Professional Documents

Culture Documents

Bid Bulletin No. 02: Philippine Economic Zone Authority Baguio City Economic Zone

Uploaded by

Xicor Jean0 ratings0% found this document useful (0 votes)

3 views4 pagesOriginal Title

Untitled

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

3 views4 pagesBid Bulletin No. 02: Philippine Economic Zone Authority Baguio City Economic Zone

Uploaded by

Xicor JeanCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 4

Philippine Economic Zone Authority

Baguio City Economic Zone

BID BULLETIN NO. 02

AUGUST 07, 2017

AMENDMENTS IN THE BIDDING DOCUMENTS

“INSTALLATION OF SEPARATE WATER SUPPLY LINE FOR BCEZ”

(BC-2017-06-052)

This Bulletin is issued to modify or amend the Bid Documents. This

shall form an integral part of the Bid Documents.

Please see below “ANNEX G”.

“ANNEX G”

Project name: Installation of Separate Water Supply Line for BCEZ

Location: Baguio City Economic Zone

Section IV. Special Conditions of Contract

GCC Clause

6.5 The Contractor shall employ the following Key Personnel :

- One Project Engineer who should be a Civil Engineer, One Materials

Engineer and One Safety Officer

*Required Engineers should have at least 3 years of responsible

character appropriate for the position.

*They shall be assigned to the project on full time basis.

- Flag men knowledgeable in directing orderly traffic flow

*Assigned full time on affected roads

51.1 The date by which “as-built” drawings is required is seven (7) days after project

completion

51.2 The amount to be withheld for failing to produce “as-built” drawings and/or

operating and maintenance manuals by the date required is P155,101.00

SECTION VI. Specification

Item

Item II Excavation

-Manual excavation is recommended on critical portions to avoid damages of PEZA

structures/facilities.

item III Partial removal of PCCP with asphalt overlay, sidewalks and gutter

- Includes hauling out of removed materials to disposal area by the

contractor. Safe disposal of materials and disposal area shall be the

responsibility of the contactor.

Item V Deep well tapping

-ball valve, check valve, union ( use brass)

Item VII PCCP restoration

- PCCP shall have a 3500 psi strength @ 7 days

- Flexure test is required on at least two (2) sets of beam samples

Item VIII Structural Concrete

- Structural concrete shall have a 3000psi compressive strength @ 28 days

- Compressive strength test is required on a set of cylinder samples

Item IX Curb and Gutter

- Structural concrete shall have a 3000psi compressive strength @ 28 days

Item XIII Main valves / water meter -( both Flange types)

- Gate Valves (non - rising PN16)

Technical specs:

Body and Bonnet :ductile Iron ,GGG50 to DIN 1693

Coating : electrostatically applied epoxy resin to DIN 30677

Internally and externally

Stem : Stainless Steel ,DIN x 20 Cr 13

Stem Sealing : NBR wiper ring ,2 NBR O-rings inside and 2 outside a plastic

Bearing, EPDM rubber machete.

Wedge: Ductile iron ,GGG50 ,core fully encapsulated with EPDM rubber with

Integral wedge nut of dezincification resistant brass.

Thrust Collar : Dezincification resistant brass

Bonnet bolts : stainless Steel A2,sealed with hot melt

Bonnet Gaskets :EPDM rubber

Hydraulic test : BS 5163(DIN 3230 /DIN 3352

Face to Face Dimension : BS 5163 (ISO 5752 S.3)

Flanges and drilling : ISO 7005-2 (EN 1092 – 2 :1997, DIN 2501

- Water Meter : PN 16

- Check Valve : PN 16

Note: all materials are Flange type connections

Item XV Painting

- For embedded pipes – apply 2 coats red oxide

- For exposed pipes :

- First and 2nd coats - red oxide

- Final coat – apply QDE blue

Note: Includes deep well tapping connections

Backfilling

Item XVIII - Affected areas shall be restored to original grass/vegetation state

- Use appropriate equipment to attain the desired degree of compaction.

Item XX Plastering –Class B

Item XXI Safety officer must have 40 hrs. Relevant training on COSH or relative job

requirement.

Note: Adopt applicable DPWH Standard Specifications unless indicated herein or stated in the

accompanying plans/drawings. Other tests may be required by the Procuring Entity.

