Professional Documents

Culture Documents

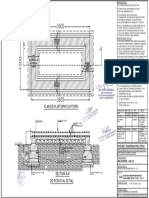

Fixed Bearing-Drawing

Uploaded by

trichandra maharjanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fixed Bearing-Drawing

Uploaded by

trichandra maharjanCopyright:

Available Formats

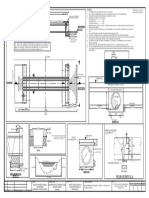

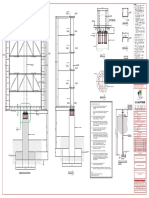

NOTES

1.0 ALL DIMENSIONS ARE IN MM UNLESS OTHERWISE

SPECIFIED.

2.0 MATERIAL :

1. TOP PLATE PISTON & POT / BOTTOM PLATE WILL BE MADE UP OF CAST STEEL

OF GRADE 340-570W OF IS : 1030.

2. STAINLESS STEEL WILL CONFIRM TO AISI:304 WITH THE SLIDING SURFACE

FINISHED SMOOTH.

3. CONFINED PTFE WILL BE OF UNFILLED QUALITY & WILL HAVE REQUIRED

PROPERTIES REGARDING TENSILE STRENGTH ETC. AS PER BS:5400 SEC 9.2 &

BS:3784 GRADE A.

4. THE CONFINED ELASTOMER INSIDE POT WILL HAVE THE FOLLOWING

PROPERTIES :

a) HARDNES - IRHD IS:3400 ( PART II ) 50 +/- 5

b) Min. TENSILE STRENGTH - MPa IS:3400 ( PART I ) 15.5

c) Min. ELONGATION AT BREAK , Max. COMPRESSION SET & ACCELERATED

AGEING WILL BE AS PER

TABLE - 1 ' PROPERTIES OF ELASTOMER ' IN IRC : 83

( PART II ).

5. ANCHOR BOLT MATERIAL AS PER GRADE 8.8 OF IS :

1367 & SLEEVE MATERIAL AS PER IS : 2062 & DETAIL OF

THREAD AS PER IS : 1367 & ACCESSORIES

CONFIRMING TO IS : 2062.

6. THE STAINLESS STEEL WILL BE WELDED ON THE

BACKING PLATE. SUITABLE NOS. OF WASHERS ARE

TO BE USED AS A PACKING TO TIGHTEN THE ANCHOR

BOLTS WITH BEARING TOP PLATE & BOTTOM PTATE.

7. INTERNAL SEAL WILL BE PROVEN TYPE POLY OXY

METHYLENE ( POM ) SEALING CHAIN.PROPERTIES AS

SPECIFIED IN THE TABLE 2 OF IRC : 83 ( PART III ) -

2002

8. EXTERNAL SEAL WILL BE GLUED WITH POT BY

ADHESIVE MATERIAL.

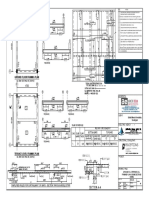

3.0 WELDING :

ALL WELDING WILL BE MANUAL METAL ARC PROCESS CONFIRMING TO IS : 816 & IS :

9595 WITH ELECTRODE AS PER IS : 814 , PRE HEATING AND POST WELD STRESS

RELIEVING TO BE DONE IF REQUIRED.

4.0 TOLERANCES :

GENERALLY AS PER CLAUSES OF BS : 5400 SEC. 9.2 SUBJECT TO THE MODIFICATIONS

:

