Professional Documents

Culture Documents

Conical Shells

Uploaded by

Eng-CalculationsOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Conical Shells

Uploaded by

Eng-CalculationsCopyright:

Available Formats

E Eng-Calculations

Conical shells

Values for calculation

Material

plate and strip/EN 10028-2/10CrMo9-10/1.7380/NT/5.2/16 < t ≤ 40

Calculation temperature

T 20 °C

Test temperature

Ttest 20 °C

Calculation pressure

P 4 MPa

Test pressure

Ptest 6 MPa

Inside diameter of the cone

Di 2016 mm

Semi angle of cone at apex

α 10 °

Testing group

Joint coefficient

z 0.7

0.2 % proof strength at temperature T

Rp 0.2/ T 300 MPa

0.2 % proof strength at temperature Ttest

Rp 0.2/ Ttest 300 MPa

1.0 % proof strength at temperature T

Rp 1.0/ T MPa

1.0 % proof strength at temperature Ttest

Rp 1.0/ Ttest MPa

Tensile strength

Rm /20 480 MPa

Tensile strength at temperature T

Rm / T MPa

Tensile strength at temperature Ttest

Rm / Ttest MPa

Calculation

Maximum value of the nominal design stress for normal

operating load cases

Rp 0.2/ T Rm /20 300 480

fd = min ( , ) = min ( , ) = 200MPa

1.5 2.4 1.5 2.4

Maximum value of the nominal design stress for testing

load cases

Rp 0.2/ Ttest 300

ftest = = = 285.7MPa

1.05 1.05

Required thickness of cone

P ⋅ Di 1 4 ⋅ 2016 1

econ = ⋅ = ⋅ = 29.67mm

2 ⋅ fd ⋅ z − P cos α 2 ⋅ 200 ⋅ 0.7 − 4 cos 10°

Required thickness of cone for testing load cases

Ptest ⋅ Di 1 6 ⋅ 2016 1

econtest = ⋅ = ⋅ = 21.72mm

2 ⋅ ftest − Ptest cos α 2 ⋅ 285.7 − 6 cos 10°

You might also like

- Solution Manual for an Introduction to Equilibrium ThermodynamicsFrom EverandSolution Manual for an Introduction to Equilibrium ThermodynamicsNo ratings yet

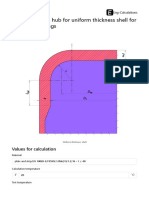

- Flat Ends With A Hub For Uniform Thickness ShellDocument5 pagesFlat Ends With A Hub For Uniform Thickness ShellEng-CalculationsNo ratings yet

- Cylindrical ShellsDocument3 pagesCylindrical ShellsEng-CalculationsNo ratings yet

- Spherical ShellsDocument3 pagesSpherical ShellsEng-CalculationsNo ratings yet

- Flat Ends Welded Directly To The ShellDocument9 pagesFlat Ends Welded Directly To The ShellEng-CalculationsNo ratings yet

- Flat End With A Full-Face Gasket For Single Isolated OpeningDocument3 pagesFlat End With A Full-Face Gasket For Single Isolated OpeningEng-CalculationsNo ratings yet

- Hemispherical EndsDocument3 pagesHemispherical EndsEng-CalculationsNo ratings yet

- Flat Ends With A Relief GrooveDocument11 pagesFlat Ends With A Relief GrooveEng-CalculationsNo ratings yet

- Conical Shells (7.6.4) EN 13445-3Document3 pagesConical Shells (7.6.4) EN 13445-3met-calcNo ratings yet

- Nozzles Which Encroach Into The Knuckle Region For Korbbogen Type EndDocument6 pagesNozzles Which Encroach Into The Knuckle Region For Korbbogen Type EndEng-CalculationsNo ratings yet

- Flat End With A Full-Face Gasket For A Pair of OpeningsDocument3 pagesFlat End With A Full-Face Gasket For A Pair of OpeningsEng-CalculationsNo ratings yet

- Flat Ends With A Hub For Uniform Thickness Shell For A Pair of OpeningsDocument5 pagesFlat Ends With A Hub For Uniform Thickness Shell For A Pair of OpeningsEng-CalculationsNo ratings yet

- Narrow Face Flange - Slip On Hub TypeDocument17 pagesNarrow Face Flange - Slip On Hub TypeEng-CalculationsNo ratings yet

