Professional Documents

Culture Documents

Grinding Aid Performance Observation 25.06.22

Uploaded by

anurag soni0 ratings0% found this document useful (0 votes)

19 views1 pageOriginal Title

Grinding Aid Performance Observation 25.06.22.xlsx

Copyright

© © All Rights Reserved

Available Formats

XLSX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

19 views1 pageGrinding Aid Performance Observation 25.06.22

Uploaded by

anurag soniCopyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

You are on page 1of 1

Grinding Aid Performance Analysis

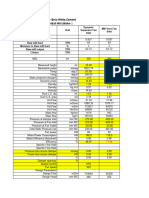

Cement Mill -1 Trial with Grinding Aid (Grade -53)

20.06.2022 Process Parameter 1-day Strength

Mill power (both Silo Elevator Recirculation vent fan Residue

Mill Feed Pholaphone Reject TPH Sep. Rpm Fan Speed Mill Blaine

drive avg.) load elevator load speed (90µ)

Without G.Aid 125-130 2100-2150 78-82 76 65-80 22-25 1250 80 98.5 290-310 2-2.5 24

With G.Aid 130-137 2050-2100 78-81 79 80-105 26-29 1220 80 98.5 290-305 2-2.5 25

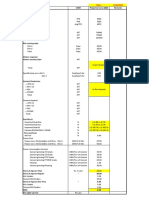

Grinding AID trial in Cement Mill -2 (Grade -PPC)

20.06.2022 Process Parameter

Silo Elevator Recirculation vent fan Residue

Mill Feed Mill power (Avg) Pholaphone Reject TPH Sep Rpm Fan Speed Mill Blaine

load elevator load speed (90µ)

Without G.Aid 130-135 1675-1720 78-81 68 150-250 40-50 1200-1300 70-75 100 340-355 2.5-3.5 16

With G.Aid 135-140 1700-1725 76-80 71 80-125 30-40 1200-1250 75-80 100 340-360 2.5-3.0 17

Grinding AID trial in Cement Mill -3 (Grade -PPC)

20.06.2022 Process Parameter

Silo Elevator Recirculation vent fan Residue

Mill Feed Mill power Pholaphone Reject TPH Sep Rpm Fan Speed Mill Blaine

load elevator load speed (90µ)

Without G.Aid 165-170 4300 80-82 73-75 150-200 80-100 1200-1275 700 100 340-355 2.5-3.5 16

With G.Aid 170-175 4400 79-81 75-78 130-160 75-90 1170-1225 700 100 350-360 2.5-3.0 17

Observation:

1. Mill Output increased in range of 5-7 TPH in PPC as well as OPC Grade

2. Mill Drive Power slightly Increased

3. No significant improvement observed in product Blaine

4. One day strength observed increased by 1 unit in PPC as well as OPC53 grade

5. PI% increased by 1% in PPC grade from 7 to 8%, whereas increased 1-day strength benefit couldn't taken into PI in OPC53 grade

You might also like

- Hind Geared Motor PDFDocument20 pagesHind Geared Motor PDFjayesh gohilNo ratings yet

- FGP 50/M - FGP 70/M - FGP 100/M - FGP 120/M - FGP 150/M: Light-Oil Burners Two Stages Progressive or ModulatingDocument6 pagesFGP 50/M - FGP 70/M - FGP 100/M - FGP 120/M - FGP 150/M: Light-Oil Burners Two Stages Progressive or ModulatingEden BenNo ratings yet

- Idah AirSaperatorDocument8 pagesIdah AirSaperatortranngt2020No ratings yet

- CCR Logsheet BbciDocument1 pageCCR Logsheet BbciherwinNo ratings yet

- Basic Rates As Per SOR 2018-19 Escalation @5% For FY 2019-20 Unit Adopted Rate SL - No. Description of Machine Activity Output of Machine OutputDocument3 pagesBasic Rates As Per SOR 2018-19 Escalation @5% For FY 2019-20 Unit Adopted Rate SL - No. Description of Machine Activity Output of Machine Outputanon_789699787No ratings yet

- Rate AnalysisDocument135 pagesRate AnalysisM/s Gogoi AssociatesNo ratings yet

- Gamma Meccanica Technical InformationDocument8 pagesGamma Meccanica Technical InformationHafiani HichamNo ratings yet

- 3700 Tech DataDocument2 pages3700 Tech DataMohamed BadranNo ratings yet

- Example of Cement Mill QuestionnaireDocument5 pagesExample of Cement Mill QuestionnaireIrfan AhmedNo ratings yet

- SOP-Startup Shutdown and Operation of Cement MillsDocument4 pagesSOP-Startup Shutdown and Operation of Cement MillsJCSNo ratings yet

- Perform Test Data After Midlife Log EDG NCP2 NPU - 21 Feb 20Document1 pagePerform Test Data After Midlife Log EDG NCP2 NPU - 21 Feb 20MR BEANo ratings yet

