Professional Documents

Culture Documents

NIMBALAKR REPORT With Pages Removed (4) (1) - Removed

Uploaded by

udayOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

NIMBALAKR REPORT With Pages Removed (4) (1) - Removed

Uploaded by

udayCopyright:

Available Formats

DESIGN & ANALYSIS OF HYDRAULIC PRRESS MACHINE FOR GAS TUBE (2022-2023)

A

PROJECT REPORT

ON

“Design and Analysis of hydraulic press Machine For Gas Tube”

Submitted In Partial Fulfillment of Requirement for the Award of Degree of

BACHELOR OF TECHNOLOGY IN

MECHANICAL ENGINEERING

Of

Dr. Babasaheb Ambedkar Technological University, Lonere

Submitted By,

Shweta Santosh Pol .

Aditya Pravin Yadav

Abhishek Ajit Khatavkar

Udaykumar Pramod Mane

Under the Guidance of

Prof.S.M.Mane.

Raosaheb Wangde Master Charitable Trust’s

Dnyanshree Institute of Engineering & Technology,

Sajjangad Road, Satara, Maharashtra, 415 013,

(India) 2022-2023

Department Of Mechanical Engineering, Dnyanshree Institute Of Engineering Page

DESIGN & ANALYSIS OF HYDRAULIC PRRESS MACHINE FOR GAS TUBE (2022-2023)

CERTIFICATE

This is to certify that the project report entitled,

“Design and Analysis of hydraulic press Machine For Gas Tube”

Submitted by,

Name of Student PRN Roll No.

Shweta Santosh Pol 1967971612004 4607

Aditya Pravin Yadav 1967971612005 4611

Abhishek Ajit Khatavkar 1967971612006 4602

Udaykumar Pramod Mane 1967971612012 4605

It is bonafide work carried out by these students under the guidance of Prof. S.M.V.Mane. It has been

accepted and approved for the partial fulfillment of requirement of Dr. Babasaheb Ambedkar

Technological University, Lonere, for the award of the degree of Bachelor of Technology (Mechanical

Engineering).This work and project report has not been earlier submittedto any other Institute or

University for the award of anydegree.

Prof. S.M.Mane. Prof. V.B.Dixit Dr. A.D. Jadhav

Guide Head of Department Principal

External Examiner

Date:

Place: Satara

Department Of Mechanical Engineering, Dnyanshree Institute Of Engineering Page

DESIGN & ANALYSIS OF HYDRAULIC PRRESS MACHINE FOR GAS (2022-

ACKNOWLEDGEMENT

Whenever a work is accomplished successfully, there are many people behind that success.

We would like to take this opportunity to sincerely thank people who helped directly or indirectly.

First and for most we gratefully acknowledge to our project guide Prof. S.M.Mane. for her guidance,

inspiration & assistance at all stages of this project work.

It is our proud privilege to express our gratitude and sincere thanks to Prof. V.B. Dixit, Head

of department, Mechanical Engineering and Dr. A. D. Jadhav, Principal, Dnyanshree Institute of

Engineering & Technology, Satara for their valuable motivation and support.

We take this opportunity to record our sincere thanks to all the faculty members of the

Department of Mechanical Engineering, Dnyanshree Institute of Engineering & Technology, Satara

for the help and encouragement. We also thank our parents for their encouragement and support.

Last but not least we are thankful to all those who, directly or indirectly, have lent their helping hand

during completion of the project.

Sr. No. Name Of student Signature

1 Shweta Santosh Pol

2 Aditya Pravin Yadav

3 Abhishek Ajit Khatavkar

4 Udaykumar Pramod Mane

Date: 19/12/2022

Place: Satara

Department Of Mechanical Engineering, Dnyanshree Institute Of Engineering Page

DESIGN & ANALYSIS OF HYDRAULIC PRRESS MACHINE FOR GAS (2022-

ABSTRACT

Design & Analysis of Hydraulic Press Machine For Gas Tube

Shweta Santosh Pol , Aditya Pravin Yadav,

Abhishek Ajit Khatavkar, Udaykumar Pramod Mane

Guide: Prof. S. M. Mane

Abstract: hydraulic press is a machine using a hydraulic cylinder to generate a compressive force. Frame,

hydraulic cylinder and press table are the main components of the hydraulic press. In this project press

frame, cylinder and press table are designed by the design procedure. They are analyzed to improve their

