Professional Documents

Culture Documents

Daily Report 28-11-2021

Daily Report 28-11-2021

Uploaded by

Ahmed MohammedOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Daily Report 28-11-2021

Daily Report 28-11-2021

Uploaded by

Ahmed MohammedCopyright:

Available Formats

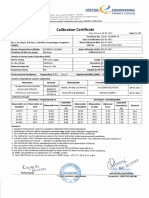

Daily Coating Inspection Report

Date: 28/11/2021

Day 25

Project : Maintenance of crude oil storage tank T1

Location : ABU-ATTIFEEL A 100- Field

Contractor : TIC Libyan branch

Specification: 20000. VAR.PAI.FUN Rev. 3 - March 2010/ 20552. VAR.PAI.FUN.

Rev. 0 – January 2005

Standards: ISO 8502-4/ ASTM D4285/ISO8501-1/ISO 8502-6/ISO8502-9/NACE RP0287

Activities:

1- Measure the weather condition.

2- Evaluation of surface cleanliness after sandblasting.

3- Performing roughness test

4 Performing soluble salt test (Bresle Batch Salt test - ISO 8502-6)

5- Checking equipment for abrasive blasting.

Findings:

1/- WEATHER CONDITION:

The measure of weather condition before sandblasting found acceptable; where the difference

between the steel surface and dew point temperature was greater than 3˚C and the RH is less than

85%. (See photos 1,2,3)

- Below table summarize reading results:

Date Time Ambient Steel Dew ∆T °C

Temp °C Temp °C Point °C % RH (Ts – Td) Comments

(Ta) (Ts) (Td)

8h00 21,6 °C 22,6 °C 0°C 23,6 % 22,6 °C Weather conditions are

28-11-2021 appropriate and acceptable

15h00 26 °C 27,5°C 8,9 °C 34 % 18,6 °C

DAILY REPORT INSPECTION OF CRUDE OIL STORAGE TANK T1 PAGE 1/7

Daily Coating Inspection Report

2/- Surface cleanliness

Random blasted areas do not comply with MOG specification. The final grade required according to

MOG specification shall be Sa 2½.

-During our inspection, we found: (See photos 4,5,6,7)

Random areas with black stains are observed in blasted surface.

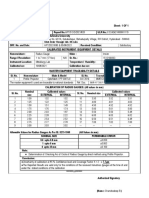

3/- Roughness test

-The surface roughness was measured on the blasted areas using Elcometer 122 Testex Replica

Tape & Elcometer 124 Thickness Gauge, which is providing a permanent peak to valley surface

profile in µm according to ISO 8503-5.

-(04) spots of roughness test was taken after sandblasting.

-Results were found acceptable and within the recommended surface profile 50-85 μm, grade

Medium G; stated in TDS. Some of the achieved profile results are listed in below table:

ROUGHNESS TEST RESULT

Acceptance criteria:

Reading, surface Level of surface

Spot N° Average, μm Result

profile, μm profile

(according to TDS*)

1 76

80,5 50-85 μm conform

2 85

*TDS: Technical data sheet.

-Some steel & weld imperfections (spatter, surface irregularity, undercut...) was found after

sandblasting. These imperfections cannot be detected before sandblasting; it is hidden by the

paint.

DAILY REPORT INSPECTION OF CRUDE OIL STORAGE TANK T1 PAGE 2/7

Daily Coating Inspection Report

-Damage on paint is observed in random areas of shell are due to sandblasting operation.

4/- Soluble salt test: (See photos 8,9,10)

Soluble salts have been measured on (02) spots using the POSITECTOR SST (Soluble Salt

Tester).

The test is done according to according to Bresle method (ISO 8502-6 & 9).

Results are summarized in below table:

BRESLE BATCH SALT TEST RESULT

Acceptance

criteria: Level of

Spot N° Reading, Salt content, mg/m2 Result

total water-soluble

salts

1 23

30 mg/m² conform

2 20

5/- Checking air compressor

-The measured temperature of portable compressor found acceptable as per MOG specification.

-The pressure gauge of portable air compressor found damaged.

Activity Progress:

Bottom Roof

Step

Pre-cleaning 100% 100%

Sandblasting/Mechanical surface 54,75 % 0%

preparation

Paint application :First coat 20,63 % 0%

Paint application :Top coat 11,10 % 0%

Final Inspection 0% 0%

DAILY REPORT INSPECTION OF CRUDE OIL STORAGE TANK T1 PAGE 3/7

Daily Coating Inspection Report

Sandblasting Progress (Details):

Date Blasted surface (m2) Date Blasted surface Date Blasted surface (m2)

(m2)

