Professional Documents

Culture Documents

Ipg2013 1951

Uploaded by

Leonardo TejedorOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ipg2013 1951

Uploaded by

Leonardo TejedorCopyright:

Available Formats

Proceedings of the ASME 2013 International Pipeline Geotechnical Conference

IPG2013

July 24-26, 2013, Bogota, Colombia

IPG2013-1951

THE CHALLENGE OF CROSSING THE ANDES, A DATA BASE ANALYSIS AND

PERU LNG PROJECT DESCRIPTION

Ariel Gasca Cardenas Edilberto Gutierrez

HUNT OIL COMPANY COLP SAC

Dallas, TX USA Lima, Perú

ABSTRACT project. A comprehensive flow chart provides general guidance

As of the date this paper is written pipelines in South for future pipeline projects in similar conditions.

America comprises 113000 kms of transmission lines including

Oil, Gas, Condensates, and refined products from which

approximately 17% (19400 kms) crosses the Andes reaching BACKGROUND

elevations up to near 5000mts. Rugged terrain combined with

the geology, weather conditions (especially rain intensity) and According to the CIA1 (2009), there are about 2 million

continuous pipe ruptures in the past impose serious challenges kilometers of pipelines installed throughout the world, 41% of

for the pipeline industry that makes the design, construction and which (793,000 km) are located in the United States, the

operation substantially different from other pipelines in the country with the world‟s greatest length of hydrocarbon

world. The records have shown that the threat of Ground transmission lines. South America represents 5.8% of the total

movement/weather-related pipeline ruptures in the Andes plays length; in other words, 112,700 km approximately, about

a significant role since the percentage of the risk associated with 18,900 km of which go through the Andes Mountains, which is

geotechnical causes is substantially higher than any other parts about 1% of the world‟s overall total (including some pipelines

such as Europe or United States. Thus the rate of pipeline that are still being designed or built).

failures due to natural forces is significant higher than the

average industry. Peru LNG is a 406km x 34in gas pipeline Figure 1 indicates the main pipelines that cross the Andes.

transporting natural gas from the jungle side of Peru to the Trasandino oil pipeline is the oldest transportation system going

Pacific Coast where a LNG terminal has been installed. Peru through the Andes, it was built in 1969 in southern Colombia

LNG´s pipeline currently holds the record of being the highest near the border with Ecuador aiming to transport the crude oil

Gas Pipeline of the world with a maximum elevation of 4901 found in the jungle region of both countries to the port of

meters above sea level. Project completion was done in May Tumaco, located in the Colombian Pacific. It is worth

2010 and lessons learnt from similar projects were taken into mentioning that this oil pipeline is still operating and it has

account since project designs. This paper is divided in two suffered around 10 ruptures up to now as a result of natural

parts. First, it compares pipeline ruptures frequencies due to forces.

natural forces in the Andes with other pipelines in different

terrains based on historical cases compiled by the authors. Alto it is important to mention the earthquakes that occurred

Secondly, it explains the different phases of Pipeline Project in after a heavy rain period in Ecuador on March 5, 1987, as they

rugged terrain from the conceptual design until the operations generated landslides and avalanches that destroyed 70 km of

stage and the role of Pipeline Geotechnical Engineers in this pipelines of the 498 km long Trans-Ecuadorian Pipeline System

process based on PERU LNG‟s pipeline experience. It also (SOTE, by its Spanish initials), turning this event into the

describes some of the main features of the PLNG pipeline greatest failure of one single pipeline in history. In that time,

1 Copyright © 2013 by ASME

60% of the country‟s profit came from the export of crude oil,

which was interrupted for approximately 6 months while the

repair works were being finished (Hall Minard L, 1991).

Figure N°2. Comparison of rupture causes in

Pipelines for different regions (Gasca A. 2012)

To illustrate the above, we need to underline that, in general,

there are 6 causes that can generate ruptures or leakages in

operating pipelines, which are the following: corrosion,

incorrect operations, damage by third parties, defective

construction or defective materials, natural (or geotechnical)

forces and „‟other causes‟‟. Entities such as the United States

Department of Transport and the CONCAWE2 and EGIG3 in

Europe have systematically collected all cases of ruptures and

their respective causes and they found that the main source of

ruptures were due to third parties and failing material or

equipment. Ruptures as a result of natural or geotechnical

forces only represented between 3% and 9% of the total.