- Flat End With A Full-Face GasketDocument3 pagesFlat End With A Full-Face GasketEng-CalculationsNo ratings yet

- Spherical Shells (7.4.3) EN 13445-3Document3 pagesSpherical Shells (7.4.3) EN 13445-3met-calcNo ratings yet

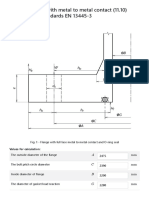

- Flange With Hole With Continuous Sealing Surface With Metal To Metal Contact (11.10.0) EN 13445-3Document4 pagesFlange With Hole With Continuous Sealing Surface With Metal To Metal Contact (11.10.0) EN 13445-3met-calcNo ratings yet

- Full Face Flange With Metal To Metal Contact (11.10) EN 13445-3Document5 pagesFull Face Flange With Metal To Metal Contact (11.10) EN 13445-3met-calcNo ratings yet

- Articulated Trunnion in The RodDocument6 pagesArticulated Trunnion in The RodEng-CalculationsNo ratings yet

- UHV Chambers - BirnbaumDocument16 pagesUHV Chambers - Birnbaumpique86No ratings yet

- 1 s2.0 S092037961000092X Main PDFDocument6 pages1 s2.0 S092037961000092X Main PDFevo2005_2006No ratings yet

- ASME e EN STDDocument23 pagesASME e EN STDmatteo2009No ratings yet

- UHV Standard ComponentsDocument101 pagesUHV Standard Componentschipulino100% (1)

- SHELL THICKNESS CHECK-ASME Section VIIIDocument2 pagesSHELL THICKNESS CHECK-ASME Section VIIIskocogluNo ratings yet

- Lethal ServiceDocument24 pagesLethal Servicewylie01No ratings yet

- Bolt Torque Calculation for Girth Flange-T-13311 - D2/D3: G * b * π * 2 g A Document2 pagesBolt Torque Calculation for Girth Flange-T-13311 - D2/D3: G * b * π * 2 g A Manoj MulikNo ratings yet

- 16 Preiss Study en 13445 Asme ViiiDocument26 pages16 Preiss Study en 13445 Asme ViiiDubaiHMARNo ratings yet

- Lethal Service GuideDocument5 pagesLethal Service GuidekingstonNo ratings yet

- Assignment CSTT 1Document21 pagesAssignment CSTT 1KHÁNH VÕ ĐĂNGNo ratings yet

- Design Check List Section VIII, Division 1: Drawing + Bill of Material (BOM)Document2 pagesDesign Check List Section VIII, Division 1: Drawing + Bill of Material (BOM)nirmalNo ratings yet

- ASME TrainingDev-Spring2014 PDFDocument8 pagesASME TrainingDev-Spring2014 PDFdeshpravinNo ratings yet

- 809-WS-ASME VIII Div 2 - Ellipsoidal Head Design - Rev0Document2 pages809-WS-ASME VIII Div 2 - Ellipsoidal Head Design - Rev0Sebastiano OrofinoNo ratings yet

- Section VIII CalDocument22 pagesSection VIII CalthodathersNo ratings yet

- Nozzle F Factor CalculationsDocument5 pagesNozzle F Factor CalculationsSivateja NallamothuNo ratings yet

- Design by AnalysisDocument22 pagesDesign by AnalysisJEELE77No ratings yet

- Astm A 20 20M - 00 PDFDocument31 pagesAstm A 20 20M - 00 PDFrc galinatoNo ratings yet

- Pipe Weight CalculatorDocument1 pagePipe Weight Calculatorkenho2No ratings yet

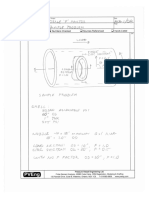

- WHRB-265!08!00 Front and Rear Mirrors, Shell CalculationDocument2 pagesWHRB-265!08!00 Front and Rear Mirrors, Shell CalculationmehmacarNo ratings yet

- Calculation For MACADocument1 pageCalculation For MACAsummit mmishraNo ratings yet

- Go Back To Wilson Supply Gas - Welding Supplies Page: AWS Class Polarity DescriptionDocument2 pagesGo Back To Wilson Supply Gas - Welding Supplies Page: AWS Class Polarity DescriptionmohamedabubackerNo ratings yet

