Professional Documents

Culture Documents

17269-ASM1801-PO QAP Wuhan Rev.02.

Uploaded by

Parikshit GaurOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

17269-ASM1801-PO QAP Wuhan Rev.02.

Uploaded by

Parikshit GaurCopyright:

Available Formats

OWNER PMC

Talcher Fertilizers Limited (TFL) Projects & Development India Ltd (PDIL)

WUHUAN Project No.:

WUHUAN ENGINEERING CO., LTD. Ammonia-Urea Plant, Talcher

17269

ZETWERK MANUFACTURING BUSNIESSES PRIVATE LIMITED

Vendor Doc. No.: CN_KA-22890/23-24/QAP/106 Rev.02 Dt.06.07.2023

QUALITY ASSURANCE PLAN

Scale/Size: Sheet 01 of 05 Rev.: 2

QUALITY ASSURANCE PLAN

PO No.: 17269-ASM1801-PO

Item Name: STEEL STRUCTURES OF AMMONIA-UREA PLANT

Item No.: As per the Drawing

02 IFA R. SHANMUGANATHAN RAMESH BABU B RAMESH BABU B

01 IFA R. SHANMUGANATHAN RAMESH BABU B RAMESH BABU B

00 IFA R. SHANMUGANATHAN RAMESH BABU B RAMESH BABU B

Rev. DESCRIPTION DEGND CHEKD APPRD AUTHD DATE

ZETWERK MANUFACTURING BUSINESSES PVT LTD.,

Oriental Towers No.461, 1st & 2nd Floor, 4th Sector,

ZETWERK MANUFACTURING BUSINESSES PRIVATE LIMITED 17th Cross, HSR Layout Bengaluru, India - 560 102.

Website: www.zetwerk.com

CUSTOMER WUHUAN ENGINEERING CO., LTD QAP NO CN_KA-22890/23-24/QAP/106 Rev.02 DATE : 06.07.2023

CUSTOMER

CLIENT TALCHER FERTILIZERS LIMITED (TFL) 17269-ASM1801-PO DATE : 27-Mar-2023

PO.NO

PMC PROJECTS & DEVELOPMENT INDIA LTD (PDIL)

PROJECT AMMONIA UREA PLANT, TALCHER

PRODUCT / NAME FABRICATION AND SUPPLY OF STRUCTURAL STEEL AND OTHER STEEL, IRON OR METAL ITEMS

DOCUMENT REF: 1. 17269 -002000- AR01 Rev.0C - General Specification of Architecture 4. 17125/17269-PP67-001 Rev.1 - Instructions for QAP/ITP Preparation

2. 17269 - 00200- ST0504 Rev.2A - Specification for Steel Fabrication 5. 17269-PP41-001 Rev.0A - Packing and Marking Specification

3. 17269-ASM1801-PO Rev.2A Technical Appendix for Structural Steel and Other Steel, Iron or Metal Items (Material 6. 17269-PP79-01 Rev.2 - Vendor Document Handling procedure

and fabrication of Ammonia-Urea Plant)

QUALITY ASSURANCE PLAN

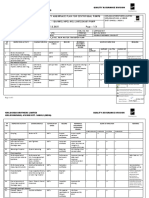

INSPECTION & QUANTUM RESPONSIBILITY

CHARACTERISTIC REFERENCE STANDARD/ FORMAT/

Sl. No. TESTING TYPE OF CHECK OF ACCEPTANCE CRITERIA WUH TFL/ REMARKS

TO BE VERIFIED DOCUMENT/ RECORDS MFG TPIA

DESCRIPTION CHECK UAN PMC

1 2 3 4 5 6 7 8 9 10 11 12 13

Pre Inspection Verification of all Approved

0.0 W H H -

Meeting Documents

1.0 DOCUMENT APPROVAL

Quality Assurance Requirements as per the TA, STD & TA/Applicable Code &

1.1 - - TA/Applicable Code & Standards - P - R R

Plan Applicable Code Standards

*WPS,PQR & WPQ for TPI Witness for NEW establishment

Welding parameter, characterstics,

1.2 WPS,PQR,WPQ - - ASME Sec IX / AWS D1.1 ASME Sec IX / AWS D1.1 - P W/R* R - Review for Existing WPS,PQR & WPQ

qualification

Spec/TA/Applicable code / Spec/TA/Applicable code /

1.3 NDE Procedures Procedures - - - P R R -

Applicable Drawings Applicable Drawings

Surface Preparation & Spec/TA/Applicable code / Spec/TA/Applicable code /

1.4 procedures - - - P R R I

Painting Applicable Drawings Applicable Drawings

2.0 RAWMATERIAL CONTROL

Visual Visual 100% Mill test certificate is mandatory for all bought out

Visual/ Dimension / Marking

Inspection materials.

