Professional Documents

Culture Documents

14V0412 - 15 - Caustic Solution Day Tank (CL-3 - INTERNAL USE) - Google Sheets - P PDF

Uploaded by

Niraj Pandya0 ratings0% found this document useful (0 votes)

8 views3 pagesThe document provides a process data sheet for a Train-1 15% Caustic Solution day tank. It includes details like the equipment tag number, name, quantity, service, capacity, operating parameters, design specifications, nozzle schedule, and material of construction. The day tank will operate continuously to store 15% caustic solution at temperatures between 35-65°C and pressures from -300 mmWC to atmospheric. It lists 14 nozzles of various sizes and ratings including for inlet, outlet, vents, instruments, and spares. The tank material is stainless steel 304.

Original Description:

Original Title

14V0412 - 15 _ Caustic Solution Day Tank (CL-3_ INTERNAL USE) - Google Sheets_P.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document provides a process data sheet for a Train-1 15% Caustic Solution day tank. It includes details like the equipment tag number, name, quantity, service, capacity, operating parameters, design specifications, nozzle schedule, and material of construction. The day tank will operate continuously to store 15% caustic solution at temperatures between 35-65°C and pressures from -300 mmWC to atmospheric. It lists 14 nozzles of various sizes and ratings including for inlet, outlet, vents, instruments, and spares. The tank material is stainless steel 304.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

8 views3 pages14V0412 - 15 - Caustic Solution Day Tank (CL-3 - INTERNAL USE) - Google Sheets - P PDF

Uploaded by

Niraj PandyaThe document provides a process data sheet for a Train-1 15% Caustic Solution day tank. It includes details like the equipment tag number, name, quantity, service, capacity, operating parameters, design specifications, nozzle schedule, and material of construction. The day tank will operate continuously to store 15% caustic solution at temperatures between 35-65°C and pressures from -300 mmWC to atmospheric. It lists 14 nozzles of various sizes and ratings including for inlet, outlet, vents, instruments, and spares. The tank material is stainless steel 304.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

AARTI INDUSTRIES LIMITED

Technology Initiative No Technology Intiative Name Division Zone

084 SCMP Photochlorination Jasper 4

Document No: PIN-084-AIL-PM4-PR11-019

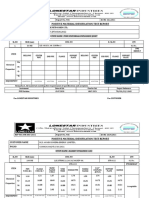

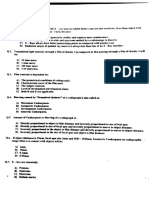

Process Data Sheet for Train-1 15% Caustic Solution Day Tank

Rev No Name Document status Signature Date

Rushabh

A Rushabh Rachhadiya IFR 25-Jan-2023

Prepared By Rachhadiya

Rev No Name Document status Signature Date

A Sagar vanam IFR Sagr vanam 27-Jan-2023

Checked By Samyak

A Samyak Gaikwad IFR 29-Jan-2023

Gaikwad

Rev No Name Document status Signature Date

A Rajendra wagh IFR Rajendra wagh 30-Jan-2023

Approved By

AARTI INDUSTRIES Process Data Sheet - Storage Tank / Day Tank / Settlers /

AARTI INDUSTRIES LIMITED Process Data Sheet - Storage Tank / Day Tank / Settlers / Reciever

Reciever

LIMITED

PROJECT : SCMP Photochlorination MOC/PROJEC 084 PROJECT : SCMP Photochlorination MOC/PROJECT NO : 084

T NO

Sr No DIVISION : Jasper ZONE: 4 DIVISION : Jasper ZONE: 4

DOC. NO : PIN-084-AIL-PM4-PR11-019 DATE : 25-Jan-2023 Sr No DOC. NO : PIN-084-AIL-PM4-PR11-019 DATE : 25-Jan-2023

IDENTITY 2.1 IDENTITY

Data shall be provided by Process / Operation Team Data shall be provided by Process / Operation Team

Following parameters shall be required for Selection, Design & Procurement Following parameters shall be required for Selection, Design & Procurement

