Professional Documents

Culture Documents

QC Flowchart TLV 20 Series

Uploaded by

Muhammad Taufiek AkbarCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

QC Flowchart TLV 20 Series

Uploaded by

Muhammad Taufiek AkbarCopyright:

Available Formats

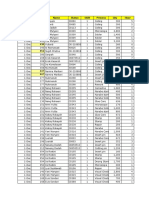

No Form.

QA-030002-QMS-11

QC FLOWCHART File No.QF-0013-TLV20-1st

Name of item Code No. Factory Prepare date approve Check Prepare R Edition Date approve Check Prepare

e 24,01,2019 Ratna Siti Tri

TLV 20 Series 1

SPI

PT. SPI PT. SPI PT. SPI

All code No. QA COIL QA COIL QA COIL

v

18-May-16 28 JUNI 2016 28 JUNI 2016

i

28 JUNI 2016

s

RATNA SITI N. YELNI

e

Check Point

Flowchart Confirmation Measuring

Degree Record Opr Insp Cert Jig Related Standart

Equipment

▽ Bobin Broken, bari Random Check Incoming Insp. ○ ○ Calliper Incoming Insp. Inruction

▽ Core Broken, crack (ANSIZ1.4) Record Work Intruction

◇ Incoming Insp. 5Pcs/normal Check RoHS Free Indication

◇ Label Check (10pcs/abnormal)

○ Bobin Assy Core Position , all quantity in QC Guarantee card ○ Automatic bobin Bobin assy jig Work Instruction

Core broken, bobin broken process Check report assy machine Check RoHS Free Indication

Appearance

▽ Pin Pin condition Random Check Incoming Insp. ○ ○ Micrometer Incoming Insp. Inruction

◇ Incoming Insp. Appearance, dimention (ANSIZ1.4) Record Calliper Work Intruction

◇ Label Check 5Pcs/normal

(10pcs/abnormal)

○ Insert pin Check tension Working start QC Guarantee card ○ Automatic pin assy Tension Meter Work Instruction

Appearance,spatial distance, all quantity in Check report machine Croket hook Check RoHS Free Indication

Length of pin, process Starting check

Make sure pin out of bobbin Check tension form

hole( based on spec)

▽ Wire Wire scratches, Wire damage Random Check Incoming Insp. ○ ○ Micrometer Incoming Insp. Inruction

◇ Incoming Insp. Pin hole test (ANSIZ1.4) Record Regulator Work Intruction

◇ Label Check Appearance, dimention 3 place/5m/ Calliper

Label Check Bobbin

○ Coiling Check tension Working start QC Guarantee card ○ Automatic coiling Tension Meter Work Instruction

Coiling on thepin Turn Quantity,Wire scratches, all quantity in Check report machine Processing Inspection

Wire damage,coiled shape, process Starting check Instruction for Production

Appearance,spatial distance, Check tension form Check RoHS Free Indication

Coiling on the pin Direction

Qty.Turn on the pin (follow list)

○ Pin press & Cutting Condition, Bobbin broken All quantity QC Guarantee card ○ Pin press machine Jig pin press Work Intruction

Cutting Pin bot bend,Length balance Process Check report

(based on spec) Starting check

Check length form

▽ Solder Solder condition Random Check Incoming inspection report ○ ○ Visual Incoming Inspection

▽ Flux, Thinner Flux and thinner condition (ANSIZ1.4) Instruction

◇ Incoming Insp. Check RoHS Free Indication

◇ Label Check

○ Solder Temp Follow work intruction Before start QC Guarantee card ○ ○ Solder lifter Waterpass Processing Inspection

Dipping time follow temperature Working Solder temp.report Machine Temp. Prove Instruction for Production

Solder content < 500 ppm 2 Times / Shift Vol.solder report Volume level Work Instruction

Solder condition(Not less, 1 Check sheet soldering check jig Check RoHS Free Indication

Not over, No solder brigding) Check report Solder Jig

Starting check Jig glue

▽ Ink Check label.Visual Random Check Incoming inspection report ○ ○ Visual Incoming Inspection

◇ Incoming Insp. Ink Condition (ANSIZ1.4) Instruction

◇ Label Check Check RoHS Free Indication

Work Instruction

○ Stamp Stamp position & condition all quantity in QC Guarantee card ○ Roller Work Intruction