This percentage distribution varies significantly when

submitting the information available for the pipelines going

Figure N°1. Main pipelines across the Andes

(Gasca A. 2012)

across the Andes, to a similar calculation, which shows that the

ruptures resulting from natural or geotechnical forces represent

about 45% of the total, being at least 5 times more than the

Although the length installed is very small compared with the percentage reported in Europe (See Figure 2). Failures due to

total global length, due to the physiographic characteristics of vandalism or terrorism were not considered part of the data base

the Andes, the analysis of the experiences in the region are of for the analysis.

particular interest for the specialists. It is publicly known that

the conditions of the design, construction and operation of the The pipeline ruptures in the Andes and even in South

pipelines in this part of the world are quite particular and America are not duly registered in an entity that groups the

require specific analysis. Particular reference needs to be made different operators in the area; however, there is a large amount

to the combined effect of high precipitations and extreme of information available that allows for making an estimate with

geotechnical conditions, which have led to a high number of an adequate degree of certainty. Figure 2 summarizes the

ruptures as a result of ground movement and with a proportion distribution of causes of ruptures in oil pipelines in different

of failures per year that is significantly higher than other regions and compares them with the Andes case. For the

pipelines in the world. particular Peruvian case, the work of Suárez Luis (2008), which

was prepared for an oil pipeline in northern Peru and started

operating in 1977, has been taken as a reference, as well as the

2 Copyright © 2013 by ASME

Figure N°3. Pipeline ruptures due to natural forces in the Andes (Gasca A. 2012)

3 Copyright © 2013 by ASME

information available on the TGP liquid pipeline which started

operating in 2004. This trend is also shown by other authors

such as Porter M., 2006.

ANALYSIS OF RUPTURES RESULTING FROM

GEOTECHNICAL CAUSES

Figure 3 summarizes all ruptures caused by natural forces

found by the authors in pipelines going across the Andes. The

information was extracted from articles, public records and web

publications. No ruptures are reported in the lower half of the

Andes where rain conditions are not severe. Most ruptures are

located on the eastern edge of the mountain range, in high

precipitation areas (more than 2000 mm per year).

Rupture frequencies in hydrocarbon transmission lines are

obtained based on the number of ruptures that occur per

pipeline length and per number of years of system operation. Figure N°5. Rupture Frequencies due to Geotechnical Factors

(Gasca A. 2012)

Frequencies of less than 1 per 1000 km-year in general terms

(all causes) are frequently found for pipelines in the United

States or Europe, as shown in Figure 4. With regard to the

Andes, rupture frequencies are higher in all of the registered THE PERU LNG GAS PIPELINE

periods. These values need to be converted into referential Peru LNG is a natural gas transport and processing project

values for the risk analysis developed by the Operators, which required the installation of 408 km and 34 inch diameter

especially when probabilistic approaches are used. gas pipeline going across the Peruvian Andes in order to deliver

natural gas to a Liquefaction Plant located on the Pacific Coast,

For the specific case of the rupture frequencies as a result at 160 km south from Lima. Said construction involved the

of geotechnical factors (i.e. landslides, avalanches, falling following relevant aspects:

rocks, etc.) the difference between the registered values in the 64% (261 km) of the route had an elevation higher

Andes is significantly higher than in Europe as is shown in than 3000 masl;

Figure 5. 41.8 % (171 km) of the route had an elevation higher

A gradually descending trend can be seen in the percentage than 4000 masl;

of ruptures in pipelines which have been operating for a larger

number of years and once the integrity programs have started The maximum elevation (Guiness record) was 4900.5

working; however, when new pipelines with deficient design masl (KP160.784);

input or in case there is not sufficient knowledge of the 379 river and ravine crossings, 143 road crossings and

geotechnical conditions of some particular places, the 22 crossings with other pipelines;

percentage of ruptures tends to increase momentarily as is 50 swamp crossings with a total length of 5,100 m;

shown by the peaks of the curves indicated in the graph.

