Professional Documents

Culture Documents

Experiment#1: Hydrology & Water Resource Management Lab

Uploaded by

Talha.jOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Experiment#1: Hydrology & Water Resource Management Lab

Uploaded by

Talha.jCopyright:

Available Formats

HYDROLOGY & WATER RESOURCE MANAGEMENT LAB

CE3541

CIVIL ENGINEERING DEPTT. CUST

EXPERIMENT#1

Estimation of Evaporation by using Standard evaporation

pan and Colorado Sunken pan

BYENGR. MEHRAN SUHDEER

Email: mehran.sudheer@cust.edu.pk

BY ENGR. MEHRAN SUDHEER 1

EXPERIMENT#1 (CE3541)

INTRODUCTION

Evaporation

Water loss due to vaporization is called Evaporation.

CIVIL ENGINEERING DEPTT. CUST

•

OR

• Evaporation is the process by which water is converted from its

liquid form to its vapor form and thus transferred from land and

water masses to the atmosphere.

• It is measured in depth units.

FIGURE 1: WATER EVAPORATION

BY ENGR. MEHRAN SUDHEER 2

EXPERIMENT#1 (CE3541)

INTRODUCTION

Evaporation in Hydrology

CIVIL ENGINEERING DEPTT. CUST

FIGURE 2: EVAPORATION IN HYDROLODY

BY ENGR. MEHRAN SUDHEER 3

EXPERIMENT#1 (CE3541)

INTRODUCTION

Evaporation in Hydrology

• Evaporation is the primary pathway that water moves from the

CIVIL ENGINEERING DEPTT. CUST

liquid state back into the water cycle as atmospheric water vapor.

• Studies have shown that the oceans, seas, lakes, and rivers provide

nearly 90 percent of the moisture in the atmosphere via

evaporation, with the remaining 10 percent being contributed by

plant transpiration.

FIGURE 3: EVAPORATION FROM LAKE FIGURE 4: EVAPOTRANSPIRATION

BY ENGR. MEHRAN SUDHEER 4

EXPERIMENT#1 (CE3541)

Factors affecting Evaporation

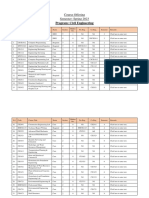

TABLE 1: FACTORS AFFECTING RATE OF EVAPORATION

Factors Affect

CIVIL ENGINEERING DEPTT. CUST

Surface Area Temperature

Increase in temperature = Increase in rate of evaporation

Warmer liquid – Greater number of molecules at the surface

layer are energetic enough to escape.

Larger surface area of water body = Greater rate of evaporation

The larger the exposed surface area, the more water particles

can escape from the water surface.

Rate of evaporation decreases with increasing humidity and

Humidity

increases with lower humidity.

Example: Wet clothes do not dry easily when air is damp and

skin feels dry in air conditioned room.

Higher the wind = Higher the rate of evaporation

Wind

Example: Drying your hair with hair dryer, the moving hot air

from the hair dryer quickly removes moisture from your hair.

BY ENGR. MEHRAN SUDHEER 5

EXPERIMENT#1 (CE3541)

Estimation of Evaporation

• Direct measurement using pans;

i. Standard Evaporation Pan

CIVIL ENGINEERING DEPTT. CUST

ii.Colorado Sunken Pan

• Indirect measurement or theoretical methods;

i. Water Budget Method

ii. Energy Budget Method

iii.Mass Transfer Method

BY ENGR. MEHRAN SUDHEER 6

EXPERIMENT#1 (CE3541)

1. Standard Evaporation Pan

• In the United States, the National Weather

Service has standardized its measurements

on the Class A evaporation pan, a cylinder

CIVIL ENGINEERING DEPTT. CUST

with a diameter of 47.5 in. (120.7 cm) that

has a depth of 10 in. (25 cm).

