Professional Documents

Culture Documents

Saic L 1004

Uploaded by

noor mohamedazeezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Saic L 1004

Uploaded by

noor mohamedazeezCopyright:

Available Formats

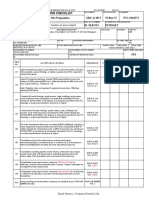

SAUDI ARAMCO ID/PIEU - 15-Nov-2017 - REV. 2016.06.00 (Standards Cutoff -June 30, 2016) Rev. 2016.06.

00 30-Jun-16

SAUDI ARAMCO INSPECTION CHECKLIST SAIC NUMBER DATE APPROVED QR NUMBER

Backfilling and Berm Construction Inspection SAIC-L-1004 15-Nov-17 CIVIL -

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID. PLANT NO.

LAYOUT DRAWING NUMBER REV. NO. PURCHASE ORDER NUMBER EC / PMCC / MCC NO.

SCHEDULED INSPECTION DATE & TIME ACTUAL INSPECTION DATE & TIME QUANTITY INSP. MH's SPENT TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO ACTIVITY NUMBER WORK PERMIT REQUIRED?

SAUDI ARAMCO INSPECTION LEVEL CONTRACTOR INSPECTION LEVEL

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

A Backilling

LPG lines, gas lines, and oil well flowlines shall have a minimum cover of

900 mm. Other lines shall have a minimum cover of 600 mm. Additional SAES-L-450

A1

cover required at road or rail crossings per SAES-L-460 shall be as noted Sec. 14.6.3

on the project drawings.

The top of the pipe, in trenches, shall not be closer to finished grade than SAES-L-450

A2

half the total cover required in sand areas. Sec. 14.9.2

In Sabkha areas, the top of the pipe shall be below the level of the SAES-L-450

A3

construction road by at least 100 mm. Sec. 14.11.2

The top of the pipe is below the original ground surface by 50 mm in SAES-L-450

A4

rippable or hard marl areas. Sec. 14.10.3a

The pipe centerline is 150 mm below the top of the finished grade when

SAES-L-450

A5 the top of rock layer is closer to finished grade elevation by more than half

Sec. 14.10.3a

pipe diameter plus 150 mm.

Spot backfilling shall be used to restrain the pipe after it has been lowered SAES-L-450

A6

into the trench. Sec. 14.6.1

SAES-L-450

A7 Any voids underneath the pipe shall be carefully backfilled.

Sec. 14.5

Spot backfilling shall have full specified cover and shall cover all SAES-L-450

A8

preformed bends a distance of 6m to each side of the center of the bends. Sec. 14.6.1

The maximum clear distance between spot backfills shall be as specified

SAES-L-450

A9 by the project design. Spot backfills shall cover the pipe for at least 4.5 m

Sec. 14.6.1

along the pipe.

Fills and cuts shall be made to reduce the number and/or magnitude of

SAES-L-450

A10 overbends and sagbends in the pipeline. Fills should be avoided in areas

Sec. 7.1.3

where the natural drainage of the surrounding area is affected.

Surveying sticks shall be used to establish dimensional controls to satisfy

SAES-L-450

A11 the inspector that the final cover will be sufficient and centered over the

Sec. 14.10.3d

pipeline.

A pad of selected bedding material shall be placed under and around the

pipe to provide a minimum cover of 200 mm above the pipe. The sand pile SAES-L-450

A12

remaining above the 200 mm cover shall be shaped to its natural angle of Sec. 14.10.3e

repose, approximately 35 degrees from the horizontal.

Provisions shall be made to prevent wash-out of the pipeline cover by rain SAES-L-450

A13

storms if the pipeline construction changes the natural drainage pattern. Sec. 7.1.4

Saudi Aramco: Company General Use

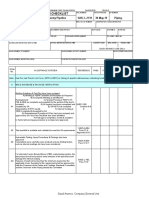

SAUDI ARAMCO ID/PIEU - 15-Nov-2017 - REV. 2016.06.00 (Standards Cutoff -June 30, 2016) Rev. 2016.06.00 30-Jun-16

SAUDI ARAMCO INSPECTION CHECKLIST SAIC NUMBER DATE APPROVED QR NUMBER

Backfilling and Berm Construction Inspection SAIC-L-1004 15-Nov-17 CIVIL -

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

To ensure the retention of sand cover in active sand areas, the backfill

SAES-L-450

A18 shall be stabilized with marl of 152 mm minimum depth, other stable

Sec. 14.9.5

material, or weathered crude oil with a minimum of 13 mm penetration.

