Professional Documents

Culture Documents

Method of Statement For Steel Framing Rev01

Uploaded by

Mǻĥmöûd GěņdƴOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Method of Statement For Steel Framing Rev01

Uploaded by

Mǻĥmöûd GěņdƴCopyright:

Available Formats

Contractor: ARAMCO VIP EXPERIENCE CENTER IN Client:

NESMA RIYADH SAUDI ARAMCO

METHOD OF STATEMENT FOR STEEL

Doc No.

TOTAL PAGES: 14 FRAMING (FIT OUT WORKS) FOR FEATURE NUI-AVEC-DOC-MOS-

CORE WALL

ARAMCO VIP EXPERIENCE CENTER - RIYADH

KING ABDULLAH FINANCIAL DISTRICT (KAFD)

BI-10-20930-0000

CONTRACT NO: 6601000184

PROJECT SPECIFIC METHOD OF STATEMENT FOR:

STEEL FRAMING FOR FEATURE CORE WALL

(FIT OUT WORKS)

01 MAR 28 2023 Khaled Gendy QAQC Manager Project Manager

Rev. Date Prepared Reviewed Approved

MOS STEEL FRAMING Page 1 of 14

Contractor: ARAMCO VIP EXPERIENCE CENTER IN Client:

NESMA RIYADH SAUDI ARAMCO

METHOD OF STATEMENT FOR STEEL

Doc No.

TOTAL PAGES: 14 FRAMING (FIT OUT WORKS) FOR FEATURE NUI-AVEC-DOC-MOS-

CORE WALL

CONTENTS

Description Page

1.0 PURPOSE 3

2.0 SCOPE 3

3.0 REFERENCES 3

4.0 DEFINITIONS 3

5.0 MANPOWER 4

6.0 TOOLS AND EQUIPMENT 4

7.0 MATERIALS STORAGE, HANDLING & PRESERVATIONS 4

8.0 PRE-INSTALLATION 5

9.0 PROCEDURES 5

10.0 Final Check 13

11.0 RESPONSIBILITY 13

12.0 SAFETY 14

13.0 QUALITY CONTROL 14

MOS STEEL FRAMING Page 2 of 14

Contractor: ARAMCO VIP EXPERIENCE CENTER IN Client:

NESMA RIYADH SAUDI ARAMCO

METHOD OF STATEMENT FOR STEEL

Doc No.

TOTAL PAGES: 14 FRAMING (FIT OUT WORKS) FOR FEATURE NUI-AVEC-DOC-MOS-

CORE WALL

1.0 PURPOSE

The purpose of this method statement is to ensure that the construction plan for the Steel

work executed, controlled and documented with compliance of the IFC drawings, Approved

Shop Drawings, Project specification and scope of work.

2.0 SCOPE

The scope of this method statement covers the Structural Steel works components and the

assembling of steel elements in the specified areas as per the Project Specification &

Applicable Saudi ARAMCO standards for ARAMCO VIP EXPERIENCE CENTER located in KAFD-

Riyadh. The method statement shall also describe the erection as per approved Shop drawings.

3.0 REFERENCE STANDARDS AND CODES

Project Specifications 051200,055000,055213,055300,057000

12-SAMSS-008 -- Erection of Structural and Miscellaneous Steel

12-SAMSS-007 -- Fabrication of Structural and Miscellaneous Steel

12-SAMSS-005 -- Marking of Metal Products

SACSM Saudi Aramco construction safety manual

GI 2.100 Work Permit System /Procedure (GI-General Instructions).

IFC Issued for Construction Drawings.

AISC American Institute of Steel Construction

* Code of Standard Practices for Steel Building and Bridges

AISI American Iron and Steel Institute

SDI Steel Deck Institute

SJI Steel Joist Institute

4.0 DEFINITIONS AND ABBREVIATIONS

SAES Saudi Aramco Engineering Standards

SATIP Saudi Aramco Typical Inspection Plan

SAIC Saudi Aramco Inspection Check Lists

SAPMT Saudi Aramco Project Management Team

SAPID Saudi Aramco Project Inspection Department

QA/QC Quality Assurance/ Quality Control

HSE Health, Safety & Environment

NFPA National Fire Protection Association

MOS STEEL FRAMING Page 3 of 14

Contractor: ARAMCO VIP EXPERIENCE CENTER IN Client:

NESMA RIYADH SAUDI ARAMCO

METHOD OF STATEMENT FOR STEEL

Doc No.