• The pan rests on a carefully leveled,

wooden base which is 15 cm above ground

level and is often enclosed by a chain link

FIGURE 5-1: SCHEMATIC DIAGRAM

fence to prevent animals drinking from it.

• It is filled with water to 5 cm below the

rim, and the water level should not be

allowed to drop to more than 7.5 cm below

the rim.

• Evaporation is measured daily as the depth

of water (in in./mm) evaporates from the

pan.

• At the end of 24 hours, the amount of

water to refill the pan to exactly previously FIGURE 5-2:

recorded level from its top is measured. SATNDARD EVAPORATION PAN

BY ENGR. MEHRAN SUDHEER 7

EXPERIMENT#1 (CE3541)

1. Standard Evaporation Pan

• The water should be regularly renewed, at least weekly, to eliminate

extreme turbidity.

• The pan, if galvanized, is painted annually with aluminium paint.

CIVIL ENGINEERING DEPTT. CUST

• Screens over the pan are not a standard requirement and should

preferably not be used.

• The site should preferably be having grass, 20 by 20 m, open on all sides to

permit free circulation of the air.

• It is preferable that stations be located in the Centre or on the leeward

side of large cropped fields.

• Pan readings are taken daily in the early morning at the same time that

precipitation is measured.

• Measurements are made in a stilling well that is situated in the pan near

one edge.

• The stilling well is a metal cylinder of about 10 cm in diameter and some

20 cm deep with a small hole at the bottom.

BY ENGR. MEHRAN SUDHEER 8

EXPERIMENT#1 (CE3541)

2. Colorado Sunken Pan

• The Colorado sunken pan is 92 cm (3 ft.)

square and 46 cm (18 in) deep, made of 3

mm thick iron, placed in the ground with

CIVIL ENGINEERING DEPTT. CUST

the rim 5 cm (2 in) above the soil level.

• Also, the dimensions 1 m square and 0.5 m

deep are frequently used.

• The water level is maintained at or slightly

below ground level, i.e., 5-7.5 cm below

FIGURE 6-1: SCHEMATIC DIAGRAM-1

the rim.

• Measurements are taken similarly to those

for the standard pan.

• Siting and environment requirements are

also similar to those of Class A pan.

• Sunken Colorado pans are sometimes

preferred in crop water requirements

studies, as these pans give a better direct

estimation of the reference FIGURE 6-2:

evapotranspiration than standard pan. SCHEMATIC DIAGRAM-2

BY ENGR. MEHRAN SUDHEER 9

EXPERIMENT#1 (CE3541)

Procedure

Measuring Principle

An evaporation pan provides a measurement of the combined effect of temperature,

CIVIL ENGINEERING DEPTT. CUST

humidity, windspeed and sunshine on the reference crop evapotranspiration ETo. The

principle of the evaporation pan is the following:

• The pan is installed in the field.

• The pan is filled with a known quantity of water (the surface area of the pan is

known and the water depth is measured).

• The water is allowed to evaporate during a certain period of time (usually 24

hours). For example, each morning at 7 o’clock a measurement is taken. The

rainfall, if any, is measured simultaneously.

• After 24 hours, the remaining quantity of water (i.e. water depth) is measured.

• The amount of evaporation per time unit (the difference between the two

measured water depths) is calculated; this is the pan evaporation: E pan (in mm/24

hours).

• The E pan is multiplied by a pan coefficient, K pan, to obtain the ETo.

BY ENGR. MEHRAN SUDHEER 10

EXPERIMENT#1 (CE3541)

Observation & Calculation

The pan evaporation is multiplied by a pan coefficient to obtain the

reference crop evapotranspiration.