25.3 km of potential landslide areas and 13 km of sand

dunes;

120 sections with steep ground (more than 25 degrees

of inclination) requiring special construction

techniques;

14,000 erosion control works installed along the

corridor in the mountainous section (especially along

the first 304 km);

1.2 million cubic meters of ditch fill material obtained

by processing the existing subsoil or imported subsoil

from nearby quarries;

1370 Ha of ground negotiated for an average of 33.6

wide Right of Way intervened during construction;

Nearly 4000 crossed plots;

Figure N°4. Oil Pipelines Rupture Frequencies in different

regions (Gasca A. 2012)

4 Copyright © 2013 by ASME

The project also included the commissioning of 408 2. COCAWE: Conservation of Clean Air, Water and

and 61 km of Fiber Optic Cable (FOC) for Environment in Europe.

communications and geotechnical monitoring 3. EGIG: European Gas pipeline Incident data Group.

respectively. The FOC for geotechnical monitoring 4. SOTE: Sistema de Oleoducto Trans-Ecuatoriano

was installed at the far eastern end of the route where 5. TGP: Transportadora de gas del Perú

the rains are more intense; 6. FOC: Fiber Optic Cable

600,000 tons of excavated rock (blasting);

Perú LNG started operations in May 2010 and since then, ACKNOWLEDGEMENTS

no leakages have been registered that can jeopardize the

integrity of its pipeline. Although this is about a relatively short The authors wish to thank Christian Silva (COLP‟s Engineer)

period, special importance also has been given to the for his help collecting information as well as the support

geotechnical issues based on the experience of other pipelines provided by Igor Salazar, General Manager of Peru LNG and

crossing the same mountain range and which have reported Barbara Bruce, General Manager of Huntoil Peru.

failures shortly after the start of their operations.

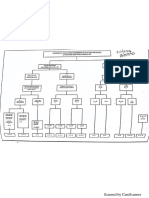

Figure 6 shows the development of the different

engineering, construction and operational phases of the pipeline

and the particular way in which the geotechnical aspect was REFERENCIAS

handled in each stage. The diagram may apply to any other Central Intelligent Agency (CIA). The World Factbook

project in similar conditions. 2010.

CONCAWE Oil Pipelines management Group´s Special

Task Force on pipeline spillages. Performance of European

cross-country oil pipelines. Statistical summary of reported

CONCLUSIONS spillages in 2010 and since 1971. Dec. 2011.

Although the percentage they represent is small in comparison European Gas Pipeline Incident Data Group (EGIG) 7th

with the total global length, the pipelines installed across the Report 1970-2007. Dec 2008.

Andes impose particular challenges and offer different statistics

Falabella D. et al. Innovación tecnológica y causa de fallas

for those who take part in the design, construction and operation

en gasoductos. Petrotecnia. Argentina. Agosto 2008.

process. Therefore, risk analyses should be carried out based on

the particular results of the existing pipelines in this part of the Hall Minard L. Los Terremotos del Ecuador del 5 de

world, apart from the use of bibliographic references of other Marzo de 1987. Deslizamientos y sus efectos Socio-

areas with different physiographic conditions. económicos. Colección Estudios de Geografía. Vol 9.

Escuela Politécnica Nacional. Publicación original en

The Peru LNG gas pipeline has received feedback from the inglés con el título: “The March 5, 1987 Ecuador

experiences of other pipelines developed in similar conditions Earthquakes – Mass Wasting and Socioeconomic Effects”.

and has established a unique application model of Geotechnical The National Academy Press, Washington D.C. 1991.

Engineering for the different phases of the project, from the Porter M. et al. Andean pipelines – a challenge for natural

conceptual design up to the operation of the transportation hazard and risk managers. BGC Engineering.

system itself. Suárez C. Luis. Oleoducto Norperuano. Operaciones

Oleoducto PETROPERU S.A. Presentación en Power

The different pipeline operators in South America are to be Point.

brought together in order to centralize the information on causes

of spills or leakages in order to centralize such information for Sweeney M. et al. Pipelines in Rugged Terrain: A database,

future analysis as is done in other parts of the world. Making a historic risks and pipeline vulnerability. Terrain and

special distinction for hydrocarbon transport systems involving Geohazard Challenges facing onshore oil and gas pipelines.

crossing a mountain range like the Andes, would be even better. London, U.K. 2004.