performance and quality for press working operation. Using the optimum resources possible in designing

the hydraulic press components can effect reduction in the cost by optimizing the weight of material

utilized for building the structure. An attempt has been made in this direction to reduce the volume of

material. So in this project we consider an industrial application project consisting of mass minimization

of H frame type hydraulic press. This press has to compensate the forces acting on the Gas Tube and has

to fulfil certain critical constraints. Here we use implementation for analysis and optimization of

hydraulic press. The aim of this project is to integrate the mechanical system of hydraulic press with

hydraulic system to facilitate the ease of operation to manufacture the smaller parts in a bulk. In the

present scenario, time constrain is a crucial part for completion of any production process. Thus, with the

aid of atomization, the production time can be reduced as well as higher degree of accuracy can be

achieved as the human efforts will be alleviated. Thus an attempt has been made to provide the smooth

and rapid functioning of press work with the help of hydraulic system.

Key Words: Hydraulic press, Frame Structure, Press work, Hydraulic cylinder, Analysis.

Department Of Mechanical Engineering, Dnyanshree Institute Of Engineering Page v

DESIGN & ANALYSIS OF HYDRAULIC PRRESS MACHINE FOR GAS (2022-

LIST OF FIGURES

Figure No Name of the figure Page No

1 Block Diagram 3

1.5.1 Electric Motor 4

1.5.2 Hydraulic cylinder 4

1.5.3 Gas tube 5

1.5.4 Oil tank 5

1.5.5 induction hard chrome plated shaft 6

1.5.6 Die mounting bracket 11

1.5.7 Die 23

1.5.8 Tube resting plate 23

4.4.7 Flow Chart Of Design &Analysis 25

Methodology

4.5 3D Model Of Hydraulic press Machine 26

Department Of Mechanical Engineering, Dnyanshree Institute Of Engineering Page

DESIGN & ANALYSIS OF HYDRAULIC PRRESS MACHINE FOR GAS (2022-

LIST OF TABLE

Table No Name of the table Page No.

4.7 Part list 35

LIST OF ABBREVIATIONS

Abbreviations Meaning

LPM Liter Per Minute

MS Mild Steel

SS Stainless steel

CI Cast Iron

Department Of Mechanical Engineering, Dnyanshree Institute Of Engineering Page

DESIGN & ANALYSIS OF HYDRAULIC PRRESS MACHINE FOR GAS (2022-

INDEX

Title Ⅰ

Certificate Ⅱ

Sponsorship Letter Ⅲ

Acknowledgement ⅠⅤ

Abstract V

List of Figure VI

List of Table VII

List of Abbreviations VII

Index VIII

CHAPTER 1: INTRODUCTION 1-6

1.1 Introduction 2

1.2 Block Diagram 3

1.3 Problem Definition 3

1.4 Objective 3

1.5 Component & Specification 4-6

CHAPTER 2: LITRETURE REVIEW 7-9

CHAPTER 3: METHODOLOGY 10-13

3.1 Research Of Methodology 12

CHAPTER 4: DESIGN, DEVELOPMENT & DRAWING 14-28

4.1 Material Selection 15

4.4 Drawing 23

4.5 3D Model Machine 27

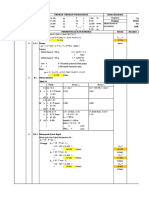

4.6 Calculation 28

CHAPTER 9: REFERENCES 29

Department Of Mechanical Engineering, Dnyanshree Institute Of Engineering Page

DESIGN & ANALYSIS OF HYDRAULIC PRRESS MACHINE FOR GAS (2022-

CHAPTER 1 INTRODUCTION

Department Of Mechanical Engineering, Dnyanshree Institute Of Engineering Page 9

DESIGN & ANALYSIS OF HYDRAULIC PRRESS MACHINE FOR GAS (2022-

1.1 INTRODUCTION :

The purpose of this work is to understand the knowledge of design ,analysis and mechanism of

hydraulic press machine. The design is an environment friendly and uses simple mechanism

properties such as hydraulic system, press mechanism and sensor system etc. In this, some press

force is needed to press the gas tube. The design is so done that the knowledge of designing,

mechanism and forces are increased. This project consists of designing and analysis of hydraulic

press machine for gas tube, considering various important parameters.