CIVIL ENGINEERING DEPTT. CUST

ETо = K pan × E pan

ETо = Reference crop evapotranspiration

K pan = Pan coefficient

E pan = Pan evaporation

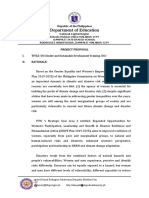

TABLE 2: EXPERIMENTAL OBSERVATIONS AND CALCULATIONS

Water depth before Water depth after Evaporation ETо

Sr. No Evaporation Evaporation [K pan × E pan]

(mm) (mm) (mm/24hrs) (mm/24hrs)

1

BY ENGR. MEHRAN SUDHEER 11

EXPERIMENT#1 (CE3541)

Determination of K Pan

• When using the evaporation pan to estimate the ETo, in fact, a comparison

is made between the evaporation from the water surface in the pan and

CIVIL ENGINEERING DEPTT. CUST

the evapotranspiration of the standard grass.

• Of course, the water in the pan and the grass do not react in exactly the

same way to the climate. Therefore, a special coefficient is used (K pan)

to relate one to the other.

• The pan coefficient, K pan, depends on:

i.The type of pan used.

ii.The pan environment: if the pan is placed in a fallow or cropped area.

iii.The climate: the humidity and wind speed.

• For evaporation pan, the K pan varies between 0.35 and 0.85.

• Average K pan = 0.70.

• If the pan factor is not known the average value can be used.

BY ENGR. MEHRAN SUDHEER 12

EXPERIMENT#1 (CE3541)

Determination of K Pan

If more accuracy is required, the pan factors can be taken from the table

below;

CIVIL ENGINEERING DEPTT. CUST

TABLE 3:

Pan Coefficients (Kp) for Standard pan for different pan siting and environment and

different levels of mean relative humidity and wind speed

Case A CASE B

Class A Pan

Pan is placed in short green cropped area Pan is placed in dry fallow area

Low Medium High Low Medium High

RH mean (%) RH mean (%)

<40 40-70 > 70 <40 40-70 > 70

Wind speed Windward side Windward side

(m/s) distance of green distance of green

crop crop

(m) (m)

1 .55 .65 .75 1 .70 .8 .85

Light 10 .65 .75 .85 10 .60 .7 .80

<2 100 .70 .80 .85 100 .55 .65 .75

1000 .75 .85 .85 1000 .50 .60 .70

1 .50 .60 .65 1 .65 .75 .80

Moderate 10 .60 .70 .75 10 .55 .65 .70

2-5 100 .65 .75 .80 100 .50 .60 .65

1000 .70 .80 .80 1000 .45 .55 .60

1 .45 .50 .60 1 .60 .65 .70

Strong 10 .55 .60 .65 10 .50 .55 .65

5-8 100 .60 .65 .70 100 .45 .50 .60

1000 .65 .70 .75 1000 .40 .45 .55

1 .40 .45 .50 1 .50 .60 .65

Very Strong 10 .45 .55 .60 10 .45 .50 .55

8 100 .50 .60 .65 100 .40 .45 .50

1000 .55 .60 .65 1000 .35 .40 .45

BY ENGR. MEHRAN SUDHEER 13

EXPERIMENT#1 (CE3541)

Determination of K Pan

TABLE 4:

Pan Coefficients (Kp) for Colorado sunken pan for different pan siting and environment

and different levels of mean relative humidity and wind speed

CIVIL ENGINEERING DEPTT. CUST

Case A CASE B

Class A Pan

Pan is placed in short green cropped area Pan is placed in dry fallow area

Low Medium High Low Medium High

RH mean (%) RH mean (%)

<40 40-70 > 70 <40 40-70 > 70

Wind speed Windward side Windward side

(m/s) distance of green distance of green

crop crop

(m) (m)

