Professional Documents

Culture Documents

Unit IG2 - Risk Assessment: Element 9

Uploaded by

Jithu RajuOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Unit IG2 - Risk Assessment: Element 9

Uploaded by

Jithu RajuCopyright:

Available Formats

GWG Unit IG2 – Risk Assessment

Element 9:

Work Equipment

© Copyright Green world Group

Learning Outcomes

9.1 Outline general requirements for work equipment

9.2 Explain the hazards and controls for hand-held tools

GWG

9.3 Describe the main mechanical and non-mechanical hazards of

machinery

9.4 Explain the main control measures for reducing risk from machinery

hazards.

© Copyright Green world Group

Work Equipment

Types

• Hand tools

• Power tools

GWG • Machinery

• Access equipment

© Copyright Green world Group

Work Equipment

Selection and Suitability

Work equipment should be carefully selected to ensure it is

GWG appropriate for the:

• Task

• Environment

• Machine to meet basic safety standards, e.g. CE or ISI

marked.

© Copyright Green world Group

Prevention of Access

To dangerous parts of Machinery :

• Fixed guards

GWG • Other guards and protective devices

• Protective appliance

• IITS

© Copyright Green world Group

Maintenance

Work equipment should be maintained in a safe working condition,

according to any

• legal standards that exist

GWG • Manufacturer’s recommendation

Hazards

• Unintentional starting of machinery

• The release of stored energy e.g. pressure, electrical power.

• Limited access/egress

• Residues

• Mechanical hazards

• Heat or cold surfaces

• Confined spaces

• Working at height

© Copyright Green world Group

Maintenance

Precautions

• Isolate electrical power

• Permit to work procedures

GWG • Locking out and tagging off of any services or

piped energy to the machine

• Dissipate heat energy by allowing machinery to

cool

• Stored power to be released or secured

• Barrication with signs

• Provide suitable and sufficient lighting and

means of access

• PPE

• Ventilation

• Trained, competent and authorised persons to

perform the work

© Copyright Green world Group

Environmental Factors

Equipment should be,

• Stable

GWG • Controls appropriately marked

• Have appropriate warning signs

Lighting should be,

• Adequate

• Environmentally suitable

Space should be adequate,

• Operators to move around work

equipment safely

• Prevent others coming into dangerous

parts

© Copyright Green world Group

End-of-Section Quiz

GWG

Flashing lights and beacons comes under which category of

controls of work equipment?

a. Administrative control

b. Awareness control

c. Presence sensing device

d. Personal protective equipment

© Copyright Green world Group

Unit IG2: Element 9.2

Hand-Held Tools

GWG

© Copyright Green world Group

Handheld Non-Power Tools

Examples:

• Chisel

• Hammer

GWG • Screwdriver

• Axe

© Copyright Green world Group

Handheld Non-Power Tools

Hazards:

• Misuse

GWG • Handle may come loose

• Tool may be blunt requiring excessive force

• Tool may shatter during use

Control Measures:

• Conditions and fitness for use

• Safe use requirements

• Suitability for purpose and environment

© Copyright Green world Group

Portable Power Tools

Portable power tools create greater risk than simple hand tools because:

•The force generated by the tool are far greater

(For e.g.. A ruptured disc from a disc cutter will cut an arm off, which is not

GWG going to happen when use of hand saw)

Power tools also presents additional hazards :-

As per the type of tool used

© Copyright Green world Group

Electric Drill

Hazards:

• Contact with electricity

• Entanglement: loose clothing or hair become entangled with

GWG rotating shaft

• Injection: puncture of skin by drill bit

• Contact : contact with rotating shaft and drill bit

• Ejection: hit by flying debris or broken drill bit

Precautions:

• Pre-use check to ensure there is no damage and is fit for the task

• Ensure there are isolation measures

• Ensure drill bit is sharp

• Ensure material is clamped down securely

• PPE

© Copyright Green world Group

End-of-Section Quiz

GWG

Which doesn’t come under the factor to consider under suitability

of hand tools?