1. PLAN DIMENSIONS : 0 TO + 5 MM

2. OVERALL HEIGHT : 0 TO + 3 MM

3. HEIGHT OF ELASTOMER : + 5 %

4. HEIGHT OF ANY STEEL COMPONENT

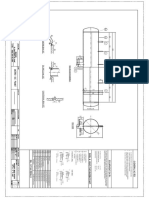

SECTIONAL ELEVATION OF BEARING a) MACHINED : 0 TO +1MM

b) UNMACHINED : CLASS 2 OF IS: 4897

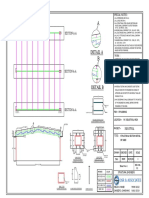

5.0 FINISHING :

TOP PLAN 1. ALL NON WORKING SURFACES WILL BE COATED WITH TWO COATS OF EPOXY

PRIMER AND ONE OR MORE COATS EACH OF HIGH BUILD EPOXY PAINT

REINFORCED WITH MIO (MICACEOUS IRON OXIDE) & FINISH PAINT AFTER SHOT

BLASTING TO SA 2 1/2 QUALITY AS PER IS : 9954. TOTAL DRY FILM THICKNESS > /

= 160 microns. OVERALL HEIGHT : 0 TO + 3 MM.

2. ANCHOR SLEEVES WILL BE GALVANISED / EPOXY COATED BEFORE DESPATCH.

3. THE MATING SURFACE OF THE CYLINDER OF THE POT AND THAT OF THE

PISTON SHALL BE METALLURGICALLY HARDENED TO A VALUE NOT LESS THAN

300 BHN.

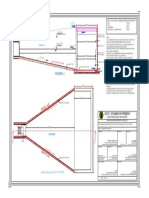

6.0 INSTALLATION :

1. Installation tolerances

a) Location of bearing : +/-3mm

b) Level of bearing (max.) : +/-5mm

c) Horizantality of bearing : 1 in 200 in any direction.

2. MATERIAL IN CONTACT WITH BEARING : SUPERSTRUCTURE : CONCRETE ( M25

GRADE MIN. ) ; PEDESTAL : CONCRETE ( M40 GRADE MIN. )

3. DISMANTLING OF BEARING AT SITE IS NOT RECOMMENDED. IF REQUIRED ,

SPECIAL CARE SHOULD BE TAKEN.

4. CLAMPS ( FOR TRANSPORTATION AND ERECTION ) ARE TO BE REMOVED AFTER

INSTALLATION AT AN APPROPRIATE TIME.

5. THE GROUT OF THE BEDDING MORTAR SHALL BE HIGH STRENGTH FREE FLOW

NON SHRINK GROUT SUCH AS CONBEXTRA - GP2 OR EQUIVALENT.

7.0 GREASING:

SILICON GREASE WILL BE APPLIED AT PTFE STAINLESS STEEL INTERFACE AFTER

TESTING. TESTS

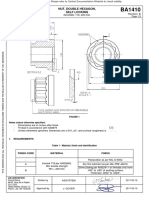

1. RAW MATERIALS : NECESSARY TEST CERTIFICATES FOR ALL RAW MATERIALS

SHALL BE FURNISHED BY MANUFACTURERS.

2. 2. TEST ON CASTING : TEST SPECIFIED IN IS : 1030 WILL BE PERFORMED.

CASTINGS SHALL BE ULTRA-SONICALLY TESTED AND CERTIFICATES

SUBMITTED. QUALITY LEVEL OF CASTING SHALL BE LEVEL 3 AS PER IS : 9565.

3. TEST ON WELDING : ALL WELDING WILL BE TESTED BY DYE PENETRATION

METHOD AS PER Et=19 BW=337.0 B2=18 3mm THK. S.S. PLATE Ll=50

DETAIL OF ANCHOR SLEEVE 4.

THE MANUFACTURER

ACCEPTANCE TESTS ON BEARINGS SHALL BE CARRIED AS PER CL.928.6.2.3 OF

IRC 83 - PART - III OF 2002.

a) PART - III OF 2002. ALL TEST ON BEARING WILL BE CARRIED OUT IN PRESENCE

SECTIONAL ELEVATION b)

OF REPRESENTATIVE OF CLIENT / CONSULTANT / CONTRACTOR.

BEARINGS WILL BE CHECKED FOR OVERALL DIMENSIONS.

c) BEARINGS WILL BE VERTICAL LOAD TESTED TO 1.25 x DESIGN LOAD.

d) A PAIR OF BEARINGS SELECTED AT RANDOM WILL UNDERGO TESTING IN

TOP PLATE e)

ORDER TO DETERMINE THE COEFFICIENT OF FRICTION AT DESIGN LOAD.