TOTAL PAGES: 14 FRAMING (FIT OUT WORKS) FOR FEATURE NUI-AVEC-DOC-MOS-

CORE WALL

5. 0 MANPOWER

We do need only the following manpower..

1. 1 civil engineer

2. 4 Civil steel fixers

3. 6 helpers

In total of 11 persons

6.0 TOOLS AND EQUIPMENT

The tools and equipment needed should be in good condition and must be checked by the

leadman and safety personal prior putting it in use. These includes the following:

Hydraulic Trolley.

Drilling tools.

Metal scanning tools.

Electric drill or Battery operated drill machines

Movable or wheeled scaffoldings.

Chain block.

Lifting Slings.

Calibrated Torque Wrench.

Quality control testing equipment.

Hole saw.

7. 0 MATERIAL STORAGE, HANDLING AND PRESERVATIONS

Deliver structural steel to Project site in such quantities and at such times to ensure

continuity of installation.

Store materials to permit easy access for inspection and identification. Keep steel

members off ground and spaced by using pallets, platforms, or other supports and

spacers.

Protect steel members and packaged materials from corrosion and deterioration.

Avoid storing materials on structures in a way that could overload, distortion, or harm

the members or supporting structures. As instructed, repair or replace damaged

materials or structures.

Store fasteners, washers…etc.) In a protected place in sealed containers with

manufacturer's labels intact.

MOS STEEL FRAMING Page 4 of 14

Contractor: ARAMCO VIP EXPERIENCE CENTER IN Client:

NESMA RIYADH SAUDI ARAMCO

METHOD OF STATEMENT FOR STEEL

Doc No.

TOTAL PAGES: 14 FRAMING (FIT OUT WORKS) FOR FEATURE NUI-AVEC-DOC-MOS-

CORE WALL

Protect structural steel works by approved adequate measures from constructional

hazards during and after erection.

8.0 PRE-INSTALLATION

The site engineer will ensure that all steel material and documentation (MTS, MRI,

Shop drawings, MOS) are approved prior commencing the activity.

Conduct a meeting with the consultant to inform and discuss any concerns related

to the Steel Frame erection.

Check the stored material to see if it is still in good condition, and metal accessories

if get rusted.

Verify, with certified steel Erector present, elevations of concrete- and masonry-

bearing surfaces and locations of anchor rods, bearing plates, and other

embedment’s for compliance with requirements.

Prepare a certified survey of existing conditions. Include bearing surfaces, anchor

rods, bearing plates, and other embedment’s showing dimensions, locations, angles,

and elevations.

Proceed with installation only after unsatisfactory conditions have been corrected.

9. PROCEDURES

Submit detailed method statement of fabrication and erection after taking into account all site

logistics and constraints. Refer to constructability section and contractor scope of work.

Base Plates, Bearing Plates, and Levelling Plates: Clean concrete- and masonry-bearing

surfaces of bond-reducing materials and roughen surfaces prior to setting plates. Clean

bottom surface of plates.

Set plates for structural members on wedges, shims, or setting nuts as required.

Snug-tighten anchor rods after supported members have been positioned and plumbed.

Do not remove wedges or shims but, if protruding, cut off flush with edge of plate

before packing with grout.

Promptly pack grout solidly between bearing surfaces and plates so no voids remain.

Neatly finish exposed surfaces; protect grout and allow to cure. Comply with

manufacturer's written installation instructions for shrinkage-resistant grouts.

Align and adjust various members that form part of complete frame or structure before

permanently fastening. Before assembly, clean bearing surfaces and other surfaces that

will be in permanent contact with members.

