Professional Documents

Culture Documents

Cooling Tower Piping Methodology

Uploaded by

Erwin Sto'domingoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

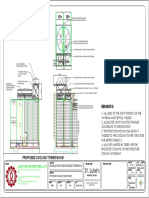

Cooling Tower Piping Methodology

Uploaded by

Erwin Sto'domingoCopyright:

Available Formats

Cooling Tower Piping Methodology

1.After Delivery of pipes and parts to the site hauling and segregation is

done to ensure and orderly installation.

2.Lay outing of the area and positioning of guide post.

3.Cutting down of pipes into size.

4.Fabrication of pipe segments and positioning to the area.

5.Fabrication and Installation of pipe support

6.Pipe fit up and tuck in of pipes to designated position

7.Full welding of pipes and flanges.

8.Securing of pipe segments on the top of pipe support using U-bolts

9.Installation of remaining pipe segments like elbows, tee, & joints.

10. Bolting of the flange connection with rubber gasket and

securing it in place

11. Final inspection of piping to the prepare it for leak testing and

flushing of pipes

Prepared by: Approved by:

Erwin R, Sto Domingo Daniel Ison_

Project in Charge Technical Manager

You might also like

- Construction Methodology Building OfficeDocument2 pagesConstruction Methodology Building OfficeElvyn Fabellore HerreraNo ratings yet

- Work Method Statement For Duct Installation: GeneralDocument2 pagesWork Method Statement For Duct Installation: Generalnice hossainNo ratings yet

- Main ER - SCOPE OF WORKSDocument6 pagesMain ER - SCOPE OF WORKSLeo DignadiceNo ratings yet

- Pre-Commissioning Checklist For New Assets Water Sites: Page 1 of 5Document5 pagesPre-Commissioning Checklist For New Assets Water Sites: Page 1 of 5u nizami0% (1)

- 0011-wms For Plumbing WorkDocument6 pages0011-wms For Plumbing WorkRaman BhadouriaNo ratings yet

- WATER SUPPLY EditDocument7 pagesWATER SUPPLY EditJia100% (1)

- Method Statement of Pipeline WorksDocument13 pagesMethod Statement of Pipeline Worksमनिसभेटुवाल86% (21)

- Construction Procedures of Concrete Encasement, Anchor, and Thrust BlocksDocument3 pagesConstruction Procedures of Concrete Encasement, Anchor, and Thrust BlocksJoe Mari CapaNo ratings yet

- Millau Viaduct Case StudyDocument14 pagesMillau Viaduct Case StudyDevendra Kumar KumarNo ratings yet

- MOS Mechanical Pipes LayingDocument3 pagesMOS Mechanical Pipes Layingmagdi badranNo ratings yet

- Construction Method Statement-GeneralDocument6 pagesConstruction Method Statement-GeneralShakila Nishani100% (1)

- Construction Methodology For RCP Pipe Laying Tapping To ExixtingDocument2 pagesConstruction Methodology For RCP Pipe Laying Tapping To ExixtingfelipeNo ratings yet

- Method Statement - Cable Tray ErectionDocument2 pagesMethod Statement - Cable Tray Erectionsoubhagya33% (3)

- Drainage & Retaining WallDocument3 pagesDrainage & Retaining WallMichael AjibadeNo ratings yet

- Method Statement For Installation of Water Reticulation Pipe by Pipe Jacking (Under Road)Document1 pageMethod Statement For Installation of Water Reticulation Pipe by Pipe Jacking (Under Road)Tuanren WuNo ratings yet

- Building Specs of NFC Juicing Plant Civil/ Structural/ Architectural/ PlumbingDocument6 pagesBuilding Specs of NFC Juicing Plant Civil/ Structural/ Architectural/ PlumbingMark Anthony Capito AñosNo ratings yet

- Construction of Pipe CulvertDocument3 pagesConstruction of Pipe CulvertnaseebNo ratings yet

- Technical Specifications (Architectural)Document32 pagesTechnical Specifications (Architectural)Ulysses MagbualNo ratings yet

- Technical Offer For Servomotor Upgrade FiplaDocument7 pagesTechnical Offer For Servomotor Upgrade Fiplaaloysius akpanNo ratings yet

- Acp pf3 Pipeline ConstructionDocument2 pagesAcp pf3 Pipeline ConstructionAHMED LASSOUEDNo ratings yet

- Method Statements For Watersupply NetworkDocument19 pagesMethod Statements For Watersupply NetworkShahab KhanNo ratings yet