BEARINGS SELECTED AT RANDOM WILL BE TESTED FOR PERMISSIBLE

ROTATION.

f) THE CERTIFICATES FOR LOAD TESTING AND DIMENSIONS OF ALL BEARINGS

WILL BE SUBMITTED TO THE DEPARTMENT.

TOP PLAN

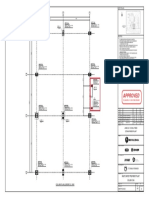

PROJECT TITLE

.

4-Lane Gwarko Flyover Project

.

TOP PLAN CLIENT

TOP PLAN .

SECTIONAL ELEVATION

BOTTOM PLATE

SECTIONAL ELEVATION SECTIONAL ELEVATION

DRAWING TITLE

ELASTOMER BRASS RING

Fixed Bearing

DATE: DESIGN/DRAWN BY: APPROVED BY:

TECHNICAL DATA

347 Mt 580 27 398 34 6 18 400 27 90 32 51 580 10 120 20 60 20+20 645 645 65 16 50 250 250 01.12.2022

DRAWING NO. REV. NO.

No.

Load Capacity Dt Tt Dp Tp h1 h2 Di/di he Tcw Tc Hc Db h4 HT Dbolt Lbolt of. C1 C Cl Ct D L L1 . 00

Bolt.

You might also like

- Guided (L) Bearing DrawingDocument1 pageGuided (L) Bearing Drawingtrichandra maharjanNo ratings yet

- Chauraghat Road Structural GAD R1Document18 pagesChauraghat Road Structural GAD R1Aicons Engineering Pvt. Ltd.No ratings yet

- 508-GEN.00-CVL-002 - 0 - Lighting Pole FoundationDocument1 page508-GEN.00-CVL-002 - 0 - Lighting Pole Foundationrahman fatahNo ratings yet

- Pump Foundation Analysis and Design ReportDocument18 pagesPump Foundation Analysis and Design ReportArchana ArchuNo ratings yet

- CC Wall Reinforcement DetailsDocument8 pagesCC Wall Reinforcement DetailsDushyant JadaunNo ratings yet

- Structural column and foundation detailingDocument1 pageStructural column and foundation detailingHarbhajan SinghNo ratings yet

- Final Structural DWG of Public ToiletDocument5 pagesFinal Structural DWG of Public ToiletSalin ShresthaNo ratings yet

- Notes: Total No. of Installation 1 NoDocument1 pageNotes: Total No. of Installation 1 Noaung aungNo ratings yet

- GWRE153Document1 pageGWRE153fkdnldNo ratings yet

- For Review and Approval: SECTION-1-1Document1 pageFor Review and Approval: SECTION-1-1Mandar GNo ratings yet

- F2 - Liquid ReceiverDocument1 pageF2 - Liquid ReceiverStan LeyNo ratings yet

- 115 - El-Adm-03Document1 page115 - El-Adm-03Fun TonNo ratings yet

- Earthing Schemes FOR Terminals and DepotsDocument31 pagesEarthing Schemes FOR Terminals and DepotsYash Bardhan SinghNo ratings yet

- Wind Mill Road 1 Row Pipe Culvert 600mm Dia at CH 1.40 KM: Section at A-A Section at B-BDocument1 pageWind Mill Road 1 Row Pipe Culvert 600mm Dia at CH 1.40 KM: Section at A-A Section at B-BsohanpmeharwadeNo ratings yet

- SRD - 111 - S CWDT 01 02.05.2022Document1 pageSRD - 111 - S CWDT 01 02.05.2022Nishant KarthikeyanNo ratings yet

- HPC 2x1000Document1 pageHPC 2x1000Shivam SharmaNo ratings yet

- Construction Notes: ElevationDocument1 pageConstruction Notes: ElevationJohn PaderangaNo ratings yet