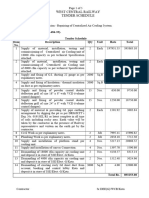

Section VIII. Bill of Quantities

Item IV Sch 40 GI pipe QTY unit

IV A. 8“ dia. 494 LM

IV B. 6 “ dia. 383 LM

IV C. 3“ dia. 127 LM

IV D. 2“ dia. 12.6 LM

IV E. 1/2“ dia. 14.50 LM

Item V Deep well Tapping QTY unit

V.A DW #22 1 lot

V.B DW #23 1 lot

V.C DW #24 1 lot

V.D DW #25 1 lot

V.E DW #26 1 lot

V.F DW #27 1 lot

V.G DW #28 1 lot

V.H DW #29 1 lot

Item XIII Main Valves / Water QTY UNIT

meter

XIII. A 8 “ dia. Gate valve 2 SET

XIII. B 8 “ dia. Check Valve 2 SET

XIII. C 8” dia. Water meter 1 SET

XIII. D 6 “ dia. Gate Valve 3 SET

XIII. E 4” Gate Valve 1 SET

XIII. F 3” dia. Gate Valve 1 SET

XIV.G 3” dia. Water meter 1 SET

XIV. H 3” dia. check valve 1 SET

SGD.

ATTY. RENE U. BAYSA

Bids and Awards Committee

Chairman

You might also like

- Design Calculation For Pipe SupportsDocument200 pagesDesign Calculation For Pipe Supportssanggytha100% (1)

- API 620 CalculationDocument114 pagesAPI 620 Calculationvikram100% (4)

- Ot SluiceDocument3 pagesOt Sluicegurumurthy38No ratings yet

- Std. Civil Estimate r2 09.04.2013Document376 pagesStd. Civil Estimate r2 09.04.2013Amarjit KulkarniNo ratings yet

- CAT Contamination ControlDocument34 pagesCAT Contamination ControlРинат Сагидов100% (1)

- Determination of Boiling Point of Organic CompoundsDocument28 pagesDetermination of Boiling Point of Organic CompoundsDotsha Raheem83% (6)

- Method Statement For Installation of Hume PipeDocument22 pagesMethod Statement For Installation of Hume PipeĐặng Quang Huy88% (8)

- Final Design Report PDFDocument63 pagesFinal Design Report PDFCHANDAN VATSNo ratings yet

- DCS-026 DTD 08.08.10 Method Statement For Water Tank Walls Casting With BlockoutsDocument12 pagesDCS-026 DTD 08.08.10 Method Statement For Water Tank Walls Casting With Blockoutsmirza057No ratings yet

- Tamil Nadu Factories Rules 1950 With FORMSDocument294 pagesTamil Nadu Factories Rules 1950 With FORMSSathish Kumar88% (8)

- Technical Bid EvaluationDocument3 pagesTechnical Bid EvaluationAdvisNo ratings yet

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerFrom EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerRating: 5 out of 5 stars5/5 (1)

- Material Specifications-ErikaDocument5 pagesMaterial Specifications-ErikaKURO100% (1)

- مواصفات الميكانيكاDocument19 pagesمواصفات الميكانيكاoth369No ratings yet

- 3 66 KV CT PT R6 Metering Dec 12Document34 pages3 66 KV CT PT R6 Metering Dec 12dkshtdkNo ratings yet

- Lubricant ChartDocument1 pageLubricant ChartBasavaraj MorabNo ratings yet

- NZS 1664-1-1997 Aluminium Structures Limit State DesignDocument8 pagesNZS 1664-1-1997 Aluminium Structures Limit State Designwey53160% (1)

- J322-ST-RP-010 - Inplace Analysis For Building B-02 - Rev 4 PDFDocument57 pagesJ322-ST-RP-010 - Inplace Analysis For Building B-02 - Rev 4 PDFgk80823No ratings yet

- 26071-100-V1A-MCAG-00315 - Isometric Drawing With BOM For Common Facilities SS-3 341-SS-114 - 002Document33 pages26071-100-V1A-MCAG-00315 - Isometric Drawing With BOM For Common Facilities SS-3 341-SS-114 - 002ogyriskyNo ratings yet

- Steel BridgesDocument44 pagesSteel BridgesSheffy Abraham100% (3)

- BS 750-1984 - Specification For Underground Fire Hydrants & Surface Box Frames & Covers PDFDocument28 pagesBS 750-1984 - Specification For Underground Fire Hydrants & Surface Box Frames & Covers PDFambition1340cn100% (2)

- Piling: Amount (QR) Item Description Quantity Unit Rate (QR)Document1 pagePiling: Amount (QR) Item Description Quantity Unit Rate (QR)Ahmed Raza100% (2)

- Flexible Hose DatasheetDocument7 pagesFlexible Hose DatasheetchintanNo ratings yet

- S-00-1360-001 Rev.0 - FC (General Specification For Piping)Document11 pagesS-00-1360-001 Rev.0 - FC (General Specification For Piping)ajmainNo ratings yet