Sr. No. Particulars UOM / Detail Data / Remarks Sr No Nozzle Schedule

1 Equipment Tag No 14V0412 Sr No Nozzle Tag Diameter (NB) Rating / Facing Service No

2 Equipment Name Train-1 15% Caustic Solution day Tank 1 M1 500 150#/RF Top manhole 1

3 Quantity 1 2 N1 80X50 150#/RF Water inlet with j pipe 1

4 Service Inorganic 3 N2 80X50 150#/RF Inlet with dip pipe 1

5 Capacity M3 60 4 N3 40 150#/RF Pump Recirculation 1

6 Operating Volume M3 48 5 N4 150 (hold) 150#/RF PSV (Hold) 1

7 Type of Operation Batch / Continuous Continuous 6 N5 25 150#/RF Nitrogen blanketing (PCV) 1

8 Operating Pressure Kg/cm2g -300 mmWC to atm 7 N6 100 150#/RF Level Transmitter 1

9 Operating Temperature, Min / Nor / Max DegC 35/50/65 8 N7 100 150#/RF Spare with Blind 1

10 Density Kg/m3 1200 N8 80 150#/RF Spare with Blind 1

2.5 kg/m2 (g) to -1000

11 Design Pressure Kg/cm2g mmWC 9 N9 50 150#/RF Pressure Transmitter 1

N10 Temperature transmitter 1

12 Design Temperature DegC 90 10 40 150#/RF (Side Mounted)

13 Diameter mm 3750 11 N11 100 150#/RF Bottom Outlet 1

14 TL-TL Height mm 5450 12 N12 100 150#/RF Vent (PRV) 1

15 Corrosion Allowance mm 0 13 N13 40 150#/RF Level Switch 1

16 Vessel MOC SS304 14

Post Weld Heat Treatment (Process

17 Requirement) NA 15

18 Insulation Required / Not Required Required 16

19 Insulation Thickness mm 40 17

20 Insulation Material Mineral wool 18

21 Fluid Characteristic Toxic / Flammable / Reactive / General Service Reactive 19

22 Heating / Cooling Jacket / Limped Coil / Tracing NA 20

23 Jacket / Coil Material NA 21

24 Jacket / Coil Design Pressure Kg/cm2g NA 22

25 Jacket Coil Design Temperature DegC NA 23

26 Jacket/Coil corrosion Allowance mm NA 24

27 Limpet type Horizontal/Vertical NA 25

28 Coil Pipe Diameter mm NA 26

29 Limpet Pitch mm NA 27

30 Limpet Stage NA 28

31 Design Code VTS 29

32 Gasket MOC PTFE 30

33 Notes 31

34 Type of support to be confirmed during DDE 32

35 PSV sizing will be confirmed during DE 33

36 34

37 35

38 36

39 37

40 38

41 39

42 40

43 41

44 42

45 43

46 44

47 45

48 46 Notes

49 47

50 48

51 49

You might also like

- Book - Sefer Yetzira - Book of Creation - Free KabbalahDocument3 pagesBook - Sefer Yetzira - Book of Creation - Free KabbalahJoshuaNo ratings yet

- ResumeDocument3 pagesResumeSaharsh MaheshwariNo ratings yet

- WMS003 Method Statement - Welding and CuttingDocument8 pagesWMS003 Method Statement - Welding and CuttingSalwyn Lopis100% (2)

- Quality Assurance Plan: High Frequency Electric Resistance Welded PipeDocument15 pagesQuality Assurance Plan: High Frequency Electric Resistance Welded PipeSachin KumarNo ratings yet

- صيانة المولدات و المحولات الكهربائيهDocument15 pagesصيانة المولدات و المحولات الكهربائيهMostafa AllamNo ratings yet

- ENIRAM - Guide To Dynamic Trim Optimization 280611 PDFDocument14 pagesENIRAM - Guide To Dynamic Trim Optimization 280611 PDFPhineas MagellanNo ratings yet

- FO-InD-HAL-PR-001 - Inspection Work Order Form - RevG - 2019!11!01 - PHE Oses Frac EquipmentDocument1 pageFO-InD-HAL-PR-001 - Inspection Work Order Form - RevG - 2019!11!01 - PHE Oses Frac EquipmentRico100% (1)

- QAP For Pipes For Hydrant and Sprinkler SystemDocument3 pagesQAP For Pipes For Hydrant and Sprinkler SystemCaspian DattaNo ratings yet