1 .75 .75 .80 1 1.1 1.1 1.1

Light 10 1.0 1.0 1.0 10 .85 .85 .85

<2 ≥100 1.1 1.1 1.1 100 .75 .75 .80

1000 .70 .70 .75

1 .65 .70 .70 1 .95 .95 .95

Moderate 10 .85 .85 .90 10 .75 .75 .75

2-5 ≥100 .95 .95 .95 100 .65 .65 .70

1000 .60 .60 .65

1 .55 .60 .65 1 .80 .80 .80

Strong 10 .75 .75 .75 10 .65 .65 .65

5-8 ≥100 .80 .80 .80 100 .55 .60 .65

1000 .50 .55 .60

1 .50 .55 .60 1 .70 .75 .75

Very Strong 10 .65 .70 .70 10 .55 .60 .65

8 ≥100 .70 .75 .75 100 .50 .55 .60

1000 .45 .50 .55

BY ENGR. MEHRAN SUDHEER 14

CIVIL ENGINEERING DEPTT. CUST

THANK YOU

BY ENGR. MEHRAN SUDHEER 15

You might also like

- Refuting/Debunking The Claim Made in Quran That Fresh and Salt Water Do Not MixDocument9 pagesRefuting/Debunking The Claim Made in Quran That Fresh and Salt Water Do Not MixAn Ga50% (6)

- Module 2Document15 pagesModule 2Divyashree BMNo ratings yet

- Estimate Water Evaporation Using Meyer's FormulaDocument51 pagesEstimate Water Evaporation Using Meyer's FormulaTheeva RajNo ratings yet

- Unit 4 EvaprationDocument5 pagesUnit 4 EvaprationHRIDYA MGNo ratings yet

- Hydrology losses and evaporation estimationDocument41 pagesHydrology losses and evaporation estimationsardar abdul saboor khanNo ratings yet

- HydrologyDocument5 pagesHydrologyPamela PomantocNo ratings yet

- Ch.4 Abstractions From PrecipitationDocument64 pagesCh.4 Abstractions From PrecipitationFervid Prim01No ratings yet

- Ce122 - 6Document26 pagesCe122 - 6공명형No ratings yet

- Falling Head Permeability TestDocument8 pagesFalling Head Permeability Testdwivediashish2100% (2)

- Chapter - Three & FourDocument35 pagesChapter - Three & FourKubaNo ratings yet

- Module 3Document21 pagesModule 3hjaquiasNo ratings yet

- Ecw311 - Topic 3 EvaporationDocument50 pagesEcw311 - Topic 3 EvaporationBernardNo ratings yet

- CH 3 EvaporationDocument68 pagesCH 3 Evaporationmengistuberhanu2015No ratings yet

- Chapter Three Water Losses: Evaporation From Water Surfaces (Lake Evaporation)Document14 pagesChapter Three Water Losses: Evaporation From Water Surfaces (Lake Evaporation)به شدار ازاد عبدالرحمن عليNo ratings yet

- Chapter Five LatestDocument14 pagesChapter Five LatestHussen MohammedNo ratings yet

- (Arunkumar, 2012) An Experimental Study On A Hemispherical Solar StillDocument7 pages(Arunkumar, 2012) An Experimental Study On A Hemispherical Solar StillDinizNo ratings yet

- Evaporation Estimation and FactorsDocument41 pagesEvaporation Estimation and FactorsGoodluck NyagybNo ratings yet

- Engineering Hydrology Chapter III: Calculating Evaporation and Evapotranspiration RatesDocument68 pagesEngineering Hydrology Chapter III: Calculating Evaporation and Evapotranspiration RatesJerrol Macaspac75% (4)

- Abstraction From PrecipitationDocument6 pagesAbstraction From PrecipitationGerald Ordoñez Delos Reyes100% (1)

- War 2103 EvaporationDocument32 pagesWar 2103 EvaporationEgana IsaacNo ratings yet

- Hydrology (Precipitation)Document12 pagesHydrology (Precipitation)Aj AguilarNo ratings yet

- Hydro Chapter 5 - EvaporationDocument4 pagesHydro Chapter 5 - EvaporationRoel SebastianNo ratings yet

- Evaporation and Evapotranspiration Measurement MethodsDocument20 pagesEvaporation and Evapotranspiration Measurement MethodsshrikanttekadeyahoocNo ratings yet