a. Non-sparking tools for flammable atmospheres

b. Safety knives with enclosed blades

c. Specially protected and insulated tools for electricians

d. Working hours

© Copyright Green world Group

Unit IG2: Element 9.3

Machinery Hazards

GWG

© Copyright Green world Group

Mechanical & Non-mechanical Hazards

Mechanical hazards

Contact with or being caught up

by dangerous moving parts

GWG • Entanglement

• Drawing in or trapping

• Shearing

• Crushing

• Cutting

• Impact

• Injection

• Stabbing or puncture

• Friction or abrasion

© Copyright Green world Group

Mechanical & Non-mechanical Hazards

Non-Mechanical hazards

From power source or things being

emitted by the machine

GWG • Electricity

• Dust and fumes

• Fire/explosion

• Noise and Vibration

• Hazardous chemicals being handled

• Radiation

• Access and Egress

• Obstructions and projections

• Manual handling

© Copyright Green world Group

Range of Machineries

GWG

© Copyright Green world Group

End-of-Section Quiz

GWG

Which ONE of the following hazard is categorized as

‘mechanical’?

a. Crushing

b. Noise

c. Electricity

d. Hazardous substance

© Copyright Green world Group

Unit IG2: Element 9.4

Control Measures for Machinery

GWG

© Copyright Green world Group

The Safeguarding

• It may be possible to eliminate the risk created by a piece of

machinery by getting rid of the machine that creates the risk.

However, this is not an option in most cases.

GWG

• Guards and other protection methods must be used to control the

risks associated with machinery.

• Even when most hazards can be eliminated through good design,

other hazards will still remain.

© Copyright Green world Group

The Safeguarding

Guards Protective Devices

• Fixed Guards

• Two-handed controls

• Interlock Guards

GWG • Hold to Run

• Automatic Guards

• Adjustable/self-adjusting guards • Protective appliances

• Trip Devices

© Copyright Green world Group

The Safeguarding

Application of Safeguard – p258

Fixed Guards Interlock Guards Automatic Guards Adjustable/

self-adjusting guards

GWG

Trip Devices Two-handed controls Hold to Run Protective appliances

© Copyright Green world Group

Fixed Guard

• A fixed guard is a physical barrier that prevents a person from

coming into contact with dangerous moving parts

GWG • It must be designed in such a way that it is not possible to reach

in and contact dangerous parts

© Copyright Green world Group

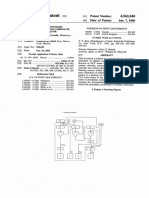

Interlock Guard

Basic principle of an interlocked guard

• Power to the machine is disabled and the machine will not

GWG operate until the guard is in place

• Either the guard is locked shut until it is safe for the guard to

open, or the act of opening the guard stops the dangerous parts

and disables power.

© Copyright Green world Group

Push Away Guard

• Designed to physically remove from danger any part of a person

exposed to that danger

GWG • Physically pushing the operator away

• Suitable only for slow stroke machines like lathe, printing press

© Copyright Green world Group

Trip Devices

• Not a physical barrier

• Uses sensors to detect presence of operator and stop the

GWG machine

• They include:

✓ Pressure mats

✓ Photo-electric devices

© Copyright Green world Group

Two Hand Control

• Two-handed controls ensure the operator is standing away from

the danger area when causing dangerous movements.

GWG • They force the operator to use both hands to operate the

machine controls

© Copyright Green world Group

Protection Appliances

• Jigs

• Holders

GWG • Push stick

• Designed to keep operators’ hands away from danger

© Copyright Green world Group

IITS

• The topic to be covered in training shall include

• Identification of the hazards

GWG • Operation and working of various safeguards and devices

• Appropriate use of provided safeguards

• Authorized person to install, maintain the guards

• The selection and use of PPE

© Copyright Green world Group

Personal Protective Equipment

Workers must be provided with the appropriate personal protective

equipment

GWG • Fit-for-purpose

• Suitability

• Provided at no cost to employees

• Consultation

• Training

• Storage

© Copyright Green world Group

Photocopier

• The internal parts of the photocopiers are fully enclosed, and the

access doors are interlocked to guarantee that the machine

GWG comes to a stop when the doors are opened for maintenance

work or clearing paper jam

• A program schedule of portable appliance testing

• Use in a ventilated room

© Copyright Green world Group

Bench Grinder

• Confirm all the guards are positioned and secured properly before

using a grinder

GWG • Wheels to be encased with fixed guard to prevent ejection of

pieces of broken wheel

• Install adjustable guard with toughened glass over wheel to

protect the operator

• Adjust tool rests as close as possible to wheels.

• Never adjust rests while wheels are moving

• A program schedule of PAT (Portable Appliance Testing) be

implemented

• Extract ventilation is fitted to the wheel encasing to remove dust

at source

• Use appropriate PPE: goggles, gloves, safety boots, etc

© Copyright Green world Group

Pedestal Drill

• Inspect equipment before use

• Motor and drive enclosed by fixed guard

GWG • The spindle must have an adjustable guard

• Work-piece must be clamped securely in vice and / or to table

use cutting fluids where possible to reduce friction and cutting

forces.

