Professional Documents

Culture Documents

Cement Mill Reliability Action Plan

Uploaded by

anurag soni0 ratings0% found this document useful (0 votes)

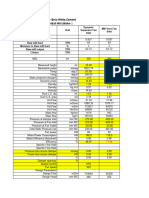

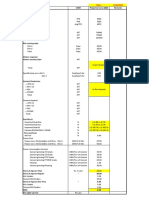

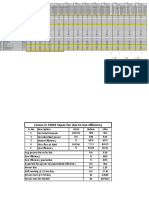

8 views3 pagesThe document lists 16 issues related to cement production including low mill output, media passing problems, reliability concerns, high bag house pressure, mill tripping, clinker and temperature issues, and additive and dedusting line problems. An action plan is provided with responsibilities assigned to address the issues such as grinding media top-ups, mill regradations, diaphragm replacements, rotor sealing, bag replacements, improving water systems, gypsum crusher repairs, silo top diverter reliability, reducing clinker temperature, ensuring continuous additive feeding, and moisture control. Target completion dates are listed as immediate effect or the next opportunity.

Original Description:

Original Title

Cement Mill Reliability Action Plan.xlsx

Copyright

© © All Rights Reserved

Available Formats

XLSX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document lists 16 issues related to cement production including low mill output, media passing problems, reliability concerns, high bag house pressure, mill tripping, clinker and temperature issues, and additive and dedusting line problems. An action plan is provided with responsibilities assigned to address the issues such as grinding media top-ups, mill regradations, diaphragm replacements, rotor sealing, bag replacements, improving water systems, gypsum crusher repairs, silo top diverter reliability, reducing clinker temperature, ensuring continuous additive feeding, and moisture control. Target completion dates are listed as immediate effect or the next opportunity.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

8 views3 pagesCement Mill Reliability Action Plan

Uploaded by

anurag soniThe document lists 16 issues related to cement production including low mill output, media passing problems, reliability concerns, high bag house pressure, mill tripping, clinker and temperature issues, and additive and dedusting line problems. An action plan is provided with responsibilities assigned to address the issues such as grinding media top-ups, mill regradations, diaphragm replacements, rotor sealing, bag replacements, improving water systems, gypsum crusher repairs, silo top diverter reliability, reducing clinker temperature, ensuring continuous additive feeding, and moisture control. Target completion dates are listed as immediate effect or the next opportunity.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

You are on page 1of 3

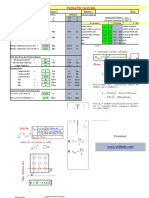

S No

Issues

1

Low Mill output

2

3

4 Media passing problem through diaphragm

5 Folaphone reliability to be improved

6 Comparatively high clinker size of Unit-1

7 Higher Product Reisdue in fine cement

9 High bag house DP in CM04

Mills Tripping due to inlet/outlet slide shoe

10 temperature

Cement temperature and Mill chute jamming

11

problem

Mill chute jamming due to large size POP

12

feeded with gypsum

Mill tripping due to silo top diverter stuck

13 problem

14 High Clinker temperature

15 Additive feeding problem

16 Dedusting line jamming problem

Action Plan Responsibility

Grinding media top up to be done: -

1. Cement mill 1: - 50 Mt Top up needed to make up 90% of

recommended filling.

2. Cement mill 2: - 55 Mt Top up needed to make up 90% of

recommended filling Mr. Anurag soni

3. Cement mill 3: - 60 Mt Top up needed to make up 95% of

recommended filling

4. Cement mill 4: - 40 Mt Top up needed to make up 90% of

recommended filling

Cement mill-2 regradation to be done Mr. Anurag soni

Cement mill-4 regradation to be done Mr. Anurag soni

Cement mill-3 outlet diaphragm liner to be replaced, currently

having 15/17 mm media passing problem frequently.

Mr. Gaurav / Mr. Abdur

Cement mill-4 intermediate diaphragm to be replaced, media Rahman

passed from first chamber to second chamber

Cement mill 1&2 to be checked and repair, frequent media

passing problem observed.

Need to replace it with high reliability indication Mr Vikram Patel

Need to reduce Unit-1 clinker size Mr. Ashish Sharma

Rotor sealing to be done effectively to reduce residues Mr. Gaurav Sharma

Remaining bags to be replaced in Bag house Mr. Gaurav Sharma

Issue regarding temperature increase to be resolved by

providing additional pump or heat exchangers Mr. Gaurav Sharma

Water pump availability to be improved and possible leakage

from lines needs to be checked in every maintenance, water Mr. Gaurav Sharma

spray type to change from jet type to spray type.

