Professional Documents

Culture Documents

Rotator Permit New

Uploaded by

Hrishikesh CE0 ratings0% found this document useful (0 votes)

15 views1 pageThis document is a work permit for the installation of a rotator and idler. It contains 20 observation points to check such as the condition of the equipment, installation alignment, safety measures, and supervisor approval. Upon completion and confirmation that all observation points are satisfied and safety measures are in place, the supervisor signs off on the permit to authorize the installation.

Original Description:

Original Title

Rotator permit new

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document is a work permit for the installation of a rotator and idler. It contains 20 observation points to check such as the condition of the equipment, installation alignment, safety measures, and supervisor approval. Upon completion and confirmation that all observation points are satisfied and safety measures are in place, the supervisor signs off on the permit to authorize the installation.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

15 views1 pageRotator Permit New

Uploaded by

Hrishikesh CEThis document is a work permit for the installation of a rotator and idler. It contains 20 observation points to check such as the condition of the equipment, installation alignment, safety measures, and supervisor approval. Upon completion and confirmation that all observation points are satisfied and safety measures are in place, the supervisor signs off on the permit to authorize the installation.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 1

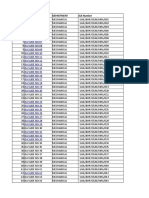

Complete PERMIT for all Rotator installation.

Date and Time PERMIT Issued _____________________

Integrated Management System Work Permit

PED/SOP/1 1

(ISO 9001:2008,ISO 14001:2004, OHSAS 18001:2007)

Page Page 1

Manufacturing Department Revision 4

ROTATOR & IDLER INSTALLATION

Process Equipment Division Date 16-06-16

PERMIT

JOB NO. LOCATION: _______

ROTATOR AND IDLER NO _________________

Sr. No. Observation Tick Yes/ Not Remarks

No Appilicable

1 Condition of Rotator and idler checked Yes/ No

2 Lead screw is in working condition Yes/ No

3 Variable speed pannel fitted on stand. Yes/ No

4 Cable connection socket + cable in good condition Yes/ No

with conduit pipe

5 Same make of rotator/ idler used Yes/ No

6 Same inter distance of rollers kept. Yes/ No

7 Angle of rotator calculated as per formula. Yes/ No

8 Weight of equipment/shell is within safe loading Yes/ No

capacity of rotators & Idlers

9 Rotators/ idlers to be installed on the rail. Yes/ No

10 To avoid movement of Rotator/ Idler Stiffeners are Yes/ No

welded on

11 Rotator & Idler Wheel diagonal distances are checked Yes/ No

for

alignment

12 Motor is not facing Gangway. Yes/ No

13 No fouling with nozzle/attachment anticipated. Yes/ No

14 Drift ofjob after installation on rotator observed & is Yes/ No

within range.

15 Marking of rotating Band on the job & observe the Yes/ No

drift.

16 Electrical Cable & Gas pipe line are laid properly Yes/ No

around the Rotator installation to avoid leakage & cuts.

17 Make sure emergency stop button available on Yes/ No

Pendant.

18 Double Earthing provided. Yes/ No

19 Provisions to be made for keeping the pendant on Yes/ No

rotator.

20 All rotating coupling shall be safe guarded. Yes/ No

21 All removable cover of rotator/idlers must be in its Yes/ No

position. Su

p erv

isor sign: Operator Details:

Prepared By: Mr. Jatin Sanghadia Approved By : Mr. Gurmeet

Date : 21-6-16 Date : 21-6-16

You might also like

- JAPL-F-HE-006-Paywelder ChecklistDocument1 pageJAPL-F-HE-006-Paywelder ChecklistAli HassanNo ratings yet

- New Mobile Crawler Crane ChecklistDocument2 pagesNew Mobile Crawler Crane ChecklistsunilNo ratings yet

- 6 Performance ChecksDocument17 pages6 Performance ChecksVitthal DeokateNo ratings yet

- Annex-1: Test Procedures For Different Types of 'Igred'Document3 pagesAnnex-1: Test Procedures For Different Types of 'Igred'Fundary ShopNo ratings yet

- EHS VI 08 FaranaDocument2 pagesEHS VI 08 Faranashamshad ahamedNo ratings yet

- Draft Maintenance Check List For 220Mm Point Machine (Clamp Type) Installed at Thick Web Switch LayoutDocument5 pagesDraft Maintenance Check List For 220Mm Point Machine (Clamp Type) Installed at Thick Web Switch Layoutexam proNo ratings yet