Rawmaterials : Identification of materials as In accordance with

Report and Approved Make :Refer Below note

2.1 Plate, Rolled Sections Dimensional Check Measurment 10% per relevant material relevant material Specification & P RW* - -

MTC / test

etc… Specification Approved Drawings

certificate *10 % Random Witness by TPIA during Incoming

& Approved Drawings

Physical & Chemical Review of Mfg TC 100% Inspection of RM (plate, Rolled Sections, Other

section etc..)

3.0 BOUGHTOUT ITMES

1.Verification of Batch Test Document In accordance with Standards/ In accordance with Standards/ List of Approved Make :

3.1 Paint Certificates Review/BTC 100% WUHUAN Specification & WUHUAN Specification & TC/BTC P R - - Refer Below Note & Painting Procedure No:

2. Visual Review Approved Drawing Approved Drawing CN-KA-22890-ZET/WECL/SPP/01 Dt.11-05-2023

1.Verification of Batch Test Document In accordance with Standards/ In accordance with Standards/

Fastneres

3.2 Certificates Review/BTC 100% WUHUAN Specification & WUHUAN Specification & TC/BTC P R - -

(Bolt, Nut & Washers)

2. Visual Review Approved Drawing Approved Drawing

1.Verification of Batch Test Document Electrodes Confirming to List of Approved Make :

Welding In accordance with Standards/

3.3 Certificates Review/BTC 100% ASME Sec II Part C Ed'2019 TC/BTC P R - - Refer Below Note

Consumbales WUHUAN Specification &

2. Visual Review /IS:814:2004

In accordance with

In accordance with Calibration

Calibration for testing 1.Verification of Calibration Record manufactures

3.4 Document Review 100% manufactures recommendation List / P R - -

Measuring Equipment 2. Ensure Calibration recommendation and NABL

and NABL norms Record

norms

Form No : ZET-QA-F-01 REV.00 Dt.03.08.2020 Page 1 of 4

ZETWERK MANUFACTURING BUSINESSES PVT LTD.,

Oriental Towers No.461, 1st & 2nd Floor, 4th Sector,

ZETWERK MANUFACTURING BUSINESSES PRIVATE LIMITED 17th Cross, HSR Layout Bengaluru, India - 560 102.

Website: www.zetwerk.com

CUSTOMER WUHUAN ENGINEERING CO., LTD QAP NO CN_KA-22890/23-24/QAP/106 Rev.02 DATE : 06.07.2023

CUSTOMER

CLIENT TALCHER FERTILIZERS LIMITED (TFL) 17269-ASM1801-PO DATE : 27-Mar-2023

PO.NO

PMC PROJECTS & DEVELOPMENT INDIA LTD (PDIL)

PROJECT AMMONIA UREA PLANT, TALCHER

PRODUCT / NAME FABRICATION AND SUPPLY OF STRUCTURAL STEEL AND OTHER STEEL, IRON OR METAL ITEMS

DOCUMENT REF: 1. 17269 -002000- AR01 Rev.0C - General Specification of Architecture 4. 17125/17269-PP67-001 Rev.1 - Instructions for QAP/ITP Preparation

2. 17269 - 00200- ST0504 Rev.2A - Specification for Steel Fabrication 5. 17269-PP41-001 Rev.0A - Packing and Marking Specification

3. 17269-ASM1801-PO Rev.2A Technical Appendix for Structural Steel and Other Steel, Iron or Metal Items (Material 6. 17269-PP79-01 Rev.2 - Vendor Document Handling procedure

and fabrication of Ammonia-Urea Plant)

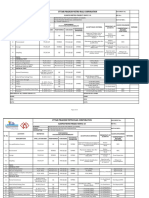

QUALITY ASSURANCE PLAN

INSPECTION & QUANTUM RESPONSIBILITY

CHARACTERISTIC REFERENCE STANDARD/ FORMAT/

Sl. No. TESTING TYPE OF CHECK OF ACCEPTANCE CRITERIA WUH TFL/ REMARKS

TO BE VERIFIED DOCUMENT/ RECORDS MFG TPIA

DESCRIPTION CHECK UAN PMC

1 2 3 4 5 6 7 8 9 10 11 12 13

4.0 PROCESS QUALIFICATION

NDE Personnels Review of NDE

4.1 Personal Qualification 100% SNT - TC - 1 A or Equivalent SNT - TC - 1 A or Equivalent P R - -

Qualification documents Certificates

Welding Procedure Specification

Welding Procedure Specifications already

(WPS) & Procedure Qualification Review of Record Approved

Welding / Welder ASME Sec IX / AWS D1.1 & established with supporting Procedure

4.2 Record (PQR) / 100% ASME Sec IX / AWS D1.1 WPS, PQR P R - -

Qualification Approved Drawings Qualification record shall be submitted for review