Gypsum crusher to be repaired

Gypsum feeding screen at gypsum yard to be modified to Mr. Gaurav Sharma

reduce screen size

Silo top diverter reliability to be improved Mr. Gaurav Sharma

Clinker temperature to be reduced upto 140-150 from 170-180 Mr. Ashish Sharma

Continuous additive feeding required to avoid quality

deviations. Mr. Lokesh saini

Continuous tracking needed , also moisture to be locked in Mr. Anurag soni/ Mr.

compressed air Gaurav Sharma

Target

Next Opportunity

30.11.2021

Next Opportunity

Next Opportunity

30.11.2021

Immedieate Effect

Next Opportunity

Immedieate Effect

Next Opportunity

Immedieate Effect

Immedieate Effect

Immedieate Effect

Immedieate Effect

Immedieate Effect

You might also like

- Concrete Technology Notes 2Document10 pagesConcrete Technology Notes 2Munir HalimzaiNo ratings yet

- Farm Mechanics Machinery and its Use to Save Hand Labor on the Farm.From EverandFarm Mechanics Machinery and its Use to Save Hand Labor on the Farm.Rating: 5 out of 5 stars5/5 (1)

- RA Casing CementingDocument66 pagesRA Casing CementingAnonymous 9AZe3w0% (1)

- Cementing Basics: - Primary Cementing - Repair (Squeeze Cementing)Document52 pagesCementing Basics: - Primary Cementing - Repair (Squeeze Cementing)qazim786No ratings yet

- Professor Dr. Md. Jahangir AlamDocument47 pagesProfessor Dr. Md. Jahangir AlamShah Mohammad IqbalNo ratings yet

- Pile Cap Design Calculations With CSI SAFEDocument6 pagesPile Cap Design Calculations With CSI SAFEroshanNo ratings yet

- Pumped ConcreteDocument7 pagesPumped ConcreteSa ReddiNo ratings yet

- Asphalt Mix DesignDocument34 pagesAsphalt Mix DesignEmmanuel Mends FynnNo ratings yet

- Spe62752 Viscous Pill InfoDocument1 pageSpe62752 Viscous Pill InfoAkkassin AbdullayevNo ratings yet

- FAT Procedure of LV SwitchboardsDocument17 pagesFAT Procedure of LV SwitchboardsWilliam Wong100% (2)

- Fineness Test On CementDocument13 pagesFineness Test On CementTvsp Sekhar50% (2)

- Solar System Worksheets For KS3Document7 pagesSolar System Worksheets For KS3ashleyNo ratings yet

- 1 Cement MillDocument52 pages1 Cement MillZegera Mgendi100% (3)

- 26" Section - Cementing - Checklist.Document2 pages26" Section - Cementing - Checklist.Yougchu Luan100% (1)

- Dailyprogress Report Nov 2016Document52 pagesDailyprogress Report Nov 2016Vinod Kumar VermaNo ratings yet

- Exam Agile Domande Esame PMI ACPDocument28 pagesExam Agile Domande Esame PMI ACPbzx300100% (1)

- SOP For CCM OperationDocument3 pagesSOP For CCM OperationMurali Krishnan Nair100% (3)

- Fan Eff Calculation'Document119 pagesFan Eff Calculation'Durga Prasad100% (1)

- Cement Mill Control DB MSDocument30 pagesCement Mill Control DB MSShakil Ahmad100% (2)

- P 19Document31 pagesP 19Debraj DattaNo ratings yet

- Toledo Glass Pavilion AnalysisDocument4 pagesToledo Glass Pavilion Analysisbryanpansing67% (3)

- Steel Pile InstallationDocument24 pagesSteel Pile Installationknthnp100% (1)

- Testing of Cement: Free Powerpoint Templates Free Powerpoint TemplatesDocument23 pagesTesting of Cement: Free Powerpoint Templates Free Powerpoint TemplatesVivekChaudharyNo ratings yet

- Part XI Mud Related Drilling Problems and SolutionsDocument72 pagesPart XI Mud Related Drilling Problems and SolutionsSlim.BNo ratings yet