- Cable Connection List - Power & Control Cables-Ammonia Storage Plant # 90Document18 pagesCable Connection List - Power & Control Cables-Ammonia Storage Plant # 90Sandeep GuptaNo ratings yet

- Asf Itp 1171 001Document7 pagesAsf Itp 1171 001el_sharkawy2011No ratings yet

- Steam Trap & Piston Valve Qap PDFDocument1 pageSteam Trap & Piston Valve Qap PDFajmainNo ratings yet

- D62 - 691 - 5 - C4-Specification Sheets PDFDocument26 pagesD62 - 691 - 5 - C4-Specification Sheets PDFSoumiyaNo ratings yet

- IVR-050212116123 - 22-1-Rev.0 - Enmas - True FabDocument6 pagesIVR-050212116123 - 22-1-Rev.0 - Enmas - True FabPavul RajNo ratings yet

- Imir 1714Document1 pageImir 1714abhijit007beraNo ratings yet

- 1.wash Pipe 8-1-8 SN NNDocument1 page1.wash Pipe 8-1-8 SN NNMuhammad Rijal sembiringNo ratings yet

- IVR 010101105622 - 488 1 Rev.0Document6 pagesIVR 010101105622 - 488 1 Rev.0maheshpanditNo ratings yet

- RFI Welding TestDocument18 pagesRFI Welding TestDimas agungNo ratings yet

- EM00043-ALMAHA-MAR-0015 Rev ADocument8 pagesEM00043-ALMAHA-MAR-0015 Rev Aafzal empirestateNo ratings yet

- Checklist Fire StopDocument9 pagesChecklist Fire StopAnonymous DMdGdsOENo ratings yet

- Sumed - TK 01-2017 Rev 0Document4 pagesSumed - TK 01-2017 Rev 0Kareem AbdelazizNo ratings yet

- Technical Data Sheet For StayWire - D1Document4 pagesTechnical Data Sheet For StayWire - D1sm.kdh.nsNo ratings yet

- Pmi ReportDocument5 pagesPmi ReportMANIMARAN QCNo ratings yet

- Not For Approval: Thyssenkrupp Industrial Solutions (Usa), IncDocument25 pagesNot For Approval: Thyssenkrupp Industrial Solutions (Usa), IncJorge SalazarNo ratings yet

- Reliance Industries Limited Line History Sheet For Low Alloy Steel PipingDocument2 pagesReliance Industries Limited Line History Sheet For Low Alloy Steel PipingRavi ShankarNo ratings yet

- QAP HMEL 7480000754 L08722A501-SignedDocument3 pagesQAP HMEL 7480000754 L08722A501-SignedSuyog GawandeNo ratings yet

- 100 KLPD of 2G Ethanol From Biomass at Iocl PanipatDocument7 pages100 KLPD of 2G Ethanol From Biomass at Iocl PanipatSuraj ShettyNo ratings yet

- Spam Karian Timur Pipeline ProjectDocument14 pagesSpam Karian Timur Pipeline ProjectTeguh SilaNo ratings yet

- RT Request: Hail Surface Facilities Eps ProjectDocument4 pagesRT Request: Hail Surface Facilities Eps ProjectAnonymous AdofXEYAgENo ratings yet

- IPS-MBD20031-In-512 - Data Sheet of Rotameter - ADocument3 pagesIPS-MBD20031-In-512 - Data Sheet of Rotameter - ANikhil KarkeraNo ratings yet

- Pending List PDFDocument2 pagesPending List PDFProduction Unit IVNo ratings yet

- IVR 010101374023 - 10 1 Rev.0Document5 pagesIVR 010101374023 - 10 1 Rev.0PRADEEP GAIKWADNo ratings yet

- With Strainer, Piston QapDocument1 pageWith Strainer, Piston QapajmainNo ratings yet

- Posorja Multipurpose Terminal Terminal Works: Contractor EngineerDocument3 pagesPosorja Multipurpose Terminal Terminal Works: Contractor Engineerhz135874No ratings yet