• The guard should be interlocked by the suitable power to avoid

the inadvertent starting of the machine when the guard is open.

• Drill bit to be securely clamped in the chuck

• A program schedule of PAT

• Goggles, gloves and safety boots to be worn by operator

© Copyright Green world Group

Bench Mounted Circular Saw

• Motor and drives to be fitted with fixed guard

• Saw blade to be mounted with adjustable guard

GWG • Machinery should, wherever possible, be equipped with

mechanical feeding devices.

• Push sticks are an additional device used to keep hands away

from the blade.

• Emergency stop button accessible by operator

• Appropriate PPE such as ear protection, goggles, safety boots to

be worn by operator

© Copyright Green world Group

Chainsaw

• Engine part of the chain saw to be encased by fixed guard

• Electrical cables to be double insulated

GWG • Ear protection, goggles, safety boots and long pants to be worn

by operator

• Use restricted to trained operators only

© Copyright Green world Group

Basic Characteristics of a Guard

• Suitable for the purpose

• Of good design and built, sound material and adequate strength

GWG • Maintained in an effective state and working order and in good

repair

• Not create any increased risk to health or safety

• Not be quickly bypassed or disabled

• Be situated at sufficient distance from the risk zone

• Not block the view of the operating cycle of the machinery

• Compatible

• Allows maintenance without removal

© Copyright Green world Group

End-of-Section Quiz

GWG

Push sticks are an additional device used to keep hands away

from the blade.

a. True

b. False

© Copyright Green world Group

End-of-Element Quiz

1. Before buying new equipment the buyer will need to think about ____

GWG a. What it will be used for

b. Who will use it

c. Where and how it will be used

d. All the above

2. The major requirement of a guard is

a. To block ventilation

b. Should be easy to remove

c. To withstand the force from ejected particles

d. To increase the risk to workers

© Copyright Green world Group

End-of-Element Quiz

3. A fixed guard has moving parts to prevent access to the dangerous parts of

the machinery.

a. True

b. False

GWG

4. Which ONE of the following doesn’t come under the category ‘hand tools’?

a. Screwdriver

b. Hammer

c. Plier

d. Photocopier

5. When a moving part directly strikes a person, such as with the accidental

movement of a robot’s working arm when maintenance is taking place is ___

hazard.

a. Impact

b. Stabbing

c. Cutting

d. Crushing

© Copyright Green world Group

PO BOX 83127

DUBAI, UNITED ARAB EMIRATES

TEL : +971 42 52 88 05

EMAIL: info@greenwgroup.com

UAE, INDIA, ANGOLA, NIGERIA, OMAN, SAUDI ARABIA

www.greenwgroup.com

© Copyright Green world Group

You might also like

- 2020 APR GWG Unit IG2 Element 8 v03 S PDFDocument61 pages2020 APR GWG Unit IG2 Element 8 v03 S PDFprinceNo ratings yet

- Topic 3 - Hazard (Mechanical)Document36 pagesTopic 3 - Hazard (Mechanical)Ekanabila AzharNo ratings yet

- Element 3 - Part 7 PDFDocument51 pagesElement 3 - Part 7 PDFQue EnaNo ratings yet

- Ysmart Technology Co., LTD.: Gti Grid SeriesDocument6 pagesYsmart Technology Co., LTD.: Gti Grid SeriesLeandro GomesNo ratings yet

- Lecture 7 8Document46 pagesLecture 7 8Mahmil ButtNo ratings yet

- Achines Afety: Dr. Muhammad Usman FarooqDocument44 pagesAchines Afety: Dr. Muhammad Usman FarooqAmeer HãmzäNo ratings yet

- IG Element 9 Work EquipmentDocument61 pagesIG Element 9 Work EquipmentAjith Kumar AjithNo ratings yet

- 2020-APR - GWG - Unit-IG1 - Element - 4 - v03 - SDocument55 pages2020-APR - GWG - Unit-IG1 - Element - 4 - v03 - SJakeer hussain ShaikNo ratings yet

- Tools, MachinesDocument41 pagesTools, MachinesEzequiel ValdesNo ratings yet

- Welding Robots Technology System Issues and Applications - J Norberto PiresDocument76 pagesWelding Robots Technology System Issues and Applications - J Norberto PireshetpinNo ratings yet