- Final Report CE 137Document9 pagesFinal Report CE 137Angelie UmambacNo ratings yet

- Evaporation: Isohyetal MethodDocument9 pagesEvaporation: Isohyetal MethodAnonymous aE0YYlCOKNo ratings yet

- UNIT-2 Abstactions and RunoffDocument17 pagesUNIT-2 Abstactions and RunoffKushaal RajNo ratings yet

- Lake Evaporation FactorsDocument9 pagesLake Evaporation FactorsEdgar Cyrelle EscritorNo ratings yet

- EvaporationDocument9 pagesEvaporationEdgar Cyrelle EscritorNo ratings yet

- Losses From Precipitation: Module-2Document40 pagesLosses From Precipitation: Module-2rohitNo ratings yet

- Water Adsorption Desorption On Aluminum SurfaceDocument6 pagesWater Adsorption Desorption On Aluminum SurfacemakfirsefaNo ratings yet

- Evaporation and Evapotranspiration 4Document17 pagesEvaporation and Evapotranspiration 4Harith EmaadNo ratings yet

- Measurement of EvaporationDocument35 pagesMeasurement of EvaporationJonathan MatonNo ratings yet

- EvaporationDocument115 pagesEvaporationGuevara, Blez M.No ratings yet

- UNIT 4 - 15-11-23 - CompleteDocument99 pagesUNIT 4 - 15-11-23 - Completedivyasingh9140475467No ratings yet

- Hydro 2 Evaporation LectureDocument19 pagesHydro 2 Evaporation Lecturebsnow5325No ratings yet

- Chapter 3. Evaporation, Transpiration & Infiltration: BFC 32002 HydrologyDocument51 pagesChapter 3. Evaporation, Transpiration & Infiltration: BFC 32002 HydrologyAsyiqindiniaNo ratings yet

- Explain Briefly The Evaporation ProcessDocument4 pagesExplain Briefly The Evaporation ProcessChristian GarciaNo ratings yet

- Crop Evapotranspiration - Calculate Water Needs Using Kc, ETo FactorsDocument15 pagesCrop Evapotranspiration - Calculate Water Needs Using Kc, ETo FactorsChrissdavieNo ratings yet

- EVAPORATIONDocument52 pagesEVAPORATIONRica Marie MarilaoNo ratings yet

- CE 334 - Module 3.1Document44 pagesCE 334 - Module 3.1Samson EbengaNo ratings yet

- S.1 B.inggris The Example of REPORTDocument7 pagesS.1 B.inggris The Example of REPORTYana VictiNo ratings yet

- EvaporationDocument8 pagesEvaporationEdgar Cyrelle EscritorNo ratings yet

- Water losses from precipitation evaporationDocument31 pagesWater losses from precipitation evaporationShehrozNo ratings yet

- ExperimentDocument3 pagesExperimentNitesh 19CV46No ratings yet

- Chapter 3 PAT202 Evaporation 2Document24 pagesChapter 3 PAT202 Evaporation 2Justin FernandezNo ratings yet

- Rate of Evaporation of LiquidsDocument14 pagesRate of Evaporation of LiquidsiulefwlbNo ratings yet

- Hydrology EvapotranspirationDocument10 pagesHydrology Evapotranspiration202040101No ratings yet

- Evaporation: by Brook A. (DR.)Document22 pagesEvaporation: by Brook A. (DR.)siay mekonnen0% (1)

- Lecture 6 - Evaporation and TranspirationDocument31 pagesLecture 6 - Evaporation and TranspirationtekellamerZ aka tekellamer100% (1)

- Abstraction of PrecipitationDocument36 pagesAbstraction of PrecipitationRiot AyaseNo ratings yet

- Lecture 5 EvaporationDocument15 pagesLecture 5 EvaporationCLARISE OLARTENo ratings yet