- Perform Test Data After Midlife Log EDG NCP2 NPU - 21 Feb 20Document1 pagePerform Test Data After Midlife Log EDG NCP2 NPU - 21 Feb 20MR BEANo ratings yet

- Machinery Rate AnalayisiDocument10 pagesMachinery Rate Analayisianon_789699787No ratings yet

- DatasheetsDocument10 pagesDatasheetsArslan NisarNo ratings yet

- Bharat Aluminium Company LTDDocument9 pagesBharat Aluminium Company LTDAnil RaiNo ratings yet

- Catalog BurnerDocument6 pagesCatalog BurnerSEPTADONAI TRISNANo ratings yet

- Powerkit Engine 6M11 Series: General SpecificationsDocument3 pagesPowerkit Engine 6M11 Series: General SpecificationsstorkbNo ratings yet

- DR ModelCBR May09Document8 pagesDR ModelCBR May09scax25No ratings yet

- Powerkit Engine 6M21 Series: General SpecificationsDocument2 pagesPowerkit Engine 6M21 Series: General SpecificationsstorkbNo ratings yet

- Acel Rate Using EQ DryDocument2 pagesAcel Rate Using EQ DryNymi D621No ratings yet

- Manual For Pneumatic Automatic Feeder SpecificationDocument18 pagesManual For Pneumatic Automatic Feeder SpecificationhaisamnagyNo ratings yet

- Test Certificate WA380-6Document1 pageTest Certificate WA380-6Henry SalasNo ratings yet

- Marine Engine-6M33 Series: General SpecificationsDocument3 pagesMarine Engine-6M33 Series: General SpecificationsRahulNo ratings yet

- WATSON MARLOW SQP 500 DatenblattDocument4 pagesWATSON MARLOW SQP 500 DatenblattDicle KarabiberNo ratings yet

- Powerkit Engine 6M33 Series: General SpecificationsDocument2 pagesPowerkit Engine 6M33 Series: General SpecificationsstorkbNo ratings yet

- Blast Furnace OverviewDocument26 pagesBlast Furnace OverviewResego PhiriNo ratings yet

- SOP-startup Shutdown and Operation of Raw MillDocument4 pagesSOP-startup Shutdown and Operation of Raw MillJCS100% (1)

- Egm80Af: General DataDocument4 pagesEgm80Af: General Datammiled mounirNo ratings yet

- 11 TR DFDocument1 page11 TR DFCharlie MendozaNo ratings yet

- Home About Us Products Contact UsDocument17 pagesHome About Us Products Contact UsShrikant KanthNo ratings yet

- nc150s Isuzu 4le2x Us 200gpa0001420 - Us PDFDocument2 pagesnc150s Isuzu 4le2x Us 200gpa0001420 - Us PDFjuanpantera24No ratings yet

- MTU 16V4000G63 Diesel Generating Sets Technical DataDocument6 pagesMTU 16V4000G63 Diesel Generating Sets Technical DataMahnooshNo ratings yet

- Engineering Catalog: CD250M Dri-Prime Pump Engineering DataDocument7 pagesEngineering Catalog: CD250M Dri-Prime Pump Engineering DataNils Enrique Hansen GamarraNo ratings yet

- Engine Performance Data at 1500 RPM: B5.9 1 Cummins IncDocument4 pagesEngine Performance Data at 1500 RPM: B5.9 1 Cummins Incmk100% (1)

- Cummins 300kva 750kva Silent Diesel Generator Price - JET POWER - JessicaDocument3 pagesCummins 300kva 750kva Silent Diesel Generator Price - JET POWER - JessicaAlexis ParadaNo ratings yet

- Coal Mill, Feeder & PULV 1Document7 pagesCoal Mill, Feeder & PULV 1sambhuNo ratings yet

- 00 Submittal PAQDocument52 pages00 Submittal PAQpriyangani dmmikaNo ratings yet

- Rate Analysis Programme MorthDocument362 pagesRate Analysis Programme MorthAman SrivastavaNo ratings yet

- Marine Engines: Customer BenefitsDocument3 pagesMarine Engines: Customer BenefitsAlbertoNo ratings yet

- FR94438 6BTAA5.9-G12 Datasheet - 01 - enDocument5 pagesFR94438 6BTAA5.9-G12 Datasheet - 01 - enEko SulistyoNo ratings yet

- Iveco 200 KvaDocument1 pageIveco 200 KvaMohamed EL-NASHARNo ratings yet

- Data Motor (New)Document10 pagesData Motor (New)riskyputrautama28No ratings yet

- Mahindra Navistar Engine Technical DataDocument8 pagesMahindra Navistar Engine Technical DatabaljeetjatNo ratings yet

