Professional Documents

Culture Documents

Efficient pre-cleaning machine UNIclean B 12

Uploaded by

Kuamr 1234Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Efficient pre-cleaning machine UNIclean B 12

Uploaded by

Kuamr 1234Copyright:

Available Formats

Rieter - UNIclean B 12

Efficient and reliable pre-cleaning

RIETER – YOUR SYSTEMS SUPPLIER

Integrated installations from Rieter off er more than just spinning machinery covering the entire process range from the fi ber to the yarn. Perfect coordination of

the

machines throughout the process chain ensures economical manufacturing of the required yarn quality. In addition to its machine expertise and as a result of

numerous technical innovations, Rieter off ers its customers support from the original business idea right through to the achievement of market success through

yarn innovations.

RIETER – YOUR PARTNER FOR THE FUTURE

With Rieter as your partner you benefi t from the following supplementary services:

· Complete mill planning, spinning schedule computation and cost calculation

· Automation options tailored exactly to customer needs

· SPIDERweb data acquisition system for on-line monitoring of the entire spinning mill

· Process optimization and technical recommendations derived

from broad-based technological expertise covering all spinning process stages right through to downstream processing

· World-wide service network and intensive customer training on-site or at the Rieter Training Center

· Spare parts deliveries, a broad range of innovative and technically superb solutions in the sphere of conversions

You can have confi dence in solutions from Rieter!

The UNIclean B 12 is an effi cient cleaning and dust extracting machine which is used directly downstream from the bale opening. Cotton and other natural fi bers

such as fl ax can be cleaned and freed from dust. Feeding of the card room is guaranteed for a total of 1 400 kg/h card sliver production.

ECONOMICAL

· Production of up to 1 400 kg/h card sliver

· Available for lower production rates of up to 1 000 kg/h card sliver

· Optimum raw material utilization

· Low air and space requirements

· Low maintenance

FLEXIBLE

· For all types of cotton

· Easy adjustment whilst running

· Multiple assortment operation possible

TECHNOLOGY

· Continuous throughput machine without nipping and the use of grid knives results in gentle cleaning

· High cleaning performance

· Intensive dust extraction

· VarioSet

SYSTEM MODULE

· Part of the Rieter blowroom philosophy

· Connection to the blowroom control system UNIcontrol or UNIcommand

Mode of operation

THE UNIQUE WORKING PRINCIPLE :The material is fed to the UNIclean B 12 where it is picked up by special pins and passed fi ve times mechanically over the

cleaning grid. During the process the raw material is guided over the integrated dust extracting filter where dust, fi ber fragments and fi ne trash particles are

stripped off mechanically. The combination of newly developed grid bars, optimized material flow and increased dedusting area guarantees an effi cient cleaning

effect also at high rates of production. The cleaning process is not affected by air currents and is thus controlled and effective.

Only approx. 0,5 m3/s of dust-laden air has therefore to be removed. The trash removed drops into the waste chamber and is transferred to the waste removal

system by an airlock cylinder. Since the UNIclean B 12 occupies little space it can be incorporated easily into other manufacturers’ lines. Thus the cleaning

performance of existing installations is enhanced.

Effective cleaning and dust extraction

CLEANING CONCEPT :The UNIfloc supplies very small tufts of material. The

UNIclean exploits this large surface area. Located immediately downstream from the bale opener, the UNIclean removes loose trash particles,

fiber fragments and dust. It is designed for intensive cleaning. The subsequent process stages have to remove only a small fraction of the trash.

At the same time the fi bers are treated gently. Results in practice have shown fiber

yields to be up to 2% higher than when conventional blowroom lines are used. That pays off .

OPTIMUM CLEANING :High cleaning performance and low losses of good fiber can be quickly checked by visual waste control. The quality of

waste removal can also be assessed whilst the machine is in operation.

SIMPLE AND REPRODUCIBLE SETTINGS

Two independent setting parameters: cleaning intensity and relative quantity of waste, are the secrets of the selective cleaning action of the UNIclean B 12. Each

of the VarioSet 110 working points corresponds to one setting of material speed and grid angle. Compared to conventional lines fiber yield is increased while

effective cleaning is performed.

VERY EASY OPERATION

Two values are entered to the VarioSet: cleaning intensity set between 0,0 and 1,0, and relative quantity of waste set between 1 and 10. These values are

entered directly into the machine itself or are loaded via the control system. The machine settings are made automatically, even whilst the machine is in operation.

