Professional Documents

Culture Documents

Method Statement - Installation of Cable Tray & Laying of DC, AC Cables

Uploaded by

Ibrahim EsmatOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Method Statement - Installation of Cable Tray & Laying of DC, AC Cables

Uploaded by

Ibrahim EsmatCopyright:

Available Formats

Project Name: Al Dahra 1.

2MW PV Project

METHOD STATEMENT

INSTALLATION OF CABLE TRAY

&

LAYING OF DC/AC CABLES

METHOD STATEMENT FOR INSTALLTION OF CABLE TRAY&LAYING Page1

OF DC/AC CABLES

Project Name: Al Dahra 1.2MW PV Project

Contents:

1. Purpose

2. Scope

3. Definitions

4. References

5. Proposed Materials

6. Equipment’s Required

7. Manpower Required

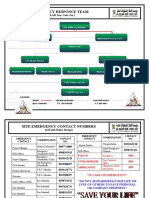

8. Responsibility & Supervision

9. Safety Precautions

10. Methodology

11. Attachments

• Risk Assessment

• Drawings

METHOD STATEMENT FOR INSTALLTION OF CABLE TRAY&LAYING Page2

OF DC/AC CABLES

Project Name: Al Dahra 1.2MW PV Project

1. Purpose:

The purpose of this Method Statement is to provide guidelines for installation of cable tray and routing

of DC/AC cables on rooftop in accordance with the ADDC standards & specifications.

Scope:

This method statement explains the procedure for installation of cable tray and routing of DC/AC

cables on rooftop in AL Dahra food Industries.

Definitions:

Client - AL DAHRA FOOD INDUSTRIES

PV Contractor - Complete Energy solutions /Golden Falcon Technical services

RA - Risk Assessments

PM - Project Manager

PE - Project Engineer

HSE - Health, Safety & Environment

QA/QC - Quality Assurance / Quality Control Engineer

References: -

ADDC Standard specifications

Contract Stamp Drawing

Approved Shop drawings

Contract B.O.Q

Particular specifications

5. Proposed Materials:

Warning Tape

Measuring Tape

Setout Markers

Safety Gloves

METHOD STATEMENT FOR INSTALLTION OF CABLE TRAY&LAYING Page3

OF DC/AC CABLES

Project Name: Al Dahra 1.2MW PV Project

Tool/ Equipment’s Required:

Tool Box

Battery Drill

Allen Key

Measuring Tape

Setting out markers

Sprit Level

Manpower Required:

Supervisory

➢ Electrical supervisor

➢ Foreman

➢ HSE Advisor

➢ QA & QC Engineer

➢ Electrical Technician

Direct

➢ Labor

➢ Chain Man

➢ Flag Man

Responsibility & Supervision:

QA/ QC Engineer: Ensures that all materials, testing and procedures are carried

out strictly in accordance with the Contract Specifications, Conditions of Contract

and project Quality Plan.

Project/Site Engineer: Will work directly at site with the surveyor to ensure that all the

required information has been provided to proceed with the works, and that the works comply

with the

project specifications and method statements. He liaises with the consultant's staff with respect to

inspections and approvals, aided by the Foremen. He reports to the Project Manager.

METHOD STATEMENT FOR INSTALLTION OF CABLE TRAY&LAYING Page4

OF DC/AC CABLES

Project Name: Al Dahra 1.2MW PV Project

Construction Manager: Electrical: Directly supervises the supervisors and Foremen/ Assistant

Foremen. He is responsible to ensure that all the correct procedures have been followed and that

any necessary permits, drawings, and method statements for the Works have been obtained in

advance. He is responsible for the control of all safety measures at the site. He liaises with

Client with respect to site inspections, defining technical solutions and the control of safety

measures. He reports directly to the Project Manager. He is a member of the Safety Committee

HSE Officer: He visits the activities on site and checks if the works are carried out as per laws,

Health, Safety and Environmental Plan and method statements. He advises all members of the

hierarchic line on any shortcomings or additional measures to be taken and reports to the

Project Manager. He has the power to stop the works immediately if required.