- 6924 Ext 13 0Document38 pages6924 Ext 13 0thuanNo ratings yet

- Weekly and Monthaly Check ListDocument76 pagesWeekly and Monthaly Check Listmuhammad.younisNo ratings yet

- U1 Coh em Gen Bar ChartDocument1 pageU1 Coh em Gen Bar ChartSHITESH KUMARNo ratings yet

- K019 - OHSE Builder Hoist ChecklistDocument1 pageK019 - OHSE Builder Hoist ChecklistRajib MondalNo ratings yet

- Precommissioning Activities Reinstatement ChecklistDocument1 pagePrecommissioning Activities Reinstatement ChecklistYusufNo ratings yet

- Eon Series: Installation, Operation & Maintenance ManualDocument38 pagesEon Series: Installation, Operation & Maintenance ManualA SuhardimanNo ratings yet

- Elecon Eon Installation Maintenance ManualDocument38 pagesElecon Eon Installation Maintenance Manualbudibuzen23No ratings yet

- EHS-VI-10-Tower CraneDocument1 pageEHS-VI-10-Tower Craneshamshad ahamedNo ratings yet

- 7.wheel Loader Daily Checklist - OkDocument7 pages7.wheel Loader Daily Checklist - Okmuhammad.younisNo ratings yet

- EON New ManualDocument38 pagesEON New ManualS S ThakurNo ratings yet

- Site PM View Report Del-1Document14 pagesSite PM View Report Del-1Anonymous QRWtQtNH37No ratings yet

- Pre-Mob Inspection Checklists 2 January 2016Document378 pagesPre-Mob Inspection Checklists 2 January 2016slamet4riadiNo ratings yet

- Dozer Checklist: Y N Y NDocument1 pageDozer Checklist: Y N Y NEkaWulandariNo ratings yet

- Ga2 28:6:23Document1 pageGa2 28:6:23john HuntNo ratings yet

- Crawler CraneDocument2 pagesCrawler CraneFarukBasyoriNo ratings yet

- E-380kVA KOEL DG Set drg.-R1 15.09.2022Document2 pagesE-380kVA KOEL DG Set drg.-R1 15.09.2022Electrical RadicalNo ratings yet

- Telehandler ChecklistDocument1 pageTelehandler ChecklistSteinol SolutionsNo ratings yet

- Bongaigaon Unit-1 Reapir ScheduleDocument1 pageBongaigaon Unit-1 Reapir SchedulePremkishanNo ratings yet

- Ga2 27:6:23Document1 pageGa2 27:6:23john HuntNo ratings yet

- DGW201M: Owner'S and Operator'S ManualDocument32 pagesDGW201M: Owner'S and Operator'S ManualthuanNo ratings yet

- Final Hira SkemDocument565 pagesFinal Hira Skemsoumya ranjan beheraNo ratings yet

- (UG10) Builder Hoist PDFDocument2 pages(UG10) Builder Hoist PDFavinashNo ratings yet

- Tractor 1989 520-H 520-HC OM #810514R1Document32 pagesTractor 1989 520-H 520-HC OM #810514R1attilabajusNo ratings yet

- Joint Inspection Report MechanicalDocument8 pagesJoint Inspection Report MechanicalRohan SharmaNo ratings yet

- Technician Name Done Date & Sites Id Done Date & Sites IdDocument26 pagesTechnician Name Done Date & Sites Id Done Date & Sites IdkoshurNo ratings yet

- 9° GP190 VX (B909) 9 Ton. REPARO DO EIXO MOTOR E DO CONJUNTO DIFERENCIALDocument114 pages9° GP190 VX (B909) 9 Ton. REPARO DO EIXO MOTOR E DO CONJUNTO DIFERENCIALRobinson AmaralNo ratings yet

- Toaz - Info Cat Compact Start Up and Commissioning Checklist PRDocument19 pagesToaz - Info Cat Compact Start Up and Commissioning Checklist PRKhaled Naseem Abu-SabhaNo ratings yet

- 007 Mobile Crane ChecklistDocument2 pages007 Mobile Crane Checklistchandral86No ratings yet

- Preheater Elevator Work Report 3 Check List 45NS0702Document4 pagesPreheater Elevator Work Report 3 Check List 45NS0702eliasNo ratings yet