In this project, designing & analysis of a machine to press the gas tube so the shape of gas tube

will be change according to our requirement . As well as the analysis of structure, base plate and

other parts of plates was very important in order to carry out this project to ensure that what are

needs to do. This project involves the process of designing and analysis of different parts of this

hydraulic press machine considering forces and ergonomic factor for people to use. This project is

mainly about generating a new concept of analysis and designing that would make easier to reduce

cost and easier to press gas tube. After the design has completed, it was transformed to its analysis

part where the design is used for guideline.

Department Of Mechanical Engineering, Dnyanshree Institute Of Engineering Page

You might also like

- 3D Concrete Printing Technology: Construction and Building ApplicationsFrom Everand3D Concrete Printing Technology: Construction and Building ApplicationsNo ratings yet

- FINAL YEAR PROJECT REPORT OneDocument54 pagesFINAL YEAR PROJECT REPORT OneNishanth HGNo ratings yet

- Pneumatic Riveting Machine - Project ReportDocument48 pagesPneumatic Riveting Machine - Project ReportTanvi Khurana82% (11)

- Mechanical Final Year Projetct - Hydraulic BicycleDocument96 pagesMechanical Final Year Projetct - Hydraulic BicycleTarun GuptaNo ratings yet

- Profile Cutting of Metals On CNC Plasma MachineDocument30 pagesProfile Cutting of Metals On CNC Plasma MachineKranthi Kumar ReddyNo ratings yet

- MGMT and Cost Accounting - Colin DruryDocument25 pagesMGMT and Cost Accounting - Colin Druryapi-24690719550% (2)

- Hydraulic Press Design for Gas Tube FormingDocument39 pagesHydraulic Press Design for Gas Tube FormingudayNo ratings yet

- A Project: "Design and Analysis of Hydraulic Press Machine For Gas Tube"Document58 pagesA Project: "Design and Analysis of Hydraulic Press Machine For Gas Tube"udayNo ratings yet

- Major Project ReportDocument63 pagesMajor Project ReportVirat Kiran0% (1)

- Visvesvaraya Technological Univeversity: Design and Fabrication of Semi Automatic Pneumatic Sheet Metal Cutting MachineDocument36 pagesVisvesvaraya Technological Univeversity: Design and Fabrication of Semi Automatic Pneumatic Sheet Metal Cutting MachineVinay KumarNo ratings yet

- Design and Fabrication of Pneumatic Sheet Metal Cutting MachineDocument26 pagesDesign and Fabrication of Pneumatic Sheet Metal Cutting MachineMALLIKARJUN KATARENo ratings yet

- Self-Balancing Two-Wheeler Using GyroscopeDocument33 pagesSelf-Balancing Two-Wheeler Using Gyroscopemilan mottaNo ratings yet

- MAYUR AVDHUT FINAL PROJECTDocument52 pagesMAYUR AVDHUT FINAL PROJECTnileshlawande09No ratings yet

- Modelling and Assembly of Cam Shaft in Fusion 360Document28 pagesModelling and Assembly of Cam Shaft in Fusion 360CHINNANo ratings yet

- Water Fuelled Vechile Project Analysis C PDFDocument76 pagesWater Fuelled Vechile Project Analysis C PDFbabuNo ratings yet

- Hydraulic Bicycle Design and Simulation (2020-2021Document93 pagesHydraulic Bicycle Design and Simulation (2020-2021Tarun GuptaNo ratings yet

- Mega Project ReportDocument40 pagesMega Project ReportChaitanyaNo ratings yet

- Rocket Motor Head-end Structural AnalysisDocument83 pagesRocket Motor Head-end Structural AnalysisRudra Sai SandeepNo ratings yet

- Final Report 2021-22Document33 pagesFinal Report 2021-22Chetan KarigarNo ratings yet

- Report 2021Document59 pagesReport 2021Bhushan LoharNo ratings yet

- Ashish Industrial PDFDocument8 pagesAshish Industrial PDFAvinash SableNo ratings yet

- "Approaching Thermal Analysis of Pulse-Jet Engine": A Project Report ONDocument32 pages"Approaching Thermal Analysis of Pulse-Jet Engine": A Project Report ONSimran SainiNo ratings yet

- Happy FinalDocument32 pagesHappy FinalRaju MehtaNo ratings yet

- Ansys Analysis of Truss BeamDocument22 pagesAnsys Analysis of Truss Beamabhishekbachchan626No ratings yet