Having a better knowledge of the history and difficulties will U.S. Department of Transportation. Pipeline and

make it possible to anticipate and foresee difficulties in new Hazardous Material Safety Administration (PHMSA). All

projects. Pipeline Incidents by cause 1992-2011.

NOMENCLATURE

1. CIA: Central Intelligent Agency. United States of

America.

5 Copyright © 2013 by ASME

Figure N°6. Oil Pipeline Geotechnics in different stages of the Project. Andean Case. (Gasca A. 2012)

6 Copyright © 2013 by ASME

You might also like

- WP - Natural Gas Leak Detection White Paper-2021Document5 pagesWP - Natural Gas Leak Detection White Paper-2021Jose BrionNo ratings yet

- Inspection and Monitoring Systems Subsea Pipelines: A Review PaperDocument40 pagesInspection and Monitoring Systems Subsea Pipelines: A Review PaperDanny BoysieNo ratings yet

- XXI Paper 044Document9 pagesXXI Paper 044RICARDO3454No ratings yet

- Pipeline Domino Effect - 2016Document17 pagesPipeline Domino Effect - 2016Rayane CavalcantiNo ratings yet

- Offshore Pipeline Decommissioning Scale and ContextDocument4 pagesOffshore Pipeline Decommissioning Scale and ContextHieu Le TrungNo ratings yet

- Emissions From Tropical Hydropower and The IPCCDocument15 pagesEmissions From Tropical Hydropower and The IPCCHayana DullahNo ratings yet

- Process Safety and Environmental Protection: Tomaso Vairo, Marco Pontiggia, Bruno FabianoDocument11 pagesProcess Safety and Environmental Protection: Tomaso Vairo, Marco Pontiggia, Bruno FabianoKk TheNo ratings yet

- Carling 1994Document15 pagesCarling 1994Valter AlbinoNo ratings yet

- Downhole Separation TechnologyDocument47 pagesDownhole Separation TechnologySebastian Gomez Betancourt100% (1)

- Science of The Total EnvironmentDocument15 pagesScience of The Total EnvironmentCristian GuayacNo ratings yet

- Cross-Country Pipeline Safety AssessmentDocument11 pagesCross-Country Pipeline Safety AssessmentRaúlNo ratings yet

- Oil and Gas Pipeline Failure ModellingDocument9 pagesOil and Gas Pipeline Failure Modellingrramirez11No ratings yet

- 2015 - Managing Marine Geohazard RiskDocument22 pages2015 - Managing Marine Geohazard Riskfaris nauvalNo ratings yet

- Fire Safety Journal Volume 43 issue 8 2008 (doi 10.1016 - j.firesaf.2008.01.002) Mercedes GГіmez-Mares; Luis ZГЎrate; Joaquim Casal - Jet fires aDocument6 pagesFire Safety Journal Volume 43 issue 8 2008 (doi 10.1016 - j.firesaf.2008.01.002) Mercedes GГіmez-Mares; Luis ZГЎrate; Joaquim Casal - Jet fires aigor VladimirovichNo ratings yet

- TMP 7 F03Document11 pagesTMP 7 F03FrontiersNo ratings yet

- Shahrim 2020 IOP Conf. Ser. Earth Environ. Sci. 479 012041Document11 pagesShahrim 2020 IOP Conf. Ser. Earth Environ. Sci. 479 012041Fagner SouzaNo ratings yet

- 8 BN G3 BNBNC VGQ YG7 SD 3 H GQ FDocument15 pages8 BN G3 BNBNC VGQ YG7 SD 3 H GQ FDeav MillionNo ratings yet

- Energy: Aleksandar Josifovic, Jennifer J. Roberts, Jonathan Corney, Bruce Davies, Zoe K. ShiptonDocument18 pagesEnergy: Aleksandar Josifovic, Jennifer J. Roberts, Jonathan Corney, Bruce Davies, Zoe K. ShiptonDiegoAlonsoNo ratings yet

- Assessment of The Potential For Hydrogen Production From Renewable Resources in ArgentinaDocument11 pagesAssessment of The Potential For Hydrogen Production From Renewable Resources in ArgentinaTobias Paixao TavaresNo ratings yet