- Pressure Test in Accordance With The Standard Din en 13445: Inspecta GroupDocument14 pagesPressure Test in Accordance With The Standard Din en 13445: Inspecta GroupNanang PhNo ratings yet

- Mozzle Repad Design ToolDocument2 pagesMozzle Repad Design ToolSiddiqui Muhammad AshfaqueNo ratings yet

- Comparison ASME KTADocument7 pagesComparison ASME KTAAndres_Pastor1987No ratings yet

- Deaera DesignDocument13 pagesDeaera DesignBhanu K PrakashNo ratings yet

- PD5500 - 133 - RectangularFlange CalculationDocument9 pagesPD5500 - 133 - RectangularFlange CalculationDarshan PanchalNo ratings yet

- Scope PED 97 23 EGDocument54 pagesScope PED 97 23 EGpham hoang quanNo ratings yet

- Unstiffened Cylinders EN 13445-3 - 8.5.2 PDFDocument4 pagesUnstiffened Cylinders EN 13445-3 - 8.5.2 PDFfrlamontNo ratings yet

- Weld Shear Stress Check For FAVID Clips Welded On CladDocument3 pagesWeld Shear Stress Check For FAVID Clips Welded On CladrsubramaniNo ratings yet

- Welding Calculation ModulDocument5 pagesWelding Calculation ModulricardoNo ratings yet

- Pvdci 1.2 Pressure Vessel Design As Per AsmeDocument15 pagesPvdci 1.2 Pressure Vessel Design As Per AsmeAdekimi EmmanuelNo ratings yet

- Tailing LugDocument2 pagesTailing Lugjagannadha varmaNo ratings yet

- Spherical Shells en 13445-3 - 7.4.3Document3 pagesSpherical Shells en 13445-3 - 7.4.3met-calc100% (1)

- Using The ASME VIII-1 Nozzle F Factor (UG-37)Document7 pagesUsing The ASME VIII-1 Nozzle F Factor (UG-37)stalin_83No ratings yet

- Eqn Reference ASME BPVC r1sDocument5 pagesEqn Reference ASME BPVC r1sagarcia654127No ratings yet

- Channel Thickness Calculation: 1 Design Data: CO2 Condenser / Liquefier Design Code of ConstructionDocument6 pagesChannel Thickness Calculation: 1 Design Data: CO2 Condenser / Liquefier Design Code of ConstructionGaurav BedseNo ratings yet

- What Is NACE - MR0175 - MR0103 - en - Us - 17202Document1 pageWhat Is NACE - MR0175 - MR0103 - en - Us - 17202super51214No ratings yet

- Beam Spreadsheet: Ignore Lateral Torsional BucklingDocument5 pagesBeam Spreadsheet: Ignore Lateral Torsional BucklingPurnima ArkalgudNo ratings yet

- HE Header E535Document91 pagesHE Header E535rizal mubarokNo ratings yet

- Bolts Torque CalculatorDocument2 pagesBolts Torque CalculatorsopapilasNo ratings yet

- Flat Ends Welded Directly To The Shell For A Pair of OpeningsDocument8 pagesFlat Ends Welded Directly To The Shell For A Pair of OpeningsEng-CalculationsNo ratings yet

- Flat End With A Full-Face Gasket For A Pair of OpeningsDocument3 pagesFlat End With A Full-Face Gasket For A Pair of OpeningsEng-CalculationsNo ratings yet

- Fatigue Strength of Unwelded ComponentsDocument2 pagesFatigue Strength of Unwelded ComponentsEng-CalculationsNo ratings yet

- Flat Ends With A Hub For Uniform Thickness Shell For A Pair of OpeningsDocument5 pagesFlat Ends With A Hub For Uniform Thickness Shell For A Pair of OpeningsEng-CalculationsNo ratings yet

- Junction Between The Large End of A Cone and A Cylinder Without A KnuckleDocument3 pagesJunction Between The Large End of A Cone and A Cylinder Without A KnuckleEng-CalculationsNo ratings yet

- Flat Ends Welded Directly To The Shell For A Pair of OpeningsDocument8 pagesFlat Ends Welded Directly To The Shell For A Pair of OpeningsEng-CalculationsNo ratings yet