If the line passes through a sand dune, the width of leveled, stabilized

SAES-L-450

A19 right-of-way shall be 3 m on each side of the pipeline plus 1 m for every 1

Sec. 14.9.5

m of dune height (or fill height) in both the "cut" and the "fill" areas.

The sand bedding under the pipe and backfill over the pipe can be SAES-L-450

A20 compacted to provide additional restraint around the buried pipe to reduce Sec. 14.9.5

pipe deflection and stress under the weight of sand dune. Commentary Note

Except for crossings with concrete slabs, concrete encasement, bridges,

SAES-L-460

A21 or culverts, the minimum cover over carrier steel pipe or steel casing shall

Sec. 7.1

be in accordance with Table 1 of this Section.

Table 1 – Minimum Cover for Pipeline Crossings Under Railroads and

Highways (See Notes)

Minimum Cover (1)

Railroad Crossings Location Cased Uncased

Under track structure proper(except

1.7m (3)

secondary and industry track)

Under track structure proper (for secondary

1.4 m (3)

and industry track)

Under all other surfaces within right-of-way or

0.9 m (3)

from bottom of ditches

For pipelines transporting highly volatile

1.2 m (3)

liquid (HVL)

Minimum Cover (2)

SAES-L-460

A22 Highway Crossings Location Cased Uncased Sec. 7.1

Table 1

Under highway surface proper 1.2m 1.2m

Under all other surfaces within the right-

of-way or from the 0.9m 0.9m

bottom of ditches

For pipelines transporting highly volatile

1.2m 1.2m

liquid (HVL) (4)

Notes: (1) Measured from the top of the casing pipe to the base of the rail.

(2) Measured from the top of the pipe to the bottom of the final finished

ground surface, such as asphalt road surface. (3) Uncased crossings

under railroads are not permitted. See paragraph 6.3. (4) For the purpose

of this standard, HVL is a hazardous liquid that will form a vapor cloud

when released to the atmosphere and that has a vapor pressure

exceeding 276 kPa (40 psia) at 37.8°C.

B Berm Construction

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PIEU - 15-Nov-2017 - REV. 2016.06.00 (Standards Cutoff -June 30, 2016) Rev. 2016.06.00 30-Jun-16

SAUDI ARAMCO INSPECTION CHECKLIST SAIC NUMBER DATE APPROVED QR NUMBER

Backfilling and Berm Construction Inspection SAIC-L-1004 15-Nov-17 CIVIL -

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

The remaining backfill and berm shall be placed in a manner to avoid

disturbing the sand pad. Coarse material shall not be placed on top of the

SAES-L-450

B1 sand pad and be allowed to roll down. Backfill shall not contain rock larger

Sec. 14.10.3f

than 150 mm size. The ramped sides of the dike shall not be steeper than

35 degrees.

The width of the flat top of the dike berm shall be at least twice the pipe SAES-L-450

B2

diameter along the overall minimum cover above the top of the pipe. Sec. 14.10.3g

Berm width shall be increased by 600mm for every 300mm additional

SAES-L-450

B3 cover required at vertical and horizontal bends in the pipeline. The

Sec. 14.10.3g

ramped sides of the dike shall not be steeper than 35 degrees.

The entire dike shall be stabilized with marl of 152 mm minimum depth or

by spraying with weathered crude oil to saturate the outer surface. The SAES-L-450

B4

crude shall penetrate a minimum of 12 mm. Typically, this requires Sec. 14.10.3h

approximately 4.5 L/m² (1 gal/yd²) of berm surface.