Perform necessary adjustments to compensate for discrepancies in elevations and

alignment.

Level and plumb individual members of structure.

MOS STEEL FRAMING Page 5 of 14

Contractor: ARAMCO VIP EXPERIENCE CENTER IN Client:

NESMA RIYADH SAUDI ARAMCO

METHOD OF STATEMENT FOR STEEL

Doc No.

TOTAL PAGES: 14 FRAMING (FIT OUT WORKS) FOR FEATURE NUI-AVEC-DOC-MOS-

CORE WALL

Perform pre-installation verification as indicated in RCSC prior to installation.

The steel frame will be erected along the wall. Secure approved RFI copy for structure.

The works shall be executed in accordance with the following methodology and

sequence:

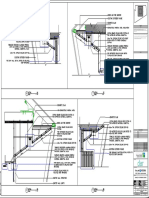

Drill holes into concrete core wall for the required depth.

Drill holes into the R.C slabs at a distance of 600mm from core wall to set the base plate

and upper plate, to facilitate the required distance needed for the CATWALK

passageway.

Install the modular framing parts starting with the lower level going up by each module

until reaching the 14th floor slab.

Chain Hoist System

The system used to lift the modules from the ground and place them in their designed

location is the following:

COMPREHENSIVE SKETCH ONLY (NOT SCALED)

It consists of two scaffolding placed 2.5m apart (Module width=2.2m) with a steel tube

in the middle connected at both sides using double clamps. On the middle of the steel

tube will be placed a chain hoist that will lift the modules from the ground.

Analysis of steel tube:

Section: CHS; 3mm THK

Span: 2.5m

End Supports: Pinned

Maximum Load: 150 Kg

Design Load: 200 Kg

Results:

MOS STEEL FRAMING Page 6 of 14

Contractor: ARAMCO VIP EXPERIENCE CENTER IN Client:

NESMA RIYADH SAUDI ARAMCO

METHOD OF STATEMENT FOR STEEL

Doc No.

TOTAL PAGES: 14 FRAMING (FIT OUT WORKS) FOR FEATURE NUI-AVEC-DOC-MOS-

CORE WALL

As seen in the previous results, the CHS can withstand the applied load by the modules

and the system can be used to lift the steel frame.

MOS STEEL FRAMING Page 7 of 14

Contractor: ARAMCO VIP EXPERIENCE CENTER IN Client:

NESMA RIYADH SAUDI ARAMCO

METHOD OF STATEMENT FOR STEEL

Doc No.

TOTAL PAGES: 14 FRAMING (FIT OUT WORKS) FOR FEATURE NUI-AVEC-DOC-MOS-

CORE WALL

MOS STEEL FRAMING Page 8 of 14

Contractor: ARAMCO VIP EXPERIENCE CENTER IN Client:

NESMA RIYADH SAUDI ARAMCO

METHOD OF STATEMENT FOR STEEL

Doc No.

TOTAL PAGES: 14 FRAMING (FIT OUT WORKS) FOR FEATURE NUI-AVEC-DOC-MOS-

CORE WALL

Lateral anchorage will take place where required to connect the modular framing parts

to the concrete wall.

The following dimensions must be controlled: A -Steel line to outer bolt row

Diagonal distance between bolt groups.

Distance from axis centre line to bolt row, Distance between bolts.

Distance between frame axes.

Distance between Steel Lines Levels Foundations Anchor Bolt protrusions

MOS STEEL FRAMING Page 9 of 14

Contractor: ARAMCO VIP EXPERIENCE CENTER IN Client:

NESMA RIYADH SAUDI ARAMCO

METHOD OF STATEMENT FOR STEEL

Doc No.

TOTAL PAGES: 14 FRAMING (FIT OUT WORKS) FOR FEATURE NUI-AVEC-DOC-MOS-

CORE WALL

Tightening

• Check all connections to be sure that all bolts have been installed.

• All the bolts shall be brought to snug tight position before tensioning.