- Climate Change Impacts On Subsea Cables and Ramifications For National Security-A Legal PerspectiveDocument28 pagesClimate Change Impacts On Subsea Cables and Ramifications For National Security-A Legal PerspectiveHoover InstitutionNo ratings yet

- 03 Corrosion PDFDocument16 pages03 Corrosion PDFImam Saja DechNo ratings yet

- Environment & Sustainability, AusencoDocument9 pagesEnvironment & Sustainability, AusencoAdrian Luis Hernandez GarciaNo ratings yet

- Case Studies in Chemical and Environmental EngineeringDocument7 pagesCase Studies in Chemical and Environmental Engineeringsebas barbsoaNo ratings yet

- Pipeline Damage Prediction by Det. Models and AIDocument10 pagesPipeline Damage Prediction by Det. Models and AIНикита ВязиковNo ratings yet

- HPPs in The BalkandDocument32 pagesHPPs in The BalkandAriel PantinNo ratings yet

- Pipeline Corrosion Control in Oil and Gas Industry: A Case Study of NNPC/PPMC System 2A PipelineDocument4 pagesPipeline Corrosion Control in Oil and Gas Industry: A Case Study of NNPC/PPMC System 2A PipelineAbdulMajidYousoffNo ratings yet

- Historical Analysis of U S Onshore HazarDocument13 pagesHistorical Analysis of U S Onshore HazarAndrzej BąkałaNo ratings yet

- Development of A Thresholds Approach For Real-Time Flash Flood Prediction in Complex Geomorphological River Basins PDFDocument18 pagesDevelopment of A Thresholds Approach For Real-Time Flash Flood Prediction in Complex Geomorphological River Basins PDFDora Marcela Benìtez RamirezNo ratings yet

- DAM Case 1Document6 pagesDAM Case 1Manmohan SinghNo ratings yet

- ArcticNatech OEDocument16 pagesArcticNatech OEbillNo ratings yet

- Winter2014 PDFDocument15 pagesWinter2014 PDFSandra MontoyaNo ratings yet

- K Factor in Ecuadorian Basins CompressedDocument15 pagesK Factor in Ecuadorian Basins CompressedDaniel Alfredo Delgado GutierrezNo ratings yet

- 3causes of Failure of Flexible Pavement (A CaseDocument18 pages3causes of Failure of Flexible Pavement (A CaseMeleseNo ratings yet

- LNGDocument24 pagesLNGpurabi bora100% (1)

- Reported Tailings Dam FailuresDocument7 pagesReported Tailings Dam FailuresRaffy GalutanNo ratings yet

- Floods From Tailings Dam FailuresDocument9 pagesFloods From Tailings Dam FailuresJulio Montenegro GambiniNo ratings yet

- 10 1016@j Jclepro 2019 02 174Document36 pages10 1016@j Jclepro 2019 02 174Tony HerreraNo ratings yet

- Air Pollution PassDocument13 pagesAir Pollution PassMajddiNo ratings yet

- TarjomeFa F874 EnglishDocument14 pagesTarjomeFa F874 EnglishVictor Henrique Gonçalves PedreiraNo ratings yet

- Quantitative Risk Assessment of The Italian Gas Distribution Network Journal of Loss Prevention in The Process IndustriesDocument13 pagesQuantitative Risk Assessment of The Italian Gas Distribution Network Journal of Loss Prevention in The Process IndustriesRaúlNo ratings yet

- Assessment of Soil Susceptibility To Erosion Using The Epm and Rusle Models: The Case of Venetikos River CatchmentDocument17 pagesAssessment of Soil Susceptibility To Erosion Using The Epm and Rusle Models: The Case of Venetikos River CatchmentAron AlvaNo ratings yet

- A Generalised Framework To Predict Undrained Uplift Capacity of Buried Offshore PipelinesDocument49 pagesA Generalised Framework To Predict Undrained Uplift Capacity of Buried Offshore PipelinesaaaNo ratings yet

- BP Risk Factors Frecuebcies p145024Document19 pagesBP Risk Factors Frecuebcies p145024ortizgradexNo ratings yet

- Shale Gas and Fracking in EuropeDocument6 pagesShale Gas and Fracking in EuropeHERNAN CORTEZ FARFANNo ratings yet

