Professional Documents

Culture Documents

320dl Pilot Valve Test N Adjust

Uploaded by

Daniel Rhasty-ghee AhmanorOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

320dl Pilot Valve Test N Adjust

Uploaded by

Daniel Rhasty-ghee AhmanorCopyright:

Available Formats

2014/11/13 Relief Valve (Pilot) - Test and Adjust (RENR7295-17)

SMCS - 5072 i05954301

Specification

Note: Certain machines will default to "Economy Mode" at machine startup. Change to "High Hydraulic

Power Mode" before performing the test procedure.

Table 1

"Relief Valve (Pilot) - Test and Adjust"

Engine Speed

Machine Settings Speed Dial "10"

AEC switch OFF

Item Specification Actual

Pilot relief valve pressure 4100 ± 200 kPa (595 ± 29 psi)

Introduction

The pilot relief valve is located on the mounting base for the pilot oil filter. The pilot relief valve limits the

pressure in the pilot system. The pilot relief valve setting is adjustable.

Required Tools

Illustration 1 g02571852

Tooling (A) 198-4240 Digital Pressure Indicator Gp

Table 2

Tool Item Qty Part Number Description

A 198-4240 Digital Pressure Indicator Gp

A1 1 198-4234 Digital Pressure Indicator

A2 1 198-4238 Pressure Sensor 34,450 kPa (5,000 psi)

A3 1 198-4236 Adapter Cable As

Machine Preparation

1. Position the machine on level ground.

2. Stop the engine.

3. Release the pressure in the hydraulic system. Refer to Testing and Adjusting, "Hydraulic System

Pressure - Release".

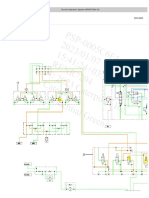

Illustration 2 g01631853

Pilot relief valve (located in pump compartment)

(1) Locknut

(2) Adjustment screw

(3) Pressure tap

(4) Pilot filter

4. Connect a 34,450 kPa (5,000 psi) pressure sensor to pressure tap (3).

Test Procedure

1. Start the engine.

2. Place the machine controls at the following settings: engine speed dial "10" and AEC switch OFF.

Refer to Testing and Adjusting, "Engine Performance - Test (Engine Speed)" for engine rpm

settings.

3. Increase the hydraulic oil temperature to 55° ± 5°C (131° ± 9°F).

4. Check the pilot relief valve setting at pressure tap (3).

5. The pilot relief valve setting should be 4100 ± 200 kPa (595 ± 29 psi). If the pilot relief valve setting

is not within the specification, then adjust the pilot relief valve.

Adjustment Procedure

1. In order to adjust the pilot relief valve, loosen locknut (1).

2. Turn adjustment screw (2) until the pressure reading at pressure tap (3) is within the specification.

Note: Turn adjustment screw (2) clockwise in order to increase the pressure. Turn adjustment

screw (2) counterclockwise in order to decrease the pressure.

Note: Always make final pressure adjustments on pressure rise.

3. Tighten locknut (1) to a torque of 49 ± 5 N·m (36 ± 4 lb ft).

4. Test the pressure setting again. Refer to "Test Procedure".

Note: Normal operation of the engine and pumps are necessary for the pressure adjustment. If the

results of the pressure adjustments are not correct, then check the engine and the pump characteristic

curve.

PSP-0005C6FA

2023/01/07

07:43:23+03:00

i02437332

© 2023 Caterpillar Inc.

