Professional Documents

Culture Documents

Material Properties:: Design of Concrete Beam

Material Properties:: Design of Concrete Beam

Uploaded by

king taugOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Material Properties:: Design of Concrete Beam

Material Properties:: Design of Concrete Beam

Uploaded by

king taugCopyright:

Available Formats

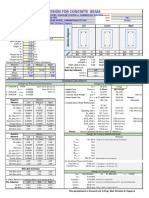

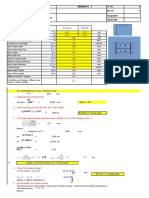

Project Name: Cons.

of MPB Design by:

Owner: Brgy. Pitogo Mark: B2

Location: ZDS Date: 01/29/2023

Check by: Zulkiflee M. Taug

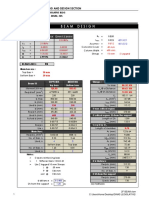

DESIGN OF CONCRETE BEAM Structural Excell Program

Material Properties: Left Mid Right

Concrete f'c = 20.7 MPa

Reinforcing fy = 275 MPa

Stirrup fy = 230 MPa

Beam Data

Span type = Both ends continuous

Span Length = 4.65 m

width, b = 0.3 m

height, h = 0.5 m

flexure bar Ø = 20 mm

shear bar Ø = 10 mm Layer 1 = 4 Layer 1 = 2 Layer 1 = 4

Torsion bar Ø = 16 mm Layer 2 = 4 8 pcs Layer 2 = 0 2 pcs Layer 2 = 4 8 pcs

Top

Top

Top

Layer 3 = 0 Layer 3 = 0 Layer 3 = 0

Stress Result (Any FEA or Frame Analysis)

Ratio = 0.916 Ratio = 0.907 Ratio = 0.458

Moment Left Mid Right

Layer 1 = 4 Layer 1 = 4 Layer 1 = 4

TB [kN-m] 211.84 60.85 105.99

Layer 2 = 0 4 pcs Layer 2 = 0 4 pcs Layer 2 = 0 4 pcs

Bot

Bot

Bot

BB [kN-m] 18.78 43.56 42.68

Layer 3 = 0 Layer 3 = 0 Layer 3 = 0

Left Mid Right Ratio = 0.148 Ratio = 0.344 Ratio = 0.337

Shear 145.06 0 103.57 ● Check Minimum Depth of Beam

Torsion 0.08 0 0.08 Depth = 0.22 Depth use is ok Table 409.3.1.1

4xDepth = 1.76 Depth use is ok Sec. 418.6.2.1a

ServiceMoment 193.23 58.1 99.49 Width (200 or 0.3h) = 0.2 Width use is ok Sec. 418.6.2.1b

SUMMARY CALCULATIONS

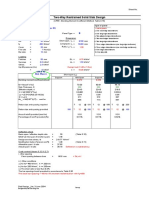

Design for Flexural Reinforcement Design for Stirrups

Used Maximum Vu = 145.06 kN Legs = 2

Top Moment Left Mid Right

The Beam Section is Adequate

Mu (kN.m) = 211.84 60.85 105.99

Distance = @50mm @2●Height

β1 value = 0.85 0.85 0.85

Applied Force, Vu = 140.38 kN 80 kN

Remarks = Doubly! Doubly! Doubly! Sec. 409.6.3.1

Concrete Strength, φVc= 75.07 kN 75.07 kN

ρmax = 0.02899 0.00731 0.02899

Concrete Strength, Vs max= 300.28 kN 300.28 kN

ρmin = 0.00509 0.00509 0.00509

Vmax = 375.35 kN 375.35 kN

ρused = 0.01995 0.00476 0.01995

● Compute Area Reinforcement

Reduction Fac = 0.9 0.9 0.9

Vs = 87.08 kN 6.58 kN

Neutral Axis = 96.1 54.9 96.1

Vs = 200.19 kN 200.19 kN

a= 81.68 46.67 81.68 Table 409.7.6.2.2

Spacing_max = 220 mm 220 mm Table 409.7.6.2.2

Tensile Strain = 0.0101 0.021 0.0101

Av_used = 157.08 mm² 157.08 mm²

ΦMn (kN.m) = 231.35 67.12 231.35

Av/S_req = 0.86 mm²/m 0.06 mm²/m

Av/S_min1 = 367.93 mm²/m 367.93 mm²/m

Table 409.6.3.3a

Bot Moment Left Mid Right Av/S_min2 = 456.52 mm²/m 456.52 mm²/m

Table 409.6.3.3b

Mu (kN.m) = 18.78 43.56 42.68 Av/S_used = 860.48 mm²/m 456.52 mm²/m

β1 value = 0.85 0.85 0.85 S_req = 182.55 mm 344.08 mm

Remarks = Doubly! Doubly! Doubly! S_used = 100 mm 150 mm

ρmax = 0.01414 0.01397 0.01414 10mm : 1@50mm 10@100mm 5@150mm REST @ 250mm O.C. TO C.L.