- BLNG TPI ChecklistDocument2 pagesBLNG TPI ChecklistSajith VenkitachalamNo ratings yet

- Boom Lift - Man Lift Inspection ChecklistsDocument3 pagesBoom Lift - Man Lift Inspection ChecklistsAgung Tri SugihartoNo ratings yet

- 3092834-Varco Bulletin On TDSDocument9 pages3092834-Varco Bulletin On TDSSushil GuptaNo ratings yet

- 279000ProfSeriesSingle 1Document77 pages279000ProfSeriesSingle 1Rocky ZNo ratings yet

- Hda Operational ManualDocument48 pagesHda Operational ManualDouglas DuarteNo ratings yet

- Launcher WInch Machine Digital-1-5Document2 pagesLauncher WInch Machine Digital-1-5Girish PhalkeNo ratings yet

- SB 10091506 2280Document28 pagesSB 10091506 2280sesentorodriguezNo ratings yet

- Owner'S and Operator'S Manual: DGW400DM-380ADocument38 pagesOwner'S and Operator'S Manual: DGW400DM-380AAlejandro Hernández RojasNo ratings yet

- Work Instructions For Generator Alignment at Site Rev 02-S88Document14 pagesWork Instructions For Generator Alignment at Site Rev 02-S88gregoriojunior100% (1)

- 038 Pozicioner RTX 1200 EngDocument16 pages038 Pozicioner RTX 1200 EngICE MEDIA CONCEPTNo ratings yet

- Telehandler ChecklistDocument1 pageTelehandler Checklistjapv_pasNo ratings yet

- Inctruktsiya Po Ekspluatatsii John Deere 572 582 592Document356 pagesInctruktsiya Po Ekspluatatsii John Deere 572 582 592Cristian VerdeNo ratings yet

- Pre Mob Flatbed Truck Daily Inspection Checklist FormDocument3 pagesPre Mob Flatbed Truck Daily Inspection Checklist Formagusbudianto.dk168No ratings yet

- Transmision Automatica Altima Bolletin.Document19 pagesTransmision Automatica Altima Bolletin.Brian MorenoNo ratings yet

- Bench DrillingDocument1 pageBench DrillingPiyush VyasNo ratings yet

- Rota Disc OPERATORS MANUALDocument53 pagesRota Disc OPERATORS MANUALCoco BangoNo ratings yet

- Manual de Operacio Dgw201Document34 pagesManual de Operacio Dgw201Amando FuentesNo ratings yet

- RFKS Gear Motor Operation ManualDocument24 pagesRFKS Gear Motor Operation ManualMajid KhanNo ratings yet

- Operator & Service ManualDocument29 pagesOperator & Service ManualCESARALARCON1No ratings yet

- Swing CheckDocument2 pagesSwing Checkfcof123237483% (6)

- John Deere 3800 Telescopic Handler ManualDocument196 pagesJohn Deere 3800 Telescopic Handler Manuallorant0511No ratings yet

- E021-Checklist LT PanelDocument1 pageE021-Checklist LT Panelaudiihussain67% (3)

- Drilling Fluids Processing HandbookFrom EverandDrilling Fluids Processing HandbookRating: 4.5 out of 5 stars4.5/5 (4)

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideFrom EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideRating: 4.5 out of 5 stars4.5/5 (8)

- How to Rebuild & Modify Ford C4 & C6 Automatic TransmissionsFrom EverandHow to Rebuild & Modify Ford C4 & C6 Automatic TransmissionsRating: 5 out of 5 stars5/5 (5)

- General Specifications: To Be Used in Pricing The Bills of QuantitesDocument73 pagesGeneral Specifications: To Be Used in Pricing The Bills of QuantitesKevin Chikwado IlohNo ratings yet

- Arena ZagrebDocument22 pagesArena Zagrebkarl errolNo ratings yet

- Uttern D62 - 2016 Parts CatalogueDocument64 pagesUttern D62 - 2016 Parts CatalogueSimenNo ratings yet

- Building and Environment: Nima Izadyar, Wendy Miller, Behzad Rismanchi, Veronica Garcia-HansenDocument18 pagesBuilding and Environment: Nima Izadyar, Wendy Miller, Behzad Rismanchi, Veronica Garcia-Hansenmercyella prasetyaNo ratings yet