Foreman/Asst. Foreman: Directly supervises the work activity on the site and has full control

over the use of the labor, plant and equipment. He ensures that the work is carried out in full

compliance with the specifications, and in a manner that is conform to the Safety, Quality and

Environmental requirements. He reports to the Coordinator/Supervisor when the work is

completed.

Safety Precautions:

A regular inspection carried out daily by HSE advisor to the site.

All the safety measure should be taken during the work following the (HSE plan,

Method Statement & Risk assessment).

All the time, all workers to be wearing appropriate PPE within working area and adjacent to

road area.

All tools and equipment to be in good working condition.

Regardless of severity, any injuries should be reported to supervision concerned immediately

& recorded in the first aid/incident record book.

A tool box talks to be done prior to commencement of the activity.

METHOD STATEMENT FOR INSTALLTION OF CABLE TRAY&LAYING Page5

OF DC/AC CABLES

Project Name: Al Dahra 1.2MW PV Project

Workers shall be briefed on environmental hazards associated with materials to be used for

the works to prevent physical hazards.

Ample shade shall be provided as rest areas for workers against extreme exposure to

weather conditions.

Ensure availability of adequate drinking water on site at all times.

Ensure all workers aware of the hazards/ Risks associated with the Task.

Appropriate signage shall be placed at site as per the approved shop drawing.

Area will be strictly controlled and entry restricted for unauthorized persons. Hoardings

showing the area restricted will be provided at site.

Work should be carried under strict competent supervision.

Abu Dhabi code of safety practices will be followed up for our activities.

ADDC system safety rule must be followed.

9.1 Task specific PPE

Hard Hat/safety Helmet

Safety shoes

High Visibility vests

Safety gloves

Safety goggles

Full body safety harness

Methodology:

Prior Activities to be Completed:

Approved PTW must be obtained prior to commence the work

All relevant authorities NOC must be attained prior to start of any major activity.

Continuous temporary fencing will be provided in areas accessible to public use.

Continuous temporary barricading will be provided to enclose the site and necessary warning

signs shall be set up.

Approval of Shop drawings and method statement in accordance with Contract Specification,

Contract Drawings and Scope of Work shall be obtained prior to the start of work at site.

Inspection for all tools used for the activity shall be done prior to start the work on site.

Safety precautions to be in place prior to the commencement of the site works.

METHOD STATEMENT FOR INSTALLTION OF CABLE TRAY&LAYING Page6

OF DC/AC CABLES

Project Name: Al Dahra 1.2MW PV Project

Working at Height (OSHAD CoP 23 V3.0 July 2016)

All work at height is appropriately planned, assessed, organized and appropriately

Supervised

All work at height takes account of weather conditions that could endanger health

All PPE requirements shall be in accordance with OSHAD-SF – CoP 2.0 – Personal

Protective Equipment and safety

All work on roofs are as per regulation 3.16

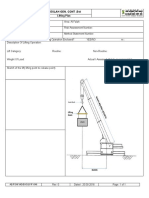

Cable Tray Installation and Laying of DC/AC cables

To make sure that the entire installation is in conformance and in accordance with the design intent

of the project for the Electrical and Low Voltage System in addition to the specification and as per

approved shop drawings and comply with Local and International Standards.

Adhere to the drawings as closely as possible. The right is reserved to vary the runs and sizes of

Cable Trays / and to make offsets but maintain as far as possible the free area of each duct work

section, where necessary to accommodate conditions arising at the warehouse

Before beginning installation in any area, examine all parts of the adjoining work onto which

applicable work is to be placed. Should any condition be found which will prevent the proper

execution of the work, installation shall not proceed in that area until such conditions are corrected

by the contractor.

Cable Tray shall be stored on site under cover in dry, well ventilated storage facilities.

Where sizes of Cable Trays are not detailed on drawing then tray shall be adequately sized to

support the cables without bunching and a 25% reserve margin shall be allowed in size and weight

be loaded.

All routes are chosen to allow ease of access to all cables when installed. All horizontal cables are

to be set around all vertical rising services as necessary. Ensure sufficient clearance from soffit for

every installation.