ρmin = 0.00189 0.00432 0.00429

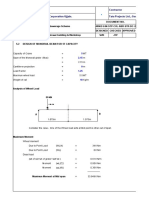

Design for Torsion Reinforcements

ρused = 0.00952 0.00952 0.00952

Tc = 4 < 0.08 kN-m, not to be considered!

Reduction Fac = 0.9 0.9 0.9

Total(Av+t)= 1.85 <= Av+t(prov) = 157.08 mm², O.K.

Neutral Axis = 79.6 67.7 79.6

Total(Av+t)min= 68.48 <= Av+t(prov) = 157.08 mm², O.K.

a= 67.66 57.55 67.66

Tensile Strain = 0.0136 0.0165 0.0136

ΦMn (kN.m) = 126.67 126.7 126.67

● Check Minimum according to Sec. 418.6.3

a.) 1. Least 2 at both top and bot

2. Min bar 2 (0.25*√fc)*bd/fy

3 1.4*bd/fy

3. Max bar 11 0.025*bd

b.) Positive moment at joint face shall be at least one half the negative ...

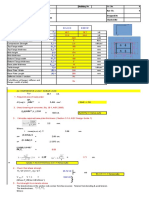

Design for Crack Control Exposure Condition = 10mm : 1@50mm 10@100mm 5@150mm REST @ 250mm O.C. TO C.L.

Left Mid Right

Mcr = 35.26 kN-m 35.26 kN-m 35.26 kN-m

Remark = Beam is cracking! Beam is cracking! Beam is cracking!

Crack Width = 0.563 mm 0.563 mm 0.303 mm

Table 4.1 = Crack width is not ok Crack width is not ok Crack width is ok

Table 4.2 = Since dt = 20mm > 10mm, ok! Since dt = 20mm > 10mm, ok! Since dt = 20mm > 10mm, ok!

Table 4.3 = Since S = 66.67mm > 50mm, ok! Since S = 66.67mm > 50mm, ok! Since S = 66.67mm > 50mm, ok!

You might also like

- Hollow Pot Slabs DesignDocument4 pagesHollow Pot Slabs Designchris100% (4)

- Solution Manual for an Introduction to Equilibrium ThermodynamicsFrom EverandSolution Manual for an Introduction to Equilibrium ThermodynamicsNo ratings yet

- Material Properties:: Design of Concrete BeamDocument1 pageMaterial Properties:: Design of Concrete BeamMark Christian EsguerraNo ratings yet

- Material Properties:: Design of Concrete BeamDocument16 pagesMaterial Properties:: Design of Concrete BeamVerna Balang MartinezNo ratings yet

- Material Properties:: Design of Concrete BeamDocument4 pagesMaterial Properties:: Design of Concrete Beamaljer misoNo ratings yet

- Material Properties:: Design of Concrete BeamDocument1 pageMaterial Properties:: Design of Concrete BeamRBV DESIGN & BUILD SERVICESNo ratings yet

- Material Properties:: Design of Concrete BeamDocument4 pagesMaterial Properties:: Design of Concrete BeamRBV DESIGN & BUILD SERVICESNo ratings yet

- Material Properties:: Design of Concrete BeamDocument4 pagesMaterial Properties:: Design of Concrete BeamRBV DESIGN & BUILD SERVICESNo ratings yet

- Material Properties: Reinforcement Details: Design of Concrete BeamDocument1 pageMaterial Properties: Reinforcement Details: Design of Concrete BeamNick OperarioNo ratings yet

- Roof BeamDocument7 pagesRoof BeamNick OperarioNo ratings yet

- 5CD2 - E439 - 91C0 - 4CB4.: Material PropertiesDocument1 page5CD2 - E439 - 91C0 - 4CB4.: Material PropertiesMark Christian EsguerraNo ratings yet

- 5CD2 - E439 - 91C0 - 4CB4.: Material PropertiesDocument1 page5CD2 - E439 - 91C0 - 4CB4.: Material PropertiesMark Christian EsguerraNo ratings yet

- Design of BeamDocument1 pageDesign of Beampobre3nga3bataNo ratings yet

- Slab Design (Pillai & Menon) (Ex 11.1)Document2 pagesSlab Design (Pillai & Menon) (Ex 11.1)Md Ghani HaiderNo ratings yet