- Energy Isolation and LOTO PracticeDocument30 pagesEnergy Isolation and LOTO PracticeMageshNo ratings yet

- Genie GR 8Document132 pagesGenie GR 8johnNo ratings yet

- Machine Guarding PowerPoint PresintationDocument38 pagesMachine Guarding PowerPoint PresintationGopinathbabuNo ratings yet

- Genie Sisor 3268Document266 pagesGenie Sisor 3268mfcallejasmNo ratings yet

- 2020-APR - GWG - Unit-IG2 - Element - 5 - v03 - SDocument48 pages2020-APR - GWG - Unit-IG2 - Element - 5 - v03 - SJakeer hussain ShaikNo ratings yet

- G Unit ManualDocument223 pagesG Unit ManualAjai ArifNo ratings yet

- Control of Hazardous Energies-3bDocument35 pagesControl of Hazardous Energies-3bMakotoNo ratings yet

- Achine Afeguarding Hecklist: Requirements For All SafeguardsDocument3 pagesAchine Afeguarding Hecklist: Requirements For All SafeguardsKhalid MahmoudNo ratings yet

- Achine Afeguarding Hecklist: Requirements For All SafeguardsDocument3 pagesAchine Afeguarding Hecklist: Requirements For All SafeguardsKhalid MahmoudNo ratings yet

- IGC2 Element4 Work Equipment HazardsDocument69 pagesIGC2 Element4 Work Equipment HazardsZakirhasNo ratings yet

- 1-Machine SafetyDocument59 pages1-Machine Safetyᜇᜒᜌᜓᜈᜎ᜔ᜇ᜔ ᜊᜒᜇᜓᜌ᜔100% (3)

- Genie Service Manual GS4390RTDocument316 pagesGenie Service Manual GS4390RTAdonay GalvanNo ratings yet

- 04 indigoNXT AWN HB enDocument262 pages04 indigoNXT AWN HB enNikolaNo ratings yet

- Digital Ground Overcurrent Relay Manual Type: Gdr-B01Document53 pagesDigital Ground Overcurrent Relay Manual Type: Gdr-B01Huy Vũ Lâm ĐoànNo ratings yet

- KYONGBO GDR-M01 영문 사용설명서 (V1.10)Document79 pagesKYONGBO GDR-M01 영문 사용설명서 (V1.10)MarkusKunNo ratings yet

- Ridgid CD 100Document271 pagesRidgid CD 100SmisliNestoNo ratings yet

- Module 5 - Hand Tools - Power ToolsDocument25 pagesModule 5 - Hand Tools - Power Toolsdoni poNo ratings yet

- Our Product Range Eod / Iedd: Personal Protection EquipmentDocument2 pagesOur Product Range Eod / Iedd: Personal Protection EquipmentGaston TecheraNo ratings yet

- Unit IG2 - Risk Assessment: Chemical and Biological AgentsDocument53 pagesUnit IG2 - Risk Assessment: Chemical and Biological AgentsJithu RajuNo ratings yet

- Regulatory RequirementDocument43 pagesRegulatory RequirementRajiv DandekhyaNo ratings yet

- Fy10 Sh-20856-10 Machine GuardingDocument200 pagesFy10 Sh-20856-10 Machine GuardingKim Lien TrinhNo ratings yet

- Advantest R3267 Opt66 BluetoothDocument149 pagesAdvantest R3267 Opt66 BluetoothDrewNo ratings yet

- Advantest r3264 r3267 r3273 Spectrum Analyzer Om Vol1 eDocument400 pagesAdvantest r3264 r3267 r3273 Spectrum Analyzer Om Vol1 eCarlos Henrique RibeiroNo ratings yet

- Installation Manual: WarningDocument52 pagesInstallation Manual: WarningresisternxNo ratings yet

- Manual Motor VT - 275 - v6 PDFDocument112 pagesManual Motor VT - 275 - v6 PDFCarlos Ruiz Rodriguez100% (1)

- Basic Occupatio Nal Safety & Health: 1) The Principles of Machine GuardingDocument7 pagesBasic Occupatio Nal Safety & Health: 1) The Principles of Machine GuardingHurty James DayonNo ratings yet

- RT3422 Tapping Tool ManualDocument48 pagesRT3422 Tapping Tool ManualJesus amésquitaNo ratings yet

- Detector de Dombustible de GasDocument37 pagesDetector de Dombustible de GasMaty BqNo ratings yet