- 015 ASP CatalogueDocument24 pages015 ASP CatalogueJavan Omiti100% (1)

- ASTM-A572-A572M-21 (1)Document3 pagesASTM-A572-A572M-21 (1)13393m210No ratings yet

- A Template For EPC Project Management and Execution: Richard P Helper, PSP William MihelichDocument53 pagesA Template For EPC Project Management and Execution: Richard P Helper, PSP William MihelichEr Mangesh Mohite100% (1)

- Scada Pro - 3 - Example - Steel - EN PDFDocument79 pagesScada Pro - 3 - Example - Steel - EN PDFrelu59No ratings yet

- Education Quality Reform in Afghanistan (EQRA) Programs' TA Requirements 2018-2021Document2 pagesEducation Quality Reform in Afghanistan (EQRA) Programs' TA Requirements 2018-2021wafiullah sayedNo ratings yet

- Pyro Bloc ModulesDocument2 pagesPyro Bloc ModulesGurdeep Sungh AroraNo ratings yet

- Especificaciones Vinil Polyflor Mystique PP Oct 2013Document1 pageEspecificaciones Vinil Polyflor Mystique PP Oct 2013Henry ValenciaNo ratings yet

- PR EN 16907-1-2016 PDFDocument136 pagesPR EN 16907-1-2016 PDFVishwakarma VishwakarmaNo ratings yet

- Outline Design Specification For Phase IV (Revision 1) (July 2019) 29072019 PDFDocument141 pagesOutline Design Specification For Phase IV (Revision 1) (July 2019) 29072019 PDFMaitrabarun KarjeeNo ratings yet

- 1) Vitruvius: Wrote Treaties On Architecture Called de ArchitecturaDocument56 pages1) Vitruvius: Wrote Treaties On Architecture Called de ArchitecturaPooja MantriNo ratings yet

- Alibag House: by - Nari GandhiDocument10 pagesAlibag House: by - Nari GandhiHIMA Mini100% (2)

- BS 3533 PDFDocument22 pagesBS 3533 PDFKarunakaran Nallasingam100% (2)

- 210 Assignment 4: 19113089 Nikhil KumarDocument13 pages210 Assignment 4: 19113089 Nikhil KumarNIKHIL KUMARNo ratings yet

- Hydraulic Cylinder BoomDocument2 pagesHydraulic Cylinder BoomHamed SaeedyNo ratings yet

- Hydraulic Power SteeringDocument6 pagesHydraulic Power SteeringMohamad Nadzri YahayaNo ratings yet

- Calculation - Cutting Length of Circular Stirrups - Tutorials Tips Civil Engineer PDFDocument4 pagesCalculation - Cutting Length of Circular Stirrups - Tutorials Tips Civil Engineer PDFfelixNo ratings yet

- 车道 (二) 地下层平面图 1 Car ramp (1) B1FL PLAN: Date Description Rev NoDocument3 pages车道 (二) 地下层平面图 1 Car ramp (1) B1FL PLAN: Date Description Rev NoKarma NorbuNo ratings yet

- Appendix A - Invitation To Tender - Epoxy Flooring Subcontract WorksDocument22 pagesAppendix A - Invitation To Tender - Epoxy Flooring Subcontract WorksJay GalvanNo ratings yet

- 4600 BrochureDocument4 pages4600 Brochuresergix zNo ratings yet

- Suraj Polymers NandedDocument45 pagesSuraj Polymers NandedabhishekbagleNo ratings yet

- Settlement Reducing Piles in Piled Basements and ShaftsDocument3 pagesSettlement Reducing Piles in Piled Basements and Shaftsvenkateswara rao pothinaNo ratings yet

- Godrej Golf Links Ready ReckonerDocument1 pageGodrej Golf Links Ready ReckonerATS GREENSNo ratings yet

- Bending Moment Lab (CES511)Document8 pagesBending Moment Lab (CES511)Alif AkhmizanNo ratings yet

- EQ SERIES IOM (English)Document15 pagesEQ SERIES IOM (English)Ramses Escauriza Sotillo50% (2)

- Drilling Junk Sub: Operation & Maintenance ManualDocument8 pagesDrilling Junk Sub: Operation & Maintenance ManualShag ShaggyNo ratings yet

- Construction Company Website ContentDocument10 pagesConstruction Company Website ContentMohamed AbdelfatahNo ratings yet