- Marine Engine-6170 Series: General SpecificationsDocument3 pagesMarine Engine-6170 Series: General SpecificationsTrần Hoài VinhNo ratings yet

- Piling & Concrete Rate AnlysisDocument79 pagesPiling & Concrete Rate AnlysisfinesomalinNo ratings yet

- Powerkit Engine 12M33 Series: General SpecificationsDocument2 pagesPowerkit Engine 12M33 Series: General SpecificationsstorkbNo ratings yet

- Performance Curves of A Peerless End Suction Type 1430 PumpDocument2 pagesPerformance Curves of A Peerless End Suction Type 1430 PumpMark Anthony Salazar ArcayanNo ratings yet

- 350/M - FGP 450/M - FGP 550/M: Light-Oil Burners Two Stages Progressive or ModulatingDocument4 pages350/M - FGP 450/M - FGP 550/M: Light-Oil Burners Two Stages Progressive or ModulatingKarthik AnandanNo ratings yet

- WD10Document3 pagesWD10service alatberatNo ratings yet

- Standard Data Book (Road & Bridge)Document10 pagesStandard Data Book (Road & Bridge)Anonymous aNyCxZWNo ratings yet

- FD Fan Sop - OpgDocument7 pagesFD Fan Sop - OpgNarayanan KharthiNo ratings yet

- Bently Nevada SolutionsDocument40 pagesBently Nevada SolutionsNapoleon Rafael CalleNo ratings yet

- PreliminaryDocument4 pagesPreliminaryIng Victor MendezNo ratings yet

- Cummins Engine QST30-G4 PDFDocument6 pagesCummins Engine QST30-G4 PDFGermán Andrés100% (1)

- BMR Orbit Hydraulic Motor With Spool ValveDocument10 pagesBMR Orbit Hydraulic Motor With Spool ValveHai VanNo ratings yet

- 6170 SpesDocument3 pages6170 SpesAmin GuiNo ratings yet

- Speed Chart Mabre PumpDocument2 pagesSpeed Chart Mabre PumpIsrael Gibran Cañas RodriguezNo ratings yet

- Heat Balance Line 1 - Birla White CementDocument18 pagesHeat Balance Line 1 - Birla White Cementanurag soniNo ratings yet

- Raw Mill - Birla White CementDocument9 pagesRaw Mill - Birla White Cementanurag soniNo ratings yet

- Critical Parameter For High Sulphur Fuel.Document1 pageCritical Parameter For High Sulphur Fuel.anurag soniNo ratings yet

- Heat Balance Line 2 - Birla White CementDocument16 pagesHeat Balance Line 2 - Birla White Cementanurag soniNo ratings yet

- Shadowing A DH - Learning Record - Anurag Soni 26.11.2021Document1 pageShadowing A DH - Learning Record - Anurag Soni 26.11.2021anurag soniNo ratings yet

- Coal Mill - Birla White CementDocument8 pagesCoal Mill - Birla White Cementanurag soniNo ratings yet

- Fan Efficiency With GRR Losses - CM03Document2 pagesFan Efficiency With GRR Losses - CM03anurag soniNo ratings yet

- Influencing For Impact-Notes-My Learning Diary-Ashok GundetiDocument3 pagesInfluencing For Impact-Notes-My Learning Diary-Ashok Gundetianurag soniNo ratings yet

- Evolve - Pre-Work - Influencing For Impact - Session 1 - GauravDocument1 pageEvolve - Pre-Work - Influencing For Impact - Session 1 - Gauravanurag soniNo ratings yet

- Weekly Planning June W3-22Document2 pagesWeekly Planning June W3-22anurag soniNo ratings yet

- Pre-Work - Impactful Conversations and Collaboration - Anurag SoniDocument1 pagePre-Work - Impactful Conversations and Collaboration - Anurag Sonianurag soniNo ratings yet

- FIN701 Finance AS1744Document17 pagesFIN701 Finance AS1744anurag soniNo ratings yet

- Cement Ball-Mill-Heat-BalanceDocument3 pagesCement Ball-Mill-Heat-Balanceanurag soni100% (1)

- Cement Mill Reliability Action PlanDocument3 pagesCement Mill Reliability Action Plananurag soniNo ratings yet

- Final Exam-ECO720-2112-1&2 VSDocument4 pagesFinal Exam-ECO720-2112-1&2 VSanurag soniNo ratings yet

- FIP Team 1 EntrepreneureshipDocument18 pagesFIP Team 1 Entrepreneureshipanurag soniNo ratings yet

- Final Exam-MAN790-2204, VIVEK SHUKLA VS17495Document8 pagesFinal Exam-MAN790-2204, VIVEK SHUKLA VS17495anurag soniNo ratings yet

- Evolve - Level 3 - Project Planner - Your NameDocument4 pagesEvolve - Level 3 - Project Planner - Your Nameanurag soniNo ratings yet