Welder Performance Qualifcation As Applicable & WPQ

& Approval

(WPQ)

5.0 INPROCESS CONTROL

Marking and cutting Approved

Profile Cutting,Drawing Dimension Measurement / In accordance with Approved Drawing ,

5.1 of plates, beam, 100% Drawing/ P R - -

& NoTwist / Bend Visual IS 7215 & IS 1852

channels etc. Cutting Plan

Assembly of Parts, Holes Location,

Fit-up of Fabricated Measurement/ Inspection

5.2 Size, Orientation, Twist, Bend, 100% In accordance with Approved Drawing & is 7215 P R - -

Parts Visual Report

Straightness

Welding / All Welding Shall be as Per

Check WPS/WPQ, Weld Parameter Measurment / Inspecton

5.3 Weld Visual 100% IS : 816 and IS 9595 Using Electrodes Confirming To P RW - - Witness for final weld Visual

Weld Visual & Size Visual Report

Examination IS:814, AWS D1.1 & ASME Sec IX

In accordane with Approved ASME Sec V'Ed 2019 / AWS D1.1

NDT on Final Fillet Random Witness by TPIA /WUHUAN during final

5.4 Weld discontinuity on surface area DP Test 10% Drawing & ASME SEC V , 2020 Clause 8.14.5, & Approved DPT Report P RW - -

Weld Inspection

SE 165 Procedure

*1. UT Test Should 100% for all Beams connected

with columns, Vertical brace, Crane beams and all

ASME Sec V Ed'2019/ AWS D1.1 -

NDT on Butt weld 100%/ * In accordane with Approved cantilever parts.

5.5 Weld Joint defects UT Test 2020 - Clause No. 8.13 & UT Report P RW - -

Joint - UT if any 20 % Drawing & ASME Sec V 2.UT test should 20% on others excluding the first

Approved Procedure

items.

Random Witness by TPIA during final Inspection

Dimensional Overall Dimensions of Assembly,

In Accordance with Approved

Inspection after Holes Location, Size, Orientation as Measurment / In accordance with Approved Inspeciton

5.6 100% Drawing, Specification & P RW - - Completeness check

Welding (Black) per Drawing. Visual Drawing Report

IS 7215

(Before Painting) Twist, Bend, Straightness

Form No : ZET-QA-F-01 REV.00 Dt.03.08.2020 Page 2 of 4

ZETWERK MANUFACTURING BUSINESSES PVT LTD.,

Oriental Towers No.461, 1st & 2nd Floor, 4th Sector,

ZETWERK MANUFACTURING BUSINESSES PRIVATE LIMITED 17th Cross, HSR Layout Bengaluru, India - 560 102.

Website: www.zetwerk.com

CUSTOMER WUHUAN ENGINEERING CO., LTD QAP NO CN_KA-22890/23-24/QAP/106 Rev.02 DATE : 06.07.2023

CUSTOMER

CLIENT TALCHER FERTILIZERS LIMITED (TFL) 17269-ASM1801-PO DATE : 27-Mar-2023

PO.NO

PMC PROJECTS & DEVELOPMENT INDIA LTD (PDIL)

PROJECT AMMONIA UREA PLANT, TALCHER

PRODUCT / NAME FABRICATION AND SUPPLY OF STRUCTURAL STEEL AND OTHER STEEL, IRON OR METAL ITEMS

DOCUMENT REF: 1. 17269 -002000- AR01 Rev.0C - General Specification of Architecture 4. 17125/17269-PP67-001 Rev.1 - Instructions for QAP/ITP Preparation

2. 17269 - 00200- ST0504 Rev.2A - Specification for Steel Fabrication 5. 17269-PP41-001 Rev.0A - Packing and Marking Specification

3. 17269-ASM1801-PO Rev.2A Technical Appendix for Structural Steel and Other Steel, Iron or Metal Items (Material 6. 17269-PP79-01 Rev.2 - Vendor Document Handling procedure

and fabrication of Ammonia-Urea Plant)

QUALITY ASSURANCE PLAN

INSPECTION & QUANTUM RESPONSIBILITY

CHARACTERISTIC REFERENCE STANDARD/ FORMAT/

Sl. No. TESTING TYPE OF CHECK OF ACCEPTANCE CRITERIA WUH TFL/ REMARKS

TO BE VERIFIED DOCUMENT/ RECORDS MFG TPIA

DESCRIPTION CHECK UAN PMC

1 2 3 4 5 6 7 8 9 10 11 12 13

6.0 SURFACE PREPARATION & PAINTING

Surface shall be Free from visible Surface Preparation : :All steel works shall be blasted to a

Oil, Grease and dirt and from mill Visual 100% minimum standard as per IS 8501 Part 1 - SSPC -SP10 P R - -

scale,rust & foreign matter (Sa-2-1/2), Swedish standard SIS 05 5900.