Earth continuity conductors shall be provided across gaps in all Cable Tray runs and bolted

connections.

Support shall be by means of steel brackets installed at intervals necessary to provide a rigid fixing

and to ensure that deflection does not exceed 5mm mid span of support when fully loaded.

Treatment of cut edges as per cut edges to be included. Supports for Tray (spacing) shall be as per

standard practice and manufacturer's recommendations.

METHOD STATEMENT FOR INSTALLTION OF CABLE TRAY&LAYING Page7

OF DC/AC CABLES

Project Name: Al Dahra 1.2MW PV Project

Additional support shall be provided where the Cable Tray changes direction or cables drop out of

the cable tray. Dome headed bolts, nuts and washers of finish suitable to the tray shall be used

between trays.

Any cut ends supports, rods, etc, must be corrosion protected by use of galvanized or equal. No

extended rods to be left.

The cable tray shall be installed with a 40mm minimum space between the structure and the tray.

All cable shall be securely fixed to the tray, work and the complete installation must be carried out

in a neat manner without crossovers.

Cables on face-up horizontally fixed tray must be secured by use of the tie wraps where not in view.

If cables are bunched or single cables greater than 25sq mm are installed, cleats or metal straps shall

be used.

Attachments:

Risk Assessment

METHOD STATEMENT FOR INSTALLTION OF CABLE TRAY&LAYING Page8

OF DC/AC CABLES

You might also like

- Method Statement For Installation of Cable Tray or TrunkingDocument13 pagesMethod Statement For Installation of Cable Tray or TrunkingNaing Win TunNo ratings yet

- Cable Testing MSRADocument20 pagesCable Testing MSRASalman Pattikkad0% (1)

- Mos 7006&7030Document8 pagesMos 7006&7030mutasim.jadallaNo ratings yet

- Method Statement & Risk Assessment Installation of Water Supply WorksDocument15 pagesMethod Statement & Risk Assessment Installation of Water Supply WorksAbu Muhammed KhwajaNo ratings yet

- Method Statement For Installation of Earthing System: South Plage at The Pearl Qatar InfrastructureDocument23 pagesMethod Statement For Installation of Earthing System: South Plage at The Pearl Qatar InfrastructureMariam Awad100% (2)

- Method Statement For Structured Cabling System InstallationDocument9 pagesMethod Statement For Structured Cabling System InstallationAnandu Ashokan50% (2)

- Electrical Feeder System Method StatementDocument7 pagesElectrical Feeder System Method StatementAngelo Castro100% (1)

- Method Statement For Wiring Accessories InstallationDocument9 pagesMethod Statement For Wiring Accessories InstallationAnandu AshokanNo ratings yet

- METHOD STATEMENT FOR Cable Tray InstallationDocument16 pagesMETHOD STATEMENT FOR Cable Tray InstallationsindalisindiNo ratings yet

- Method Statement For Fire Alarm and Emergency System InstallationDocument9 pagesMethod Statement For Fire Alarm and Emergency System InstallationAnandu Ashokan100% (1)

- Method Statement & Risk Assessment For Installation of Drainage WorksDocument16 pagesMethod Statement & Risk Assessment For Installation of Drainage WorksAbu Muhammed KhwajaNo ratings yet

- Method Statement For MV Power Cables & Accessories InstallationDocument9 pagesMethod Statement For MV Power Cables & Accessories InstallationAdil HasanovNo ratings yet

- Method Statemnet For 11kV Cable SATDocument47 pagesMethod Statemnet For 11kV Cable SATZaheer Ahamed92% (12)

- Method Statement For LV Cables, Wiring For Lighting and Power InstallationDocument11 pagesMethod Statement For LV Cables, Wiring For Lighting and Power InstallationAnandu Ashokan50% (2)

- Method - Statement - For Water Proofing RCC WorkDocument10 pagesMethod - Statement - For Water Proofing RCC Workirfan khanNo ratings yet

- Method Statement & Risk Assessment Installation of Structured Cabling SystemDocument16 pagesMethod Statement & Risk Assessment Installation of Structured Cabling SystemAbu Muhammed KhwajaNo ratings yet