Diversion ditches and/or culverts for flood water shall be provided to keep SAES-L-450

B5

the pipeline cover from acting as a dam or as a channel bank. Sec. 14.10.3i

REMARKS:

REFERENCE DOCUMENTS:

1- SAES-L-460 -- Pipeline Crossings Under Roads and Railroads, 22 July 2014

2- SAES-L-450 -- Construction of On-Land and Near Shore Pipelines, 12 October 2015

Contractor / Third-Party Saudi Aramco

Construction Representative* PMT Representative

Work is Complete and Ready for Inspection: T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Inspector PID Representative

Performed Inspection Work / Rework May Proceed T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Supervisor Proponent and Others

Quality Record Approved: T&I Witnessed QC Record Reviewed Work Verified

Name, Organization,

Name, Sign and Date:

Initials and Date:

*Person Responsible for Completion of Quality Work / Test Y = YES N = NO F = FAILED

Saudi Aramco: Company General Use

You might also like

- Saic L 1004Document2 pagesSaic L 1004Hussain Nasser Al- NowiesserNo ratings yet

- Saic L 1002Document2 pagesSaic L 1002Hussain Nasser Al- NowiesserNo ratings yet

- SAIC-L-2113 Installation of Pipelaying-StringingDocument6 pagesSAIC-L-2113 Installation of Pipelaying-StringingMurugananthamParamasivamNo ratings yet

- SAIC-L-2106 Rev 7Document8 pagesSAIC-L-2106 Rev 7Jaseel KanhirathingalNo ratings yet

- Saic L 1001Document2 pagesSaic L 1001noor mohamedazeezNo ratings yet

- Saudi Aramco Inspection Checklist: Cast-In-Place Concrete Grade & Site Preparation SAIC-Q-1011 15-Nov-17 MAH-SA-RFI-C2626Document3 pagesSaudi Aramco Inspection Checklist: Cast-In-Place Concrete Grade & Site Preparation SAIC-Q-1011 15-Nov-17 MAH-SA-RFI-C2626Abdul HannanNo ratings yet

- SAIC-K-4020 Rev 08 - Chilled Water Piping Lay-OutDocument4 pagesSAIC-K-4020 Rev 08 - Chilled Water Piping Lay-Outranausman1987No ratings yet

- Saudi Aramco Inspection Checklist: Storm Water Drainage Systems Installation SAIC-S-4060 PlumbDocument2 pagesSaudi Aramco Inspection Checklist: Storm Water Drainage Systems Installation SAIC-S-4060 PlumbAiman RahmanNo ratings yet

- Saudi Aramco Inspection Checklist: Pipeline Right of Way (ROW) Inspection SAIC-L-1001 30-Oct-17 CivilDocument2 pagesSaudi Aramco Inspection Checklist: Pipeline Right of Way (ROW) Inspection SAIC-L-1001 30-Oct-17 CivilAhmad BassemNo ratings yet

- Saic L 2114 SfnyDocument3 pagesSaic L 2114 Sfnykhansalman51thNo ratings yet

- SAIC-W-2006 Rev 8Document4 pagesSAIC-W-2006 Rev 8saravananmenmathiNo ratings yet

- Saic Q 1011Document2 pagesSaic Q 1011Shazab NawazNo ratings yet

- Saic S 4058Document6 pagesSaic S 4058Engr IrfanNo ratings yet

- SAIC-X-3104 Rev 3Document4 pagesSAIC-X-3104 Rev 3Imran khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument4 pagesSaudi Aramco Inspection ChecklistManoj KumarNo ratings yet

- Saudi Aramco Inspection Checklist: Fill Placement and Compaction Inspection SAIC-A-1004 8-Nov-15 CivilDocument3 pagesSaudi Aramco Inspection Checklist: Fill Placement and Compaction Inspection SAIC-A-1004 8-Nov-15 CivilAhsaan MughalNo ratings yet

- Saic Q 1011Document2 pagesSaic Q 1011Hussain Nasser Al- Nowiesser100% (1)

- Saudi Aramco Inspection Checklist: Fill Placement and Compaction Inspection SAIC-A-1004 30-Apr-17 CivilDocument3 pagesSaudi Aramco Inspection Checklist: Fill Placement and Compaction Inspection SAIC-A-1004 30-Apr-17 Civilkarthi51289No ratings yet

- SAIC-L-2084 Material Storage and Preservation (EE) PDFDocument3 pagesSAIC-L-2084 Material Storage and Preservation (EE) PDFAnonymous S9qBDVkyNo ratings yet