Appearance process Stamp Pad List

Jig glue Give Indication RoHS Free

▽ Glue Check label.Visual Random Check Incoming inspection report ○ ○ Visual Incoming Inspection

◇ Incoming Insp. Glue condition (ANSIZ1.4) Instruction

◇ Label Check Work Instruction

Check RoHS Free Indication

○ Glue Apply Glue position & condition all quantity in QC Guarantee card ○ Dispenser Nozzle Work Instruction

Appearance process Starting check Air press Jig glue List

Check report

○ Drying Drying product condition all quantity in Oven Temp. report ○ Machine oven Temp. prove Work Instruction

Drying stamp condition process QC Guarantee card Timer List

Check report

Starting check

◇ Visual Check Appearance visual all all quantity in Visual check report ○ ○ Visual Terminal Check Work Instruction

Core broken,stamping, Glue process QC Guarantee card Jig Processing Inspection

Winding condition, pin, pitch, etc Instruction for Production

List

○ Pin Press Appearance pin measurement All quantity QC Guarantee card ○ Pin Press Machine Jig pin press Work Instruction

Pin balance Process

◇ Electrical check Follow standart electrical All quantity Starting Check ○ HVT Socket jig Work Intruction

(L meter、HVT、 Check Pin pitch Process QC Guarantee card ○ L meter Socket jig Processing Inspection

Rasio) Check report ○ Rasio Socket jig Instruction for Production

List

◇ Check Pin Appearance pin measurement all quantity in Visual check report ○ ○ Visual Check pin jig Work Instruction

Pin balance process QC Guarantee card List

○ Packing Packing methode, Stamp box All quantity QC Guarantee card ○ Equipment packing Work Instruction

Label product, qty label Process Give RoHS Free Indication

Outgoing Electrical check Random Check Outgoing Insp. ○ L meter Calliper Outgoing Insp. Inruction

Inspection Measurement check (ANSIZ1.4) Report R meter Work Intruction

Appearance check 5Pcs/normal HVT meter List

(10pcs/abnormal)

Packing Export Packing methode, Stamp box All quantity Delivery check ○ Work Intruction

Label product, qty label Process Report

▽ Export Delivery place, Qty Delivery

Mark ○

Process Remarks

▽ Ware House, Material

◇□ Inspection

〇 Transportation

You might also like

- QAP StructureDocument2 pagesQAP Structureayoki100% (1)

- Miscellaneous Tools Inspection Report (DPT) Page 1 of 1: Scope of Inspection Dye Penetrant Test On Ends & Full BodyDocument1 pageMiscellaneous Tools Inspection Report (DPT) Page 1 of 1: Scope of Inspection Dye Penetrant Test On Ends & Full BodyhamanjaloosNo ratings yet

- Final Inspection Report TurbineDocument20 pagesFinal Inspection Report TurbineMuhammad ZakiNo ratings yet

- Aql Report For Men and Ladies Barbour (New)Document146 pagesAql Report For Men and Ladies Barbour (New)Diether Jay DenampoNo ratings yet

- Form Pengukuran GroundingDocument2 pagesForm Pengukuran GroundingghooestiepNo ratings yet

- Control Plan PQCT TableIIDocument1 pageControl Plan PQCT TableIIRehman LatifNo ratings yet

- Control Plan PQCT TableII PDFDocument1 pageControl Plan PQCT TableII PDFRehman LatifNo ratings yet

- Control Plan PQCT TableII PDFDocument1 pageControl Plan PQCT TableII PDFVinh DuongvanNo ratings yet

- Inspection Standard: Daily Inprocess Inspection/Prod./Rejection ReportDocument3 pagesInspection Standard: Daily Inprocess Inspection/Prod./Rejection ReportPrakash kumarTripathiNo ratings yet

- Check Sheet Inspection: Position Actual Dimension Remark Drawing / SketchDocument1 pageCheck Sheet Inspection: Position Actual Dimension Remark Drawing / SketchJovianto PrisilaNo ratings yet

- List of Proposed External Provider (Suppliers) and Sources For Permanent MaterialsDocument14 pagesList of Proposed External Provider (Suppliers) and Sources For Permanent MaterialstuaburgmailcomNo ratings yet

- Attn: Akebono Braxe Astra VietnamDocument5 pagesAttn: Akebono Braxe Astra VietnamanhthoNo ratings yet