- Method Statement-Intake Leak TestDocument5 pagesMethod Statement-Intake Leak Testharun yucelNo ratings yet

- Yas Acres Lighting System T&C Method StatementDocument17 pagesYas Acres Lighting System T&C Method StatementARUNNo ratings yet

- MS of Hoarding WorkDocument5 pagesMS of Hoarding WorkLOURLINE TANGZONo ratings yet

- 3.2 Method - Statement - For - Construction - of - Civil - WorksDocument23 pages3.2 Method - Statement - For - Construction - of - Civil - WorksJoseph EgonaNo ratings yet

- UntitledDocument18 pagesUntitledPramod SinghNo ratings yet

- Method Statement For Installation of Telephone PABXDocument2 pagesMethod Statement For Installation of Telephone PABXmujtiobamaliblNo ratings yet

- Method Statement For Sewer System MakkahDocument36 pagesMethod Statement For Sewer System MakkahToufeeq.HSE AbrarNo ratings yet

- Method Statement For Installation of PA SystemDocument2 pagesMethod Statement For Installation of PA SystemmujtiobamaliblNo ratings yet

- ملف ممتاز عن الرشاشاتDocument13 pagesملف ممتاز عن الرشاشاتakram husseinNo ratings yet

- Method Statement For PEX Pipes and Fittings InstallationDocument9 pagesMethod Statement For PEX Pipes and Fittings InstallationAnandu AshokanNo ratings yet

- Electrical Method of Statement For Installation & Termination of Cables and Wires - Method Statement HQDocument6 pagesElectrical Method of Statement For Installation & Termination of Cables and Wires - Method Statement HQRahul Raj SinghNo ratings yet

- Method Statement For Cable Laying 03Document8 pagesMethod Statement For Cable Laying 03paulloh64No ratings yet

- Vesda System Method StatementDocument6 pagesVesda System Method Statementsanthilal100% (2)

- Table of Contents: Method Statement FOR Lightning Protection System InstallationDocument10 pagesTable of Contents: Method Statement FOR Lightning Protection System Installationw fathyNo ratings yet

- 00 - MS - Wires and Cables InstallationDocument9 pages00 - MS - Wires and Cables InstallationEslam TahaNo ratings yet

- Method of Statement For MV&LV SwitchgearsDocument12 pagesMethod of Statement For MV&LV SwitchgearsUtku Can Kılıç100% (1)

- Method Statement For Cable Tray and Truncking InstallationDocument9 pagesMethod Statement For Cable Tray and Truncking InstallationAnandu AshokanNo ratings yet

- Method StatementDocument9 pagesMethod StatementRawofi Abdul mateenNo ratings yet

- 00 - MS - Telephone or Data System InstallationDocument9 pages00 - MS - Telephone or Data System Installationsudeep karunNo ratings yet

- Electrical Identification Installation Method StatementDocument9 pagesElectrical Identification Installation Method Statementwalid khamaesahNo ratings yet

- 01 Method Statment G I Conduit Access Rev 02Document5 pages01 Method Statment G I Conduit Access Rev 02mahroof mkuttyNo ratings yet

- Table OF: Method Statement FOR Wires AND Cables InstallationDocument235 pagesTable OF: Method Statement FOR Wires AND Cables InstallationMuhammad Jamil Khan100% (1)

- Rev - 04 - Ms - Earthing or Grounding of Panel Boards, Lighting and Power Wiring InstallationDocument6 pagesRev - 04 - Ms - Earthing or Grounding of Panel Boards, Lighting and Power Wiring Installationanon_534254691No ratings yet

- Method Statement For PVC Conduits InstallationDocument9 pagesMethod Statement For PVC Conduits InstallationAnandu AshokanNo ratings yet

- The Method Statement For Construction WorkDocument13 pagesThe Method Statement For Construction WorkAinAniza100% (1)

- Method Statement LV Distribution Boards Installation PDF FreeDocument9 pagesMethod Statement LV Distribution Boards Installation PDF Freetristan guarinoNo ratings yet

- Method Statement LV Distribution Boards InstallationDocument9 pagesMethod Statement LV Distribution Boards InstallationAnandu Ashokan100% (1)