- Saic M 1005Document4 pagesSaic M 1005noor mohamedazeezNo ratings yet

- SAIC-S-4002 Rev 7Document6 pagesSAIC-S-4002 Rev 7Muhammad TariqNo ratings yet

- Saudi Aramco Inspection Checklist: Gravity Sewer Piping Installation Inspection SAIC-L-2138 25-May-05 PlumbDocument3 pagesSaudi Aramco Inspection Checklist: Gravity Sewer Piping Installation Inspection SAIC-L-2138 25-May-05 PlumbHesham HelalNo ratings yet

- Saudi Aramco Inspection Checklist: Fill Placement and Compaction Inspection SAIC-A-1004 30-Apr-13 CivilDocument3 pagesSaudi Aramco Inspection Checklist: Fill Placement and Compaction Inspection SAIC-A-1004 30-Apr-13 CivilJeffrey Lipata Jr.No ratings yet

- Saudi Aramco Inspection Checklist: Final Inspection For Types I - V Fences SAIC-M-1005 30-Oct-17 CivilDocument4 pagesSaudi Aramco Inspection Checklist: Final Inspection For Types I - V Fences SAIC-M-1005 30-Oct-17 CivilAhmad BassemNo ratings yet

- SAIC-S-4056 Rev 7Document3 pagesSAIC-S-4056 Rev 7Eswari AnandNo ratings yet

- Saic A 1004Document3 pagesSaic A 1004Saragadam DilsriNo ratings yet

- SAIC-A-2006 Rev 7Document5 pagesSAIC-A-2006 Rev 7Shyam Sundar GayenNo ratings yet

- Saic M 1034Document2 pagesSaic M 1034noor mohamedazeezNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistManoj KumarNo ratings yet

- Saic A 1004Document2 pagesSaic A 1004Hussain Nasser Al- Nowiesser0% (1)

- Saic S 4057Document5 pagesSaic S 4057Engr IrfanNo ratings yet

- Saic A 1004Document3 pagesSaic A 1004Ansar Ali VemmullyNo ratings yet

- Saic A 1004Document2 pagesSaic A 1004pradeepthalava97No ratings yet

- Saic-H-2029Document12 pagesSaic-H-2029mominNo ratings yet

- Saic A 1004Document2 pagesSaic A 1004Son AbanadorNo ratings yet

- Saudi Aramco Inspection Checklist: In-Process Welding Inspection SAIC-W-2006 30-Apr-13 WeldDocument3 pagesSaudi Aramco Inspection Checklist: In-Process Welding Inspection SAIC-W-2006 30-Apr-13 WeldManoj KumarNo ratings yet

- SAIC-D-2020 Tank Trim Installation MAS-rlcDocument3 pagesSAIC-D-2020 Tank Trim Installation MAS-rlcAnonymous S9qBDVkyNo ratings yet

- Saudi Aramco Inspection Checklist: Review Procedure - Post Test Reinstatement & Checklist SAIC-A-2006 31-Dec-14 PipingDocument5 pagesSaudi Aramco Inspection Checklist: Review Procedure - Post Test Reinstatement & Checklist SAIC-A-2006 31-Dec-14 PipingpravinNo ratings yet

- Saic A 1004Document3 pagesSaic A 1004Rauf ChaudharyNo ratings yet

- Saic A 1005.Document3 pagesSaic A 1005.Shazab NawazNo ratings yet

- Saudi Aramco Inspection Checklist: Fill Placement and Compaction Inspection SAIC-A-1004 31-Nov-2019 CivilDocument2 pagesSaudi Aramco Inspection Checklist: Fill Placement and Compaction Inspection SAIC-A-1004 31-Nov-2019 CivilyazNo ratings yet

- Saic A 1004Document2 pagesSaic A 1004usmanNo ratings yet

- Saudi Aramco Inspection Checklist: In-Process Welding Inspection (API Tanks) SAIC-W-2086 31-Aug-11 WeldDocument3 pagesSaudi Aramco Inspection Checklist: In-Process Welding Inspection (API Tanks) SAIC-W-2086 31-Aug-11 WeldAnonymous 4e7GNjzGWNo ratings yet

- SAIC-T-5916 Rev 8building Premises Distribution System - Installation of Backbone Cable Tray SystemDocument3 pagesSAIC-T-5916 Rev 8building Premises Distribution System - Installation of Backbone Cable Tray Systemhomsalwaled88No ratings yet