Caterpillar:

Confidential Green

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Stone Retaining Wall DesignDocument25 pagesStone Retaining Wall DesignSafi Zabihullah Safi82% (17)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Structural Precast Concrete Handbook LowresDocument346 pagesStructural Precast Concrete Handbook LowresVance Kang75% (20)

- Plastics Pipe Institute Handbook of Polyethylene PipeDocument312 pagesPlastics Pipe Institute Handbook of Polyethylene Pipeoripopunk100% (2)

- FDFDSFDocument15 pagesFDFDSFAnderson Nuñez SaldañaNo ratings yet

- 330bl NFC AdjustDocument10 pages330bl NFC AdjustDaniel Rhasty-ghee AhmanorNo ratings yet

- Cat Vib Roller Brake PumpDocument4 pagesCat Vib Roller Brake PumpDaniel Rhasty-ghee AhmanorNo ratings yet

- 320dl Main Relief Valve Test N AdjustDocument4 pages320dl Main Relief Valve Test N AdjustDaniel Rhasty-ghee AhmanorNo ratings yet

- 330bl NFC Test N AdjustDocument2 pages330bl NFC Test N AdjustDaniel Rhasty-ghee AhmanorNo ratings yet

- 330bl Pump Output Flow TestDocument3 pages330bl Pump Output Flow TestDaniel Rhasty-ghee AhmanorNo ratings yet

- 330bl Output Flow AdjustDocument3 pages330bl Output Flow AdjustDaniel Rhasty-ghee AhmanorNo ratings yet

- Excavator Switches TestDocument7 pagesExcavator Switches TestDaniel Rhasty-ghee AhmanorNo ratings yet

- Exacvators Solenoids TestDocument5 pagesExacvators Solenoids TestDaniel Rhasty-ghee AhmanorNo ratings yet

- 320dl Stick LoweringDocument5 pages320dl Stick LoweringDaniel Rhasty-ghee AhmanorNo ratings yet

- Diagnostic OperationDocument11 pagesDiagnostic OperationDaniel Rhasty-ghee AhmanorNo ratings yet

- 320dl Stick SystemDocument8 pages320dl Stick SystemDaniel Rhasty-ghee AhmanorNo ratings yet

- 320dl Swing SystemDocument10 pages320dl Swing SystemDaniel Rhasty-ghee AhmanorNo ratings yet

- Excavator Sensors TestDocument2 pagesExcavator Sensors TestDaniel Rhasty-ghee AhmanorNo ratings yet

- 320dl Stick Drift Reduction ValveDocument3 pages320dl Stick Drift Reduction ValveDaniel Rhasty-ghee AhmanorNo ratings yet

- 160m Hyd TroubleshootDocument8 pages160m Hyd TroubleshootDaniel Rhasty-ghee AhmanorNo ratings yet

- 320dl Pilot Valve Travel SystemDocument3 pages320dl Pilot Valve Travel SystemDaniel Rhasty-ghee AhmanorNo ratings yet

- 320dl Swivel SystemDocument2 pages320dl Swivel SystemDaniel Rhasty-ghee AhmanorNo ratings yet

- 320dl Bucket Hydraulic SystemDocument3 pages320dl Bucket Hydraulic SystemDaniel Rhasty-ghee AhmanorNo ratings yet

- 32odl Swing Oil Makeup SystemDocument4 pages32odl Swing Oil Makeup SystemDaniel Rhasty-ghee AhmanorNo ratings yet

- 320dl Fuel Pump Remove and InstallDocument17 pages320dl Fuel Pump Remove and InstallDaniel Rhasty-ghee AhmanorNo ratings yet

- 320dl Main Control Valve DissDocument17 pages320dl Main Control Valve DissDaniel Rhasty-ghee AhmanorNo ratings yet

- 320dl Joystick AssemblingDocument6 pages320dl Joystick AssemblingDaniel Rhasty-ghee AhmanorNo ratings yet

- 320dl Joystick AssyDocument7 pages320dl Joystick AssyDaniel Rhasty-ghee AhmanorNo ratings yet

- Hyd SCHM 160mDocument2 pagesHyd SCHM 160mDaniel Rhasty-ghee AhmanorNo ratings yet

- 320dl Main Hyd Pump DissDocument23 pages320dl Main Hyd Pump DissDaniel Rhasty-ghee AhmanorNo ratings yet

- 14H Lubrication SystemDocument6 pages14H Lubrication SystemDaniel Rhasty-ghee AhmanorNo ratings yet