- Egypt and USADocument25 pagesEgypt and USAMark ManNo ratings yet

- Marine Pollution BulletinDocument13 pagesMarine Pollution BulletinDairy of a FoodieNo ratings yet

- IBP1436 - 19 Failure in 30" Gas Pipeline Due To Degradation of Its 3-Layer Polyethylene Coating (Case Study)Document9 pagesIBP1436 - 19 Failure in 30" Gas Pipeline Due To Degradation of Its 3-Layer Polyethylene Coating (Case Study)barraocos emailsNo ratings yet

- Photo SuffosionDocument12 pagesPhoto SuffosionAugarit LawadessaNo ratings yet

- Offshore GeotechnicsDocument124 pagesOffshore GeotechnicsthiyakiNo ratings yet

- Tailings Dam Failure Statistical Analysis Draft LacasseDocument23 pagesTailings Dam Failure Statistical Analysis Draft LacasseMaría José MendozaNo ratings yet

- FaizahCheRos2020 DamBreakAnalysisofTemenggorDamDocument10 pagesFaizahCheRos2020 DamBreakAnalysisofTemenggorDamBwanika MarkNo ratings yet

- Estimating Reservoir Evaporation Losses For The United States: Fusing Remote Sensing and Modeling ApproachesDocument46 pagesEstimating Reservoir Evaporation Losses For The United States: Fusing Remote Sensing and Modeling ApproachesAdrian AbitanNo ratings yet

- 23) Climate Change ImpactsDocument55 pages23) Climate Change ImpactsAmith Unnimadhavan UNo ratings yet

- 1 s2.0 S0956053X07002577 Main PDFDocument9 pages1 s2.0 S0956053X07002577 Main PDFsantiago reyesNo ratings yet

- Ipc2016 64085finalDocument9 pagesIpc2016 64085finalAndrés MolinaNo ratings yet

- The Impact of Climate Change On The Wave Energy Resource Potential of The Atlantic Coast of Iberian PeninsulaDocument13 pagesThe Impact of Climate Change On The Wave Energy Resource Potential of The Atlantic Coast of Iberian PeninsulaAjabgul MajidiNo ratings yet

- Ipeline Ntegrity and Ecurity: Alan Murray and Rafael G. MoraDocument27 pagesIpeline Ntegrity and Ecurity: Alan Murray and Rafael G. Moraajikabba2001No ratings yet

- Blue Spot ModelDocument10 pagesBlue Spot Modelsridharprojects2023No ratings yet

- Katebi Et Al Pipeline PaperDocument13 pagesKatebi Et Al Pipeline PaperCurtis PattersonNo ratings yet

- Hydraulic Fracturing Explained: Evaluation, Implementation, and ChallengesFrom EverandHydraulic Fracturing Explained: Evaluation, Implementation, and ChallengesNo ratings yet

- Design Standards Volume 3 01 DrainageDocument34 pagesDesign Standards Volume 3 01 DrainageLeonardo TejedorNo ratings yet

- Ipg2013 1960Document9 pagesIpg2013 1960Leonardo TejedorNo ratings yet

- Ipg2013 1907Document6 pagesIpg2013 1907Leonardo TejedorNo ratings yet

- Ipg2013 1931Document7 pagesIpg2013 1931Leonardo TejedorNo ratings yet

- Ipg2013 1935 PDFDocument7 pagesIpg2013 1935 PDFLeonardo TejedorNo ratings yet

- SSG Appendix C - Design and Construction Guidance v2-2Document212 pagesSSG Appendix C - Design and Construction Guidance v2-2Leonardo TejedorNo ratings yet

- Design Standards Volume 3 02 DrainageDocument90 pagesDesign Standards Volume 3 02 DrainageLeonardo TejedorNo ratings yet

- Ipg2013 1914Document8 pagesIpg2013 1914Leonardo TejedorNo ratings yet

- Ipg2013 1928 PDFDocument5 pagesIpg2013 1928 PDFLeonardo TejedorNo ratings yet

- Clase 6. Diagramas Sucs y AahstoDocument2 pagesClase 6. Diagramas Sucs y AahstoLeonardo TejedorNo ratings yet