- Test Protocol: ForDocument7 pagesTest Protocol: Forqc deNo ratings yet

- 710 R 002 (Sulfur Guard)Document5 pages710 R 002 (Sulfur Guard)idilfitriNo ratings yet

- 9500-WGEL-S003-ISGP-G00000-MP-4306-00017 - 01A - MTO PFF - by LayoutDocument7 pages9500-WGEL-S003-ISGP-G00000-MP-4306-00017 - 01A - MTO PFF - by Layoutsuresh100% (1)

- Informe Radiografico para Piezas Moldeadas Radiographic Report For CastingDocument2 pagesInforme Radiografico para Piezas Moldeadas Radiographic Report For CastingSathish JayaprakashNo ratings yet

- This Supply Is Composed of Two PartsDocument92 pagesThis Supply Is Composed of Two PartsShyammurugesanNo ratings yet

- Inspection Report: 1 - Reference SectionDocument2 pagesInspection Report: 1 - Reference SectionMahesh RINANo ratings yet

- Epc Revitalization Project of RCC Ru Vi Balongan: Attachment - 1Document1 pageEpc Revitalization Project of RCC Ru Vi Balongan: Attachment - 1Tommy ArjanggiNo ratings yet

- PR For BV - NON-METALLIC - R0 - DIGHADocument6 pagesPR For BV - NON-METALLIC - R0 - DIGHADipali DaveNo ratings yet

- BB2 Rev03Document8 pagesBB2 Rev03Ahmed El-AzharyNo ratings yet

- Manufacturing Quality PlanDocument4 pagesManufacturing Quality PlanDIENSHNo ratings yet

- Final Insepection Reports and WPS PQRDocument14 pagesFinal Insepection Reports and WPS PQRVikas Verma100% (1)

- Visit Report: TUV Control No.: TUV SAP No: 8115236437 (Branch: Report NoDocument4 pagesVisit Report: TUV Control No.: TUV SAP No: 8115236437 (Branch: Report NoVinay YadavNo ratings yet

- MR For Pipeline Bulk Materials, Rev.ADocument31 pagesMR For Pipeline Bulk Materials, Rev.ASandeepNBabuNo ratings yet

- Ms Facing SheetDocument8 pagesMs Facing Sheetafzal empirestateNo ratings yet

- Welder Qualification Test Certificate: Weld Test Details Range of ApprovalDocument1 pageWelder Qualification Test Certificate: Weld Test Details Range of ApprovalRamkunwar YadavNo ratings yet

- Trailer 2 - Ali HasanDocument1 pageTrailer 2 - Ali HasanmohamadazizhudliNo ratings yet

- Agirm Agn 4500210653 Itp 001 02 Kas3 Iso Seawater Strainer Forward Sea ChestDocument6 pagesAgirm Agn 4500210653 Itp 001 02 Kas3 Iso Seawater Strainer Forward Sea ChestRJS TUTORIALNo ratings yet

- 17269-ASM1801-PO QAP Wuhan Rev.02.Document5 pages17269-ASM1801-PO QAP Wuhan Rev.02.Parikshit GaurNo ratings yet

- Technical Procurement Specification TPS No.: Status: Origination Department: P.O/W.O No.: Project: Location: Client: Pruchaser: Vendor: ItemDocument9 pagesTechnical Procurement Specification TPS No.: Status: Origination Department: P.O/W.O No.: Project: Location: Client: Pruchaser: Vendor: Itemrafikul123No ratings yet

- Quality Plan (Incoming) : Assy / Sub-Assy Name: Format No: Assy / Sub-Assy No: Latest Drawing Reference DetailsDocument5 pagesQuality Plan (Incoming) : Assy / Sub-Assy Name: Format No: Assy / Sub-Assy No: Latest Drawing Reference DetailsScientific KingNo ratings yet

- 520A - Control Valve - 1Document3 pages520A - Control Valve - 1Nikhil KarkeraNo ratings yet

- Pressure Reducing Station Qap Alfa LavalDocument1 pagePressure Reducing Station Qap Alfa LavalajmainNo ratings yet

- Data Sheet For Anchor (2472)Document2 pagesData Sheet For Anchor (2472)Romawi Stevyandi100% (1)