- Evaporation Group 2Document26 pagesEvaporation Group 2XaneNo ratings yet

- EVAPORATIONDocument11 pagesEVAPORATIONEmmanuel AtakosNo ratings yet

- EH Lec - 7Document8 pagesEH Lec - 7Arsalan AhmadNo ratings yet

- EVAPORATIONDocument13 pagesEVAPORATIONGuevara, Blez M.No ratings yet

- RRL 1stDocument3 pagesRRL 1stDanelle Lei C. CandaNo ratings yet

- 09 Heat Rejection SystemsDocument14 pages09 Heat Rejection Systemsscarpredator5No ratings yet

- Monitoring of Water Quality: The Contribution of Advanced TechnologiesFrom EverandMonitoring of Water Quality: The Contribution of Advanced TechnologiesNo ratings yet

- L-02 Analysis and Design of One-Way Slab System (Part I) (Fall 2020) - ColorDocument48 pagesL-02 Analysis and Design of One-Way Slab System (Part I) (Fall 2020) - Colorkamran aliNo ratings yet

- Fortuner Specs-SheetDocument1 pageFortuner Specs-SheetTalha.jNo ratings yet

- CE Spring 2023 Course OfferingDocument3 pagesCE Spring 2023 Course OfferingTalha.jNo ratings yet

- TIMETABLE CE FALL 2021 05 8 2021 12.09 PM 1Document4 pagesTIMETABLE CE FALL 2021 05 8 2021 12.09 PM 1Talha.jNo ratings yet

- Water 12 00679 v2Document21 pagesWater 12 00679 v2Talha.jNo ratings yet

- Approved Course Outline For MSc. CRP 07 12 2021Document2 pagesApproved Course Outline For MSc. CRP 07 12 2021Talha.jNo ratings yet

- Cust BS CE Spring 2023 exam scheduleDocument3 pagesCust BS CE Spring 2023 exam scheduleTalha.jNo ratings yet

- Interpersonal RelationshipsDocument27 pagesInterpersonal RelationshipsTalha.jNo ratings yet

- Steel Structure Analysis and Design of Truss Using STAAD PRO and Manual Calculations Semester Project (Part - 01)Document6 pagesSteel Structure Analysis and Design of Truss Using STAAD PRO and Manual Calculations Semester Project (Part - 01)Talha.jNo ratings yet

- Lec 3Document39 pagesLec 3Talha.jNo ratings yet

- HRWMmanualDocument63 pagesHRWMmanualTalha.jNo ratings yet

- Nicomacheon EthicsDocument5 pagesNicomacheon EthicsTalha.jNo ratings yet

- Geotechnical Foundation Engineering: Bearing Pressure & CapacityDocument89 pagesGeotechnical Foundation Engineering: Bearing Pressure & CapacityTalha.jNo ratings yet

- Risk Management Assignment 1Document5 pagesRisk Management Assignment 1oluwapelumi koyaNo ratings yet

- Development Costs: Clackamas CountyDocument6 pagesDevelopment Costs: Clackamas Countypriyanshi SharmaNo ratings yet

- PSYCHOLOGICAL EFFECTS OF COLORS AND SHAPES ON CHILDRENDocument9 pagesPSYCHOLOGICAL EFFECTS OF COLORS AND SHAPES ON CHILDRENAsif AhmedNo ratings yet

- Cades Cove Fall 2022 Prescribed Burn MapDocument1 pageCades Cove Fall 2022 Prescribed Burn MapWVLT NewsNo ratings yet

- "MNO3704 AssessmentDocument16 pages"MNO3704 AssessmentTshepi BajiNo ratings yet

- Environmental Value Systems and ModelsDocument14 pagesEnvironmental Value Systems and ModelsMichaella SallesNo ratings yet

- Stratigraphic NomenclatureDocument11 pagesStratigraphic NomenclatureRitesh KumarNo ratings yet

- Life Cycle Assessment of A Smartphone: January 2016Document11 pagesLife Cycle Assessment of A Smartphone: January 2016Katarina MuzicaNo ratings yet