• Position the bolt to snug tight by manual operation using an ordinary spud

Wrench. A full effort of a man using an ordinary spud wrench would bring the

bolt to a snug tight position. No wrench extension or long wrenches should be

used to bring the bolt to a snug tight position in order to avoid tensioning.

• Once the sung tight position is achieved, the outer face of the nut shall be

match-marked with the protruding bolt before final tightening.

• Tightening still proceed until the desired nut rotation meets requirements.

• A visual check on the match-marks will indicate when the correct rotation has

been achieved.

• Tightening shall be carried out by manual wrench, or air / electric impact

wrench.

MOS STEEL FRAMING Page 10 of 14

Contractor: ARAMCO VIP EXPERIENCE CENTER IN Client:

NESMA RIYADH SAUDI ARAMCO

METHOD OF STATEMENT FOR STEEL

Doc No.

TOTAL PAGES: 14 FRAMING (FIT OUT WORKS) FOR FEATURE NUI-AVEC-DOC-MOS-

CORE WALL

MOS STEEL FRAMING Page 11 of 14

Contractor: ARAMCO VIP EXPERIENCE CENTER IN Client:

NESMA RIYADH SAUDI ARAMCO

METHOD OF STATEMENT FOR STEEL

Doc No.

TOTAL PAGES: 14 FRAMING (FIT OUT WORKS) FOR FEATURE NUI-AVEC-DOC-MOS-

CORE WALL

MOS STEEL FRAMING Page 12 of 14

Contractor: ARAMCO VIP EXPERIENCE CENTER IN Client:

NESMA RIYADH SAUDI ARAMCO

METHOD OF STATEMENT FOR STEEL

Doc No.

TOTAL PAGES: 14 FRAMING (FIT OUT WORKS) FOR FEATURE NUI-AVEC-DOC-MOS-

CORE WALL

10. FINAL CHECK

- After completing all clips and accessories, a final inspection of the structure will be made.

- M12 bolts torqueing is taken into consideration, also used calibrated torque wrench to 100

Nm.

- Check all connection to ensure all bolts are installed as per approved S.D and calculations.

- Clean up the site.

- All clear height, width and length to be checked.

- Handing over the Structure.

The steel structure erection is a major and important part of the project. It is very important to

have a stringent look on the erection schedule as well as delivery schedule. The driving element

between the both schedules is the delivery schedule if the erection team is efficiently working at site.

The Schedule will be submitted separately after approving the Steel drawings.

11. RESPONSIBILITY

The site engineer is responsible for planning the required resources and carry out the erection

of Steel framing utilizing the approved material, and as per the best industry standard. The

engineer should coordinate with other disciplines and to resolve and conflict that may arise.

The construction manager shall follow up with the site engineer to ensure the work is carried

out as per the committed schedule. He should notify the management team of any issue that

may delay the completion of the work and propose solution to mitigate such risks.

QC Inspector shall be responsible in monitoring and inspection of the work and ensures that

the work is performed and properly documented in accordance with ITP, MOS, and industry

Standards.

Safety Supervisor shall be responsible in monitoring safety aspects and ensuring that the work

is done in accordance with Safety Standard Procedure.

He shall carry out regular toolbox talk to raise the workers’ awareness about maintaining the

PPE and how to carry out the job with zero LTI.

MOS STEEL FRAMING Page 13 of 14

Contractor: ARAMCO VIP EXPERIENCE CENTER IN Client:

NESMA RIYADH SAUDI ARAMCO

METHOD OF STATEMENT FOR STEEL

Doc No.

TOTAL PAGES: 14 FRAMING (FIT OUT WORKS) FOR FEATURE NUI-AVEC-DOC-MOS-

CORE WALL

12. SAFETY

Obtain necessary work permits from the concerned Representative intended for the job before

starting any work.

Arrange all required safety equipment and tools for the commencement of the work.

Provide warning sign and sufficient barricade on working area. Only assigned personnel will be

allowed in the area to maintain a safe work environment.

Conduct safety briefing to all working crew to remind them of all the safety requirements on

the job. All work force will comply with occupational HSE compliance policy by wearing

overalls, safety shoes, googles, gloves, and, helmets.