- Part 1 - General: SECTION 15060 Hangers, Supports and Piping SpecialtiesDocument11 pagesPart 1 - General: SECTION 15060 Hangers, Supports and Piping SpecialtiesahmadNo ratings yet

- METHOD STATEMENT BridgeDocument2 pagesMETHOD STATEMENT BridgeSyira100% (2)

- Plumbing Method StatementDocument8 pagesPlumbing Method StatementNawarathna Engineering Dept.100% (1)

- Control of Sewerage and Surface Water DrainageDocument5 pagesControl of Sewerage and Surface Water DrainageTAHER AMMARNo ratings yet

- JKR Technical Spec - SewerageDocument11 pagesJKR Technical Spec - SewerageFareez RazakNo ratings yet

- Ir 3415 01Document1 pageIr 3415 01sameer hajwaniNo ratings yet

- 15 02 16 Scope of WorksDocument3 pages15 02 16 Scope of WorksRicarte Pillos IIINo ratings yet

- Method StatementDocument9 pagesMethod Statementtmopeli3130No ratings yet

- Control of Sewerage and Surface Water DrainageDocument4 pagesControl of Sewerage and Surface Water DrainageMichaelJamesBanawisNo ratings yet

- Methodology For Minor Bridges / Under Passes 1.0 Scope: Continental Engineering CorporationDocument10 pagesMethodology For Minor Bridges / Under Passes 1.0 Scope: Continental Engineering Corporationvenkateswara rao PothinaNo ratings yet

- Jbptppolban GDL Jhohanesve 12387 4 Bab5 8Document34 pagesJbptppolban GDL Jhohanesve 12387 4 Bab5 8Alexius YuliusNo ratings yet

- SECTION 02800 Cured in Place (Cip) Sewer Lining Part 1 - General 1.1Document10 pagesSECTION 02800 Cured in Place (Cip) Sewer Lining Part 1 - General 1.1cloantafNo ratings yet

- Metro Project LATESTDocument39 pagesMetro Project LATESTRahul ChauhanNo ratings yet

- برج طاقة خطوات تنفيذDocument3 pagesبرج طاقة خطوات تنفيذHassanien AlkhafajiNo ratings yet

- Ms For Basement WallsDocument3 pagesMs For Basement WallsMicheal B HaizenNo ratings yet

- Demolition Works Presentation 07052017 HCE COMMENT 1Document104 pagesDemolition Works Presentation 07052017 HCE COMMENT 1Yam BalaoingNo ratings yet

- Epic ProposalDocument8 pagesEpic ProposalMahpuja JulangNo ratings yet

- Technical CapabilityDocument15 pagesTechnical CapabilityS Victor SeleNo ratings yet

- 00 - MS - Electrical Galvanized Conduits InstallationDocument9 pages00 - MS - Electrical Galvanized Conduits Installationwalid khamaesah100% (1)

- Guino Bat AnDocument156 pagesGuino Bat AnMarvin CarcidoNo ratings yet

- Monitoring Form During Implementation - WaterDocument18 pagesMonitoring Form During Implementation - WaterAyna LaoNo ratings yet

- A Good Practice Guide For The Electrofusion Jointing of Larger Diameter Polyethylene Pressure PipesDocument20 pagesA Good Practice Guide For The Electrofusion Jointing of Larger Diameter Polyethylene Pressure PipesHilal Al KhuzaimiNo ratings yet

- MS For Basement One SlabDocument3 pagesMS For Basement One SlabMicheal B HaizenNo ratings yet

- SECTION 23 21 00: Underground Chilled Water Systems (Issued Ad-6)Document4 pagesSECTION 23 21 00: Underground Chilled Water Systems (Issued Ad-6)vuhalamNo ratings yet

- Robert C. Macatangay: Pipe FitterDocument3 pagesRobert C. Macatangay: Pipe FitterHarry DemeterioNo ratings yet

- Final MethodologiesDocument21 pagesFinal Methodologiesmarlon mamacNo ratings yet

- Quotation 40sqm W JacuzziDocument3 pagesQuotation 40sqm W JacuzziZee De Vera LaderasNo ratings yet

- Method Statement PlumbingDocument8 pagesMethod Statement Plumbinggvs raoNo ratings yet

- Swimming Pool Construction MethodologyDocument4 pagesSwimming Pool Construction MethodologyJayChristian Quimson67% (3)

- خطوات تنفيذ الخDocument3 pagesخطوات تنفيذ الخMohammed K. HayderNo ratings yet

- Method Statement Upvc UndergroundDocument2 pagesMethod Statement Upvc UndergroundMohammad AbrarNo ratings yet

- Work Method Statement FOR Street LightingDocument4 pagesWork Method Statement FOR Street LightingLynn MailNo ratings yet