All structures steel

works Surface

6.1 one coat of two pack zinc rich epoxy primer meeting SSPC Paint Paint Report Total DFT : 50+120 = 170 Miconrs

Preparation & PRIMER PAINT

Painting 20 level 1 DFT : 50 microns Ref : SPECIFICATION FOR PAINTING DOCU No.TS -

Visual & DFT

100% P RW - - 2001 (Attachement for 17269-002000-AR01)

Check

1 final coat of two packs, Polyamide Cured Epoxy. DFT : 120 Painting Testing Requ : Pls refer the Procedure No

FINAL PAINT

Microns per coat (Colour : Grey RAL No: 7010) : CN-KA-22890-ZET/WECL/SPP/01 Dt.11-05-2023

1. Hammer Test

Total DFT :

Surface Treatment of 2. Preece Test

Galvanizing/ 10% IS 4759 & Approved Drawing , TA Galvanizing

6.2 Electro forged 3. Mass of Zinc Coating P RW - -

Visual as per Lot coating Thickness shall be 120 Microns DFT Report Coating Thickness shall be 120 Microns

Gratings (Galvanizing) 4. Coating Thickness visual for Finish

(DFT)

7.0 FINAL CLEARANCE

1)Fitments of all components,

Finish product as per

Completeness of all Dimensions measurments. Visual/ Finish product as per approved Inspection *Match Mark Hard Punch to be Done.

7.1 100% approved Drawings and P R - -

previous Stages 2) Review of previous stage reports. Measurement Drawings and Specification Report Same should be Highlighted after Painting

Specification

3) Workmanship

Packing to be as per

7.2 Dispatch Packing Visual - - P R - -

Purchase Order/Drawing Requirement,WUHUAN Guidelines

Inspection Release

7.3 Complete Documents Review - As per the Purchase Order Terms &Specifications - P H R I

Note

Quality Original Documents to be submit prior to

dispatch to WUHUAN

7.4 Final Dossier Complete Inspection Reports Review - As per the Purchase Order Terms & Condition - P R R -

LEGEND : P- PERFORM, W - WITNESS, A - APPROVAL, R - REVIEW OF DOCUMENTS, RW - RANDOM WITNESS W - WITNESS , I- INFORMATION, MTC - MANUFACTURER TEST CERTIFICATE, BTC - BATCH TEST CERTIFICATE

NDT : NON - DESTRUCTIVE TESTING, UT : ULTRASONIC TEST, DPT: DYE PENETRANT TEST, AWS: AMERICAN WELDING SOCIETY, IS - INDIAN STANDARDS, PO - PURCHASE ORDER, DFT - DRY FILM THICKNESS

Form No : ZET-QA-F-01 REV.00 Dt.03.08.2020 Page 3 of 4

ZETWERK MANUFACTURING BUSINESSES PVT LTD.,

Oriental Towers No.461, 1st & 2nd Floor, 4th Sector,

ZETWERK MANUFACTURING BUSINESSES PRIVATE LIMITED 17th Cross, HSR Layout Bengaluru, India - 560 102.

Website: www.zetwerk.com

CUSTOMER WUHUAN ENGINEERING CO., LTD QAP NO CN_KA-22890/23-24/QAP/106 Rev.02 DATE : 06.07.2023

CUSTOMER

CLIENT TALCHER FERTILIZERS LIMITED (TFL) 17269-ASM1801-PO DATE : 27-Mar-2023

PO.NO

PMC PROJECTS & DEVELOPMENT INDIA LTD (PDIL)

PROJECT AMMONIA UREA PLANT, TALCHER

PRODUCT / NAME FABRICATION AND SUPPLY OF STRUCTURAL STEEL AND OTHER STEEL, IRON OR METAL ITEMS

DOCUMENT REF: 1. 17269 -002000- AR01 Rev.0C - General Specification of Architecture 4. 17125/17269-PP67-001 Rev.1 - Instructions for QAP/ITP Preparation