- Nozzles Which Encroach Into The Knuckle Region For Korbbogen Type EndDocument6 pagesNozzles Which Encroach Into The Knuckle Region For Korbbogen Type EndEng-CalculationsNo ratings yet

- Narrow Face Flange - Smooth BoreDocument17 pagesNarrow Face Flange - Smooth BoreEng-CalculationsNo ratings yet

- Nozzles Which Encroach Into The Knuckle Region For Kloepper Type EndDocument7 pagesNozzles Which Encroach Into The Knuckle Region For Kloepper Type EndEng-CalculationsNo ratings yet

- Narrow Face Flange - Slip On Hub Type For External PressureDocument23 pagesNarrow Face Flange - Slip On Hub Type For External PressureEng-CalculationsNo ratings yet

- Full Face Flanges With Metal To Metal ContactDocument6 pagesFull Face Flanges With Metal To Metal ContactEng-CalculationsNo ratings yet

- Narrow Face Flange - Slip On Hub TypeDocument17 pagesNarrow Face Flange - Slip On Hub TypeEng-CalculationsNo ratings yet

- The Flow Characteristic (Hydraulic Cylinder)Document18 pagesThe Flow Characteristic (Hydraulic Cylinder)Eng-CalculationsNo ratings yet

- The Flow Characteristic (Gearbox)Document6 pagesThe Flow Characteristic (Gearbox)Eng-CalculationsNo ratings yet

- Hemispherical EndsDocument3 pagesHemispherical EndsEng-CalculationsNo ratings yet

- Key(s) For Shaft Hub ConnectionDocument7 pagesKey(s) For Shaft Hub ConnectionEng-CalculationsNo ratings yet

- Flat Face Flanges With Metal-To-metal Contact Outside The Bolt Circle For Class 1 Flange Assembly (Identical Flange Pairs)Document15 pagesFlat Face Flanges With Metal-To-metal Contact Outside The Bolt Circle For Class 1 Flange Assembly (Identical Flange Pairs)Eng-CalculationsNo ratings yet

- Square Head For Shaft-Hub ConnectionDocument7 pagesSquare Head For Shaft-Hub ConnectionEng-CalculationsNo ratings yet

- Hydrodynamic Calculation Vertical Lift GatesDocument35 pagesHydrodynamic Calculation Vertical Lift GatesEng-CalculationsNo ratings yet

- Hydrodynamic Calculation Butterfly Valve Lenticular Disc $S - D 0.26$Document30 pagesHydrodynamic Calculation Butterfly Valve Lenticular Disc $S - D 0.26$Eng-CalculationsNo ratings yet

- The Flow Characteristic (Crank Mechanism)Document8 pagesThe Flow Characteristic (Crank Mechanism)Eng-CalculationsNo ratings yet

- Hydrodynamic Calculation Butterfly Valve Lenticular Disc $S - D$ 0.16Document30 pagesHydrodynamic Calculation Butterfly Valve Lenticular Disc $S - D$ 0.16Eng-CalculationsNo ratings yet

- Articulated Trunnion in The RodDocument6 pagesArticulated Trunnion in The RodEng-CalculationsNo ratings yet

- Contact Stress of The Sphere in The Sphere SocketDocument3 pagesContact Stress of The Sphere in The Sphere SocketEng-CalculationsNo ratings yet

- Contact Stress Two SphereDocument3 pagesContact Stress Two SphereEng-CalculationsNo ratings yet

- Contact Stress Two CylindersDocument3 pagesContact Stress Two CylindersEng-CalculationsNo ratings yet

- Thickness of Shells Under Internal Pressure For Cylindrical ShellsDocument2 pagesThickness of Shells Under Internal Pressure For Cylindrical ShellsEng-CalculationsNo ratings yet

- New Product Development ProcessDocument12 pagesNew Product Development ProcessAyushi SinghNo ratings yet

- AnyLogic 6 System Dynamics Modeling TutorialDocument25 pagesAnyLogic 6 System Dynamics Modeling TutorialAlphonso AndrewsNo ratings yet

- Ise Online Access For Introduction To Operations Research 11Th Edition Hillier Full ChapterDocument51 pagesIse Online Access For Introduction To Operations Research 11Th Edition Hillier Full Chapterdarrell.berry639100% (4)