- Global Ocean Monitoring Current-1 Copy 3Document59 pagesGlobal Ocean Monitoring Current-1 Copy 3Francisco Vasconcelos JuniorNo ratings yet

- Calibration of Self-Contained Breathing Apparatus: Dr. Nour F. AttiaDocument14 pagesCalibration of Self-Contained Breathing Apparatus: Dr. Nour F. AttiaAhmed AwwadNo ratings yet

- Daily Work Progress Report: Italconsult SpaDocument14 pagesDaily Work Progress Report: Italconsult Spaayaz hasanNo ratings yet

- WIP TechnicalDocument3 pagesWIP TechnicalSuehNo ratings yet

- Salman Sahuri - Identification of Deforestation in Protected Forest AreasDocument9 pagesSalman Sahuri - Identification of Deforestation in Protected Forest AreaseditorseajaetNo ratings yet

- 201210221219130.laporan Eia Damansara-Shah Alam Elevated Highway-Ukmpakarunding PDFDocument480 pages201210221219130.laporan Eia Damansara-Shah Alam Elevated Highway-Ukmpakarunding PDFmanimaran75100% (1)

- Hydrochemistry and Assessment of Ground Water Quality of Al-ShekhanDocument9 pagesHydrochemistry and Assessment of Ground Water Quality of Al-ShekhanAymen AlsudanyNo ratings yet

- Isobaric Device Brine/ Seawater Mixing Effect - What Does It Mean To The SWRO Plant Designer and Operator?Document3 pagesIsobaric Device Brine/ Seawater Mixing Effect - What Does It Mean To The SWRO Plant Designer and Operator?Befal desalinasi indonesiaNo ratings yet

- 4. ĐỀ 4Document5 pages4. ĐỀ 4teachingielts2023No ratings yet

- Department of Education: Republic of The PhilippinesDocument9 pagesDepartment of Education: Republic of The PhilippinesAnatasukiNo ratings yet

- Protecting India's Ecologically Sensitive AreasDocument87 pagesProtecting India's Ecologically Sensitive Areasgaurav mandalNo ratings yet

- WMO Greenhouse Gas BulletinDocument10 pagesWMO Greenhouse Gas BulletinWHYY NewsNo ratings yet

- M1 Introduction To The Contemporary World and Globalization LectureDocument13 pagesM1 Introduction To The Contemporary World and Globalization LectureJOSHUALUIS GARCIANo ratings yet

- Chapte R7: Corporate Social Responsibility: The ConceptDocument24 pagesChapte R7: Corporate Social Responsibility: The ConceptAshish YadavNo ratings yet

- Bibliographic Review and Comparison of Optimal Sizing Methods For Hybrid Renewable Energy SystemsDocument15 pagesBibliographic Review and Comparison of Optimal Sizing Methods For Hybrid Renewable Energy Systemsarmen.karimi.1994No ratings yet

- RENK Hydropower en PDFDocument11 pagesRENK Hydropower en PDFhamdaNo ratings yet

- Clean Cookstoves and Fuels:: A Catalog of Carbon Offset Projects and Advisory Service ProvidersDocument84 pagesClean Cookstoves and Fuels:: A Catalog of Carbon Offset Projects and Advisory Service ProvidersNyasimi GeoffreyNo ratings yet

- Water: Ipeat Calibration Tool of SWATDocument17 pagesWater: Ipeat Calibration Tool of SWATCristhian HuilcapazNo ratings yet

- CPI Data DashboardExtractDocument21 pagesCPI Data DashboardExtractAimane CAFNo ratings yet

- 30 Đề Thi Vào Lớp 10 Môn Tiếng AnhDocument105 pages30 Đề Thi Vào Lớp 10 Môn Tiếng AnhHoàng Ngân NguyễnNo ratings yet

- 9 Energy Consumption in BuildingsDocument39 pages9 Energy Consumption in BuildingsBavithra KNo ratings yet