- Roof Plan: Batangas State UniversityDocument1 pageRoof Plan: Batangas State UniversityRuellynne Barberan BonifacioNo ratings yet

- SD-208 - Rev 2Document1 pageSD-208 - Rev 2sathishNo ratings yet

- Tender Drawing For StructuralDocument12 pagesTender Drawing For StructuralSaif MohammadNo ratings yet

- Amar Factory To Jail Road Culvert-1410Document1 pageAmar Factory To Jail Road Culvert-1410AATVIK SHRIVASTAVANo ratings yet

- Notes: Total No. of Installation 1noDocument1 pageNotes: Total No. of Installation 1noaung aungNo ratings yet

- Module Mounting StructureDocument4 pagesModule Mounting StructureHusainNo ratings yet

- ANNEX C. Storey BLK Classroom Structural and Architectural DrawingsDocument6 pagesANNEX C. Storey BLK Classroom Structural and Architectural DrawingsLaki ENNo ratings yet

- General notes and column schedule for building foundationDocument1 pageGeneral notes and column schedule for building foundation025Karthik ReddyNo ratings yet

- WS 005Document1 pageWS 005Er Navneet JassiNo ratings yet

- 9 MTR Octagonal Pole - 231023 - 151810Document1 page9 MTR Octagonal Pole - 231023 - 151810Rohit SarafNo ratings yet

- Nut, Double Hexagon, Self Locking: Page 1/3Document3 pagesNut, Double Hexagon, Self Locking: Page 1/3Renato WatanabeNo ratings yet

- Nut, Double Hexagon, Self Locking: Page 1/3Document3 pagesNut, Double Hexagon, Self Locking: Page 1/3Renato WatanabeNo ratings yet

- Sa-Ami-521-Mosu-000xxx (SCC Building Sections)Document1 pageSa-Ami-521-Mosu-000xxx (SCC Building Sections)tanyadeasis8No ratings yet

- Proposed Water Cooling Tank (Bricks Wall)Document5 pagesProposed Water Cooling Tank (Bricks Wall)Haitham NegmNo ratings yet

- Governing SpecificationsDocument1 pageGoverning SpecificationsAshley JeyahNo ratings yet

- General Notes BridgeDocument6 pagesGeneral Notes BridgeEnglish for KidsNo ratings yet

- Sydney Football Stadium Lifting Drawing (0008) - Lifting Drawing PDFDocument1 pageSydney Football Stadium Lifting Drawing (0008) - Lifting Drawing PDFEmon RayNo ratings yet

- Tank GADocument1 pageTank GAleeNo ratings yet

- Mounting Pan-MSA-00204Document1 pageMounting Pan-MSA-00204Jorge HadechineNo ratings yet

- General Notes:: LegendsDocument1 pageGeneral Notes:: LegendsajindesignjoshualopezNo ratings yet

- Mark Up Holding Ss WWTP 2Document1 pageMark Up Holding Ss WWTP 2rhynaka23No ratings yet

- Stair ChungDocument3 pagesStair ChungKS LeeNo ratings yet

- TITEDocument1 pageTITEDrew GozarNo ratings yet

- Copper Coated Solid Wire for Welding Low Alloy SteelsDocument1 pageCopper Coated Solid Wire for Welding Low Alloy SteelsAshok RajNo ratings yet

- CHECK in Erection DrawingDocument34 pagesCHECK in Erection DrawingAMIT TIWARINo ratings yet

- Amar Factory To Jail Road Culvert-710Document1 pageAmar Factory To Jail Road Culvert-710AATVIK SHRIVASTAVANo ratings yet

- Section B-B: C C 1a 1aDocument1 pageSection B-B: C C 1a 1aAli KayaNo ratings yet

- Reinforcement Detail of Berkheda Fore WayDocument1 pageReinforcement Detail of Berkheda Fore WayvishalNo ratings yet

- SF1521 60070 2S - PDDDocument1 pageSF1521 60070 2S - PDDpayoseNo ratings yet

- HPC1 X 1000Document1 pageHPC1 X 1000Shivam SharmaNo ratings yet

- Marker EVAC.Document1 pageMarker EVAC.LGU-Catanauan Engineering OfficeNo ratings yet