- Saudi Aramco Inspection Checklist: In-Process Inspection of APCS-113 Coating Systems Application SAIC-H-2049 31-Mar-19Document3 pagesSaudi Aramco Inspection Checklist: In-Process Inspection of APCS-113 Coating Systems Application SAIC-H-2049 31-Mar-19harisNo ratings yet

- SAIC-K-2026 Suction Disch Piping Instal-SXS-RLC-f PDFDocument2 pagesSAIC-K-2026 Suction Disch Piping Instal-SXS-RLC-f PDFAnonymous S9qBDVkyNo ratings yet

- Saic L 2139Document9 pagesSaic L 2139Kumar RNo ratings yet

- SAIC-Q-1040 Placement and Compaction of Sub-Base and Aggregate Base Course Materials InspectioDocument3 pagesSAIC-Q-1040 Placement and Compaction of Sub-Base and Aggregate Base Course Materials InspectioAbdul Hannan0% (1)

- Saic G 2023Document2 pagesSaic G 2023Noor Mohamed AzeezNo ratings yet

- Saic-H-2027Document3 pagesSaic-H-2027momin0% (1)

- SAIC-W-2007 Rev 8Document6 pagesSAIC-W-2007 Rev 8saravananmenmathiNo ratings yet

- Saudi Aramco Inspection Checklist: Galvanic CP Anode Installation and Pre-Commissioning SAIC-X-3103 15-Dec-19 CPDocument3 pagesSaudi Aramco Inspection Checklist: Galvanic CP Anode Installation and Pre-Commissioning SAIC-X-3103 15-Dec-19 CPAwais NaeemNo ratings yet

- Saic L 2115Document4 pagesSaic L 2115khuram shahzadNo ratings yet

- Saic D 2025Document10 pagesSaic D 2025jerinNo ratings yet

- Saic A 1005Document3 pagesSaic A 1005mohammadNo ratings yet

- Saudi Aramco Inspection Checklist: Final Inspection For Types I - V Fences SAIC-M-1005 1-Nov-09 CivilDocument4 pagesSaudi Aramco Inspection Checklist: Final Inspection For Types I - V Fences SAIC-M-1005 1-Nov-09 CivilWaleed MedhatNo ratings yet

- Saic M 1033Document7 pagesSaic M 1033noor mohamedazeezNo ratings yet

- Saic A 1003Document2 pagesSaic A 1003Hussain Nasser Al- NowiesserNo ratings yet

- SAIC-A-2006 Rev 6Document16 pagesSAIC-A-2006 Rev 6biplabpal2009No ratings yet

- Saic A 1010Document1 pageSaic A 1010Naushad AlamNo ratings yet

- Saic K 4006Document2 pagesSaic K 4006mohamadNo ratings yet

- Saic A 1010Document1 pageSaic A 1010Naushad AlamNo ratings yet

- Saic M 1034Document2 pagesSaic M 1034noor mohamedazeezNo ratings yet

- Saic M 1035Document4 pagesSaic M 1035noor mohamedazeezNo ratings yet

- Saudi Aramco Inspection Checklist: Fencing Types I - V Installation Inspection SAIC-M-1002 30-Oct-17 CivilDocument4 pagesSaudi Aramco Inspection Checklist: Fencing Types I - V Installation Inspection SAIC-M-1002 30-Oct-17 CivilAhmad BassemNo ratings yet

- Saic M 1001Document8 pagesSaic M 1001noor mohamedazeezNo ratings yet

- Saic M 1004Document2 pagesSaic M 1004noor mohamedazeezNo ratings yet

- Saic M 1005Document4 pagesSaic M 1005noor mohamedazeezNo ratings yet

- Saic M 1032Document2 pagesSaic M 1032noor mohamedazeezNo ratings yet

- Saic M 1033Document7 pagesSaic M 1033noor mohamedazeezNo ratings yet

- Saic M 1031Document3 pagesSaic M 1031noor mohamedazeezNo ratings yet

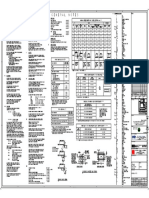

- General Notes PDFDocument1 pageGeneral Notes PDFnoor mohamedazeezNo ratings yet

- Wordbank 15 Youtube Writeabout1Document2 pagesWordbank 15 Youtube Writeabout1Olga VaizburgNo ratings yet