Continuous monitoring and inspection shall be implemented by the site supervisor/foreman

together with the assigned safety supervisor in the area. Any unsafe practices while performing

the work activities shall be corrected immediately to avoid stoppage of the work.

Good housekeeping shall be maintained throughout the work activity. The work site shall be

kept clean and safe. Do not keep any standby materials on the scaffolding.

Safety Supervisor shall monitor the work activities to help and protect all assigned workers

against exposure to safety hazards. He shall ensure that Personal Protective Equipment (PPE’s)

are supplied and worn at all times.

13. QUALITY CONTROL

All Testing and Inspection shall be coordinated by Inspector.

QC Inspector shall be assigned to ensure the quality control and assurance requirement of the

project.

QC Inspector shall be responsible to conduct all required inspection / documentation and to

ensure that all applicable requirements, codes, and standards are complied with.

Contractor must utilize the applicable inspection and test form reflected on approved

SATIP.

MOS STEEL FRAMING Page 14 of 14

You might also like

- Sraco-Const-Doc-Mos-08 - Concrete Masonry Units and PlasteringDocument13 pagesSraco-Const-Doc-Mos-08 - Concrete Masonry Units and PlasteringMohammed Perwez AlamNo ratings yet

- Method of Statement For Drywall-1Document15 pagesMethod of Statement For Drywall-1Mǻĥmöûd GěņdƴNo ratings yet

- Steel Erection Method StatementDocument16 pagesSteel Erection Method StatementPangky AbasoloNo ratings yet

- Method Statement of Cladding Sheeting at A-Frame and Wind Wall at ACC Project SiteDocument10 pagesMethod Statement of Cladding Sheeting at A-Frame and Wind Wall at ACC Project SiteJethin SurendranNo ratings yet

- Method Statement of Pipe RackDocument8 pagesMethod Statement of Pipe RackLEIXIAO ZHANGNo ratings yet

- P140I Fencing WorksDocument5 pagesP140I Fencing WorkskbldamNo ratings yet

- Ms For Space Frame AssemblingDocument13 pagesMs For Space Frame Assemblingmoytabura96100% (2)

- 002-PDS-CON-009 Method Statement For Material Management at SiteDocument13 pages002-PDS-CON-009 Method Statement For Material Management at SiteMalik ZamanNo ratings yet

- Method StatementDocument31 pagesMethod StatementMuneeb KhanNo ratings yet

- Leak Test Procedure for Anchor SleevesDocument13 pagesLeak Test Procedure for Anchor SleevesAmeerHamzaWarraichNo ratings yet

- Method Statement of Installing I-BeamDocument1 pageMethod Statement of Installing I-BeamfaizbukhariNo ratings yet

- MS-G-003 - General Method Statement For Horizontal PumpDocument19 pagesMS-G-003 - General Method Statement For Horizontal PumpNGUYEN VINHNo ratings yet

- MIP17-MS-3003 METHOD OF STATEMENT FOR PIPELINE CROSSING ABOVE EXISTING CORRIDOR Rev.0Document22 pagesMIP17-MS-3003 METHOD OF STATEMENT FOR PIPELINE CROSSING ABOVE EXISTING CORRIDOR Rev.0AmeerHamzaWarraichNo ratings yet

- Method Statement Pipe Re-Routing Saudi BinladinDocument11 pagesMethod Statement Pipe Re-Routing Saudi BinladinShyju MelepurathNo ratings yet

- Scaffold Plan Completeness ChecklistDocument6 pagesScaffold Plan Completeness ChecklistRamil LazaroNo ratings yet

- Method of Statement For Demolition WorksDocument10 pagesMethod of Statement For Demolition Worksbabjihanumanthu100% (1)

- Installation of Aluminium Cladding Method StatementDocument4 pagesInstallation of Aluminium Cladding Method StatementAllan Bryan Sario0% (1)

- Method Statement For For Cable Tray and Conduit Installation With Risk AssesmentDocument9 pagesMethod Statement For For Cable Tray and Conduit Installation With Risk Assesmentobasiigwe8499No ratings yet