- Reports Material Fiberline Up2 AjgDocument10 pagesReports Material Fiberline Up2 AjgAndika PradanaNo ratings yet

- BGRL (Satara-Sangli) - Spur Spread-3 - JP-Arc Strike - R0 - Code A - 26.02.2021Document6 pagesBGRL (Satara-Sangli) - Spur Spread-3 - JP-Arc Strike - R0 - Code A - 26.02.2021Aditya IngawaleNo ratings yet

- Native Inspection - Report - CleanedDocument6 pagesNative Inspection - Report - CleanedPrathamesh OmtechNo ratings yet

- PSR&LLDocument15 pagesPSR&LLZain AbidiNo ratings yet

- Gopinat Engee Welder Certi.Document2 pagesGopinat Engee Welder Certi.Silpa KumariNo ratings yet

- Discipline: Rev. No.: Size: Document No.: Unit / Area NameDocument5 pagesDiscipline: Rev. No.: Size: Document No.: Unit / Area NameRishabh VermaNo ratings yet

- Applied Process Control SystemsDocument263 pagesApplied Process Control SystemsMuhammad Shahid GhaniNo ratings yet

- Table of ContentsDocument131 pagesTable of ContentsNiraj PandyaNo ratings yet

- Table of ContentsDocument131 pagesTable of ContentsNiraj PandyaNo ratings yet

- Civil EDB - B224-999-81-41-EDB-1001 - Civil EDBDocument68 pagesCivil EDB - B224-999-81-41-EDB-1001 - Civil EDBNiraj PandyaNo ratings yet

- Ferrous - Non Ferrous MaterialDocument9 pagesFerrous - Non Ferrous MaterialNiraj PandyaNo ratings yet

- API 650 Water Storage TankDocument60 pagesAPI 650 Water Storage TankSyed Mustafa HussainNo ratings yet

- 101 C161 R0DDocument237 pages101 C161 R0DNiraj PandyaNo ratings yet

- Orientation Course in Planning DeptDocument29 pagesOrientation Course in Planning DeptNiraj PandyaNo ratings yet

- RT Level 3 Mock Up 2Document7 pagesRT Level 3 Mock Up 2Niraj PandyaNo ratings yet

- LPT NotesDocument17 pagesLPT NotesNiraj PandyaNo ratings yet

- 1Document100 pages1Niraj PandyaNo ratings yet

- 1 SS PP 014 Add2.2Document3 pages1 SS PP 014 Add2.2Niraj PandyaNo ratings yet

- PERTCPM PresentationDocument20 pagesPERTCPM PresentationNiraj PandyaNo ratings yet

- Appendix 1 SR No Description Price Inr RemarksDocument1 pageAppendix 1 SR No Description Price Inr RemarksNiraj PandyaNo ratings yet

- Mechanical Polishing and Electro Polishing Procedure RevDocument13 pagesMechanical Polishing and Electro Polishing Procedure RevNiraj PandyaNo ratings yet

- 17-Surface Roughness and Machining Symbols FullDocument17 pages17-Surface Roughness and Machining Symbols FullNiraj PandyaNo ratings yet

- Use This Table To Convert Between Commonly Used Leak Rate UnitsDocument2 pagesUse This Table To Convert Between Commonly Used Leak Rate UnitsNiraj PandyaNo ratings yet

- Pressure Vessel IIT Mumbai PDFDocument12 pagesPressure Vessel IIT Mumbai PDFNiraj PandyaNo ratings yet

- 17865Document2 pages17865Niraj PandyaNo ratings yet

- Ansi Typeb18 22 1Document1 pageAnsi Typeb18 22 1Niraj PandyaNo ratings yet

- Engineering Design Guideline - HX Rev 3Document24 pagesEngineering Design Guideline - HX Rev 3axle_ramNo ratings yet

- E - C& I Standards GSR - Rev03Document23 pagesE - C& I Standards GSR - Rev03Niraj Pandya0% (1)

- Power and Horsepower in Electrical MotorsDocument3 pagesPower and Horsepower in Electrical MotorsNiraj PandyaNo ratings yet

- 316L Imp4Document11 pages316L Imp4Suresh JeevaNo ratings yet

- E - C& I Standards GSR - Rev03Document23 pagesE - C& I Standards GSR - Rev03Niraj Pandya0% (1)