- Ipg2013 1950Document9 pagesIpg2013 1950Leonardo TejedorNo ratings yet

- JotHi RamanujamDocument58 pagesJotHi RamanujamLeonardo TejedorNo ratings yet

- Ipg2013 1971Document7 pagesIpg2013 1971Leonardo TejedorNo ratings yet

- MACRO1 - Reference - Manual MacaferriDocument65 pagesMACRO1 - Reference - Manual MacaferriLeonardo TejedorNo ratings yet

- Rockfall Protection Snow Barriers: Engineering A Better SolutionDocument16 pagesRockfall Protection Snow Barriers: Engineering A Better SolutionLeonardo TejedorNo ratings yet

- Scientific ManualDocument42 pagesScientific ManualLeonardo TejedorNo ratings yet

- Improved Testing Method of Dynamic Cone Penetrometer in Laboratory For Evaluating Compaction Properties of Soil SubgradeDocument14 pagesImproved Testing Method of Dynamic Cone Penetrometer in Laboratory For Evaluating Compaction Properties of Soil SubgradeLeonardo TejedorNo ratings yet

- Use of The Dynamic Cone Penetrometer in Shallow Pavement ApplicationsDocument7 pagesUse of The Dynamic Cone Penetrometer in Shallow Pavement ApplicationsLeonardo Tejedor100% (1)

- Wendi Goldsmith, Donald Gray, John McCullah (Auth.) - Bioengineering Case Studies - Sustainable Stream Bank and Slope Stabilizatio PDFDocument239 pagesWendi Goldsmith, Donald Gray, John McCullah (Auth.) - Bioengineering Case Studies - Sustainable Stream Bank and Slope Stabilizatio PDFLeonardo TejedorNo ratings yet

- (Proceedings in Earth and Geosciences Series 2.) Iwasaki, Yoshinori - Mangushev, R. A. - Sakharov, I. v. - Zhussupbekov, AskarDocument482 pages(Proceedings in Earth and Geosciences Series 2.) Iwasaki, Yoshinori - Mangushev, R. A. - Sakharov, I. v. - Zhussupbekov, AskarLeonardo TejedorNo ratings yet

- Tech Brief 2006Document6 pagesTech Brief 2006Leonardo TejedorNo ratings yet

- International Society For Soil Mechanics and Geotechnical EngineeringDocument7 pagesInternational Society For Soil Mechanics and Geotechnical EngineeringLeonardo TejedorNo ratings yet

- Comparative Study On Estimation Methods of DynamicDocument12 pagesComparative Study On Estimation Methods of DynamicLeonardo TejedorNo ratings yet

- Slope Stabilization and Erosion ControlDocument306 pagesSlope Stabilization and Erosion ControlburreiroNo ratings yet

- Clay Minerals PDFDocument196 pagesClay Minerals PDFLuis VilchezNo ratings yet

- The National Academies Press: Cost-Effective and Sustainable Road Slope Stabilization and Erosion Control (2012)Document81 pagesThe National Academies Press: Cost-Effective and Sustainable Road Slope Stabilization and Erosion Control (2012)Leonardo TejedorNo ratings yet

- Logo FinalDocument1 pageLogo FinalLeonardo TejedorNo ratings yet

- The Use of Dynamic Cone Penetrometer To Predict Resilient Modulus of Subgrade SoilsDocument18 pagesThe Use of Dynamic Cone Penetrometer To Predict Resilient Modulus of Subgrade SoilsLeonardo TejedorNo ratings yet

- DynamicsDocument159 pagesDynamicsEDEN2203No ratings yet

- Mil DTL 11891g EngDocument96 pagesMil DTL 11891g EngJohn DrakosNo ratings yet

- Student Counseling Management System Project DocumentationDocument4 pagesStudent Counseling Management System Project DocumentationShylandra BhanuNo ratings yet

- Vashi Creek Water Quality NaviMumbaiDocument27 pagesVashi Creek Water Quality NaviMumbairanucNo ratings yet

- Human Behavior in OrganizationDocument85 pagesHuman Behavior in OrganizationNeric Ico Magleo100% (1)

- Certified Tester AI Testing Overview of Syllabus: International Software Testing Qualifications BoardDocument18 pagesCertified Tester AI Testing Overview of Syllabus: International Software Testing Qualifications BoardEzio Auditore da FirenzeNo ratings yet