- 160m Hyd Pump Control Valve SysDocument8 pages160m Hyd Pump Control Valve SysDaniel Rhasty-ghee AhmanorNo ratings yet

- 320dl Main Control Valve AssemblingDocument17 pages320dl Main Control Valve AssemblingDaniel Rhasty-ghee AhmanorNo ratings yet

- 14 G Braking System of OperationDocument34 pages14 G Braking System of OperationDaniel Rhasty-ghee AhmanorNo ratings yet

- En1991 1 4 SseDocument30 pagesEn1991 1 4 Sseprasadnn2001No ratings yet

- K200 and FIL 2 Errors. Case No. DC119429Document62 pagesK200 and FIL 2 Errors. Case No. DC119429Mikal SmithNo ratings yet

- Log TimeDocument9 pagesLog TimeWawan Misbahul AnwarNo ratings yet

- AH06524Document2 pagesAH06524Valeria MartinezNo ratings yet

- Fkasa - Norhamiza Rossli (Cd9298)Document24 pagesFkasa - Norhamiza Rossli (Cd9298)Farahana AnuarNo ratings yet

- Formulas CoolersDocument39 pagesFormulas Coolersbasaca132No ratings yet

- Structures: Huu-Tai Thai, Tuan Ngo, Brian UyDocument26 pagesStructures: Huu-Tai Thai, Tuan Ngo, Brian UyHit PopatNo ratings yet

- Specifications: Pressure TransducerDocument5 pagesSpecifications: Pressure TransducerTahaNo ratings yet

- 777D.Schematic ElectricDocument2 pages777D.Schematic ElectricDedeNo ratings yet

- Getting Started With Oracle APEX 4 On Oracle Database 11g Express EditionDocument7 pagesGetting Started With Oracle APEX 4 On Oracle Database 11g Express EditionbobysiswantoNo ratings yet

- Evolution-L Tech DataDocument12 pagesEvolution-L Tech DataDaniel SanguinéNo ratings yet

- Welcome To Reason Drum Kits 2.0Document3 pagesWelcome To Reason Drum Kits 2.0Apostolos MantzouranisNo ratings yet

- HTML4 Vs HTML5 ComparisonDocument8 pagesHTML4 Vs HTML5 ComparisonPallab DattaNo ratings yet

- Imran Babatunde ProjectDocument38 pagesImran Babatunde ProjectOpeyemi JamalNo ratings yet

- PDF Kta19mDocument2 pagesPDF Kta19mNguyễn Văn CảnhNo ratings yet

- Data Centre EssentialsDocument6 pagesData Centre EssentialssoumendebguptaNo ratings yet

- Egnmlgza PDF 1501674388Document121 pagesEgnmlgza PDF 1501674388FLY XNo ratings yet

- Alldrill Drilling Manual PDFDocument29 pagesAlldrill Drilling Manual PDFSenoNo ratings yet

- Agile Curriculum SkillsoftDocument2 pagesAgile Curriculum Skillsoftanonymous_034aNo ratings yet

- Is 1200 13 1994 PDFDocument10 pagesIs 1200 13 1994 PDFSudarshan GadalkarNo ratings yet

- Topic 6 - Process CostingDocument7 pagesTopic 6 - Process CostingMuhammad Alif100% (1)

- Indian Standard: Code of Practice For Plastics Pipe Work For Potable Water SuppliesDocument18 pagesIndian Standard: Code of Practice For Plastics Pipe Work For Potable Water SuppliesRosa JoseNo ratings yet

- Assuming That All The Elements of Epicyclic Gear Train Are Moving atDocument15 pagesAssuming That All The Elements of Epicyclic Gear Train Are Moving atMuhammad FarhalNo ratings yet

- Pump Hydraulic CalculationsDocument14 pagesPump Hydraulic CalculationsJosue GonzalezNo ratings yet

- D&D RequirementsDocument2 pagesD&D RequirementsJanak DoshiNo ratings yet

- Moraga Rotary Newsletter March 28 2017Document4 pagesMoraga Rotary Newsletter March 28 2017mayfrlNo ratings yet