- S.P. Engineering Works: Part Inspection ReportDocument1 pageS.P. Engineering Works: Part Inspection ReportshalinmishraNo ratings yet

- Regulator General Operation and Maintenance Manual PDFDocument78 pagesRegulator General Operation and Maintenance Manual PDFAyyuby Fahni AndhikaNo ratings yet

- Inspection Standard: Daily Inprocess Inspection/Prod./Rejection ReportDocument5 pagesInspection Standard: Daily Inprocess Inspection/Prod./Rejection ReportPrakash kumarTripathiNo ratings yet

- Assy Oil Level Gauge P/No.: 5511692860 Oil Dipstick P/No.: 5501660444 Bracket Oil P/No.:5511692862Document1 pageAssy Oil Level Gauge P/No.: 5511692860 Oil Dipstick P/No.: 5501660444 Bracket Oil P/No.:5511692862Naswadi NawiNo ratings yet

- Rapid Fe1 TPX CMM SPN 0001 0901Document6 pagesRapid Fe1 TPX CMM SPN 0001 0901Đình NamNo ratings yet

- Inspection Report: KG-AH13 Rev. Drawing ADocument2 pagesInspection Report: KG-AH13 Rev. Drawing Along nguyễn vănNo ratings yet

- HACCP Blank Form 3Document1 pageHACCP Blank Form 3kristinemaemutiaNo ratings yet

- F-QC-01 Schedule For QC CheckDocument2 pagesF-QC-01 Schedule For QC CheckMechtek LabNo ratings yet

- Itp E0841-12Document4 pagesItp E0841-12Asep Barkah MuhadiNo ratings yet

- CONVEYORDocument1 pageCONVEYORfaiqnashrullahNo ratings yet

- Mas Register Civil 09-01-2020Document5 pagesMas Register Civil 09-01-2020Kannan MurugesanNo ratings yet

- Dashboard Export ReportDocument1 pageDashboard Export ReportSalman Ahmad KhanNo ratings yet

- Asrin's 采购申请表Purchasing Form202310211509000175546Document1 pageAsrin's 采购申请表Purchasing Form202310211509000175546AsrinNo ratings yet

- Test Certificate: Customer Saleh Zaid Ai Quralshi&Parteners TradDocument5 pagesTest Certificate: Customer Saleh Zaid Ai Quralshi&Parteners Tradalkaf08No ratings yet

- AnRing T-Joint Holder Orifice PlateDocument1 pageAnRing T-Joint Holder Orifice PlateFauzan RusmayadiNo ratings yet

- PT 001 PDFDocument1 pagePT 001 PDFDang sonNo ratings yet

- Air Damper Control System671 PDFDocument1 pageAir Damper Control System671 PDFSteve WanNo ratings yet

- Elom-35q-419 R4Document1 pageElom-35q-419 R4ariyakkannaa0% (1)

- Check Sheet Inspection: Position Actual Dimension Remark Drawing / SketchDocument1 pageCheck Sheet Inspection: Position Actual Dimension Remark Drawing / SketchJovianto PrisilaNo ratings yet

- Punch List For Blower Aug - 27Document2 pagesPunch List For Blower Aug - 27Siriepathi SeetharamanNo ratings yet

- Fit-Up Piping B192-5-S2Document22 pagesFit-Up Piping B192-5-S2Prathamesh OmtechNo ratings yet

- Invoice: No, Sjay-OsDocument1 pageInvoice: No, Sjay-Osajanta6788No ratings yet

- Riwayat Revisi No. Tanggal Isi Perubahan P.I.C Sebelum SesudahDocument3 pagesRiwayat Revisi No. Tanggal Isi Perubahan P.I.C Sebelum SesudahEva WidyasariNo ratings yet

- OML 58 Phase 1 Project Welders Qualification Log: Candiate IdDocument9 pagesOML 58 Phase 1 Project Welders Qualification Log: Candiate IdTheophilus OrupaboNo ratings yet

- Shift Log Book-10.08.23Document1 pageShift Log Book-10.08.23shaikshaju007No ratings yet

- Welder Test 18 December 2018Document1 pageWelder Test 18 December 2018NEMO MEMBUATNo ratings yet