- 1 PDFDocument3 pages1 PDFFatima Ja'aferNo ratings yet

- TEPZZ 48 Z74B - T: European Patent SpecificationDocument13 pagesTEPZZ 48 Z74B - T: European Patent SpecificationLong An DoNo ratings yet

- Minerals and Their UsesDocument15 pagesMinerals and Their UsesAnonymous i6E1p4RtPNo ratings yet

- Ceramics: Ceramic Tile Adhesives From The Producer's Perspective: A Literature ReviewDocument13 pagesCeramics: Ceramic Tile Adhesives From The Producer's Perspective: A Literature ReviewEray GÜRNo ratings yet

- RDSO GuidelineDocument57 pagesRDSO GuidelineSyed Nizam ElahiNo ratings yet

- Characterizing Curing-Cement Slurries by Permeability, Tensile Strength, and ShrinkageDocument6 pagesCharacterizing Curing-Cement Slurries by Permeability, Tensile Strength, and ShrinkageAry RachmanNo ratings yet

- Test Report: M/S Pcil & MBPCL Joint VentureDocument7 pagesTest Report: M/S Pcil & MBPCL Joint VentureImran KhanNo ratings yet

- Catappa) and Its Fruits Are Scattered EverywhereDocument18 pagesCatappa) and Its Fruits Are Scattered EverywhereRichelle ValienteNo ratings yet

- Fly Ash Literature Review PDFDocument8 pagesFly Ash Literature Review PDFaflsqrbnq100% (1)

- Developing Together. Building With Each Other.: We Create Chemistry For Advanced ConstructionDocument5 pagesDeveloping Together. Building With Each Other.: We Create Chemistry For Advanced ConstructionAlex Paye AncoNo ratings yet

- Barangay Divina Pastora ConcretingDocument8 pagesBarangay Divina Pastora ConcretingJuDeNo ratings yet

- Cemex HBR Case AnalysisDocument3 pagesCemex HBR Case Analysisnikhilsharma550% (4)

- Conbextra BB80Document3 pagesConbextra BB80talatzahoorNo ratings yet

- Soil Stabilization With Using Waste Materials Against Freezing Thawing EffectDocument3 pagesSoil Stabilization With Using Waste Materials Against Freezing Thawing EffectArham SheikhNo ratings yet

- Effects of Pressure and Temperature On Well Cement Degradation by Supercritical CODocument9 pagesEffects of Pressure and Temperature On Well Cement Degradation by Supercritical COemefakoveNo ratings yet

- Concrete: Building Technology 1: Div 03Document65 pagesConcrete: Building Technology 1: Div 03arki_37826160No ratings yet

- Info On Paver BlocksDocument6 pagesInfo On Paver BlocksGaneshNo ratings yet

- Compressive Strength of CementDocument3 pagesCompressive Strength of CementRama shankarNo ratings yet

- Petitioner vs. vs. Respondents Santiago, Tinga & Associates: Second DivisionDocument7 pagesPetitioner vs. vs. Respondents Santiago, Tinga & Associates: Second DivisionAndré BragaNo ratings yet

- Dapson New ProjectDocument60 pagesDapson New ProjectAderemi AbidemiNo ratings yet

- ACI 239R-18 - OptDocument28 pagesACI 239R-18 - OptdinoNo ratings yet

- Vernacular and Earthen Architecture - Conservation and Sustainability - Proceedings of SOStierra2017, 3rd Restapia, 3rd Versus, Valencia, Spain, 14-16 September 2017 PDFDocument846 pagesVernacular and Earthen Architecture - Conservation and Sustainability - Proceedings of SOStierra2017, 3rd Restapia, 3rd Versus, Valencia, Spain, 14-16 September 2017 PDFHellen Souza100% (2)

- An Experimental Investigation of Mahogany Carpel Ash As Cement Replacement in Concrete 2 PDFDocument9 pagesAn Experimental Investigation of Mahogany Carpel Ash As Cement Replacement in Concrete 2 PDFAdler ValdezNo ratings yet

- Research Paper On BambooDocument8 pagesResearch Paper On Bamboo01shubhamupadhyayNo ratings yet

- A Study On The Specific Rate of Breakage of Cement MaterialsDocument7 pagesA Study On The Specific Rate of Breakage of Cement MaterialshamidNo ratings yet

- VedsDocument4 pagesVedsAmit Kumar ShuklaNo ratings yet

- Trail Mix M37-AccropodeDocument36 pagesTrail Mix M37-AccropodeKeerti Bongu50% (2)

- Basf SCCDocument14 pagesBasf SCCTrasheyNo ratings yet

- Cement Energy GuideDocument70 pagesCement Energy GuideAmr A. NaderNo ratings yet

- Building in A BagDocument4 pagesBuilding in A BagNguyen Do Hung33% (3)