- One Way Continuous SlabDocument12 pagesOne Way Continuous Slabvenkatesh19701No ratings yet

- Struc Ex Pro Rectangular Beam Design CalculationDocument1 pageStruc Ex Pro Rectangular Beam Design Calculationpobre3nga3bataNo ratings yet

- Design of Slabs: Input DataDocument6 pagesDesign of Slabs: Input Datagewegw3gNo ratings yet

- Client Contractor Ujjain Municipal Corporation-Ujjain. Tata Projects Ltd.,-SecunderabadDocument32 pagesClient Contractor Ujjain Municipal Corporation-Ujjain. Tata Projects Ltd.,-Secunderabadepe civil1No ratings yet

- Doubly Reinforced Concrete Beam Design - InvestigationDocument4 pagesDoubly Reinforced Concrete Beam Design - InvestigationMark Brien Vincent YbañezNo ratings yet

- Footing Design - Studio AoartmentDocument23 pagesFooting Design - Studio AoartmentMUKESH RAJENDRANo ratings yet

- FootingDocument5 pagesFootingAbdul AzeemNo ratings yet

- Elevator Wall 1Document588 pagesElevator Wall 1kanokoNo ratings yet

- Slab Design OriginalDocument4 pagesSlab Design Originalsyed kashif pervezNo ratings yet

- Design of Two-Way SlabDocument1 pageDesign of Two-Way Slabpobre3nga3bataNo ratings yet

- Camber by Coefficients of Pci-Bridge Design ManualDocument4 pagesCamber by Coefficients of Pci-Bridge Design ManualFAIZAN AHMED100% (1)

- Concrete Steel: Selected Design Case: 2Document25 pagesConcrete Steel: Selected Design Case: 2venu manikantaNo ratings yet

- Beam Number: Project Name: 15-Mar-20 Engr. Mark Christian D. Esguerra Passed Engineer: DateDocument2 pagesBeam Number: Project Name: 15-Mar-20 Engr. Mark Christian D. Esguerra Passed Engineer: DateMark Christian EsguerraNo ratings yet

- Design Calculation: Base Pressure OkayDocument2 pagesDesign Calculation: Base Pressure Okaymassive85No ratings yet

- Flight 1: Main Staircase DesignDocument17 pagesFlight 1: Main Staircase DesignSatwik SantoshNo ratings yet

- 2 Cell Box CulvertDocument22 pages2 Cell Box Culvertabhijeet sahuNo ratings yet

- PCC Tow Wall Type 1 - Height 0.8mDocument6 pagesPCC Tow Wall Type 1 - Height 0.8mPrabha KaranNo ratings yet

- Design of Reinforced Concrete Beam: 2 Legs Number of Ties (Vertical) 2 Legs Number of Ties (Horizontal)Document3 pagesDesign of Reinforced Concrete Beam: 2 Legs Number of Ties (Vertical) 2 Legs Number of Ties (Horizontal)Andro RebuyasNo ratings yet

- Bearing Capacity Calculation Shallow Found - FinalDocument2 pagesBearing Capacity Calculation Shallow Found - Finalabcd efghNo ratings yet

- Concentric Foundation Revised 2.15Document5 pagesConcentric Foundation Revised 2.15Eldho GeorgeNo ratings yet

- (From Is 875-Part 3) : Pxl/AwDocument2 pages(From Is 875-Part 3) : Pxl/AwSantosh BapuNo ratings yet

- Doubly Reinforced Concrete Beam Design - DesignDocument3 pagesDoubly Reinforced Concrete Beam Design - DesignMark Brien Vincent YbañezNo ratings yet

- Pier 28+545Document155 pagesPier 28+545mayank007aggarwalNo ratings yet

- Strap Beam FootingDocument6 pagesStrap Beam FootingBinod Raj GiriNo ratings yet

- Reinforced Concrete Beam DesignDocument3 pagesReinforced Concrete Beam DesignMark Brien Vincent YbañezNo ratings yet

- Top LVL of Landing SlabDocument3 pagesTop LVL of Landing SlabMuhammad HasanNo ratings yet

- Laporan Pondasi Pasar R.2Document34 pagesLaporan Pondasi Pasar R.2Dio Akbar HakimNo ratings yet

- 1989 RC Beam DesignDocument7 pages1989 RC Beam Designsamloo1997No ratings yet

- Design of Staging of 19 M (Span) Bridge of Jorabat Flyover Assam Road Project (As-03)Document5 pagesDesign of Staging of 19 M (Span) Bridge of Jorabat Flyover Assam Road Project (As-03)Masud Amin100% (1)