2. 17269 - 00200- ST0504 Rev.2A - Specification for Steel Fabrication 5. 17269-PP41-001 Rev.0A - Packing and Marking Specification

3. 17269-ASM1801-PO Rev.2A Technical Appendix for Structural Steel and Other Steel, Iron or Metal Items (Material 6. 17269-PP79-01 Rev.2 - Vendor Document Handling procedure

and fabrication of Ammonia-Urea Plant)

QUALITY ASSURANCE PLAN

INSPECTION & QUANTUM RESPONSIBILITY

CHARACTERISTIC REFERENCE STANDARD/ FORMAT/

Sl. No. TESTING TYPE OF CHECK OF ACCEPTANCE CRITERIA WUH TFL/ REMARKS

TO BE VERIFIED DOCUMENT/ RECORDS MFG TPIA

DESCRIPTION CHECK UAN PMC

1 2 3 4 5 6 7 8 9 10 11 12 13

REF : Doc. No.: PC009/E/4001/P-II/Sec.15 Sheet 51 of 91 & Sheet 48 of 91 - Talcher Fertilizers Limited Vendor List

Prepared by: Zetwerk Manufacturing Businesses Pvt Ltd Reviewed By : Zetwerk Manufacturing Businesses Pvt Ltd Approved By : M/s. WUHUAN ENGINEERING CO., LTD

Name : R Shanmuganathan Name : B. Ramesh Babu Name :

Signature : Date.06.07.2023 Signature : Date : 06.07.2023 Signature : Date:

Designation : Manager - QA Designation : General Manager - QA/QC Designation

Form No : ZET-QA-F-01 REV.00 Dt.03.08.2020 Page 4 of 4

You might also like

- Business Class m2 Workshop ManualDocument2,354 pagesBusiness Class m2 Workshop ManualWilfredo A Molina63% (8)

- Quality Assurance Plan: High Frequency Electric Resistance Welded PipeDocument15 pagesQuality Assurance Plan: High Frequency Electric Resistance Welded PipeSachin KumarNo ratings yet

- 9276 T IF INS SC05A - Rev R05Document202 pages9276 T IF INS SC05A - Rev R05Sandip SurNo ratings yet

- Saipem Approved AUT ProcedureDocument25 pagesSaipem Approved AUT ProcedureKuppan Srinivasan100% (1)

- MQP of Dry Type TransformersDocument6 pagesMQP of Dry Type TransformersNaresh RajuNo ratings yet

- ItpDocument2 pagesItpVinay YadavNo ratings yet

- Quality Assurance Plan FOR Hot Induction Bend: Format No. Rev. No. 01 Rev. Date 20.02.2020 RMTL-KCS-QA&C-FF-001Document9 pagesQuality Assurance Plan FOR Hot Induction Bend: Format No. Rev. No. 01 Rev. Date 20.02.2020 RMTL-KCS-QA&C-FF-001Sachin KumarNo ratings yet

- Itp Piping Rev 0Document2 pagesItp Piping Rev 0Angel Rebollo100% (1)

- 2111-122-QVC-G-001 - Civil Works FQP For DSTPS FGD Package-Proposed PDFDocument22 pages2111-122-QVC-G-001 - Civil Works FQP For DSTPS FGD Package-Proposed PDFMANNANo ratings yet

- Approved QAP For AMNS Other BaysDocument8 pagesApproved QAP For AMNS Other BaysParikshit GaurNo ratings yet

- Spec ReferenceDocument40 pagesSpec ReferencesohaibNo ratings yet

- Steel Plant Switching Circuits DiagramDocument1 pageSteel Plant Switching Circuits DiagramSUSOVAN BISWAS0% (1)

- Sam 305 Technical 1575546291Document29 pagesSam 305 Technical 1575546291Rahul MeenaNo ratings yet

- Supply, Fabrication, Erection, Testing & Chemical Anchor of Steel Structure at KLM Plant Bin Qasim KarachiDocument1 pageSupply, Fabrication, Erection, Testing & Chemical Anchor of Steel Structure at KLM Plant Bin Qasim KarachiTanveer Rajput EngrNo ratings yet

- QAP For Ducting V1 R0Document1 pageQAP For Ducting V1 R0Hema NandhNo ratings yet

- Report Control Room Lawe 220218-RE0Document78 pagesReport Control Room Lawe 220218-RE0ajiNo ratings yet

- r2b p2 205 03 P Dal Kar752 4-5-01001 Rev.b Instrument Wiring Diagram ReviewedDocument6 pagesr2b p2 205 03 P Dal Kar752 4-5-01001 Rev.b Instrument Wiring Diagram ReviewedjonathanNo ratings yet