- Python - Data EngineeringDocument34 pagesPython - Data EngineeringChetan PatilNo ratings yet

- The First-Fourth Books of The HitopadésaDocument116 pagesThe First-Fourth Books of The HitopadésaMiguel RosaNo ratings yet

- 02.certificate of Compliance FM UkDocument10 pages02.certificate of Compliance FM Ukmyatthura870No ratings yet

- Miracle Mills 300 Series Hammer MillsDocument2 pagesMiracle Mills 300 Series Hammer MillsSNo ratings yet

- 2021 3 AbstractsDocument168 pages2021 3 AbstractsLong An ĐỗNo ratings yet

- St. Louis College of Bulanao: Title/Topic Technical English I Introduction To Police Report WritingDocument41 pagesSt. Louis College of Bulanao: Title/Topic Technical English I Introduction To Police Report WritingNovelyn LumboyNo ratings yet

- Formal Report Expt 5Document6 pagesFormal Report Expt 5AnonymouscatNo ratings yet

- MiningDocument3 pagesMiningDherick RaleighNo ratings yet

- How The Audiences Feel Closer and Connected To Their Culture With StorytellingDocument7 pagesHow The Audiences Feel Closer and Connected To Their Culture With Storytellingmarcelo quezadaNo ratings yet

- Anatomy & Physiology MCQsDocument26 pagesAnatomy & Physiology MCQsMuskan warisNo ratings yet

- Budget of Work Inquiries Investigations and Immersion 19 20Document1 pageBudget of Work Inquiries Investigations and Immersion 19 20alma florNo ratings yet

- Conceptualizing On Structure Functionalism and Its Applications On Patriotism Study During Covid-19 Pandemic in MalaysiaDocument7 pagesConceptualizing On Structure Functionalism and Its Applications On Patriotism Study During Covid-19 Pandemic in MalaysiaMuhammadSyaqirAimanNo ratings yet

- The Magical Number 5: Towards A Theory of Everything?Document27 pagesThe Magical Number 5: Towards A Theory of Everything?cesarfrancaNo ratings yet

- NCR Supplier PPAP Training PresentationDocument166 pagesNCR Supplier PPAP Training PresentationRajeev ChadhaNo ratings yet

- 3-Storeyed 31-3-2015-Schedule PDFDocument1 page3-Storeyed 31-3-2015-Schedule PDFSi Thu AungNo ratings yet

- Chapter 1 MPLS OAM Configuration Commands ...................................................................... 1-1Document27 pagesChapter 1 MPLS OAM Configuration Commands ...................................................................... 1-1Randy DookheranNo ratings yet

- Labour Law Assignment - Gross NegligenceDocument6 pagesLabour Law Assignment - Gross NegligenceOlaotse MoletsaneNo ratings yet

- Evolis User ManualDocument28 pagesEvolis User ManualIonmadalin1000No ratings yet

- Fiitjee All India Test Series: Concept Recapitulation Test - Iv JEE (Advanced) - 2019Document13 pagesFiitjee All India Test Series: Concept Recapitulation Test - Iv JEE (Advanced) - 2019Raj KumarNo ratings yet

- Examiners' Report Principal Examiner Feedback January 2018Document7 pagesExaminers' Report Principal Examiner Feedback January 2018WandaNo ratings yet

- History of Computer ReviewerDocument10 pagesHistory of Computer ReviewerNeil Andrew Aliazas78% (9)

- Sheet Metal Cutting Using Geneva MechanismDocument27 pagesSheet Metal Cutting Using Geneva MechanismsingamNo ratings yet

- Steam TableDocument3 pagesSteam TableMUHAMAD SAUKINo ratings yet

- UnitPlan (P.E) Grade 6Document13 pagesUnitPlan (P.E) Grade 6Lou At CamellaNo ratings yet

- One Plan Student 1Document7 pagesOne Plan Student 1api-465826207No ratings yet

- Effect of Liquidity Risk On Performance of Deposit Money Banks in NigeriaDocument6 pagesEffect of Liquidity Risk On Performance of Deposit Money Banks in NigeriaEditor IJTSRDNo ratings yet