- Standard Operating Procedure - Fibre Optic InstallationDocument17 pagesStandard Operating Procedure - Fibre Optic InstallationKaavi MaharajNo ratings yet

- 00 - MS - Devices Wires InstallationDocument8 pages00 - MS - Devices Wires Installationhossam_24_6_722542No ratings yet

- Method Statement For Installation of Ahu FahuDocument12 pagesMethod Statement For Installation of Ahu FahuRoger Akl75% (4)

- Msra-For Block WorksDocument13 pagesMsra-For Block WorksSyed AliNo ratings yet

- 00 - MS - MV Cable Pulling and InstallationDocument9 pages00 - MS - MV Cable Pulling and Installationanon_534254691100% (1)

- Mos Power OutletsDocument10 pagesMos Power OutletsASAN BASARI MOHAMED BUHARINo ratings yet

- BEW - Method Statement For Electrical Conduiting in Concealed WallDocument9 pagesBEW - Method Statement For Electrical Conduiting in Concealed WallArun UdayabhanuNo ratings yet

- Method Statement For GI Conduits InstallationDocument9 pagesMethod Statement For GI Conduits InstallationAnandu AshokanNo ratings yet

- Method Statement For Power Transformer BIAL STPDocument10 pagesMethod Statement For Power Transformer BIAL STPRUPESH KUMAR100% (2)

- Light Test Method for PepsiCo Multan DuctingDocument6 pagesLight Test Method for PepsiCo Multan DuctingRaheel AhmedNo ratings yet

- LBS 007 LRED RAMS MEP HVAC 03 (Method Statement For Ventilation Fan)Document10 pagesLBS 007 LRED RAMS MEP HVAC 03 (Method Statement For Ventilation Fan)faizan khanNo ratings yet

- Method - Statement - For Termite ProofingDocument8 pagesMethod - Statement - For Termite Proofingirfan khanNo ratings yet

- Method Statement For Demolation and Installation of Chain Link Fencing & Boundery Wall For Site Temporary Facilites ClientDocument8 pagesMethod Statement For Demolation and Installation of Chain Link Fencing & Boundery Wall For Site Temporary Facilites ClienteshwarNo ratings yet

- Installation of Plumbing Sanitary Fixtures: Standard Method StatementDocument12 pagesInstallation of Plumbing Sanitary Fixtures: Standard Method StatementPhuNguyenHoangNo ratings yet

- Automate Curva Well Drill PumpDocument3 pagesAutomate Curva Well Drill PumpJuancho PaduaNo ratings yet

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- The IEE Wiring Regulations Explained and IllustratedFrom EverandThe IEE Wiring Regulations Explained and IllustratedRating: 4 out of 5 stars4/5 (14)

- 47.internal Audit 18001 ChecklistDocument6 pages47.internal Audit 18001 ChecklistIbrahim EsmatNo ratings yet

- RA - Inverters Installation 2)Document10 pagesRA - Inverters Installation 2)Karimo KilaniNo ratings yet

- RA - PV Module Installation on ROOFDocument9 pagesRA - PV Module Installation on ROOFIbrahim EsmatNo ratings yet

- 001 project-risk-register - -nyngan-solar-power-station - - operations-phaseDocument27 pages001 project-risk-register - -nyngan-solar-power-station - - operations-phaseIbrahim EsmatNo ratings yet

- OSHE-F-13, Near Miss ReportDocument1 pageOSHE-F-13, Near Miss ReportIbrahim EsmatNo ratings yet

- OSHE-F-09, Hotwork Permit FormDocument1 pageOSHE-F-09, Hotwork Permit FormIbrahim EsmatNo ratings yet

- OSHE-F-08, Excavation PermitDocument2 pagesOSHE-F-08, Excavation PermitIbrahim EsmatNo ratings yet

- Training Matrix TemplateDocument6 pagesTraining Matrix TemplateIbrahim EsmatNo ratings yet

- Installation Risk AssessmentDocument5 pagesInstallation Risk AssessmentIbrahim Esmat100% (1)

