As per AWS D1.1 Site Register / UT Report W W&R

in case of Bridge Girder

Random as per available

RT ……… position in case of Bridge As per AWS D1.1 Site Register / UT Report W W&R

Gireder only

Dimension Visual & Measurement 100%

Hole Matching Visual Random

3.9 Trial Assembly As per approved drawing / IS:7215 Inspection Report / Protocol W W

Camber Visual & Measurement 100%

Straightness Measurement 100%

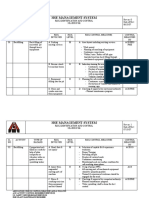

SCOPE OF

REFERENCE INSPECTION

SL. DESCRIPTION OF FREQUENCY OF

CHARACTERISTICS TYPE OF CHECK ACCEPTANCE CRITERIA DOCUMENTS / REMARKS

NO. MATERIALS CHECK

SPECIFICATION

SIL RVNL

4 Surface Preparation and Painting

Primer

Avg. DFT (As per

Minimum 3 point for each

4.1 Painting manufacturer As per contact specification Painting Inspection Report W R

mark No

specification)

Final Coat

As per approved drawing & control

5 Match Marking Visual Inspection Visual Random Dispatch Clearance Report W R

assembly

Legend :

W – Witness , R – Review, R/W - Review or witness, DFT – Dry Film Thickness, UT – Ultrasonic test, DT-Destructive test, RT – Radiography test, MTC – Manufacturer test Certificates.

DPT – Dye Penetration test, NDT-Non Destructive Test

You might also like

- STANDARD QUALITY ASSURANCE PLAN FOR AC MOTORSDocument6 pagesSTANDARD QUALITY ASSURANCE PLAN FOR AC MOTORSSonti Mani kumar100% (1)

- Carrier Twinning InstructionsDocument38 pagesCarrier Twinning InstructionsMarsha FewNo ratings yet

- Part 2 - ITP Details: Inspection & Test Plan For Precast Concrete WorksDocument5 pagesPart 2 - ITP Details: Inspection & Test Plan For Precast Concrete WorksErickson Malicsi100% (2)

- Quality Assurance Plan: High Frequency Electric Resistance Welded PipeDocument15 pagesQuality Assurance Plan: High Frequency Electric Resistance Welded PipeSachin KumarNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Soil Stabilization ProjectDocument53 pagesSoil Stabilization Projectrohit attri100% (2)

- Specification & Inspection of Api 5LDocument57 pagesSpecification & Inspection of Api 5LIrsyad RosyidiNo ratings yet

- QAP - ITP - Steel Girder ApproachDocument21 pagesQAP - ITP - Steel Girder ApproachPartha Gangopadhyay100% (1)

- MQAP - Long Rod InsulatorDocument8 pagesMQAP - Long Rod InsulatorRajitha BoppaNo ratings yet

- QAP LotahalDocument1 pageQAP LotahalRahul YadavNo ratings yet

- QAP Check ListDocument1 pageQAP Check Listbed passNo ratings yet

- ISRO EOT Crane QAPDocument17 pagesISRO EOT Crane QAPSuleman Khan100% (1)

- Tunnel Work: Material Inspection and Testing Plan (Itp)Document6 pagesTunnel Work: Material Inspection and Testing Plan (Itp)aksinhadce2No ratings yet

- QAPDocument3 pagesQAPsriram.5230No ratings yet

- Sample Quality Assurance Plan For Welded Ss Fittings: 25% by 1 After 100% by 2Document2 pagesSample Quality Assurance Plan For Welded Ss Fittings: 25% by 1 After 100% by 2Dhvanit JoshiNo ratings yet

- Standard QA Plan for AC Starter ComponentsDocument9 pagesStandard QA Plan for AC Starter ComponentsMukeshNo ratings yet

- Bird Guard MQP RGTLDocument3 pagesBird Guard MQP RGTLKumara SubramanianNo ratings yet