- Process Flow Diagram (PFD) : Casting Out Source ProcessDocument1 pageProcess Flow Diagram (PFD) : Casting Out Source ProcessPRAMODNo ratings yet

- CP-SS BLK-01Document5 pagesCP-SS BLK-01yogesh WakchaureNo ratings yet

- QA MATRIX SHEET - RadiatorDocument4 pagesQA MATRIX SHEET - RadiatorBaljeet SinghNo ratings yet

- Pipebook Work Package 1Document39 pagesPipebook Work Package 1Renaldo akbarNo ratings yet

- Technohertz: Process Flow ChartDocument18 pagesTechnohertz: Process Flow ChartSeetharam shanmugamNo ratings yet

- 5W SheetDocument1 page5W Sheetgagandeep isherNo ratings yet

- Assembly - 349Document2 pagesAssembly - 349mughalNo ratings yet

- RAPID-FE1-TPX-CMM-SPN-0001-0903, Rev 1Document6 pagesRAPID-FE1-TPX-CMM-SPN-0001-0903, Rev 1Đình NamNo ratings yet

- Adobe Scan 19 Sep 2023Document3 pagesAdobe Scan 19 Sep 2023Navneet YadavNo ratings yet

- PT. Semen Gresik 02-1/206.045/750 Silo and Packing Plant: PreliminaryDocument119 pagesPT. Semen Gresik 02-1/206.045/750 Silo and Packing Plant: PreliminaryAdmin VendorNo ratings yet

- Repport UT CS - 7Document1 pageRepport UT CS - 7daemsalNo ratings yet

- Final - Pump - QAP - 5P0312ABCD - Antico - Code 4 PDFDocument1 pageFinal - Pump - QAP - 5P0312ABCD - Antico - Code 4 PDFRishabh VermaNo ratings yet

- NZWN 33.1 33.2Document2 pagesNZWN 33.1 33.2abang fayyadNo ratings yet

- Nipple 0,75 X 4in S80 - New OkDocument1 pageNipple 0,75 X 4in S80 - New OkJovianto PrisilaNo ratings yet

- 49612-74l10 Gap Flush Ok FilledDocument5 pages49612-74l10 Gap Flush Ok FilledajayNo ratings yet

- ITP Format - Excel GEP 1120Document22 pagesITP Format - Excel GEP 1120raghuvarma100% (1)

- Pipe Book - 27-04-2021Document47 pagesPipe Book - 27-04-2021Francis DhanarajNo ratings yet

- North Tank Farm and Loading Arms Facilities (Pkg.4) Contract No: 6600029560 Petrofac Job No: JI-2018Document2 pagesNorth Tank Farm and Loading Arms Facilities (Pkg.4) Contract No: 6600029560 Petrofac Job No: JI-2018ratheeshNo ratings yet

- Process Flow Diagram FORDocument17 pagesProcess Flow Diagram FORMartin AdasmeNo ratings yet

- Consistency Checklist (AutoRecovered)Document3 pagesConsistency Checklist (AutoRecovered)kotaksuratnidaNo ratings yet

- NO. Inspection/Test Item Action by Remarks Reference Document (S) Acceptance Criteria Method of InspectionDocument123 pagesNO. Inspection/Test Item Action by Remarks Reference Document (S) Acceptance Criteria Method of InspectionYoseph Maulana0% (1)

- Data Bis 1Document1 pageData Bis 1Muhammad Taufiek AkbarNo ratings yet

- Output Per Operator TRANS Desember 20211Document2,505 pagesOutput Per Operator TRANS Desember 20211Muhammad Taufiek AkbarNo ratings yet

- Daily Output TLF November 2021 (Update)Document269 pagesDaily Output TLF November 2021 (Update)Muhammad Taufiek AkbarNo ratings yet

- Daily Output TLV November 2021 (Update)Document48 pagesDaily Output TLV November 2021 (Update)Muhammad Taufiek AkbarNo ratings yet

- Daily Output TLF (Cell 1 Dan 2) Sep-Des 2021 (Update)Document209 pagesDaily Output TLF (Cell 1 Dan 2) Sep-Des 2021 (Update)Muhammad Taufiek AkbarNo ratings yet

- Turbocharger BalancingDocument3 pagesTurbocharger Balancingmick.pride81No ratings yet