- 45 ErtDocument2 pages45 ErtIbrahim EsmatNo ratings yet

- OSHE-F-09, Hotwork Permit FormDocument1 pageOSHE-F-09, Hotwork Permit FormIbrahim EsmatNo ratings yet

- 46.lifting PlanDocument2 pages46.lifting PlanIbrahim EsmatNo ratings yet

- OSHE-F-13, Near Miss ReportDocument1 pageOSHE-F-13, Near Miss ReportIbrahim EsmatNo ratings yet

- OSHE-F-07 OSHE Disciplinary NoticeDocument1 pageOSHE-F-07 OSHE Disciplinary NoticeIbrahim EsmatNo ratings yet

- OSHE-F-06, OSHE Non Compliance NoticeDocument1 pageOSHE-F-06, OSHE Non Compliance NoticeIbrahim EsmatNo ratings yet

- RA - 9 - For Slab On Grade ConstructionDocument23 pagesRA - 9 - For Slab On Grade ConstructionIbrahim EsmatNo ratings yet

- Training Matrix Plan 2020Document1 pageTraining Matrix Plan 2020Ibrahim EsmatNo ratings yet

- OSHE-F-05, Monthly OSHE ReportDocument1 pageOSHE-F-05, Monthly OSHE ReportIbrahim EsmatNo ratings yet

- RA - 9 - For Slab On Grade ConstructionDocument23 pagesRA - 9 - For Slab On Grade ConstructionIbrahim EsmatNo ratings yet

- RA - 10 - For Suspended & Slab On Grade ConstructionDocument26 pagesRA - 10 - For Suspended & Slab On Grade ConstructionIbrahim EsmatNo ratings yet

- RA - 10 - For Suspended & Slab On Grade ConstructionDocument26 pagesRA - 10 - For Suspended & Slab On Grade ConstructionIbrahim EsmatNo ratings yet

- RA - PV Module Installation On Carpark Shed Structure at Seaworld AD RejectedDocument14 pagesRA - PV Module Installation On Carpark Shed Structure at Seaworld AD RejectedIbrahim EsmatNo ratings yet

- RA - 14 - For Waterproofing Membrane ApplicationDocument13 pagesRA - 14 - For Waterproofing Membrane ApplicationIbrahim EsmatNo ratings yet

- RA-shifting Installation Cubical Cutout Cable Tray in LV Room (20 (2) 5 PDFDocument8 pagesRA-shifting Installation Cubical Cutout Cable Tray in LV Room (20 (2) 5 PDFIbrahim EsmatNo ratings yet

- RA - Trays InstallationDocument12 pagesRA - Trays InstallationIbrahim EsmatNo ratings yet

- Summer Work Plan - R 0Document12 pagesSummer Work Plan - R 0Ibrahim EsmatNo ratings yet

- RA - 15 - For Production Delivery Installation of Precast Pre-Stressed ElementsDocument30 pagesRA - 15 - For Production Delivery Installation of Precast Pre-Stressed ElementsIbrahim EsmatNo ratings yet

- SWAD Cables Pulling Risk AssessmentDocument12 pagesSWAD Cables Pulling Risk AssessmentIbrahim EsmatNo ratings yet

- RA - PV Module Installation On Carpark Shed Structure at Seaworld AD RejectedDocument14 pagesRA - PV Module Installation On Carpark Shed Structure at Seaworld AD RejectedIbrahim EsmatNo ratings yet

- RA - PV Module Installation On ROOFDocument10 pagesRA - PV Module Installation On ROOFIbrahim EsmatNo ratings yet

- Townshend - Effectivness of Mindful Parents ProgramsDocument40 pagesTownshend - Effectivness of Mindful Parents ProgramsDavid ZNo ratings yet

- Florence Nightingale TheoryDocument44 pagesFlorence Nightingale TheoryAnsu MaliyakalNo ratings yet

- English File B2 2 Fourth Edition Student S Book and WorkbookDocument241 pagesEnglish File B2 2 Fourth Edition Student S Book and WorkbookPaula AlcañizNo ratings yet