- Pmi Procedure Rev.0Document5 pagesPmi Procedure Rev.0PRASHANTNo ratings yet

- Tata Consulting Engineers Limited: List of Sub Vendors For Mechanicalequipment / SystemsDocument12 pagesTata Consulting Engineers Limited: List of Sub Vendors For Mechanicalequipment / SystemsvinayNo ratings yet

- Galfar MS 000-ZX-E-77758Document22 pagesGalfar MS 000-ZX-E-77758Ramaraju RNo ratings yet

- BPX-G-G-WE-029 Specification For Pipeline, Flowlines, WellpDocument38 pagesBPX-G-G-WE-029 Specification For Pipeline, Flowlines, WellpdonaldoguerreroNo ratings yet

- Annexure-I For Gem Bid No:Gem/2021/B/1451378 Dated: 19-08-2021Document15 pagesAnnexure-I For Gem Bid No:Gem/2021/B/1451378 Dated: 19-08-2021Sravan DasariNo ratings yet

- FORM No.: PCM-8.9.1 Consultant'S Review Form For Contractor'S Submittals Fahim, Nanji & Desouza (PVT.) LTDDocument4 pagesFORM No.: PCM-8.9.1 Consultant'S Review Form For Contractor'S Submittals Fahim, Nanji & Desouza (PVT.) LTDFahad NaveedNo ratings yet

- Vol-IA - TCC-2021-04-15-02 16 52Document49 pagesVol-IA - TCC-2021-04-15-02 16 52ekafarahNo ratings yet

- NTPC Jawaharpur Thermal Project EPC Package EOT Cranes Inspection ReportDocument1 pageNTPC Jawaharpur Thermal Project EPC Package EOT Cranes Inspection ReportPrabhu SampathNo ratings yet

- Chpprint 2Document1 pageChpprint 2Prabhu SampathNo ratings yet

- 3 PDFDocument1 page3 PDFPrabhu SampathNo ratings yet

- Tata A2239 Qap Rev.00Document4 pagesTata A2239 Qap Rev.00PRASHANTNo ratings yet

- JH17ACPL08Document23 pagesJH17ACPL08prathuri sumanthNo ratings yet

- Jh17acpl05 1Document27 pagesJh17acpl05 1prathuri sumanthNo ratings yet

- II - Technical Specification CRP - Thapagundu PDFDocument98 pagesII - Technical Specification CRP - Thapagundu PDFSumukh MahekarNo ratings yet

- QAP HMEL 7480000754 L08722A501-SignedDocument3 pagesQAP HMEL 7480000754 L08722A501-SignedSuyog GawandeNo ratings yet

- JH17ACPL04Document23 pagesJH17ACPL04prathuri sumanthNo ratings yet

- QM-Q23-PL-1746 Rev 00 Perssonel QualificationDocument27 pagesQM-Q23-PL-1746 Rev 00 Perssonel QualificationRampal Rahul Rampal Rahul100% (1)

- 402-E-14 Ab B269-Rhcu-Lt-402-Mes-Qd-Tema (2) - 04-002Document14 pages402-E-14 Ab B269-Rhcu-Lt-402-Mes-Qd-Tema (2) - 04-002tarun gotiNo ratings yet

- Reliance Industries heat exchanger inspection procedureDocument3 pagesReliance Industries heat exchanger inspection procedureRajnikant PatelNo ratings yet

- Staircases & HandrailsDocument2 pagesStaircases & HandrailsPavul RajNo ratings yet

- RFI Welding TestDocument18 pagesRFI Welding TestDimas agungNo ratings yet

- BHEL QAP 41111A40411 REV 01-SignedDocument6 pagesBHEL QAP 41111A40411 REV 01-SignedSuyog GawandeNo ratings yet

- WMS For Pipe Supports ErectionDocument17 pagesWMS For Pipe Supports ErectionRamaraju RNo ratings yet

- Itp SheetsDocument23 pagesItp Sheetskeshav chaturvediNo ratings yet

- Tkii Doc. No. 706 3M0038 e 001 25Document167 pagesTkii Doc. No. 706 3M0038 e 001 25pcfssbelectrical sectionNo ratings yet

- Inspection and Test Plan Rev.0Document3 pagesInspection and Test Plan Rev.0คุณพ่อน้อง บิ๊กบอสNo ratings yet

- Annexure - I - Low Voltage Switchgear Data SheetDocument7 pagesAnnexure - I - Low Voltage Switchgear Data SheetYENDRU LALITHAKUMARINo ratings yet