- Preventive Maintenance of Automatic Capsule Filling - Pharmaceutical UpdatesDocument3 pagesPreventive Maintenance of Automatic Capsule Filling - Pharmaceutical UpdatesAhmad HamoudaNo ratings yet

- Aisc Audit Checklist For QC ManagerDocument2 pagesAisc Audit Checklist For QC ManagerSamson TatumNo ratings yet

- Corrective Action Report (CAR) : Bebitz Flanges Works PVT LTDDocument5 pagesCorrective Action Report (CAR) : Bebitz Flanges Works PVT LTDananthu.uNo ratings yet

- Connection Design As Per Bs en 1993-1-8:2005Document3 pagesConnection Design As Per Bs en 1993-1-8:2005waquarstrNo ratings yet

- Assignment 3 2022Document2 pagesAssignment 3 2022DICKSON SIMUTAMINo ratings yet

- Model 5803 Advance Control Base For The Modular Table System Maintenance and Repair ManualDocument43 pagesModel 5803 Advance Control Base For The Modular Table System Maintenance and Repair ManualSergio MontesNo ratings yet

- Maquina Modelo 1200Document4 pagesMaquina Modelo 1200Napoleon LedezmaNo ratings yet

- Comments On The Compressor Shelter PDFDocument2 pagesComments On The Compressor Shelter PDFtimothy ogbechieNo ratings yet

- Firme Nou InfintateDocument217 pagesFirme Nou InfintateC CorneliuNo ratings yet

- Vessel Lifting Lugs: Two-Plate Type: Engineering StandardDocument9 pagesVessel Lifting Lugs: Two-Plate Type: Engineering StandardJamil AhmadNo ratings yet

- BS ISO 24409-2-2014 Safety SignsDocument210 pagesBS ISO 24409-2-2014 Safety SignsPushkar Gopal100% (6)

- Loading On StructureDocument23 pagesLoading On Structurepepe wosNo ratings yet

- Friction WeldingDocument14 pagesFriction WeldingGopi NaikNo ratings yet

- Powertilt: Instruction, Service and Repair ManualDocument50 pagesPowertilt: Instruction, Service and Repair ManualSimon CooperNo ratings yet

- 07 Rawlbolts Plugs Anchors PDFDocument1 page07 Rawlbolts Plugs Anchors PDFLincolnNo ratings yet

- Fisher EZ Sliding - Stem Control Valve: The Easy - Et Valve FamilyDocument20 pagesFisher EZ Sliding - Stem Control Valve: The Easy - Et Valve FamilyAlberto GuillenNo ratings yet

- IOM - H-CE High Performance Coplanar Reduced Movement Couplings PDFDocument12 pagesIOM - H-CE High Performance Coplanar Reduced Movement Couplings PDFJhon SanabriaNo ratings yet

- Short Answers of ATDDocument8 pagesShort Answers of ATDPunith YadavNo ratings yet

- Apm E170Document130 pagesApm E170FigueiredoNo ratings yet

- 2rz - Valve Clearance InspectionDocument5 pages2rz - Valve Clearance Inspectionberdeaberdea100% (1)

- Piping Class Spec. - 1C22 (Lurgi)Document9 pagesPiping Class Spec. - 1C22 (Lurgi)otezgidenNo ratings yet

- PC100-6 S - N 40001-Up - Main Valve (1-Actuator) (10 - 10) (#40001-41229) 2Document2 pagesPC100-6 S - N 40001-Up - Main Valve (1-Actuator) (10 - 10) (#40001-41229) 2HeruNo ratings yet

- 1-22 PDF 20 NB Auto MPV ManualDocument22 pages1-22 PDF 20 NB Auto MPV ManualRagu Venkat33% (3)

- Reflected Ceiling PlanDocument1 pageReflected Ceiling PlanNeil Marc MarasiganNo ratings yet

- Crosby Terminator Warnings & Application InstructionsDocument1 pageCrosby Terminator Warnings & Application InstructionsWinston CuppNo ratings yet

- Face MillsDocument28 pagesFace MillsMatija HNo ratings yet

- LW0798 1Document284 pagesLW0798 1ferpimentel0590No ratings yet

- Installation Manual UAT (Y) P AGXYDocument136 pagesInstallation Manual UAT (Y) P AGXYJose CuevasNo ratings yet

- Price Master ListDocument20 pagesPrice Master ListKaren Balisacan Segundo Ruiz100% (1)