- Structural steel connection detailsDocument1 pageStructural steel connection detailstejas nandaniNo ratings yet

- ORISSA SCHOOL (STR-ARCH) - Model - pdf71Document1 pageORISSA SCHOOL (STR-ARCH) - Model - pdf71NISHIKANTA MONDALNo ratings yet

- 1 Dg-MahilaDocument1 page1 Dg-MahilaRohit JangidNo ratings yet

- A B C 2650 2200 4850 9700 A1: Revision No. byDocument1 pageA B C 2650 2200 4850 9700 A1: Revision No. byPaschal MazikuNo ratings yet

- Second & Upto Terrace Floor LVL (+9.45m.) Top of Grade Slab Both Ways 150 Thk. GRADE SLAB Level Match With Existing Site LVLDocument1 pageSecond & Upto Terrace Floor LVL (+9.45m.) Top of Grade Slab Both Ways 150 Thk. GRADE SLAB Level Match With Existing Site LVLSarvang PandyaNo ratings yet

- Tpl-Yiapl-Ph1&2-An-27 R0Document1 pageTpl-Yiapl-Ph1&2-An-27 R0Ramesh BabuNo ratings yet

- Drawing Sheet 4Document1 pageDrawing Sheet 4Kunal SharmaNo ratings yet

- Sec BoxDocument1 pageSec BoxsparkCENo ratings yet

- ORISSA SCHOOL (STR-ARCH) - Model - pdf73Document1 pageORISSA SCHOOL (STR-ARCH) - Model - pdf73NISHIKANTA MONDALNo ratings yet

- General notes and details for substation constructionDocument1 pageGeneral notes and details for substation constructionA.K.M Shafiq MondolNo ratings yet

- Structural Notes: General: Reinforcing SteelDocument1 pageStructural Notes: General: Reinforcing SteelMark Allan RojoNo ratings yet

- Arch Bridge 459Document1 pageArch Bridge 459trichandra maharjanNo ratings yet

- UntitledDocument1 pageUntitledtrichandra maharjanNo ratings yet

- Arch Bridge 471Document1 pageArch Bridge 471trichandra maharjanNo ratings yet

- House PaymentDocument3 pagesHouse Paymenttrichandra maharjanNo ratings yet

- Arch Bridge 457Document1 pageArch Bridge 457trichandra maharjanNo ratings yet

- Arch Bridge 456Document1 pageArch Bridge 456trichandra maharjanNo ratings yet

- Government of Nepal reviews Tinau River bridge designDocument74 pagesGovernment of Nepal reviews Tinau River bridge designtrichandra maharjanNo ratings yet

- Construction Detail Abutment 2: Hydrological DataDocument85 pagesConstruction Detail Abutment 2: Hydrological Datatrichandra maharjanNo ratings yet

- UntitledDocument1 pageUntitledtrichandra maharjanNo ratings yet

- Prefabricated Vertical Drain Test ReportDocument1 pagePrefabricated Vertical Drain Test Reporttrichandra maharjanNo ratings yet

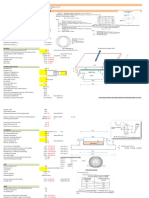

- Pot Bearing - Fix Bearing DesignDocument2 pagesPot Bearing - Fix Bearing Designtrichandra maharjanNo ratings yet

- Pot Bearing - Guided Bearing DesignDocument2 pagesPot Bearing - Guided Bearing Designtrichandra maharjanNo ratings yet

- Gwarko Sky BridgeDocument3 pagesGwarko Sky Bridgetrichandra maharjanNo ratings yet

- Note CHP 3 Material Science 281 Uitm Em110Document40 pagesNote CHP 3 Material Science 281 Uitm Em110bino_ryeNo ratings yet