- Auditing Quiz - Cash and Cash EquivalentsDocument2 pagesAuditing Quiz - Cash and Cash EquivalentsRonel CaagbayNo ratings yet

- Finrl: Deep Reinforcement Learning Framework To Automate Trading in Quantitative FinanceDocument9 pagesFinrl: Deep Reinforcement Learning Framework To Automate Trading in Quantitative FinancegyhtujrtyNo ratings yet

- Who Painted That The Authorship of Schematic Rock Art at The Los Machos Rockshelter in Southern IberiaDocument19 pagesWho Painted That The Authorship of Schematic Rock Art at The Los Machos Rockshelter in Southern Iberiasolefernandez2000No ratings yet

- Seismic Analysis From NSCP 2015Document70 pagesSeismic Analysis From NSCP 2015Irish TambisNo ratings yet

- Focus ForecastingDocument4 pagesFocus ForecastingVedant MishraNo ratings yet

- Introduction To Industry 4.0 and Industrial IoT Week 3 Quiz SolutionsDocument5 pagesIntroduction To Industry 4.0 and Industrial IoT Week 3 Quiz SolutionssathyaNo ratings yet

- Qualifying Exam Study Guide 01-26-2018Document20 pagesQualifying Exam Study Guide 01-26-2018Abella, Marilou R. (marii)No ratings yet

- International StandardDocument52 pagesInternational StandardismaelarchilacastilloNo ratings yet

- Lido - RouteManual Bulletin 01 - 2018-v4-20180510 - 0905Document8 pagesLido - RouteManual Bulletin 01 - 2018-v4-20180510 - 0905Amine ChabchoubNo ratings yet

- Imo Signs: Safety Officer's GuideDocument60 pagesImo Signs: Safety Officer's Guidemarko nežićNo ratings yet

- BOECO Hydrometer Alcohol Meter PDFDocument5 pagesBOECO Hydrometer Alcohol Meter PDFTianTrafNo ratings yet

- Local Viz Anatomy of Type PosterDocument2 pagesLocal Viz Anatomy of Type PosterdvcvcNo ratings yet

- Chapter 5.2 Solutions - Numerical Analysis 9th EditionDocument1 pageChapter 5.2 Solutions - Numerical Analysis 9th EditionAmn RaheNo ratings yet

- The Enlightenment Legacy of Darwin, Freud and MarxDocument18 pagesThe Enlightenment Legacy of Darwin, Freud and MarxPaula HicksNo ratings yet

- Tle CSS9 Q3 M6Document13 pagesTle CSS9 Q3 M6caberjhandereugeneNo ratings yet

- Cochlear Implant Brand Comparison Latest Models OnlyDocument26 pagesCochlear Implant Brand Comparison Latest Models OnlyCorina Ruiz ParedesNo ratings yet

- PHILIPS RC133V W62L62 1 xLED36S840 OC PDFDocument3 pagesPHILIPS RC133V W62L62 1 xLED36S840 OC PDFNavneet SinghNo ratings yet

- Infra-View LitDocument2 pagesInfra-View LitGavinsiauNo ratings yet

- Winning With Accountability 00Document7 pagesWinning With Accountability 00am_mail0% (1)

- Chapter 3 - Process Safety ManagementDocument43 pagesChapter 3 - Process Safety ManagementAndre Novent Chenady100% (1)

- Dual Plate 800 NB-ModelDocument1 pageDual Plate 800 NB-ModelTanmoy DuttaNo ratings yet

- GulfSea Turbine Oil Series PDFDocument2 pagesGulfSea Turbine Oil Series PDFObydur RahmanNo ratings yet

- Tienlongtech-So Tay Ac Quy PanasonicDocument75 pagesTienlongtech-So Tay Ac Quy PanasonicThuận LêNo ratings yet

- Hassas Döküm Genel HatlarıDocument56 pagesHassas Döküm Genel HatlarıUgur KayaNo ratings yet

- Review XXX ACS Guide 2014Document2 pagesReview XXX ACS Guide 2014Vinod ManjuNo ratings yet

- Keenan Et Al, 2013Document5 pagesKeenan Et Al, 2013Marcela LúciaNo ratings yet

- Checklist: I. Q & A II. Ôn tập QuizzesDocument19 pagesChecklist: I. Q & A II. Ôn tập QuizzesLê Hoàng Minh ThưNo ratings yet