- Cement Ball-Mill-Heat-BalanceDocument3 pagesCement Ball-Mill-Heat-Balanceanurag soni100% (1)

- CementingDocument53 pagesCementingUgochukwu Fidelis100% (1)

- Tests On CementDocument23 pagesTests On CementNavi Rengarajan100% (1)

- Asphalt Rubber Paving: Process OverviewDocument32 pagesAsphalt Rubber Paving: Process OverviewDaniel RangelNo ratings yet

- 2011 RT7 Urea Melt Pump DamageDocument4 pages2011 RT7 Urea Melt Pump Damagesatya_chagantiNo ratings yet

- Water Shutoff & Zone Transfer in Cambay #15 Well: Adjei Stephen Mtech Petroleum Eng Indian School of MinesDocument15 pagesWater Shutoff & Zone Transfer in Cambay #15 Well: Adjei Stephen Mtech Petroleum Eng Indian School of MinespaimanNo ratings yet

- Bitumen Water ProofingDocument23 pagesBitumen Water ProofingAkshthagowda848_1952No ratings yet

- Unit 6 Cementing, Cements and Cement SlurryDocument91 pagesUnit 6 Cementing, Cements and Cement SlurryHamid SiddiqueNo ratings yet

- Backfilling in The Underground Mining IndustryDocument9 pagesBackfilling in The Underground Mining IndustryJuan Pablo Henríquez ValenciaNo ratings yet

- Cementing: By/ Abdulrahman ShahinDocument22 pagesCementing: By/ Abdulrahman ShahinAbdulrhman Nabil ShahinNo ratings yet

- An Ambitious Project Taken Up by Kerala PWD (National Highways) - Cold in Place Recycling of Bituminous PavementDocument4 pagesAn Ambitious Project Taken Up by Kerala PWD (National Highways) - Cold in Place Recycling of Bituminous Pavementdivyadeenu9390No ratings yet

- Adjusting Slump in The FieldDocument3 pagesAdjusting Slump in The FieldMarc H. FeghaliNo ratings yet

- Fineness and Consistency of CementDocument21 pagesFineness and Consistency of CementIan Rovic CruzNo ratings yet

- A Contractors Guide To SuperplastisizersDocument3 pagesA Contractors Guide To SuperplastisizersMohan MylarappaNo ratings yet

- Testing of CementDocument17 pagesTesting of CementbinoNo ratings yet

- Fineness of Portland CementDocument4 pagesFineness of Portland CementJose Marie BorbeNo ratings yet

- Lecture #2&3 Fineness and Normal Consistency of Portland CementDocument24 pagesLecture #2&3 Fineness and Normal Consistency of Portland CementRome Lauren JavierNo ratings yet

- EJB Cold in Place RecyclingDocument68 pagesEJB Cold in Place Recyclingnvh202148No ratings yet

- Rapp-It CatalogueDocument12 pagesRapp-It CatalogueJose Martinez MillaNo ratings yet

- CementingDocument27 pagesCementingrezaNo ratings yet

- 100Th Pfeiffer Mill For India: Demand For High-Efficiency Mills Has Not Let Up!Document2 pages100Th Pfeiffer Mill For India: Demand For High-Efficiency Mills Has Not Let Up!Durga PrasadNo ratings yet

- Furma Fast DSDocument2 pagesFurma Fast DSMuhamad ZahdiNo ratings yet

- Cs - 57 Transport of Palm Oil Slurry 1Document3 pagesCs - 57 Transport of Palm Oil Slurry 1yosriNo ratings yet

- Ds2529-37 Molten-Sulphur-flyerDocument2 pagesDs2529-37 Molten-Sulphur-flyerAndy MartinNo ratings yet

- Plaster Mixing Procedures Application en IG503 PDFDocument4 pagesPlaster Mixing Procedures Application en IG503 PDFRowil GodoyNo ratings yet

- FM 1311-Specification of Split Case Pumps For FIREDocument1 pageFM 1311-Specification of Split Case Pumps For FIREKeval ShahNo ratings yet

- Fly Ash Bricks Technology - A DiscussionDocument6 pagesFly Ash Bricks Technology - A DiscussionN Gangadhar ReddyNo ratings yet

- EJB Ultra Thin Hot MixDocument52 pagesEJB Ultra Thin Hot MixBruno RamirezNo ratings yet

- Ultratech Cement: Unit: Birla WhiteDocument24 pagesUltratech Cement: Unit: Birla WhiteAbhishek LambaNo ratings yet