- Method Statement For Installation of RO Skids Pressure Vessels and Connecting Pipes R1Document8 pagesMethod Statement For Installation of RO Skids Pressure Vessels and Connecting Pipes R1abimanyubawonoNo ratings yet

- METHOD STATEMENT FOR EARLY WORKS PACKAGE Rev-3 - Emaar The ViewsDocument6 pagesMETHOD STATEMENT FOR EARLY WORKS PACKAGE Rev-3 - Emaar The Viewsaliengineer953No ratings yet

- Hold Point InspectionDocument2 pagesHold Point Inspectionnike_y2kNo ratings yet

- MS For Sonic Logging - C487Document8 pagesMS For Sonic Logging - C487Anonymous S7Cq7ZDgPNo ratings yet

- Method Statement: ApprovalDocument21 pagesMethod Statement: ApprovalzhanghuiNo ratings yet

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- Manila PeninsulaDocument7 pagesManila PeninsulaErwin Sto'domingoNo ratings yet

- SUAL LCC 50S-Layout (A3-2)Document1 pageSUAL LCC 50S-Layout (A3-2)Erwin Sto'domingoNo ratings yet

- Cooling Tower Elevation (A-A) : Team EnergyDocument1 pageCooling Tower Elevation (A-A) : Team EnergyErwin Sto'domingoNo ratings yet

- St. Luke's: RemarksDocument1 pageSt. Luke's: RemarksErwin Sto'domingoNo ratings yet

- Cooling Tower Elevation (A-A) : Team EnergyDocument1 pageCooling Tower Elevation (A-A) : Team EnergyErwin Sto'domingoNo ratings yet

- 75Mm Diameter Schedule 40 Square Tube 60Mm 60Mm 6Mm ThickDocument1 page75Mm Diameter Schedule 40 Square Tube 60Mm 60Mm 6Mm ThickErwin Sto'domingoNo ratings yet

- Ms Plate 12Mm 75Mm Diameter Schedule 40Document1 pageMs Plate 12Mm 75Mm Diameter Schedule 40Erwin Sto'domingoNo ratings yet

- Quarterly ExaminationDocument20 pagesQuarterly ExaminationErwin Sto'domingoNo ratings yet

- Cooling Tower Foundation MethodologyDocument1 pageCooling Tower Foundation MethodologyErwin Sto'domingoNo ratings yet

- Letter of IntentDocument2 pagesLetter of IntentErwin Sto'domingoNo ratings yet

- Waste Disposal ManagementDocument3 pagesWaste Disposal ManagementErwin Sto'domingoNo ratings yet

- Cooling Tower Electrical MethodologyDocument1 pageCooling Tower Electrical MethodologyErwin Sto'domingoNo ratings yet

- Boq CoverDocument1 pageBoq CoverErwin Sto'domingoNo ratings yet

- Safety Plan and Program - CSHPDocument46 pagesSafety Plan and Program - CSHPErwin Sto'domingoNo ratings yet

- Gen Physics2 - G12Document8 pagesGen Physics2 - G12Erwin Sto'domingoNo ratings yet

- Console FinalDocument56 pagesConsole FinalErwin Sto'domingoNo ratings yet

- Grade-7 EspDocument11 pagesGrade-7 EspErwin Sto'domingoNo ratings yet

- Cooling Tower Parts and Piping Materials Lifting MethodologyDocument4 pagesCooling Tower Parts and Piping Materials Lifting MethodologyErwin Sto'domingoNo ratings yet

- Boom With Mounting BoltsDocument1 pageBoom With Mounting BoltsErwin Sto'domingoNo ratings yet

- Capstone ProjectDocument8 pagesCapstone ProjectErwin Sto'domingoNo ratings yet

- Periodical Midterm ExaminationDocument20 pagesPeriodical Midterm ExaminationErwin Sto'domingoNo ratings yet

- Capstone ProjectDocument6 pagesCapstone ProjectErwin Sto'domingoNo ratings yet

- Earth and Life Science - G11 HumssDocument4 pagesEarth and Life Science - G11 HumssErwin Sto'domingoNo ratings yet

- Energy ResourcesDocument29 pagesEnergy ResourcesErwin Sto'domingoNo ratings yet

- Mixturesand Pure SubstancesDocument21 pagesMixturesand Pure SubstancesArianne Jane Mae ManNo ratings yet

- MINERALSDocument22 pagesMINERALSErwin Sto'domingoNo ratings yet

- Genphysics ModuleDocument40 pagesGenphysics ModuleErwin Sto'domingoNo ratings yet