- D-01 NocDocument29 pagesD-01 NocRochdi Sahli100% (1)

- Air Heater Powermag 101 - CoalDocument36 pagesAir Heater Powermag 101 - CoalmasgrahaNo ratings yet

- Corigendum Canal Front 12.12.11Document4 pagesCorigendum Canal Front 12.12.11Zankar R ParikhNo ratings yet

- Nitrogen Room 06-10-2022Document3 pagesNitrogen Room 06-10-2022Muhammad ShehzadNo ratings yet

- مواصفات التكييفDocument54 pagesمواصفات التكييفoth369No ratings yet

- Fdot Design Standards: 18100 1 CCTV Pole PlacementDocument26 pagesFdot Design Standards: 18100 1 CCTV Pole PlacementAlejandro MusepuNo ratings yet

- bIOLOGY TutorialDocument3 pagesbIOLOGY TutorialPd ProxyNo ratings yet

- Water BOQDocument171 pagesWater BOQLeonard TonuiNo ratings yet

- DO 028 s2018Document8 pagesDO 028 s2018Anthony TangNo ratings yet

- For Approval: Bac Mien Trung Consultancy Investment Construction and Trading Joint Stock CompanyDocument11 pagesFor Approval: Bac Mien Trung Consultancy Investment Construction and Trading Joint Stock CompanyBui Van DiepNo ratings yet

- QC911000-SLC-TEC-MTS-MEC-11A-Z00-00013 - uPVC Storm Water Drainage PipesDocument74 pagesQC911000-SLC-TEC-MTS-MEC-11A-Z00-00013 - uPVC Storm Water Drainage PipesriyasudheenmhNo ratings yet

- Sanitary Plumbing Specs - Bldg. Type 2Document6 pagesSanitary Plumbing Specs - Bldg. Type 2ton carolinoNo ratings yet

- 1000CUM Main Fuel Storage Tanks SepchDocument3 pages1000CUM Main Fuel Storage Tanks SepchBTENo ratings yet

- Section-220500 Common Work Results For Plumbing Rev 1Document17 pagesSection-220500 Common Work Results For Plumbing Rev 1刘盘石No ratings yet

- A-207a Main Structural CompletionDocument1 pageA-207a Main Structural Completionanto.subhakarNo ratings yet

- 7 SCH D Section III Technical Specification of WorkDocument8 pages7 SCH D Section III Technical Specification of Workabhishek agrawalNo ratings yet

- Appendix 3-Document FormDocument6 pagesAppendix 3-Document FormBrewer HouseNo ratings yet

- UG V 1 Direct Buried ConduitDocument4 pagesUG V 1 Direct Buried ConduitStan LeyNo ratings yet

- United Nations Development Programme-South SudanDocument34 pagesUnited Nations Development Programme-South SudanAmit SinghNo ratings yet

- Bolted Tank Specifications Final 11-5-15Document6 pagesBolted Tank Specifications Final 11-5-15Rodrigo ZapataNo ratings yet

- 23 21 14 Hydronic SpecialtiesDocument7 pages23 21 14 Hydronic SpecialtiesSoumojit SamantaNo ratings yet

- GJ-206-005 Structural Installation of VFD Panel in The PCR RoomDocument4 pagesGJ-206-005 Structural Installation of VFD Panel in The PCR RoomKuna StanbekovNo ratings yet

- 12.L-LT PVC Power CableDocument3 pages12.L-LT PVC Power CableAnkur SinhaNo ratings yet

- 19.2.9 Control Valves: Floresta Garden Infrastucture Project - The Pearl DohaDocument1 page19.2.9 Control Valves: Floresta Garden Infrastucture Project - The Pearl DohakaamNo ratings yet

- Domestic Water PipingDocument13 pagesDomestic Water PipingEN LeedNo ratings yet

- Bill 2.0 StructureDocument23 pagesBill 2.0 StructureTinny GeaNo ratings yet

- Equipment Load Sheet Benzene Meter Skid Package: Certified FinalDocument2 pagesEquipment Load Sheet Benzene Meter Skid Package: Certified FinalAdnanNo ratings yet

- SoW - 2021 SHIFT TIP - Rev 2Document16 pagesSoW - 2021 SHIFT TIP - Rev 2Ryan LabanaNo ratings yet

- Westbay Mechanial SpecsDocument174 pagesWestbay Mechanial SpecsHARISH ROHANNo ratings yet

- JPKT 00 P 1 012 Rev 0 Specification For Field Joint CoatingDocument11 pagesJPKT 00 P 1 012 Rev 0 Specification For Field Joint Coatingrohitbhat2345No ratings yet