- TPL 069 Abb Yn1m 301 542 Zab P0Document43 pagesTPL 069 Abb Yn1m 301 542 Zab P0litu_67100% (1)

- QAP-UEPL-BHOPAL-54-9550-01 Rev.03Document6 pagesQAP-UEPL-BHOPAL-54-9550-01 Rev.03udayakarnaNo ratings yet

- TMK - Insp of Fuel Filter.342Document2 pagesTMK - Insp of Fuel Filter.342sivaNo ratings yet

- MoS For Piping Support InstallationDocument19 pagesMoS For Piping Support Installationilliasuddin100% (1)

- Attachment #2 26071-203-V1A-MWB0-00003 - 002 - Sub Vendor ListDocument21 pagesAttachment #2 26071-203-V1A-MWB0-00003 - 002 - Sub Vendor ListMingyu SongNo ratings yet

- Field Quality Plan-Elevator-BrbclDocument4 pagesField Quality Plan-Elevator-BrbclVikash SinghNo ratings yet

- 100 KLPD of 2G Ethanol From Biomass at Iocl PanipatDocument7 pages100 KLPD of 2G Ethanol From Biomass at Iocl PanipatSuraj ShettyNo ratings yet

- Strucmax Ii MMS Ii Qap Ii 2023-24 Ii R0Document2 pagesStrucmax Ii MMS Ii Qap Ii 2023-24 Ii R0Prince MittalNo ratings yet

- Combined Registration Certificate QCMjIyNASXlOd2JXVjBjbThqSTBoWlJFMHdNREF5TWtJPQ-EEQLDocument2 pagesCombined Registration Certificate QCMjIyNASXlOd2JXVjBjbThqSTBoWlJFMHdNREF5TWtJPQ-EEQLDuong BachNo ratings yet

- Note SheetDocument2 pagesNote SheetVikashJainNo ratings yet

- AEPCOM-QAP-3281-58548 Rev 1Document3 pagesAEPCOM-QAP-3281-58548 Rev 1VIVEK TIWARINo ratings yet

- V-9203 Final ReportDocument25 pagesV-9203 Final Reportmechanicalccr2No ratings yet

- CNOOC Southeast Sumatra Pipeline CoatingsDocument12 pagesCNOOC Southeast Sumatra Pipeline CoatingsRokan Pipeline100% (1)

- V-9209 Final ReportDocument12 pagesV-9209 Final Reportmechanicalccr2No ratings yet

- Pex 73115 05SDDocument415 pagesPex 73115 05SDBALASUBRAMANIAM MEGHANADHNo ratings yet

- by Pass Line Mbe 6 WTRDocument2 pagesby Pass Line Mbe 6 WTRMuhamad Hifni SyahbanaNo ratings yet

- COMPANY Profile New-05-05-23Document8 pagesCOMPANY Profile New-05-05-23Parikshit GaurNo ratings yet

- 2nd COAT 4-4Document1 page2nd COAT 4-4Parikshit GaurNo ratings yet

- 2nd COAT 4-4Document1 page2nd COAT 4-4Parikshit GaurNo ratings yet

- ArcEdges QAP-R2Document4 pagesArcEdges QAP-R2Parikshit GaurNo ratings yet

- Approved Data Sheet & Painting SchemeDocument10 pagesApproved Data Sheet & Painting SchemeParikshit GaurNo ratings yet

- Test Report - 1Document25 pagesTest Report - 1Parikshit GaurNo ratings yet

- En 10025Document4 pagesEn 10025Jayesh83% (6)

- Mahatma Gandhi Labour Institute Ahmedabad: Post Graduate Diploma in Human Resource Management 2015-16 1 SemesterDocument2 pagesMahatma Gandhi Labour Institute Ahmedabad: Post Graduate Diploma in Human Resource Management 2015-16 1 SemesterParikshit GaurNo ratings yet

- BECC-101 Assignment 2020-21 (English)Document5 pagesBECC-101 Assignment 2020-21 (English)Parikshit GaurNo ratings yet

- Acc 213Document1 pageAcc 213Parikshit GaurNo ratings yet

- Test Report - 3Document23 pagesTest Report - 3Parikshit GaurNo ratings yet

- SR800 PDFDocument5 pagesSR800 PDFSudan ShresthaNo ratings yet

- Acc 212Document1 pageAcc 212Parikshit GaurNo ratings yet

- Metal Beam Crash Barrier DrawingDocument1 pageMetal Beam Crash Barrier DrawingParikshit GaurNo ratings yet

- Crash Testing Roadside BarriersDocument16 pagesCrash Testing Roadside BarriersParikshit GaurNo ratings yet