- YzcvfDocument2 pagesYzcvfCheeragNo ratings yet

- QAP For MS Pipes RevisedDocument3 pagesQAP For MS Pipes RevisedAnuj PandeyNo ratings yet

- Ac Oqa 2014Document1 pageAc Oqa 2014pm9286vNo ratings yet

- Qap Sa420Document3 pagesQap Sa420Abhishek NagNo ratings yet

- EXternal ITP PDFDocument8 pagesEXternal ITP PDFjaineranaNo ratings yet

- ITP For Handrail WeldingDocument2 pagesITP For Handrail WeldingKumar AbhishekNo ratings yet

- ITP For Fabrication & Erection of TanksDocument20 pagesITP For Fabrication & Erection of TanksosersNo ratings yet

- QAP New Customer Nov23Document1 pageQAP New Customer Nov23RND DRAWNo ratings yet

- Modelquality Assuranceplanforpot 1Document8 pagesModelquality Assuranceplanforpot 1mouni9301997No ratings yet

- Qap PDFDocument11 pagesQap PDFNirajan MarwaitNo ratings yet

- FQP-Structural SteelDocument8 pagesFQP-Structural SteelP.MannaNo ratings yet

- Cert Perno Hex 3.4 X 2-1.4Document7 pagesCert Perno Hex 3.4 X 2-1.4Abril SalinasNo ratings yet

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument2 pagesInspection & Testing Requirements Scope:: Test and Inspection PerAli RazaNo ratings yet

- Saatvik QAP-72 Cell Full CellDocument4 pagesSaatvik QAP-72 Cell Full Cellvenkatraman JNo ratings yet

- FGD Project at 2X 525 MW MPL: Document Title: FQP For General Structural Works of FGDDocument10 pagesFGD Project at 2X 525 MW MPL: Document Title: FQP For General Structural Works of FGDBhanu Pratap Choudhury100% (1)

- Water Tank Fabrication QAPDocument2 pagesWater Tank Fabrication QAPYOGESHNo ratings yet

- Checklist Fire StopDocument9 pagesChecklist Fire StopAnonymous DMdGdsOENo ratings yet

- RIAU-WV02-G10-QA-0002 - Shop Test and Inspection Plans - Rev0 PDFDocument16 pagesRIAU-WV02-G10-QA-0002 - Shop Test and Inspection Plans - Rev0 PDFSiriepathi SeetharamanNo ratings yet

- Specification Att - 3-18 - 6-51-0032 20rev 205 - Spec For Medium Voltage Induction MotorsDocument15 pagesSpecification Att - 3-18 - 6-51-0032 20rev 205 - Spec For Medium Voltage Induction MotorsAvinash ShuklaNo ratings yet

- Lattice Steel Structure Inspection and Test PlanDocument3 pagesLattice Steel Structure Inspection and Test PlanPrabhakar SvNo ratings yet

- FQP For AAC Block WorkDocument1 pageFQP For AAC Block WorkHimanshu ChaudharyNo ratings yet

- ITP-Tubular Poles - Type Test PDFDocument3 pagesITP-Tubular Poles - Type Test PDFPrabhakar SvNo ratings yet

- Field Inspection and Test ReportDocument19 pagesField Inspection and Test ReportAe SuwaphanNo ratings yet

- Model Quality Assurance Plan For Pot-Ptfe BearingsDocument8 pagesModel Quality Assurance Plan For Pot-Ptfe Bearingsghaghra bridgeNo ratings yet

- Civil FQP 22.11.22Document5 pagesCivil FQP 22.11.22Sankha Subhra JashNo ratings yet

- Qap - Structural Mechanical FabricationDocument8 pagesQap - Structural Mechanical Fabricationbharathi_pmNo ratings yet

- Summary ReportDocument24 pagesSummary ReportRonniNo ratings yet

- Sample MTC For Anchor BoltDocument1 pageSample MTC For Anchor BoltSALMAN PARVEZ ROKADIANo ratings yet