- HKKJR LJDKJ Jsy Ea Ky : Technical Specification For Under Water Cutting EquipmentDocument10 pagesHKKJR LJDKJ Jsy Ea Ky : Technical Specification For Under Water Cutting EquipmentelshadNo ratings yet

- Section 02717 - Concrete Sewer Rehabilitation by Machine-Wound PVC PipeDocument6 pagesSection 02717 - Concrete Sewer Rehabilitation by Machine-Wound PVC Pipefahren_de2015No ratings yet

- PT - ACP CBD Mech & Piping WP3 ( GPP-Sparator Area - Scruber Area) 22082019 - RMBDocument95 pagesPT - ACP CBD Mech & Piping WP3 ( GPP-Sparator Area - Scruber Area) 22082019 - RMBnazir ahmadNo ratings yet

- TTender Schedule EL-50-67-2020-21Document5 pagesTTender Schedule EL-50-67-2020-21kaygupta301102No ratings yet

- Dis Supply .Document36 pagesDis Supply .Miko AbiNo ratings yet

- Plan 1124 A 13205 Welded Steel TDocument7 pagesPlan 1124 A 13205 Welded Steel TneoNo ratings yet

- Technical - Spec - For - Safety - Relief - Valve 8Document1 pageTechnical - Spec - For - Safety - Relief - Valve 8Anonymous vwbLPTpjNo ratings yet

- Method Statement For Installation of Hume PipeDocument26 pagesMethod Statement For Installation of Hume PipemanishsinghqcmccNo ratings yet

- Appendix 1 - Bills of Quantities2Document1 pageAppendix 1 - Bills of Quantities2aini.ambreNo ratings yet

- Petrochemicals GujaratDocument55 pagesPetrochemicals GujaratsandipbpatelNo ratings yet

- Singh Lab Report 1Document4 pagesSingh Lab Report 1Yuki ZiqiNo ratings yet

- Bantex Catalogue 2023 2024 Dikompresi DikompresiDocument224 pagesBantex Catalogue 2023 2024 Dikompresi DikompresiPanggi Eko PrasetiyoNo ratings yet

- Tablet Manufacturing ProcessDocument8 pagesTablet Manufacturing ProcessNaveen KingNo ratings yet

- Allyl 1Document19 pagesAllyl 1barbara_ropeNo ratings yet

- CCCRCxToolkit-Sequence Operation Template 2007Document6 pagesCCCRCxToolkit-Sequence Operation Template 2007Humpy DumpyNo ratings yet

- Corrosion PreventionDocument21 pagesCorrosion PreventionIshan RatnakarNo ratings yet

- 3M Prestige 70 Exterior PBDocument3 pages3M Prestige 70 Exterior PBDiego Ramirez FuentesNo ratings yet

- MY Fire DampersDocument12 pagesMY Fire Dampersjames_chan2178No ratings yet

- Pololu - A4988 Stepper Motor Driver CarrierDocument7 pagesPololu - A4988 Stepper Motor Driver CarrierJuan Alberto Casares ZaragozaNo ratings yet

- PDF PDFDocument25 pagesPDF PDFelbronNo ratings yet

- Section 1, Seat No.4: Product Box CompanyDocument106 pagesSection 1, Seat No.4: Product Box CompanyKoy'z Vilailuk RadchakidNo ratings yet

- Ipc-Tm-650 2.4.24.1Document2 pagesIpc-Tm-650 2.4.24.1RaduNo ratings yet

- Omron NEC28 Instruction ManualDocument23 pagesOmron NEC28 Instruction Manualumi latifahNo ratings yet

- ANPC - Unit 1-PPT-1 PDFDocument36 pagesANPC - Unit 1-PPT-1 PDFAkash YadavNo ratings yet

- Nagoya Institute of TechnologyDocument13 pagesNagoya Institute of TechnologyOnline EarningNo ratings yet

- TroubleshootingDocument2 pagesTroubleshootingVan Khanh HuynhNo ratings yet

- BHEL - PresentationDocument32 pagesBHEL - Presentationsenthil031277No ratings yet

- Rahul Patil Electric Works 123Document12 pagesRahul Patil Electric Works 123Rahul ChitragarNo ratings yet

- Vascomill MMS FA 2 EsiteDocument1 pageVascomill MMS FA 2 EsiteDaniel ReyesNo ratings yet

- Tubular Construction Solutions For Structural ApplicationsDocument18 pagesTubular Construction Solutions For Structural Applicationsaan alfianNo ratings yet

- Brochure SC4 7Document4 pagesBrochure SC4 7vegamarco80No ratings yet

- 12843.pdf Rev 1Document5 pages12843.pdf Rev 1Saravanan KcNo ratings yet