The settings are reproducible. This provides a high level of operating convenience when batch changes are frequent.

UNIQUE MULTI-ASSORTMENT OPERATION

The material-specific working point is selected automatically on the UNIclean if the UNIfl oc is opening different assortments.

You might also like

- A 12 UNIfloc Leaflet 2936-V11 86370 Original English 86370Document2 pagesA 12 UNIfloc Leaflet 2936-V11 86370 Original English 86370Yogeshkumar j joshi100% (1)

- D 24 SpareDocument395 pagesD 24 SparevenkatspinnerNo ratings yet

- Trutzschler BRDocument90 pagesTrutzschler BRPraveen SahniNo ratings yet

- Modern Spinning Machineries Maintenance PracticalDocument116 pagesModern Spinning Machineries Maintenance Practicalmasum_austNo ratings yet

- Machinery 40 - 14Document6 pagesMachinery 40 - 14Mohamed NaeimNo ratings yet

- LCC Card Clothing InternationalDocument16 pagesLCC Card Clothing Internationalkavin bhagavathyNo ratings yet

- Required All Chemical & Auxiliaries in The Textile Dyeing Process & Their Function.Document13 pagesRequired All Chemical & Auxiliaries in The Textile Dyeing Process & Their Function.Md Raihan Hossain100% (1)

- GBS (German-Tech Braking System)Document20 pagesGBS (German-Tech Braking System)vivekpattniNo ratings yet

- Rieter Rotor Semi r36 Brochure 3101 v1 87068 enDocument28 pagesRieter Rotor Semi r36 Brochure 3101 v1 87068 enHai PhamNo ratings yet

- Industrial ReportDocument64 pagesIndustrial Reportfuad ullahNo ratings yet

- Gravure Coating Systems ReviewDocument7 pagesGravure Coating Systems ReviewHiba NaserNo ratings yet

- TWC-TM031 Dimensional Stability of Wool Textiles After Laundering 2010Document32 pagesTWC-TM031 Dimensional Stability of Wool Textiles After Laundering 2010Sebastián NúñezNo ratings yet

- NanTong TongJi Machine QuotationDocument14 pagesNanTong TongJi Machine Quotationyeneneh14No ratings yet

- Fabric Inspection Machines For KnitsDocument2 pagesFabric Inspection Machines For KnitsGarima DhimanNo ratings yet

- Manual & Troubleshooting CC3Document161 pagesManual & Troubleshooting CC3Konami BogorNo ratings yet

- Woven Orchard Protection Crop Cover SpecificationDocument18 pagesWoven Orchard Protection Crop Cover SpecificationVinay Tripathi100% (1)

- Automatic film sealing and cutting machine operation guideDocument20 pagesAutomatic film sealing and cutting machine operation guidesetavietnamNo ratings yet

- Fan TV425Document87 pagesFan TV425Khaled RabeaNo ratings yet

- PROCESS CONER II OPERATION AND MAINTENANCE GUIDEDocument24 pagesPROCESS CONER II OPERATION AND MAINTENANCE GUIDEMd Hanif SonketNo ratings yet

- 03 ITMAweaving - OKDocument38 pages03 ITMAweaving - OKHarryNo ratings yet

- Welcome ToDocument18 pagesWelcome Toنور الإسلامNo ratings yet

- Gromax Trakstar 545Document14 pagesGromax Trakstar 545Fred Wilf0% (1)

- Production Order in SAP CO01 MD16 CO02 CO15Document13 pagesProduction Order in SAP CO01 MD16 CO02 CO15Muhammad GamalNo ratings yet

- Zinser Roving Frames.: Faster - Because We Know How.Document24 pagesZinser Roving Frames.: Faster - Because We Know How.Nahesh SDNo ratings yet

- Machines UnilapDocument6 pagesMachines Unilapashar khanNo ratings yet

- Sigmasys CDocument138 pagesSigmasys CJúnior MarquesNo ratings yet

- Panasonic A5 Operation BasicDocument29 pagesPanasonic A5 Operation BasicaaauserhoyNo ratings yet

- Factors Affecting Fabric ShrinkageDocument6 pagesFactors Affecting Fabric Shrinkageনাজীম সরোয়ারNo ratings yet

- Achieve 15% Water Savings and 7% Cost Reduction in Textile ManufacturingDocument9 pagesAchieve 15% Water Savings and 7% Cost Reduction in Textile ManufacturingDiksha SinghNo ratings yet