- Grouting Inspection and Test PlanDocument1 pageGrouting Inspection and Test PlanGodwin A.udo-akanNo ratings yet

- Cert Perno Hex A490 1 X 2-3.4Document8 pagesCert Perno Hex A490 1 X 2-3.4Abril SalinasNo ratings yet

- (Electric Cable Pulling and Termination Work ITP) FINAL Rev1Document25 pages(Electric Cable Pulling and Termination Work ITP) FINAL Rev1Aous HNo ratings yet

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument2 pagesInspection & Testing Requirements Scope:: Test and Inspection PerWael ChouchaniNo ratings yet

- Almansoori Inspection Services: Travelling Block AssemblyDocument1 pageAlmansoori Inspection Services: Travelling Block AssemblyRanjithNo ratings yet

- Inspection and Testing Requirements for Saudi Aramco Pipe SpecificationsDocument2 pagesInspection and Testing Requirements for Saudi Aramco Pipe SpecificationsWael ChouchaniNo ratings yet

- Material Test Report: 600# W.N RF 3 SCH 80 H5292Document2 pagesMaterial Test Report: 600# W.N RF 3 SCH 80 H5292Gabriel De La FuenteNo ratings yet

- MDR C40 Pt. DmiDocument14 pagesMDR C40 Pt. DmiwidiNo ratings yet

- STANDARD QUALITY ASSURANCE PLAN FOR AC STARTER/CONTROL GEARDocument9 pagesSTANDARD QUALITY ASSURANCE PLAN FOR AC STARTER/CONTROL GEARSonti Mani kumarNo ratings yet

- Sample Quality Assurance Plan For Welded Cs Butt Weld Fittings (Sa 234)Document2 pagesSample Quality Assurance Plan For Welded Cs Butt Weld Fittings (Sa 234)Dhrumil ChauhanNo ratings yet

- Sample Quality Assurance Plan For Cs FlangesDocument2 pagesSample Quality Assurance Plan For Cs FlangesKaran BhanotNo ratings yet

- Certifcato Di Collaudo/Test Certificate: Info@lame-Srl.191.itDocument2 pagesCertifcato Di Collaudo/Test Certificate: Info@lame-Srl.191.itMohamed Raafat100% (1)

- M/s-PINAX STEEL ITP for Fabricated DUCT & HOPPERSDocument1 pageM/s-PINAX STEEL ITP for Fabricated DUCT & HOPPERSStructures ProductionNo ratings yet

- ITP-Tubular Poles - Sample Test PDFDocument4 pagesITP-Tubular Poles - Sample Test PDFPrabhakar SvNo ratings yet

- QAP - Screen Box - Rev 00 StampedDocument1 pageQAP - Screen Box - Rev 00 StampedRaj KumarNo ratings yet

- Inspection Test PlanDocument141 pagesInspection Test PlanKoya ThangalNo ratings yet

- BPI Specifications Rev 0Document4 pagesBPI Specifications Rev 0400KVNo ratings yet

- Raw Material & Bought Out Items InspectionDocument3 pagesRaw Material & Bought Out Items InspectionSuraj ShettyNo ratings yet

- Aluminium Formwork Work ProcedureDocument4 pagesAluminium Formwork Work ProcedurePrasanta ParidaNo ratings yet

- List of Equipments Available at Site Laboratory of PKG-1Document2 pagesList of Equipments Available at Site Laboratory of PKG-1Prasanta ParidaNo ratings yet

- Use of Stone Dust in Concreting WorksDocument2 pagesUse of Stone Dust in Concreting WorksPrasanta ParidaNo ratings yet

- Approval of M45 Trial Mix With Birla Uttam Opc 53 For PSC SlabDocument2 pagesApproval of M45 Trial Mix With Birla Uttam Opc 53 For PSC SlabPrasanta ParidaNo ratings yet