- Study of Hammer Mill Crusher Design and WorkingDocument49 pagesStudy of Hammer Mill Crusher Design and WorkinglokeshNo ratings yet

- Hydraulic Ram Pump ReportDocument42 pagesHydraulic Ram Pump ReportliviciuklNo ratings yet

- ABHI WORDfinal PDFDocument44 pagesABHI WORDfinal PDFAbel NagellaNo ratings yet

- Major 315Document40 pagesMajor 315VaishnaviNo ratings yet

- Design, Manufacture and Test A Hydraulic Ram: ThesisDocument42 pagesDesign, Manufacture and Test A Hydraulic Ram: ThesisIrfan ShaikhNo ratings yet

- Project Pnumatic Gripper Documentation (Batch 10)Document81 pagesProject Pnumatic Gripper Documentation (Batch 10)Shanmuk VarmaNo ratings yet

- Project Report HydrualiDocument54 pagesProject Report HydrualiDhruba Narayan ThakurNo ratings yet

- Visvesvaraya Technological University: Automated Rubber Tapping MachineDocument67 pagesVisvesvaraya Technological University: Automated Rubber Tapping Machinepraveen dvrNo ratings yet

- Final Year Project Report 43 Updated 4.0 PDFDocument48 pagesFinal Year Project Report 43 Updated 4.0 PDFTanishq ShettyNo ratings yet

- CPP AkDocument18 pagesCPP AkPrathmeshNo ratings yet

- Minor Project Report RohithDocument21 pagesMinor Project Report RohithpallerlakunalNo ratings yet

- Complete Report FinDocument54 pagesComplete Report FinShreyas G.SNo ratings yet

- Chaitanya Ghule CppPP (2)Document52 pagesChaitanya Ghule CppPP (2)nileshlawande95No ratings yet

- Solar Powered Wireless Pesticide RobotDocument6 pagesSolar Powered Wireless Pesticide RobotChetan KarigarNo ratings yet

- Fabrication of Water Fuel Engine With Power GenerationDocument83 pagesFabrication of Water Fuel Engine With Power GenerationBharath RajNo ratings yet

- Prestressed Bolt & JointDocument18 pagesPrestressed Bolt & JointTîwäRî RãJêêvNo ratings yet

- Visvesvaraya Technological Univeversity: Design and Fabrication of Semi Automatic Pneumatic Sheet Metal Cutting MachineDocument28 pagesVisvesvaraya Technological Univeversity: Design and Fabrication of Semi Automatic Pneumatic Sheet Metal Cutting MachineVinay KumarNo ratings yet

- Project Book (B12) - Section ''B''Document32 pagesProject Book (B12) - Section ''B''Baldev SinghNo ratings yet

- Cover Pages (Latest)Document16 pagesCover Pages (Latest)Shubham KalbhutNo ratings yet

- Report FormatDocument20 pagesReport FormatKripansh MishraNo ratings yet

- Final Report PDFDocument25 pagesFinal Report PDFRajeshwaranNo ratings yet

- "Design, Modeling and Analysis of Steam Turbine Blade": Dayananda Sagar College of EngineeringDocument66 pages"Design, Modeling and Analysis of Steam Turbine Blade": Dayananda Sagar College of EngineeringSHREENIVAS MNo ratings yet

- Chaitanya Ghule CppPPDocument56 pagesChaitanya Ghule CppPPnileshlawande95No ratings yet

- Design and Fabrication of Indexing Drill Jig For Cylindrical Work PiecesDocument52 pagesDesign and Fabrication of Indexing Drill Jig For Cylindrical Work PiecesRama KrishnaNo ratings yet

- Sample of Contents in Project Report-2Document12 pagesSample of Contents in Project Report-2Abhimanyu SinghNo ratings yet

- 85b2e309-609d-458f-b227-e14c0ae7bc18 (1)Document46 pages85b2e309-609d-458f-b227-e14c0ae7bc18 (1)chandanvk45No ratings yet

- Pneumatic Riveting and Punching MachineDocument43 pagesPneumatic Riveting and Punching MachineAnil AnukulaNo ratings yet

- Design and Analysis of Circular Over Head Water Tank Using: Staad ProDocument39 pagesDesign and Analysis of Circular Over Head Water Tank Using: Staad ProMohammed Hajra100% (1)

- Generate Power From FootstepsDocument51 pagesGenerate Power From FootstepsAkshay KNo ratings yet