- Is - 2062.2011 PDFDocument17 pagesIs - 2062.2011 PDFN GANESAMOORTHYNo ratings yet

- SBI4U - Unit 2 - Version ADocument56 pagesSBI4U - Unit 2 - Version AAllan Anthiah100% (3)

- Jborkowski PHD ThesisDocument85 pagesJborkowski PHD ThesisJakub BorkowskiNo ratings yet

- Alluminio TeoriaDocument91 pagesAlluminio TeoriaxypangioNo ratings yet

- SINCE 1922, PRECISION ENGINEERED ROTARY SPRAY HEADSDocument32 pagesSINCE 1922, PRECISION ENGINEERED ROTARY SPRAY HEADSLai Ming YihNo ratings yet

- Series QuestionsDocument5 pagesSeries QuestionsAnushka BijarniaNo ratings yet

- ViewingDocument49 pagesViewingnishasaiyed2304No ratings yet

- Compatibility Matrix FOS 8x August2019Document49 pagesCompatibility Matrix FOS 8x August2019qihanchongNo ratings yet

- First Print Errata RardinDocument5 pagesFirst Print Errata RardinMarcelo ZiulkoskiNo ratings yet

- Automated Guided VehicleDocument17 pagesAutomated Guided VehicleTedy ThomasNo ratings yet

- Resolve Wi-Fi Issues with Static IPDocument3 pagesResolve Wi-Fi Issues with Static IPAndrei ZebreniucNo ratings yet

- Multiframe AutomationDocument148 pagesMultiframe AutomationPoowadol NiyomkaNo ratings yet

- Polymer IntroDocument15 pagesPolymer IntroYUG PRATAP SINGHNo ratings yet

- Micro 133 Midterm Lecture 2 - IO Interfacing With 8255 & Assembly Language - EditedDocument10 pagesMicro 133 Midterm Lecture 2 - IO Interfacing With 8255 & Assembly Language - EditedKeilla Romabiles LeopandoNo ratings yet

- STRESS AND STRAIN CALCULATIONSDocument3 pagesSTRESS AND STRAIN CALCULATIONSSaketh BoggavarapuNo ratings yet

- Oracle Apps Technical ConsultantDocument5 pagesOracle Apps Technical ConsultantRamesh Babu KadiyamNo ratings yet

- Stabilization and Solidification of Hazardous, Radioactive, and Mixed Wastes PDFDocument391 pagesStabilization and Solidification of Hazardous, Radioactive, and Mixed Wastes PDF김혜인No ratings yet

- Hexadecimal Numeral System ExplainedDocument6 pagesHexadecimal Numeral System ExplainednaufNo ratings yet

- 01 - WELDING DEFECTS (Surface) - May 2021Document28 pages01 - WELDING DEFECTS (Surface) - May 2021Gerry Dan ChanliongcoNo ratings yet

- Quick Reference AmadeusDocument45 pagesQuick Reference AmadeusHugo BadilloNo ratings yet

- Keystone Lighting Ordering Guide & Price List 1981Document40 pagesKeystone Lighting Ordering Guide & Price List 1981Alan MastersNo ratings yet

- Production of Acrylonitrile (ANKB40303Document75 pagesProduction of Acrylonitrile (ANKB40303NUR AKMAL HISHAMNo ratings yet

- Item Description Unit QTY Rate Amount Egp. Egp. Division 2: Site Construction EarthworkDocument15 pagesItem Description Unit QTY Rate Amount Egp. Egp. Division 2: Site Construction EarthworkAmr M. AbdallahNo ratings yet

- Solidworks SimulationDocument30 pagesSolidworks SimulationDavid Raj100% (1)

- Confined Space Entry Permit - MCBCL FormDocument1 pageConfined Space Entry Permit - MCBCL FormVenkata Suresh MandavaNo ratings yet

- Digital Assignment-1 critical path and function point analysisDocument6 pagesDigital Assignment-1 critical path and function point analysisGOVARDHANNo ratings yet

- (CHEVROLET) Manual de Taller Chevrolet Sail 2010Document120 pages(CHEVROLET) Manual de Taller Chevrolet Sail 2010Nader Jimenez79% (14)

- AN5274 IC Audio Toshiba 21Document7 pagesAN5274 IC Audio Toshiba 21Abu AsyifaNo ratings yet

- Brick FinalDocument15 pagesBrick Finalindrajit sodha0% (1)

- Alspa Drive Range - Drives Solutions PDFDocument8 pagesAlspa Drive Range - Drives Solutions PDFRahul AnandNo ratings yet