- Civil Construction ProcedureDocument6 pagesCivil Construction Procedureคุณพ่อน้อง บิ๊กบอสNo ratings yet

- 002-PDS-CON-011 Method Statement For TCF ConstructionDocument18 pages002-PDS-CON-011 Method Statement For TCF ConstructionMalik ZamanNo ratings yet

- Gse Ms Ug 001 Rev 0 - Method Statement For Underground PipingDocument7 pagesGse Ms Ug 001 Rev 0 - Method Statement For Underground PipingsugumarNo ratings yet

- Demolition Method StatementDocument9 pagesDemolition Method StatementMuhammad TariqNo ratings yet

- Efficient Framing and Sheeting ErectionDocument6 pagesEfficient Framing and Sheeting Erectionjoseph chewNo ratings yet

- Method Statement Installation Os Static Equipment and InternalsDocument24 pagesMethod Statement Installation Os Static Equipment and InternalsAjin SNo ratings yet

- MIP17-HSE-JSA-022 For Installation of Overhead Powerlines - 2022 Rev.1 (Khursaniyah Area)Document14 pagesMIP17-HSE-JSA-022 For Installation of Overhead Powerlines - 2022 Rev.1 (Khursaniyah Area)AmeerHamzaWarraichNo ratings yet

- Sinopec Branch Augments HDD Anchor CapacityDocument22 pagesSinopec Branch Augments HDD Anchor CapacityAmeerHamzaWarraichNo ratings yet

- Excavation & BackfillingDocument6 pagesExcavation & BackfillingnidhinbobanNo ratings yet

- Painting Works Method StatementDocument5 pagesPainting Works Method StatementDavid SeeNo ratings yet

- Surface Preparation SWMSDocument11 pagesSurface Preparation SWMSAmit SinghNo ratings yet

- Mip17-Ms-2012 Method of Statement For Piping Fabrication Coating and Painting in Sks Jubail Facility - Rev.1Document24 pagesMip17-Ms-2012 Method of Statement For Piping Fabrication Coating and Painting in Sks Jubail Facility - Rev.1AmeerHamzaWarraichNo ratings yet

- Fabrication, Painting and Erection Method Statement for Rigging SystemDocument13 pagesFabrication, Painting and Erection Method Statement for Rigging SystemAnwar Mohiuddin50% (2)

- Method Statement For Cement Board Dry Wall PartitionsDocument10 pagesMethod Statement For Cement Board Dry Wall PartitionsComet GroupNo ratings yet

- Method Statement For Bituminous Damp Proofing For Concrete and Masonry WorkDocument11 pagesMethod Statement For Bituminous Damp Proofing For Concrete and Masonry WorkOsama Abdulkafi100% (1)

- KAPSARC-MRK-Concrete Repair work-METHOD STATEMENTDocument4 pagesKAPSARC-MRK-Concrete Repair work-METHOD STATEMENTsherwin suarezNo ratings yet

- MGB-MS-003-ST-003 Formwork InstallationDocument8 pagesMGB-MS-003-ST-003 Formwork InstallationImho Tep100% (1)

- Method Statement For Excavation & BackfillingDocument5 pagesMethod Statement For Excavation & BackfillingPaul LadjarNo ratings yet

- Doors & Window Installation - DraftDocument7 pagesDoors & Window Installation - DraftGaneshNo ratings yet

- Multiplex Vertical Structures Method StatementDocument7 pagesMultiplex Vertical Structures Method StatementAdel SaqqaNo ratings yet

- TES Tank Foundation Method of StatementDocument10 pagesTES Tank Foundation Method of StatementAishah AliasNo ratings yet

- Safety Signs On Construction SiteDocument1 pageSafety Signs On Construction SiteBëBå Wossen AssefaNo ratings yet

- Ms For Foundation Excavation and Casting.Document6 pagesMs For Foundation Excavation and Casting.botchNo ratings yet

- Method Statement For Hydraulic JackingDocument22 pagesMethod Statement For Hydraulic Jackinghwen.hh100% (1)