- ASTM C 1157: Performance Specification For Portland CementDocument13 pagesASTM C 1157: Performance Specification For Portland CementKenneth Malubay AndayaNo ratings yet

- Assignment 2 DE1Document8 pagesAssignment 2 DE1shafizmartinNo ratings yet

- DAM - Cement Additives: MA.P.E./ - SeriesDocument10 pagesDAM - Cement Additives: MA.P.E./ - SeriesSandeep RazdanNo ratings yet

- A Project Report: Maya Engineering WorksDocument2 pagesA Project Report: Maya Engineering WorksVishwendra SinghNo ratings yet

- Major Mechanical Modifications Done in Raw Material Area-Sp3Document50 pagesMajor Mechanical Modifications Done in Raw Material Area-Sp3sghane5674No ratings yet

- H4 Series: Horizontal Booster PumpsDocument1 pageH4 Series: Horizontal Booster Pumps2009tamerNo ratings yet

- SATYPAL GurjarDocument29 pagesSATYPAL GurjarsataveerNo ratings yet

- Presentation On ConcreteDocument26 pagesPresentation On Concreteaditya thakare100% (1)

- Raw Mill - Birla White CementDocument9 pagesRaw Mill - Birla White Cementanurag soniNo ratings yet

- Heat Balance Line 1 - Birla White CementDocument18 pagesHeat Balance Line 1 - Birla White Cementanurag soniNo ratings yet

- Critical Parameter For High Sulphur Fuel.Document1 pageCritical Parameter For High Sulphur Fuel.anurag soniNo ratings yet

- Heat Balance Line 2 - Birla White CementDocument16 pagesHeat Balance Line 2 - Birla White Cementanurag soniNo ratings yet

- Coal Mill - Birla White CementDocument8 pagesCoal Mill - Birla White Cementanurag soniNo ratings yet

- Shadowing A DH - Learning Record - Anurag Soni 26.11.2021Document1 pageShadowing A DH - Learning Record - Anurag Soni 26.11.2021anurag soniNo ratings yet

- Influencing For Impact-Notes-My Learning Diary-Ashok GundetiDocument3 pagesInfluencing For Impact-Notes-My Learning Diary-Ashok Gundetianurag soniNo ratings yet

- Weekly Planning June W3-22Document2 pagesWeekly Planning June W3-22anurag soniNo ratings yet

- Evolve - Pre-Work - Influencing For Impact - Session 1 - GauravDocument1 pageEvolve - Pre-Work - Influencing For Impact - Session 1 - Gauravanurag soniNo ratings yet

- Pre-Work - Impactful Conversations and Collaboration - Anurag SoniDocument1 pagePre-Work - Impactful Conversations and Collaboration - Anurag Sonianurag soniNo ratings yet

- Fan Efficiency With GRR Losses - CM03Document2 pagesFan Efficiency With GRR Losses - CM03anurag soniNo ratings yet

- Grinding Aid Performance Observation 25.06.22Document1 pageGrinding Aid Performance Observation 25.06.22anurag soniNo ratings yet

- Evolve - Level 3 - Project Planner - Your NameDocument4 pagesEvolve - Level 3 - Project Planner - Your Nameanurag soniNo ratings yet

- FIP Team 1 EntrepreneureshipDocument18 pagesFIP Team 1 Entrepreneureshipanurag soniNo ratings yet

- Final Exam-ECO720-2112-1&2 VSDocument4 pagesFinal Exam-ECO720-2112-1&2 VSanurag soniNo ratings yet

- Final Exam-MAN790-2204, VIVEK SHUKLA VS17495Document8 pagesFinal Exam-MAN790-2204, VIVEK SHUKLA VS17495anurag soniNo ratings yet

- FIN701 Finance AS1744Document17 pagesFIN701 Finance AS1744anurag soniNo ratings yet

- CapacitorDocument35 pagesCapacitorjolieprincesseishimweNo ratings yet

- Akkaya Katalog EN 2019Document66 pagesAkkaya Katalog EN 2019Juan MendozaNo ratings yet

- Draw The Orthographic Front View, Top View and Side View of The Given Object Using AutocadDocument81 pagesDraw The Orthographic Front View, Top View and Side View of The Given Object Using AutocadKartik BansalNo ratings yet