- Blasia 32Document1 pageBlasia 32Marcelo Ferreira MeloNo ratings yet

- Satr-W-2020Document1 pageSatr-W-2020Joni Carino SuniNo ratings yet

- Standard Test Methods For Bend Testing of Material For Ductility PDFDocument12 pagesStandard Test Methods For Bend Testing of Material For Ductility PDFJuan VanegasNo ratings yet

- ASNT Level II Study Guide PTDocument114 pagesASNT Level II Study Guide PTNitesh Srivastava100% (2)

- Shattaf Sink Sprayer 39219UAE - Shattaf Sink Sprayer With Push Button SprayDocument1 pageShattaf Sink Sprayer 39219UAE - Shattaf Sink Sprayer With Push Button Spraytvshow zeeNo ratings yet

- PFI Document DatabaseDocument1 pagePFI Document DatabaseedwinramonNo ratings yet

- Apcolite Premium Satin EmulsionDocument2 pagesApcolite Premium Satin EmulsionHumzah WalaNo ratings yet

- Tovcol T.A.: Chemical-Physical Characteristics (20ºC - 60% R.H.)Document2 pagesTovcol T.A.: Chemical-Physical Characteristics (20ºC - 60% R.H.)jowicvNo ratings yet

- Laundry Symbol - Wikipedia, The Free EncyclopediaDocument13 pagesLaundry Symbol - Wikipedia, The Free EncyclopediaIkkasama NaguenneNo ratings yet

- Agglomeration of Iron OresDocument41 pagesAgglomeration of Iron OresAnonymous NxpnI6jC100% (1)

- Forging BasicsDocument9 pagesForging BasicsAl EnggNo ratings yet

- Power LockDocument88 pagesPower Lockash remoNo ratings yet

- AusmeltDocument3 pagesAusmeltROMARIO3000100% (1)

- CorepinsDocument2 pagesCorepinshbhaNo ratings yet

- 008 Alloy Tool SteelDocument66 pages008 Alloy Tool SteelAbdelfattah MoheyeldinNo ratings yet

- Dovetail Deck Coating SolutionsDocument2 pagesDovetail Deck Coating SolutionsDan SmithNo ratings yet

- Vacuum-Treated Carbon and Alloy Steel Forgings For Turbine Rotors and ShaftsDocument8 pagesVacuum-Treated Carbon and Alloy Steel Forgings For Turbine Rotors and ShaftsMahsaNo ratings yet

- Semi Coated AVERY - AveryBJ993 - ENDocument2 pagesSemi Coated AVERY - AveryBJ993 - ENAhmad HaririNo ratings yet

- GratingsDocument3 pagesGratingssaurabhsubhuNo ratings yet

- Popular Woodworking No 102 May 1998Document80 pagesPopular Woodworking No 102 May 1998EliseuJoséDosSantosNo ratings yet

- Working With AcrylicDocument26 pagesWorking With AcrylicHua Hidari YangNo ratings yet

- Taha Associates. Surface Grinding WheelsDocument2 pagesTaha Associates. Surface Grinding WheelsTaha AssociatesNo ratings yet

- Blast Furnace Test QuestionsDocument3 pagesBlast Furnace Test QuestionsKhánh Vũ Ngọc AnNo ratings yet

- Cv. NEW. FAJARDocument7 pagesCv. NEW. FAJARradenkobalarifinNo ratings yet

- Welding Electrode Complete Guide (Includes Charts)Document15 pagesWelding Electrode Complete Guide (Includes Charts)Robert DelafosseNo ratings yet

- FP 247 03 Sand Cast BronzesDocument4 pagesFP 247 03 Sand Cast BronzesnfcastingsNo ratings yet

- Materials Today: Proceedings: S. Nagendharan, R. Kishore, P. Gurusamy, P. SubashDocument6 pagesMaterials Today: Proceedings: S. Nagendharan, R. Kishore, P. Gurusamy, P. SubashKishore RaviNo ratings yet

- ACF CarbFiltLitDocument2 pagesACF CarbFiltLitnandhamech25No ratings yet

- Ceramic Injection Molding (CIM)Document3 pagesCeramic Injection Molding (CIM)Metal PartsNo ratings yet