- Unit GC2 Element 4 - InternationalDocument66 pagesUnit GC2 Element 4 - InternationalOzair Ali KhanNo ratings yet

- Jig Saw Porter Cable ManualDocument44 pagesJig Saw Porter Cable ManualjunkNo ratings yet

- Burkert 6213 EvDocument14 pagesBurkert 6213 Evdavidarturo3004No ratings yet

- SA 09 2022 Mechanical Lifting FatalityDocument2 pagesSA 09 2022 Mechanical Lifting Fatalityali pudenNo ratings yet

- IG2 Element 9 Key Learning PointsDocument3 pagesIG2 Element 9 Key Learning Pointspaulin tenoNo ratings yet

- q9 Fmapproved Owners ManualDocument36 pagesq9 Fmapproved Owners ManualGhilbert Borda-alvarezNo ratings yet

- Unit GC2 Element 4 - InternationalDocument14 pagesUnit GC2 Element 4 - InternationalSatya NaiduNo ratings yet

- Safety Abrasive WheelDocument32 pagesSafety Abrasive WheelMohamed Hichem GuesmiNo ratings yet

- Safe Use of Power ToolsDocument91 pagesSafe Use of Power ToolshARINo ratings yet

- COMBAT8PROX Operators Manual 2024Document21 pagesCOMBAT8PROX Operators Manual 2024César HernándezNo ratings yet

- 8660@Gravimax@EnDocument8 pages8660@Gravimax@Enrodrigo loredoNo ratings yet

- 02 Safety - MT2200 - enDocument28 pages02 Safety - MT2200 - enjackNo ratings yet

- A-18-05867 WID All-Star Catalog 2019 LR PDFDocument158 pagesA-18-05867 WID All-Star Catalog 2019 LR PDFKALLU GuptaNo ratings yet

- New G 2300 Manual 03Document12 pagesNew G 2300 Manual 03Jasmine VaaltynNo ratings yet

- PC 4020 PDFDocument80 pagesPC 4020 PDFliviuturcuNo ratings yet

- Technical Notice GRIGRI 3Document15 pagesTechnical Notice GRIGRI 3renesantiago23100% (1)

- PSC Ergodyne Range 2021Document45 pagesPSC Ergodyne Range 2021Project Sales CorpNo ratings yet

- SSEC CAC R-32 Mini 4way IB DB68-08128A-00 EN 20181228 2Document22 pagesSSEC CAC R-32 Mini 4way IB DB68-08128A-00 EN 20181228 2ion tNo ratings yet

- Machine Guarding PDFDocument133 pagesMachine Guarding PDFbrsharmaNo ratings yet

- Dead Heat 32 Video Arcade Racing Game Operators Manual NamcoDocument105 pagesDead Heat 32 Video Arcade Racing Game Operators Manual NamcoLuis MugaNo ratings yet

- Ol-13 PPT SafetyDocument19 pagesOl-13 PPT SafetyPasker 1980No ratings yet

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- WorldDocument20 pagesWorldJithu RajuNo ratings yet

- Unit IG2 - Risk Assessment: Chemical and Biological AgentsDocument53 pagesUnit IG2 - Risk Assessment: Chemical and Biological AgentsJithu RajuNo ratings yet

- Gc3 - The Health and Candidate's Observation Safety Practical Application SheetDocument1 pageGc3 - The Health and Candidate's Observation Safety Practical Application SheetJithu RajuNo ratings yet

- Gc3 - The Health and Candidate's Observation Safety Practical Application SheetDocument1 pageGc3 - The Health and Candidate's Observation Safety Practical Application SheetJithu RajuNo ratings yet

- Gc3 - The Health and Candidate's Observation Safety Practical Application SheetDocument1 pageGc3 - The Health and Candidate's Observation Safety Practical Application SheetJithu RajuNo ratings yet

- ﻚــﺴﻔﻨﺑ ﻚﺘﻗﺎﺑ نّﻮﻛ:ﺔﻗﺎﺒﻟا ﻢــﺳا Package name: Build Your Own PlanDocument1 pageﻚــﺴﻔﻨﺑ ﻚﺘﻗﺎﺑ نّﻮﻛ:ﺔﻗﺎﺒﻟا ﻢــﺳا Package name: Build Your Own PlanJithu RajuNo ratings yet

- Air India - Interview Invitation LetterDocument2 pagesAir India - Interview Invitation LetterJithu Raju0% (3)

- Sivaji: The Boss Movies Free Watch OnlineDocument2 pagesSivaji: The Boss Movies Free Watch OnlineJithu RajuNo ratings yet