- Job Safety Analysis WorksheetDocument4 pagesJob Safety Analysis WorksheetSAHIL SHARMANo ratings yet

- MS For Concrete RepairDocument14 pagesMS For Concrete RepairDelta akathehuskyNo ratings yet

- Work Method StatementDocument10 pagesWork Method StatementMdNasruddin shaikhNo ratings yet

- METHOD STATEMENT FOR Pneumatic TestDocument11 pagesMETHOD STATEMENT FOR Pneumatic TestzahidNo ratings yet

- Method of StatementDocument23 pagesMethod of StatementDeepan TravellerNo ratings yet

- Method Statement Striking FormworkDocument3 pagesMethod Statement Striking FormworkSurya HeriwijayaNo ratings yet

- Method of Statement For HDPE Pipe InstallationDocument2 pagesMethod of Statement For HDPE Pipe InstallationYe Yint100% (2)

- Saudi Aramco welding checklistDocument2 pagesSaudi Aramco welding checklistImran khanNo ratings yet

- MST-CO-002 (MS For BLASTING AND PAINTING)Document6 pagesMST-CO-002 (MS For BLASTING AND PAINTING)Delta akathehuskyNo ratings yet

- Surface GI Conduit Installation Method StatementDocument4 pagesSurface GI Conduit Installation Method StatementJaneNo ratings yet

- Method Statements InterLock WorksDocument3 pagesMethod Statements InterLock WorksNino Celso AstilleroNo ratings yet

- SWP 05 - Installation of PipesDocument5 pagesSWP 05 - Installation of PipesGerald Wong NttNo ratings yet

- Blasting and Painting ProcedureDocument27 pagesBlasting and Painting ProcedurePerlie BellomosNo ratings yet

- TR-CA-MS-004 - B Shifting Concrete BarriersDocument14 pagesTR-CA-MS-004 - B Shifting Concrete Barrierssamer8saifNo ratings yet

- Method Statement-Fit-Out WorksDocument18 pagesMethod Statement-Fit-Out WorksВиссам АбдинNo ratings yet

- MS - Raft PouringDocument14 pagesMS - Raft PouringAby ThykkodathuNo ratings yet

- Method Statement: Construction CompanyDocument8 pagesMethod Statement: Construction CompanyDhimas Surya NegaraNo ratings yet

- Drywall Partition Installation MethodDocument12 pagesDrywall Partition Installation MethodxomilaaNo ratings yet

- Nui-Aec-Shd-Ar-012 - Ceiling Layout Details-Nui-Aec-Shd-Ar-012 ADocument1 pageNui-Aec-Shd-Ar-012 - Ceiling Layout Details-Nui-Aec-Shd-Ar-012 AMǻĥmöûd GěņdƴNo ratings yet

- Nui-Aec-Shd-Ar-012 - Ceiling Layout Details-Nui-Aec-Shd-Ar-012 BDocument1 pageNui-Aec-Shd-Ar-012 - Ceiling Layout Details-Nui-Aec-Shd-Ar-012 BMǻĥmöûd GěņdƴNo ratings yet

- Sa - Vip - Ex - Doc - S - 641 MTS For Cmu Blocks and AccessoriesDocument1 pageSa - Vip - Ex - Doc - S - 641 MTS For Cmu Blocks and AccessoriesMǻĥmöûd GěņdƴNo ratings yet

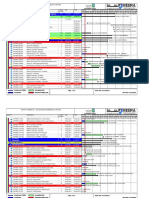

- FIT OUT SCHEDULE - VIP EXPERIENCE CENTER (Lamia)Document7 pagesFIT OUT SCHEDULE - VIP EXPERIENCE CENTER (Lamia)Mǻĥmöûd GěņdƴNo ratings yet

- Mada Data SheetDocument6 pagesMada Data SheetMǻĥmöûd GěņdƴNo ratings yet

- History of AviationDocument80 pagesHistory of AviationAmara AbrinaNo ratings yet