- PEDESTAL - P1 - VlookupDocument4 pagesPEDESTAL - P1 - Vlookupraghav abudhabiNo ratings yet

- Desige of Long Column: Input Data: Out of Plan (B)Document25 pagesDesige of Long Column: Input Data: Out of Plan (B)bra22222No ratings yet

- Pile 4.5 MDocument2 pagesPile 4.5 MRAJAT SHARMANo ratings yet

- 15m RC TG Superstructure DesignDocument22 pages15m RC TG Superstructure DesignEngineeri TadiyosNo ratings yet

- Footing Design - Studio AoartmentDocument47 pagesFooting Design - Studio AoartmentMUKESH RAJENDRANo ratings yet

- FC' 20.68 Mpa Cement Finish 1.53 Kpa Ceiling Suspended Loads 0.48 Kpa Fy 230.00 MpaDocument19 pagesFC' 20.68 Mpa Cement Finish 1.53 Kpa Ceiling Suspended Loads 0.48 Kpa Fy 230.00 Mparamel sigueNo ratings yet

- Pier Wall DesignDocument5 pagesPier Wall DesignsanilNo ratings yet

- Check For SBC P/A M /Z M /Z: Provided Area Is OkayDocument2 pagesCheck For SBC P/A M /Z M /Z: Provided Area Is OkayVikunj TilvaNo ratings yet

- Deflection Check For SlabDocument1 pageDeflection Check For Slabselvakumar sNo ratings yet

- AISC2005 Anchor Bolt5 Pin Connection NewDocument6 pagesAISC2005 Anchor Bolt5 Pin Connection NewThuyTranNo ratings yet

- AISC2005 Anchor Bolt5 Pin Connection NewDocument6 pagesAISC2005 Anchor Bolt5 Pin Connection NewThuyTranNo ratings yet

- Design of SlabsDocument42 pagesDesign of SlabsMuralidargouda BhagavantagoudarNo ratings yet

- Composite Beam-Stilt FloorDocument9 pagesComposite Beam-Stilt FloorjatinNo ratings yet

- SlabDocument621 pagesSlabkanokoNo ratings yet

- STP Design Sheets D PochampallyDocument121 pagesSTP Design Sheets D Pochampallykiran raghukiranNo ratings yet

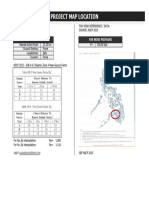

- Fault in ZamboangaDocument2 pagesFault in Zamboangaking taugNo ratings yet

- Map LocationDocument1 pageMap Locationking taugNo ratings yet

- Seismic Hazards Assessment: Date Location CoordinatesDocument5 pagesSeismic Hazards Assessment: Date Location Coordinatesking taugNo ratings yet

- Beam Design: Design By: Engr. Zulkiflee M. TaugDocument1 pageBeam Design: Design By: Engr. Zulkiflee M. Taugking taugNo ratings yet

- Design ReferenceDocument2 pagesDesign Referenceking taugNo ratings yet

- Beam Design: Planning and Design Section Design byDocument1 pageBeam Design: Planning and Design Section Design byking taugNo ratings yet

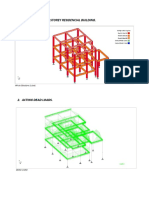

- Two Storey - Structural Design and AnalysisDocument3 pagesTwo Storey - Structural Design and Analysisking taugNo ratings yet

- Two Storey Structural DesignDocument9 pagesTwo Storey Structural Designking taugNo ratings yet

- "To Teachers": Thank You For Your Patience and Love and Support For Us Who Have in SpecialDocument1 page"To Teachers": Thank You For Your Patience and Love and Support For Us Who Have in Specialking taugNo ratings yet

- Proposed Two Storey Residencial Building With Structural Design and AnalysisDocument1 pageProposed Two Storey Residencial Building With Structural Design and Analysisking taugNo ratings yet

- Welcome Address: Zulkiflee M. Taug BSCE-IVDocument1 pageWelcome Address: Zulkiflee M. Taug BSCE-IVking taugNo ratings yet

- Laughter Is The Best Medicine: Zulkiflee M. Taug BSCE-IV Speech To InformDocument1 pageLaughter Is The Best Medicine: Zulkiflee M. Taug BSCE-IV Speech To Informking taugNo ratings yet

- Introduction of Speaker: Ladies and GentlemenDocument1 pageIntroduction of Speaker: Ladies and Gentlemenking taugNo ratings yet

- S029-Standard Details-BlockworkDocument1 pageS029-Standard Details-BlockworkWNo ratings yet

- Design Examples For The Eurocode 7Document12 pagesDesign Examples For The Eurocode 7milan_popovic_2100% (3)