- University of Cambridge International Examinations General Certificate of Education Advanced LevelDocument20 pagesUniversity of Cambridge International Examinations General Certificate of Education Advanced LeveltakundavsNo ratings yet

- Chapter No-5 Steam Condensers and Cooling Towers Marks-16Document22 pagesChapter No-5 Steam Condensers and Cooling Towers Marks-16Vera WidyaNo ratings yet

- Evolution of Finfets From 22Nm To 7Nm: September 2019Document44 pagesEvolution of Finfets From 22Nm To 7Nm: September 2019Krisumraj PurkaitNo ratings yet

- Assembly Chapter6 BDocument4 pagesAssembly Chapter6 BMr hacksNo ratings yet

- A Spectrophotometric Study of The Complex Formation Between Iron (III) and Salicylic AcidDocument6 pagesA Spectrophotometric Study of The Complex Formation Between Iron (III) and Salicylic AcidXuân ThảoNo ratings yet

- Bruker XRF SOPDocument14 pagesBruker XRF SOPsupendra phuyalNo ratings yet

- Portable Savonius Wind Turbine With Deflectors: by AdriancubasDocument15 pagesPortable Savonius Wind Turbine With Deflectors: by AdriancubasLê VinhNo ratings yet

- Introducing The 3L Small Form FactorDocument15 pagesIntroducing The 3L Small Form FactorzdjulicgmailcomNo ratings yet

- High Precision Spectroradiometer Integrating Sphere SystemDocument11 pagesHigh Precision Spectroradiometer Integrating Sphere SystemLISUN GROUPNo ratings yet

- ATF VI en FR Motul 19280 20221103Document6 pagesATF VI en FR Motul 19280 20221103larconeNo ratings yet

- Automobile Underchassis Servicing, Repair and Maintenance: James D. Artista AETC 2101Document11 pagesAutomobile Underchassis Servicing, Repair and Maintenance: James D. Artista AETC 2101Kirito CabelNo ratings yet

- TOC GTU Study Material Presentations Unit-6 18062021085644AMDocument21 pagesTOC GTU Study Material Presentations Unit-6 18062021085644AMJAYRAJSINH ZALANo ratings yet

- Main Contents: Detection of Polypropylene Fibers With USTER Quantum 3Document16 pagesMain Contents: Detection of Polypropylene Fibers With USTER Quantum 3PricopNo ratings yet

- Wdi73120 HKDocument1 pageWdi73120 HKDel WNo ratings yet

- General Diagnostic Table: Malfunction of Parts Other Than Those Listed Is Also Possible.Document2 pagesGeneral Diagnostic Table: Malfunction of Parts Other Than Those Listed Is Also Possible.miguelNo ratings yet

- SR - Single CAC - CCD (R410A, 60Hz) - CO, HP - Saudi - MFL67986307 - 0CSB0-01B (Dec.2015)Document46 pagesSR - Single CAC - CCD (R410A, 60Hz) - CO, HP - Saudi - MFL67986307 - 0CSB0-01B (Dec.2015)Omair FarooqNo ratings yet

- Parenteral Drugs: Compatibilit Y: Yosefa Asteria, S.Farm.,Apt Rs Suaka Insan BanjarmasinDocument42 pagesParenteral Drugs: Compatibilit Y: Yosefa Asteria, S.Farm.,Apt Rs Suaka Insan Banjarmasinfarida nur ainiNo ratings yet

- Selenium Interview Questions and Answers - Click4Interviews PDFDocument3 pagesSelenium Interview Questions and Answers - Click4Interviews PDFAbhilash KvNo ratings yet

- Chapter 8 Walls and Buried Structures: WSDOT Bridge Design Manual M 23-50.20 Page 8-I September 2020Document56 pagesChapter 8 Walls and Buried Structures: WSDOT Bridge Design Manual M 23-50.20 Page 8-I September 2020Vietanh PhungNo ratings yet

- 5std-Maths Concept Examinati (2013) EngDocument6 pages5std-Maths Concept Examinati (2013) Engabhishek123456No ratings yet

- Design and CFD Analysis of Centrifugal Compressor For A MicrogasturbineDocument7 pagesDesign and CFD Analysis of Centrifugal Compressor For A MicrogasturbineFurqanNo ratings yet

- Alz Ha PDFDocument16 pagesAlz Ha PDFΓεώργιος ΠαπαδόπουλοςNo ratings yet