- Plant Vs Filter by Diana WalstadDocument6 pagesPlant Vs Filter by Diana WalstadaachuNo ratings yet

- Invitation of Nomination For The Rajiv Gandhi Wildlife Conservation Award For The Year 2011&2012Document2 pagesInvitation of Nomination For The Rajiv Gandhi Wildlife Conservation Award For The Year 2011&2012Naresh KadyanNo ratings yet

- Beer Lambert'S Law: Dr. Swastika Das Professor of ChemistryDocument19 pagesBeer Lambert'S Law: Dr. Swastika Das Professor of ChemistryShabanaNo ratings yet

- NDT HandBook Volume 10 (NDT Overview)Document600 pagesNDT HandBook Volume 10 (NDT Overview)mahesh95% (19)

- BBO2020Document41 pagesBBO2020qiuNo ratings yet

- Technical and Business WritingDocument3 pagesTechnical and Business WritingMuhammad FaisalNo ratings yet

- IBS and SIBO Differential Diagnosis, SiebeckerDocument1 pageIBS and SIBO Differential Diagnosis, SiebeckerKrishna DasNo ratings yet

- Comparison of Sic Mosfet and Si IgbtDocument10 pagesComparison of Sic Mosfet and Si IgbtYassir ButtNo ratings yet

- Business OrganizationDocument32 pagesBusiness OrganizationSaugandh GambhirNo ratings yet

- Ccu 3900alDocument3 pagesCcu 3900alTourchianNo ratings yet

- Mehdi Semati - Media, Culture and Society in Iran - Living With Globalization and The Islamic State (Iranian Studies)Document294 pagesMehdi Semati - Media, Culture and Society in Iran - Living With Globalization and The Islamic State (Iranian Studies)Alexandra KoehlerNo ratings yet

- Reservoir Bag Physics J PhilipDocument44 pagesReservoir Bag Physics J PhilipJashim JumliNo ratings yet

- March 2023 (v2) INDocument8 pagesMarch 2023 (v2) INmarwahamedabdallahNo ratings yet

- Gummy Bear Story RubricDocument1 pageGummy Bear Story Rubricapi-365008921No ratings yet

- What Is An EcosystemDocument42 pagesWhat Is An Ecosystemjoniel05No ratings yet

- Vignyapan 18-04-2024Document16 pagesVignyapan 18-04-2024adil1787No ratings yet

- Online Shopping MallDocument17 pagesOnline Shopping MallMerin LawranceNo ratings yet

- Planning Effective Advertising and Promotion Strategies For A Target AudienceDocument16 pagesPlanning Effective Advertising and Promotion Strategies For A Target Audiencebakhoo12No ratings yet

- A Sample Script For Public SpeakingDocument2 pagesA Sample Script For Public Speakingalmasodi100% (2)

- Onco Case StudyDocument2 pagesOnco Case StudyAllenNo ratings yet

- Merchant Shipping MINIMUM SAFE MANNING Regulations 2016Document14 pagesMerchant Shipping MINIMUM SAFE MANNING Regulations 2016Arthur SchoutNo ratings yet

- Free PDF To HPGL ConverterDocument2 pagesFree PDF To HPGL ConverterEvanNo ratings yet

- Haymne Uka@yahoo - Co.ukDocument1 pageHaymne Uka@yahoo - Co.ukhaymne ukaNo ratings yet

- Tso C197Document6 pagesTso C197rdpereirNo ratings yet

- CAMEL Model With Detailed Explanations and Proper FormulasDocument4 pagesCAMEL Model With Detailed Explanations and Proper FormulasHarsh AgarwalNo ratings yet

- Whitepaper ITES Industry PotentialDocument6 pagesWhitepaper ITES Industry PotentialsamuraiharryNo ratings yet

- Acc 106 Account ReceivablesDocument40 pagesAcc 106 Account ReceivablesAmirah NordinNo ratings yet

- Cs Fujitsu SAP Reference Book IPDFDocument63 pagesCs Fujitsu SAP Reference Book IPDFVijay MindfireNo ratings yet

- 2017-04-27 St. Mary's County TimesDocument32 pages2017-04-27 St. Mary's County TimesSouthern Maryland OnlineNo ratings yet