- NET Memory ProfilerDocument229 pagesNET Memory ProfilerNatalia PeraltaNo ratings yet

- DF4 5 6 MedidasDocument2 pagesDF4 5 6 MedidasMiguel Ruivo AlmeidaNo ratings yet

- 11 M-Way Search TreesDocument33 pages11 M-Way Search TreesguptharishNo ratings yet

- Manual ATPDMan56Document288 pagesManual ATPDMan56Alex DavidNo ratings yet

- Biosafety and Lab Waste GuideDocument4 pagesBiosafety and Lab Waste Guidebhramar bNo ratings yet

- Assign Controlling Areas and Company Codes for Optimal Cost AccountingDocument4 pagesAssign Controlling Areas and Company Codes for Optimal Cost Accountingatsc68No ratings yet

- Protocol for Qualitative Research InterviewsDocument19 pagesProtocol for Qualitative Research InterviewsZeeshan AkhtarNo ratings yet

- IBP Cable and Pressure Transducers IncavDocument6 pagesIBP Cable and Pressure Transducers Incaveng_seng_lim3436No ratings yet

- Chapter 1 Statement of Financial PositionDocument3 pagesChapter 1 Statement of Financial PositionMartha Nicole MaristelaNo ratings yet

- Stability and Development StrategyDocument34 pagesStability and Development StrategySudan North-South Border InitiativeNo ratings yet

- Evacuation Process of HVAC SystemDocument23 pagesEvacuation Process of HVAC SystemDinesh SinghNo ratings yet

- Bank TellerDocument3 pagesBank Tellerapi-3701112No ratings yet

- Case Study:: Barangay HallDocument13 pagesCase Study:: Barangay HallReiner Gatdula50% (2)

- BIR - RMC.064-16.Tax Treatment Non-Stock Non ProfitDocument11 pagesBIR - RMC.064-16.Tax Treatment Non-Stock Non ProfitKTGNo ratings yet

- Manual Mfm383a SelecDocument4 pagesManual Mfm383a SelecPhương NguyênNo ratings yet

- Notes On Cash BudgetDocument26 pagesNotes On Cash BudgetJoshua P.No ratings yet

- A European Call Option Gives A Person The Right ToDocument1 pageA European Call Option Gives A Person The Right ToAmit PandeyNo ratings yet

- BatchGenerator UserReferenceDocument13 pagesBatchGenerator UserReferenceLuis OrtizNo ratings yet

- Cortisol II 2020-03 v6Document5 pagesCortisol II 2020-03 v6Parishan SaeedNo ratings yet

- Sgsoc Esia Oils Cameroon LimitedDocument299 pagesSgsoc Esia Oils Cameroon LimitedcameroonwebnewsNo ratings yet

- What Is Double Taxation PDFDocument3 pagesWhat Is Double Taxation PDFxyzNo ratings yet

- LTE Feature Up To FL15ADocument146 pagesLTE Feature Up To FL15AYoucef BelhadiaNo ratings yet

- Process Flow Diagram (For Subscribers Who Visits Merchant Business Premises)Document2 pagesProcess Flow Diagram (For Subscribers Who Visits Merchant Business Premises)Lovelyn ArokhamoniNo ratings yet

- Credit Role - Jai-KisanDocument2 pagesCredit Role - Jai-Kisan21-23 Shashi KumarNo ratings yet

- S141 Advanced DSP-based Servo Motion ControllerDocument8 pagesS141 Advanced DSP-based Servo Motion ControllersharkeraNo ratings yet

- Sale of Goods .Document24 pagesSale of Goods .Goodman supremacyNo ratings yet

- Tcds Easa A 359 Dornier 228 Issue 7Document53 pagesTcds Easa A 359 Dornier 228 Issue 7INFO WORKLINKNo ratings yet

- Export Promotion Capital Goods Scheme PresentationDocument32 pagesExport Promotion Capital Goods Scheme PresentationDakshata SawantNo ratings yet

- MSDS - SYCAMORE Spray PaintDocument6 pagesMSDS - SYCAMORE Spray PaintBatanNo ratings yet