- De Report PDFDocument41 pagesDe Report PDFjay kalavadiyaNo ratings yet

- 6th Sem Project ReportDocument22 pages6th Sem Project ReportGautam KoliwadNo ratings yet

- Review MINIDocument46 pagesReview MINIShubham ShindeNo ratings yet

- Rohit JAdhav CPP MicroprojectDocument9 pagesRohit JAdhav CPP Microprojectnarasihhinge4No ratings yet

- Hydraulic Disc Brake: Jawaharlal Nehru Technological University KakinadaDocument17 pagesHydraulic Disc Brake: Jawaharlal Nehru Technological University KakinadaRanganaik VaditheNo ratings yet

- Front Page Sheet CutterDocument9 pagesFront Page Sheet CutterHarry RoyNo ratings yet

- Abrassive Jet Machine Project ReportDocument47 pagesAbrassive Jet Machine Project ReportAb BasitNo ratings yet

- Cleaning and PainitngDocument36 pagesCleaning and Painitngpramo_dassNo ratings yet

- Egr Working PDFDocument23 pagesEgr Working PDFudayNo ratings yet

- Certificate Abd Other FormatDocument5 pagesCertificate Abd Other FormatudayNo ratings yet

- Function?Document1 pageFunction?udayNo ratings yet

- Automotive 4b3dd 62f7b58dDocument1 pageAutomotive 4b3dd 62f7b58dudayNo ratings yet

- Crex Rig Well Gold Mining Oil & Gas Shipping Company - 0nline Application & Interview FormDocument2 pagesCrex Rig Well Gold Mining Oil & Gas Shipping Company - 0nline Application & Interview FormudayNo ratings yet

- Seminar Report Format and ContentDocument5 pagesSeminar Report Format and ContentudayNo ratings yet

- Thermodynamic System Micro-ProjectDocument4 pagesThermodynamic System Micro-ProjectudayNo ratings yet

- Udaykumar Pramod ManeDocument1 pageUdaykumar Pramod ManeudayNo ratings yet

- If F 150 N, F 400 N, F 600 N, F 0 N, What Is The Net Force Acting On The Vehicle? A) 100 N B) 50 N C) 550 N D) 750 NDocument2 pagesIf F 150 N, F 400 N, F 600 N, F 0 N, What Is The Net Force Acting On The Vehicle? A) 100 N B) 50 N C) 550 N D) 750 NudayNo ratings yet

- SBCollect e-Receipt for student fee paymentDocument2 pagesSBCollect e-Receipt for student fee paymentudayNo ratings yet

- If F 150 N, F 400 N, F 600 N, F 0 N, What Is The Net Force Acting On The Vehicle? A) 100 N B) 50 NDocument2 pagesIf F 150 N, F 400 N, F 600 N, F 0 N, What Is The Net Force Acting On The Vehicle? A) 100 N B) 50 NudayNo ratings yet

- Details To Assembly DRAWING: Maharashtra State Board of Technical Education, MumbaiDocument4 pagesDetails To Assembly DRAWING: Maharashtra State Board of Technical Education, MumbaiudayNo ratings yet

- Details To Assembly DRAWING: Maharashtra State Board of Technical Education, MumbaiDocument4 pagesDetails To Assembly DRAWING: Maharashtra State Board of Technical Education, MumbaiudayNo ratings yet

- Thermodynamic System Micro-ProjectDocument4 pagesThermodynamic System Micro-ProjectudayNo ratings yet

- Black Body Radiation - Determination of Stefan's Constant (Simulator) - Heat & Thermodynamics Virtual Lab - Physical Sciences - Amrita Vishwa Vidyapeetham Virtual LabDocument1 pageBlack Body Radiation - Determination of Stefan's Constant (Simulator) - Heat & Thermodynamics Virtual Lab - Physical Sciences - Amrita Vishwa Vidyapeetham Virtual Labzarqullah javaidNo ratings yet

- Details To Assembly DRAWING: Maharashtra State Board of Technical Education, MumbaiDocument4 pagesDetails To Assembly DRAWING: Maharashtra State Board of Technical Education, MumbaiudayNo ratings yet

- Exp 4Document1 pageExp 4udayNo ratings yet

- Details To Assembly DRAWING: Maharashtra State Board of Technical Education, MumbaiDocument4 pagesDetails To Assembly DRAWING: Maharashtra State Board of Technical Education, MumbaiudayNo ratings yet