- TherabandDocument1 pageTherabandsuviacesoNo ratings yet

- Buss 37 ZemaljaDocument50 pagesBuss 37 ZemaljaOlga KovacevicNo ratings yet

- Legg Calve Perthes Disease: SynonymsDocument35 pagesLegg Calve Perthes Disease: SynonymsAsad ChaudharyNo ratings yet

- Tractor Price and Speci Cations: Tractors in IndiaDocument4 pagesTractor Price and Speci Cations: Tractors in Indiatrupti kadamNo ratings yet

- BKM 10e Ch07 Two Security ModelDocument2 pagesBKM 10e Ch07 Two Security ModelJoe IammarinoNo ratings yet

- 13105389Document22 pages13105389Larry RicoNo ratings yet

- Key ScientificDocument4 pagesKey ScientificGarrettNo ratings yet

- Sebaran Populasi Dan Klasifikasi Resistensi Eleusine Indica Terhadap Glifosat Pada Perkebunan Kelapa Sawit Di Kabupaten Deli SerdangDocument7 pagesSebaran Populasi Dan Klasifikasi Resistensi Eleusine Indica Terhadap Glifosat Pada Perkebunan Kelapa Sawit Di Kabupaten Deli SerdangRiyo RiyoNo ratings yet

- Constipation Treatment For Infants and ChildrenDocument2 pagesConstipation Treatment For Infants and Childrenapi-559575515No ratings yet

- Manual of GardeningDocument812 pagesManual of GardeningPrakash PatelNo ratings yet

- Facts About Concussion and Brain Injury: Where To Get HelpDocument20 pagesFacts About Concussion and Brain Injury: Where To Get HelpJess GracaNo ratings yet

- Form - Pelaporan B3Document16 pagesForm - Pelaporan B3sukma nugraNo ratings yet

- Power Divider and Combiner: EE403-Microwave Engineering MTC, EE Dep., Electromagnetic Waves GroupDocument52 pagesPower Divider and Combiner: EE403-Microwave Engineering MTC, EE Dep., Electromagnetic Waves GroupHabibat El Rahman AshrafNo ratings yet

- Missoula County Fairgrounds Phase 2Document10 pagesMissoula County Fairgrounds Phase 2Olivia IversonNo ratings yet

- BV DSG eDocument18 pagesBV DSG eIulianIonutRaduNo ratings yet

- Hodgkin LymphomaDocument44 pagesHodgkin LymphomaisnineNo ratings yet

- People of The Philippines V. Crispin Payopay GR No. 141140 2003/07/2001 FactsDocument5 pagesPeople of The Philippines V. Crispin Payopay GR No. 141140 2003/07/2001 FactsAb CastilNo ratings yet

- Essay 31 - Permissive ParentingDocument2 pagesEssay 31 - Permissive Parentingqbich37No ratings yet

- 8 Categories of Lipids: FunctionsDocument3 pages8 Categories of Lipids: FunctionsCaryl Alvarado SilangNo ratings yet

- BCA2006 BCA GuideDocument507 pagesBCA2006 BCA GuidePatrick LiaoNo ratings yet

- Social Style InventoryDocument12 pagesSocial Style InventoryMaheshwari JaniNo ratings yet

- Biology 1st Term PaperDocument2 pagesBiology 1st Term PapershrirahulambadkarNo ratings yet

- OM Hospital NEFTDocument1 pageOM Hospital NEFTMahendra DahiyaNo ratings yet

- My Public Self My Hidden Self My Blind Spots My Unknown SelfDocument2 pagesMy Public Self My Hidden Self My Blind Spots My Unknown SelfMaria Hosanna PalorNo ratings yet

- CP 1Document22 pagesCP 1api-3757791100% (1)

- Assignment On Inservice Education Sub: Community Health NursingDocument17 pagesAssignment On Inservice Education Sub: Community Health NursingPrity DeviNo ratings yet

- Fundamental Molecular Biology: GenomesDocument45 pagesFundamental Molecular Biology: GenomesMoonHoLeeNo ratings yet

- Composite Restorations: Dr. Dina NouriDocument38 pagesComposite Restorations: Dr. Dina NouriCatherine LoyolaNo ratings yet

- Me N Mine Science X Ist TermDocument101 pagesMe N Mine Science X Ist Termneelanshujain68% (19)

- 10.1.polendo (Additional Patent)Document11 pages10.1.polendo (Additional Patent)Rima AmaliaNo ratings yet