- LM Towers - Steel RFQDocument17 pagesLM Towers - Steel RFQSulumonNo ratings yet

- Creepand ShrinkageDocument9 pagesCreepand ShrinkageagnayelNo ratings yet

- CE 5154 Introduction To Bridge EngineeringDocument115 pagesCE 5154 Introduction To Bridge EngineeringDavid Gómez de la TorreNo ratings yet

- How To Design FoundationsDocument8 pagesHow To Design Foundationsjrandeep0% (1)

- Dormer Construuction DrawingDocument1 pageDormer Construuction DrawingosviNo ratings yet

- Plan Standard Plan For PCCP 0.280 M Thick and 6.7 M Wide: General NotesDocument1 pagePlan Standard Plan For PCCP 0.280 M Thick and 6.7 M Wide: General NotesMarl John PinedaNo ratings yet

- Pages From Hilti BE 500Document1 pagePages From Hilti BE 500Anonymous S7Cq7ZDgPNo ratings yet

- CTY Assig 1Document6 pagesCTY Assig 1amahlethedjNo ratings yet

- Zn-Al Tank-50kL Design 12M STAGING - SBC 8TON PER SMTDocument22 pagesZn-Al Tank-50kL Design 12M STAGING - SBC 8TON PER SMTMUKESH RAJENDRANo ratings yet

- Side Runner & Purlin DesignDocument5 pagesSide Runner & Purlin DesignArun KesbhatNo ratings yet

- Formcraft Commercial Brochure Web VersionDocument4 pagesFormcraft Commercial Brochure Web VersionAndrew ReidNo ratings yet

- Estimation & CostingDocument18 pagesEstimation & CostinghridoyNo ratings yet

- Rip Rap 1 PDFDocument2 pagesRip Rap 1 PDFNajid MohamedNo ratings yet

- 1.2.1 Typical Sections: Precast-Pretensioned Concrete Girder BridgesDocument12 pages1.2.1 Typical Sections: Precast-Pretensioned Concrete Girder Bridgesmohamed ahmedNo ratings yet

- Effect of Basalt Fibers On The Flexural Behavior of Concrete Beams Reinforced With BFRP Bars PDFDocument12 pagesEffect of Basalt Fibers On The Flexural Behavior of Concrete Beams Reinforced With BFRP Bars PDFAyan HussainNo ratings yet

- Engineering Books - Excel Sheets PDFDocument10 pagesEngineering Books - Excel Sheets PDFvenkat ramanNo ratings yet

- Pier Cap Plan: Project:-Client: - ConsultantsDocument1 pagePier Cap Plan: Project:-Client: - ConsultantsShaileshRastogiNo ratings yet

- 1 CE133P Introduction To Reinforced Concrete DesignDocument14 pages1 CE133P Introduction To Reinforced Concrete DesignJohn Cedric GarganeraNo ratings yet

- Chemical Building Works Method Statement - 2Document12 pagesChemical Building Works Method Statement - 2abahriahNo ratings yet

- Structural Safety Measures For Airplanes: University of Florida, Gainesville, Florida 32611-6250Document9 pagesStructural Safety Measures For Airplanes: University of Florida, Gainesville, Florida 32611-6250w824rg2No ratings yet

- Code Requirements For Determining Fire Resistance of Concrete and Masonry Construction AssembliesDocument32 pagesCode Requirements For Determining Fire Resistance of Concrete and Masonry Construction Assembliesمنير أحمد100% (1)

- The Canadian LRFD Standard For Cold Formed Steel DesignDocument27 pagesThe Canadian LRFD Standard For Cold Formed Steel DesignHadeer MohamedNo ratings yet

- 1.0 Design Criterea 1 1 Assumptions 1.1 Assumptions: 8M Clear Span Solid Slab Bridge DesignDocument10 pages1.0 Design Criterea 1 1 Assumptions 1.1 Assumptions: 8M Clear Span Solid Slab Bridge DesignAddisu Gizaw Addis Ye AbereyeNo ratings yet

- RCC62 Retaining WallDocument15 pagesRCC62 Retaining WallRama KrishnaNo ratings yet

- 4.WMS-04-reinforcement Steel Fixing WorkDocument11 pages4.WMS-04-reinforcement Steel Fixing Workamol100% (1)

- Rigid PavementsDocument92 pagesRigid PavementsMadhur GuptaNo ratings yet

- Boq Final NewDocument77 pagesBoq Final NewAburvarajNo ratings yet

- Concrete Chamfer - Google SearchDocument1 pageConcrete Chamfer - Google SearchgrantNo ratings yet