- Behavioral analysis of Slub yarn Fabrics on Sustainable in Technical textilesDocument9 pagesBehavioral analysis of Slub yarn Fabrics on Sustainable in Technical textilesAkash SribathNo ratings yet

- Your global textile specialistDocument61 pagesYour global textile specialistMAYANK AGARWALNo ratings yet

- Jat 810 - Air SavingDocument2 pagesJat 810 - Air SavinghirenNo ratings yet

- 60 BPM CSD For 250 ML Arvind AquaDocument17 pages60 BPM CSD For 250 ML Arvind AquaOMKAR JADHAVNo ratings yet

- Cotton Ginning ProcessesDocument16 pagesCotton Ginning ProcessesSuMit PaTilNo ratings yet

- IS 16202 Agro Textiles - Woven Ground Covers For Horticulture Application - SpecificationDocument11 pagesIS 16202 Agro Textiles - Woven Ground Covers For Horticulture Application - SpecificationVinay TripathiNo ratings yet

- Saiham Knit Profile PDFDocument14 pagesSaiham Knit Profile PDFsaidurtexNo ratings yet

- Weaving Loom Parts Catalogue Van de Wiele SpareDocument23 pagesWeaving Loom Parts Catalogue Van de Wiele SpareRamesh HspNo ratings yet

- UQ3 Techdata en 201905 PDFDocument13 pagesUQ3 Techdata en 201905 PDFVishnuMaliNo ratings yet

- Pleva BrochureDocument7 pagesPleva Brochuresyedraza1No ratings yet

- Ymt 2 ManualDocument32 pagesYmt 2 ManualRahul Patel100% (1)

- Brochure - PNEUMATIC TYRED ROLLERSDocument16 pagesBrochure - PNEUMATIC TYRED ROLLERSRiham EquipmentNo ratings yet

- Effect of Raising and Finishing ProcessDocument10 pagesEffect of Raising and Finishing ProcessShahin ghasemi nezhadNo ratings yet

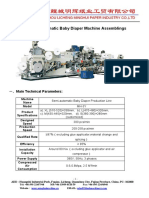

- Semi Automatic Baby Diaper Machine 2011-07-09Document6 pagesSemi Automatic Baby Diaper Machine 2011-07-09ZakNo ratings yet

- StollDocument120 pagesStollunwel comNo ratings yet

- Printing RollflexDocument153 pagesPrinting RollflexsalvatorusNo ratings yet

- Rieter c70 Card Brochure 2810 v3 89526 enDocument32 pagesRieter c70 Card Brochure 2810 v3 89526 enzubairNo ratings yet

- Object of BlendingDocument5 pagesObject of Blendingnazmul wasickNo ratings yet

- Novelty Yarns FundamentalsDocument37 pagesNovelty Yarns FundamentalsRS DEVAJATHANo ratings yet

- Rieter Special Print Recycling 3379 v1n en 02 PDFDocument44 pagesRieter Special Print Recycling 3379 v1n en 02 PDFMohamed NaeimNo ratings yet

- Quality of SocksDocument13 pagesQuality of SocksHamad HRNo ratings yet

- Trutzschler CombingDocument54 pagesTrutzschler CombingPraveen SahniNo ratings yet

- Trutzschler Auto Leveller Draw Frame TD 03 - ManualDocument18 pagesTrutzschler Auto Leveller Draw Frame TD 03 - Manualali ihsan100% (1)

- Contoh User ManualDocument74 pagesContoh User Manualaziz abdulNo ratings yet

- TT 403 Ginning TechnologyDocument45 pagesTT 403 Ginning Technologymt khan100% (2)

- DHC-100 Relative Humidity ControllerDocument1 pageDHC-100 Relative Humidity ControllerMJBControlsNo ratings yet

- English Savio Polar MDocument506 pagesEnglish Savio Polar MAyleen KuziNo ratings yet

- Sodexo Delights Premier rewards platform guideDocument4 pagesSodexo Delights Premier rewards platform guideGkiniNo ratings yet

- Frequency Cleaning / Inspection Points Lubricating Points Type of LubricantDocument3 pagesFrequency Cleaning / Inspection Points Lubricating Points Type of LubricantKrishnamurthy NatarajanNo ratings yet

- Submitted by Sakshi Singh Himadri VyasDocument39 pagesSubmitted by Sakshi Singh Himadri VyasSakshi SinghNo ratings yet

- BEN-BLEACH Desizing, Scouring and Bleaching MachineDocument16 pagesBEN-BLEACH Desizing, Scouring and Bleaching MachinearjmandquestNo ratings yet