- Security+ Guide To Network Security Fundamentals, Fifth EditionDocument52 pagesSecurity+ Guide To Network Security Fundamentals, Fifth EditionVitæ ÆgisNo ratings yet

- Assignment 1technoDocument3 pagesAssignment 1technonadiyaxxNo ratings yet

- Tendon Grouting - VSLDocument46 pagesTendon Grouting - VSLIrshadYasinNo ratings yet

- Dialux BRP391 40W DM CT Cabinet SystemDocument20 pagesDialux BRP391 40W DM CT Cabinet SystemRahmat mulyanaNo ratings yet

- MEP Works OverviewDocument14 pagesMEP Works OverviewManoj KumarNo ratings yet

- Door LockDocument102 pagesDoor LockNicolás BozzoNo ratings yet

- Impact of Child Labour On School Attendance and Academic Performance of Pupils in Public Primary Schools in Niger StateDocument90 pagesImpact of Child Labour On School Attendance and Academic Performance of Pupils in Public Primary Schools in Niger StateJaikes100% (3)

- Schindler's List Theme Sheet Music For Piano, Violin (Solo)Document1 pageSchindler's List Theme Sheet Music For Piano, Violin (Solo)Sara SzaboNo ratings yet

- Sexual Hazartment of Women at OfficeDocument3 pagesSexual Hazartment of Women at OfficeMohandas PeriyasamyNo ratings yet

- Bank Statement - Feb.2020Document5 pagesBank Statement - Feb.2020TRIVEDI ANILNo ratings yet

- 08147-416H - LEGEND - Wahl - Fact Sheets - 5StarSeries - GBDocument1 page08147-416H - LEGEND - Wahl - Fact Sheets - 5StarSeries - GBChristian ParedesNo ratings yet

- (2022) 5 SCC 661Document43 pages(2022) 5 SCC 661Swati PandaNo ratings yet

- Jurnal Chapter 1 Diesel Bhs - InggrisDocument4 pagesJurnal Chapter 1 Diesel Bhs - Inggrisandino yogaNo ratings yet

- Request For Refund or Test Date Transfer FormDocument2 pagesRequest For Refund or Test Date Transfer FormAhmed Hamdy100% (1)

- Cenomar Request PSA Form-NewDocument1 pageCenomar Request PSA Form-NewUpuang KahoyNo ratings yet

- Persons Digests For 090613Document10 pagesPersons Digests For 090613pyriadNo ratings yet

- Tracer Survey Manual - Final 2Document36 pagesTracer Survey Manual - Final 2nesrusam100% (1)

- TechRef SoftstarterDocument11 pagesTechRef SoftstarterCesarNo ratings yet

- TIDCP vs. Manalang-DemigilioDocument2 pagesTIDCP vs. Manalang-DemigilioDi ko alam100% (1)

- Goran BULDIOSKI THINK TANKS IN CENTRAL AND EASTERN EUROPE AND THE QUALITY OF THEIR POLICY RESEARCHDocument31 pagesGoran BULDIOSKI THINK TANKS IN CENTRAL AND EASTERN EUROPE AND THE QUALITY OF THEIR POLICY RESEARCHCentre for Regional Policy Research and Cooperation StudiorumNo ratings yet

- Application & Registration Form MSC International Business Management M2Document11 pagesApplication & Registration Form MSC International Business Management M2Way To Euro Mission Education ConsultancyNo ratings yet

- Genose Massal D - 6 Juli 2021Document102 pagesGenose Massal D - 6 Juli 2021Phyto LianoNo ratings yet

- Microwave Engineering MCC121, 7.5hec, 2014: Passive DevicesDocument47 pagesMicrowave Engineering MCC121, 7.5hec, 2014: Passive DevicesBruno AlvimNo ratings yet

- Multiple Linear Regression: Diagnostics: Statistics 203: Introduction To Regression and Analysis of VarianceDocument16 pagesMultiple Linear Regression: Diagnostics: Statistics 203: Introduction To Regression and Analysis of VariancecesardakoNo ratings yet

- Vehicle To Vehicle V2V Communication Scope Importa PDFDocument13 pagesVehicle To Vehicle V2V Communication Scope Importa PDFvahidinkormanNo ratings yet