- Ogl 2Document2 pagesOgl 2Prasanta ParidaNo ratings yet

- Maintenace schedule diesel generatorsDocument2 pagesMaintenace schedule diesel generatorsPrasanta ParidaNo ratings yet

- Electric Compressor Operating InstructionsDocument29 pagesElectric Compressor Operating InstructionsPrasanta ParidaNo ratings yet

- 20 - Flow Chart of Basic Activities in Proj. ExecutionDocument1 page20 - Flow Chart of Basic Activities in Proj. ExecutionPrasanta ParidaNo ratings yet

- QAP of FOB AS PER PKG3Document32 pagesQAP of FOB AS PER PKG3Prasanta Parida100% (1)

- 21 - Flow Chart For IQA Rev1Document1 page21 - Flow Chart For IQA Rev1Prasanta ParidaNo ratings yet

- 35 (Vii) - Tyre Mounted Articulated Mob - Crane (Pages 1-4)Document5 pages35 (Vii) - Tyre Mounted Articulated Mob - Crane (Pages 1-4)Prasanta ParidaNo ratings yet

- Maintenance Schedule for Transit MixerDocument4 pagesMaintenance Schedule for Transit MixerPrasanta ParidaNo ratings yet

- 08 - OrganogramDocument1 page08 - OrganogramPrasanta ParidaNo ratings yet

- DG Maintenance ManualDocument4 pagesDG Maintenance ManualPrasanta ParidaNo ratings yet

- 27 Flow Chart For Procurement Process Rev1Document1 page27 Flow Chart For Procurement Process Rev1Prasanta ParidaNo ratings yet

- 04 - Filing System - AbbreviationDocument4 pages04 - Filing System - AbbreviationPrasanta ParidaNo ratings yet

- Earth Works Method StatementDocument6 pagesEarth Works Method StatementPrasanta ParidaNo ratings yet

- 09 - FORMS (2.5.05) - Network of Simplex OfficesDocument1 page09 - FORMS (2.5.05) - Network of Simplex OfficesPrasanta ParidaNo ratings yet

- 05 - FILING SYSTEM - HRD Dept.Document3 pages05 - FILING SYSTEM - HRD Dept.Prasanta ParidaNo ratings yet

- IQA CheckList For Proj - Site (Latest) No. SIL-QC-IQAC-S-08-Pg.1-20 Dt. 26.07.10Document20 pagesIQA CheckList For Proj - Site (Latest) No. SIL-QC-IQAC-S-08-Pg.1-20 Dt. 26.07.10Prasanta ParidaNo ratings yet

- 09 10 11 - Revised CV of Tech. Mech. & Comm. PersonnelDocument3 pages09 10 11 - Revised CV of Tech. Mech. & Comm. PersonnelPrasanta ParidaNo ratings yet

- Mix Design With Jaypee Cement and Grain AdmixtureDocument1 pageMix Design With Jaypee Cement and Grain AdmixturePrasanta ParidaNo ratings yet

- Pile Head Method StatementDocument3 pagesPile Head Method StatementPrasanta ParidaNo ratings yet

- Soil Testing ReportDocument2 pagesSoil Testing ReportPrasanta ParidaNo ratings yet

- Corrected Qap For RVNL Bina Kota ProjectDocument161 pagesCorrected Qap For RVNL Bina Kota ProjectPrasanta ParidaNo ratings yet

- Method STMT For Concreting, ReinforcementDocument8 pagesMethod STMT For Concreting, ReinforcementPrasanta ParidaNo ratings yet

- Backfilling Risk Control MeasuresDocument2 pagesBackfilling Risk Control MeasuresPrasanta ParidaNo ratings yet

- Mix Design of M25, M30, M35, M40, M45with Reliance Opc 53 and Birla Gold Opc 53 GradeDocument1 pageMix Design of M25, M30, M35, M40, M45with Reliance Opc 53 and Birla Gold Opc 53 GradePrasanta ParidaNo ratings yet