- 9th Lecture PPT ThermodynamicsDocument55 pages9th Lecture PPT ThermodynamicsudayNo ratings yet

- Exp 3Document1 pageExp 3udayNo ratings yet

- The Oak Island Money Pit: Remote Viewing Summary Sheet © Daz Smith - Do Not Distribute Without PermissionDocument49 pagesThe Oak Island Money Pit: Remote Viewing Summary Sheet © Daz Smith - Do Not Distribute Without PermissionJosh RNo ratings yet

- Roland XP-60 PDFDocument36 pagesRoland XP-60 PDFeliasNo ratings yet

- Sarsi Cola Life CycleDocument3 pagesSarsi Cola Life CycleMary Joy Credo LangamanNo ratings yet

- 1.HT Cables IntroductoryDocument8 pages1.HT Cables IntroductoryHarshad ChauhanNo ratings yet

- TOEFL Exercise Meeting 1Document6 pagesTOEFL Exercise Meeting 1Cindy ElthaNo ratings yet

- Translucent ConcreteDocument10 pagesTranslucent ConcreteSamuel Julca HuingoNo ratings yet

- NOS Lab - Viva 2Document37 pagesNOS Lab - Viva 2revathysrsNo ratings yet

- Black BookDocument12 pagesBlack BookSam ShaikhNo ratings yet

- Twincat ManualDocument46 pagesTwincat ManualKahMun LimNo ratings yet

- Object Oriented Programming: in PythonDocument29 pagesObject Oriented Programming: in PythonJohn mari CadNo ratings yet

- A CHOICE THEORY OF PLANNING EXAMINED THROUGH CURITIBADocument6 pagesA CHOICE THEORY OF PLANNING EXAMINED THROUGH CURITIBAAbhishek JaniNo ratings yet

- Vapor Liquid Equilibrium GraphsDocument7 pagesVapor Liquid Equilibrium Graphsmahbub1332No ratings yet

- Elevator Control System DesignDocument12 pagesElevator Control System DesignMohamad RidwanNo ratings yet

- MTE Schedule For Autumn Semester 2023-24Document16 pagesMTE Schedule For Autumn Semester 2023-24Shreya SinghNo ratings yet

- NP CompleteDocument32 pagesNP CompleteSabaniNo ratings yet

- PRSADocument1 pagePRSARaheel ShaikhNo ratings yet

- Energy Efficient ArchitectureDocument22 pagesEnergy Efficient ArchitectureNivedita Teja GadamsettyNo ratings yet

- Efficacy of Advanced Nutrients PH Perfect® Technology in Correcting and Stabilizing PH in HydroponicsDocument12 pagesEfficacy of Advanced Nutrients PH Perfect® Technology in Correcting and Stabilizing PH in HydroponicsJean SmithNo ratings yet

- DARPA GaN AdvancesDocument4 pagesDARPA GaN Advancesbring it onNo ratings yet

- Ex B150M V5Document26 pagesEx B150M V5FahrezaNo ratings yet

- Non Isentropic FlowDocument6 pagesNon Isentropic FlowswatiNo ratings yet

- Food Web WKSTDocument3 pagesFood Web WKSTapi-396884826100% (1)

- 44,000-Year-Old Indonesian Cave Painting Rewrites Art HistoryDocument1 page44,000-Year-Old Indonesian Cave Painting Rewrites Art Historyamiit_agNo ratings yet

- 2 Math Review Q1 (Value of a 3 digit number)Document3 pages2 Math Review Q1 (Value of a 3 digit number)N Plai PlaiNo ratings yet

- Unit 2 - Fire Safety: IFE Level 4 Certificate in Fire Science and Fire SafetyDocument6 pagesUnit 2 - Fire Safety: IFE Level 4 Certificate in Fire Science and Fire SafetyDebayanbasu.juNo ratings yet

- ID Perkawinan Janda Tanpa Akta Cerai Di KepDocument15 pagesID Perkawinan Janda Tanpa Akta Cerai Di KepSiti NurhasanahNo ratings yet

- Java InterfaceDocument6 pagesJava InterfacerajuvathariNo ratings yet

- SOB EpDocument39 pagesSOB EpAddisNo ratings yet

- SFX Machine Pro Read MeDocument6 pagesSFX Machine Pro Read MeJonOstiguyNo ratings yet