- Relationship of Mothers' Knowledge and Socio-Culture to Motivation for MR ImmunizationDocument10 pagesRelationship of Mothers' Knowledge and Socio-Culture to Motivation for MR ImmunizationHanaNo ratings yet

- New Biophilia Tracker x3 FeaturesDocument15 pagesNew Biophilia Tracker x3 FeaturesMartin Haynes100% (1)

- CWTS ProposalDocument5 pagesCWTS ProposalAllana de CastroNo ratings yet

- Exerciții Pe TEXT 2Document27 pagesExerciții Pe TEXT 2Balanean TatianaNo ratings yet

- 5th Grade Reading Comprehension Worksheets - Fifth Grade Week 4Document2 pages5th Grade Reading Comprehension Worksheets - Fifth Grade Week 4Julius CesarNo ratings yet

- MDC COVID-19 Mandatory Health Safety Protocols Upon Work Resumption - V5 20200513Document13 pagesMDC COVID-19 Mandatory Health Safety Protocols Upon Work Resumption - V5 20200513Clarabelle Mae Dela RosaNo ratings yet

- Post Tonsillectomy Bleeding Clinical Practice GuidelineDocument5 pagesPost Tonsillectomy Bleeding Clinical Practice Guidelinemohamed fahmyNo ratings yet

- Profiles in Diversity Journal - Sep/Oct 2007Document201 pagesProfiles in Diversity Journal - Sep/Oct 2007Profiles in Diversity JournalNo ratings yet

- International Journal of Obstetric AnesthesiaDocument6 pagesInternational Journal of Obstetric Anesthesiaanita pratiwiNo ratings yet

- Types of Oral Communication NDocument34 pagesTypes of Oral Communication NYen AduanaNo ratings yet

- Laboratory Safety PrecautionsDocument12 pagesLaboratory Safety PrecautionsBianca GeagoniaNo ratings yet

- ER Diagram ExerciseDocument2 pagesER Diagram ExerciseFarhana NaziraNo ratings yet

- CGM Comparison For People With Insulin Treated Research July 2023Document11 pagesCGM Comparison For People With Insulin Treated Research July 2023shahirahNo ratings yet

- RhetoricDocument32 pagesRhetoricDian ValerieNo ratings yet

- Sample of A Comprehensive Narrative ReportDocument7 pagesSample of A Comprehensive Narrative ReportJanessa Andrei Perez FresnidoNo ratings yet

- PAE STAGE 2 EXAM PRACTICE With Answer Key and TapescriptDocument39 pagesPAE STAGE 2 EXAM PRACTICE With Answer Key and TapescriptaagNo ratings yet

- Healthcare: An Overview of Hospital Capacity Planning and OptimisationDocument27 pagesHealthcare: An Overview of Hospital Capacity Planning and OptimisationLy Ann LoregaNo ratings yet

- Final Alcance Lis524Document112 pagesFinal Alcance Lis524Khristine alcanceNo ratings yet

- A Case Study of Hypertensive Cardiovascular Disease (HCVD) : School of Nursing and MidwiferyDocument13 pagesA Case Study of Hypertensive Cardiovascular Disease (HCVD) : School of Nursing and Midwiferyhsiria100% (2)

- English Passion Project 2Document9 pagesEnglish Passion Project 2api-462335192No ratings yet

- Ipsg 2017Document41 pagesIpsg 2017hum JavedNo ratings yet

- IBPS Prelims CallDocument5 pagesIBPS Prelims CallPrakash RajNo ratings yet

- New Sop Piant WorkDocument6 pagesNew Sop Piant WorkBALAL AKRAMNo ratings yet

- Effectiveness of Mesotherapy On Body Contouring: BackgroundDocument7 pagesEffectiveness of Mesotherapy On Body Contouring: BackgroundNita Dewi NNo ratings yet

- Inb 372Document3 pagesInb 372SunnyNo ratings yet

- Palm Fatty Acid MSDSDocument2 pagesPalm Fatty Acid MSDSAnggun100% (1)

- A Case Report of Acute Severe Necrotizing Pancreatitis FollowingDocument4 pagesA Case Report of Acute Severe Necrotizing Pancreatitis FollowingalexNo ratings yet