- Final QAP of RBL AME RVNL PROJECTDocument84 pagesFinal QAP of RBL AME RVNL PROJECTPrasanta Parida100% (1)

- GangulyDocument14 pagesGangulyPrasanta ParidaNo ratings yet

- CR 0701 CH 10Document13 pagesCR 0701 CH 10Rıfat BingülNo ratings yet

- Building Collapse - PaperDocument9 pagesBuilding Collapse - PaperfatileNo ratings yet

- M-2 Piping Design (General)Document10 pagesM-2 Piping Design (General)ahmedalishNo ratings yet

- Proposed Marudi Bridge Over Batang Baram, Miri Division, SarawakDocument8 pagesProposed Marudi Bridge Over Batang Baram, Miri Division, SarawakKelvin LauNo ratings yet

- What Is Door and Types of DoorDocument9 pagesWhat Is Door and Types of Doorjibola harbeebNo ratings yet

- Installation Instructions: CautionDocument4 pagesInstallation Instructions: CautionVMNo ratings yet

- Connections ManualDocument90 pagesConnections ManualNiko Ništić100% (1)

- Mechanical Engineer-Syed Zain AliDocument5 pagesMechanical Engineer-Syed Zain AliSyedZainAliNo ratings yet

- EE405 Electrical System Design PDFDocument2 pagesEE405 Electrical System Design PDFSudev S0% (1)

- UntitledDocument42 pagesUntitledShafkat SaminNo ratings yet

- DesignProcedure SteelStructuresDocument53 pagesDesignProcedure SteelStructuresanuj3936100% (4)

- Manual Reparación Turbo GARRETDocument24 pagesManual Reparación Turbo GARRETFelipe Lepe MattaNo ratings yet

- Checklist For Terrace WaterproofingDocument2 pagesChecklist For Terrace WaterproofingSantosh YadavNo ratings yet

- 10 1016@j Istruc 2019 02 018Document10 pages10 1016@j Istruc 2019 02 018shak543No ratings yet

- Sewer DesignDocument234 pagesSewer Designvgbarros85780% (1)

- Energy - Solar - Water Heating System Designs - (Ebook Construction Building How To Diy) (Tec@Nz)Document8 pagesEnergy - Solar - Water Heating System Designs - (Ebook Construction Building How To Diy) (Tec@Nz)ABELWALIDNo ratings yet

- Castellated Beams Vs Cellular BeamsDocument5 pagesCastellated Beams Vs Cellular BeamsPieter SteenkampNo ratings yet

- Building Technology and Design Syllabus: Forms 1 - 4Document52 pagesBuilding Technology and Design Syllabus: Forms 1 - 4Anotidaishe Nyakudya100% (1)

- API 650 Data Sheet SummaryDocument36 pagesAPI 650 Data Sheet Summarynarongsak_371005440No ratings yet

- Handout 1Document11 pagesHandout 1Adefris FikireNo ratings yet

- Unit 305 Understanding The Practices and Procedures For The Preparation and InstallationDocument43 pagesUnit 305 Understanding The Practices and Procedures For The Preparation and InstallationRob PettitNo ratings yet

- Safety Factor For StoneDocument4 pagesSafety Factor For StonePaulNo ratings yet

- Software Verification Test of SAFE ProgramDocument5 pagesSoftware Verification Test of SAFE ProgramHaytham ZaghloulNo ratings yet

- DSR Book Vol 2 2016 (English Version) Final (Full Permission)Document258 pagesDSR Book Vol 2 2016 (English Version) Final (Full Permission)Shyam Kumar88% (16)

- Review of Related LiteratureDocument2 pagesReview of Related LiteratureRichelle DandoNo ratings yet

- Viraj Catalouge-2Document21 pagesViraj Catalouge-2Vinod GuptaNo ratings yet

- Al6061-SiC and Al7075-Al2O3 MMC PropertiesDocument13 pagesAl6061-SiC and Al7075-Al2O3 MMC PropertiesBalu BhsNo ratings yet