- L410 Maintenance Manual Chapter OverviewDocument26 pagesL410 Maintenance Manual Chapter OverviewGims BuafNo ratings yet

- Manual E7370Document12 pagesManual E7370Carlos Rodríguez MartínNo ratings yet

- Foundation Design Philosophy For Rotating EquipmentDocument7 pagesFoundation Design Philosophy For Rotating EquipmentKyaw Kyaw AungNo ratings yet

- Accident Investigation, Reporting and Analysis: Safety Engineering and Management For MEDocument38 pagesAccident Investigation, Reporting and Analysis: Safety Engineering and Management For MEAndre De VillaNo ratings yet

- Coursebook Analysis Jeremy Harmer How To Teach English Pearson 2007Document1 pageCoursebook Analysis Jeremy Harmer How To Teach English Pearson 2007Jamie Leigh McGeorgeNo ratings yet

- Powerdrive X6: Rotary Steerable System For High-Performance Drilling and Accurate Wellbore PlacementDocument6 pagesPowerdrive X6: Rotary Steerable System For High-Performance Drilling and Accurate Wellbore PlacementClOudyo VirgílioNo ratings yet

- 3.1 HW AssignmentDocument1 page3.1 HW AssignmentIntanrepuNo ratings yet

- C#Brain TeasersDocument5 pagesC#Brain TeasersNishant.kumaridNo ratings yet

- IEEE MicropowerSystemModelingWithHOMERDocument5 pagesIEEE MicropowerSystemModelingWithHOMERAnnas QureshiNo ratings yet

- Bonifacio Elementary School Answer SheetDocument17 pagesBonifacio Elementary School Answer Sheetaries sumalbagNo ratings yet

- Introductory2014 Lesson1 2DDocument32 pagesIntroductory2014 Lesson1 2DMu HardiNo ratings yet

- Monitor Transformer Temperatures with PC-414R IndicatorDocument4 pagesMonitor Transformer Temperatures with PC-414R IndicatorMKNo ratings yet

- Floriculture Industry in IndiaDocument93 pagesFloriculture Industry in Indiahshah56750% (4)

- 3x Anglais Ecran-4Document4 pages3x Anglais Ecran-4EMRE KAAN USTANo ratings yet

- CBC-Tailoring NC IIDocument66 pagesCBC-Tailoring NC IICharmaine Mae RetizaNo ratings yet

- Writing Task 1 - Integrated Question (Test #12) : Your Guide For TOEFL Writing 24+Document3 pagesWriting Task 1 - Integrated Question (Test #12) : Your Guide For TOEFL Writing 24+AstridBarraNo ratings yet

- Major Report Wood LumberDocument45 pagesMajor Report Wood LumberTorreja JonjiNo ratings yet

- MEC 2309 Lecture 00 - Course Outline and AssessmentDocument11 pagesMEC 2309 Lecture 00 - Course Outline and Assessmentlubuto TuntepeNo ratings yet

- Oracle Applications Invntory Training ManualDocument171 pagesOracle Applications Invntory Training ManualSivaNo ratings yet

- Axisymm TutorialDocument15 pagesAxisymm Tutorialmudur6No ratings yet

- Engineering Drawing Abbreviations and SymbolsDocument21 pagesEngineering Drawing Abbreviations and Symbolsshivajitagi100% (2)

- (Atlas Copco) - Industrial Power Tools 2012Document332 pages(Atlas Copco) - Industrial Power Tools 2012mg_catana100% (1)

- Tir A9 14 PDFDocument99 pagesTir A9 14 PDFGino Tironi100% (7)

- Consulting IndustryDocument34 pagesConsulting Industryaayushpahuja2824No ratings yet

- Taper Roller BearingDocument130 pagesTaper Roller BearingAbhishek KumarNo ratings yet

- Evolution - The Dissent of DarwinDocument7 pagesEvolution - The Dissent of DarwinluminitalupuliasaNo ratings yet

- Exit StrategyDocument2 pagesExit StrategyMuhammad KashifNo ratings yet

- Mass and Energy Balancing Calculations For Plant ChapterDocument50 pagesMass and Energy Balancing Calculations For Plant ChapterRamesh SoniNo ratings yet

- Linked PDFDocument337 pagesLinked PDFDmytro PichkurNo ratings yet

- Final - Research - Paper (Face Recognition)Document8 pagesFinal - Research - Paper (Face Recognition)Shambhu Kumar singhNo ratings yet