Until 04/11/2021 865,78 20/11/2021 25 *** ***

05/11/2021 25 21/11/2021 40 *** ***

06/11/2021 25 22/11/2021 40 *** ***

07/11/2021 45 23/11/2021 35 *** ***

08/11/2021 55 24/11/2021 38 *** ***

09/11/2021 30 25/11/2021 8 *** ***

10/11/2021 40 26/11/2021 0 *** ***

11/11/2021 30 27/11/2021 45 *** ***

12/11/2021 0 28/11/2021 81 *** ***

13/11/2021 47 *** *** *** ***

14/11/2021 62 *** *** *** ***

15/11/2021 44 *** *** *** ***

16/11/2021 0 *** *** *** ***

17/11/2021 40 *** *** *** ***

18/11/2021 0 *** *** *** ***

19/11/2021 30 *** *** *** ***

Total surface bottom (m2) 3014,58

2

Total Blasted surface (m ) 1650,78

Progress bottom : 54,75 %

Remaing bottom surface (m2) 1363,8

Primer coat Progress:

Primer coat applied –Total surface (m2) 622,04

Progress bottom : 20,63 %

Remaing bottom surface (m2) 2392,54

Top coat Progress:

Top coat applied –Total surface (m2) 334,69

Progress bottom : 11,10 %

Remaing bottom surface (m2) 2679,89

DAILY REPORT INSPECTION OF CRUDE OIL STORAGE TANK T1 PAGE 4/7

Daily Coating Inspection Report

Recommendations:

1- All steel and welding imperfections should be smoothly prepared without any damage to the plate

as per MOG specification & ISO ISO 8501-3. (Further examination shall be according API inspector.

2- All fittings and accessories shall be protected as per MOG specification.

3/- More ventilation should be installed to remove dust during and after grit blasting.

4/- The no conform areas after sandblasting shall be repaired to achieve the final required grade as

per MOG specification.

5/- Contact area (between pipe support and bottom plates) shall be prepared and painted as per

MOG specification.

6/-The pipe support's extremity shall carefully prepared. (Perimeter of support on deck plates)

7/- All damage on paint in shell plates shall be repaired as per MOG specification.

8/- All used abrasive material should be removed from the tank.

9/- It is recommend to use vacuum cleaner during collect of dust.

DAILY REPORT INSPECTION OF CRUDE OIL STORAGE TANK T1 PAGE 5/7

Daily Coating Inspection Report

Reference Photos:

28/11/2021 28/11/2021

8:00 AM 8:00 AM

Photo No 1 Photo No 2

28/11/2021

General view of

8:00 AM blasted surface

Photo No 3 Photo No 4

Photo No 5 Photo No 6

DAILY REPORT INSPECTION OF CRUDE OIL STORAGE TANK T1 PAGE 6/7

Daily Coating Inspection Report

Photo No 7 Photo No 8

Photo No 9 Photo No 10

Prepared by : TIC Libyan Branch Reviewed by :

Anis BEN RABEH Ismail ASSOUAD

Coating inspector Hassan ALBAWANDI

Ahmed BENHALEEM

Ali ELMARRIMI

MOG Plant Inspection dept

DAILY REPORT INSPECTION OF CRUDE OIL STORAGE TANK T1 PAGE 7/7

You might also like

- Mix Design DLC-DelDocument9 pagesMix Design DLC-DelSanjay Constructions100% (1)

- Project: Tasiast Debottlenecking Project - Tailings THICKENER/4699-THK-201Document2 pagesProject: Tasiast Debottlenecking Project - Tailings THICKENER/4699-THK-201Rekhis OussamaNo ratings yet

- DHU-NOCL - JOB EXECUTION PLAN - SupersededDocument37 pagesDHU-NOCL - JOB EXECUTION PLAN - SupersededTaofiqNo ratings yet

- Soil Test Report of 128 No. Brojopur Purba para BangladeshDocument38 pagesSoil Test Report of 128 No. Brojopur Purba para BangladeshWUB STUDENTS 68G100% (3)

- Pernod RicardDocument19 pagesPernod RicardSejalAgarwalNo ratings yet

- (E.a The Grimoire of Amaymon (Nine Demonic Gatekeepers Book 2Document27 pages(E.a The Grimoire of Amaymon (Nine Demonic Gatekeepers Book 2Ṩĸṳlḷ Kȉď60% (5)

- Manual Mycon SCV - IM20150612E PDFDocument161 pagesManual Mycon SCV - IM20150612E PDFFabiano TavaresNo ratings yet

- Method Statement For Finishing WorkspdfDocument7 pagesMethod Statement For Finishing Workspdfmohamed nabilNo ratings yet

- Shams-Alden: Item Description Unit QtyDocument10 pagesShams-Alden: Item Description Unit QtyMarghani OsamaNo ratings yet

- Sksp2redpenDocument2 pagesSksp2redpenJamal Mohamed RahamathullahNo ratings yet

- Ample Nformation Sample No: RL-01: Ement Ests EportDocument3 pagesAmple Nformation Sample No: RL-01: Ement Ests EportweamNo ratings yet

- Inspection Certificate: Manufacture DateDocument2 pagesInspection Certificate: Manufacture Datemaheshmalaichamy007No ratings yet

- UFGS 31 73 19 USACE SpecificationsDocument27 pagesUFGS 31 73 19 USACE SpecificationsHeath LEENo ratings yet

- Final Visual & Dimensional Inspection Report: GeneralDocument3 pagesFinal Visual & Dimensional Inspection Report: Generalsuria qaqcNo ratings yet

- DX23-044 Final ReportDocument126 pagesDX23-044 Final ReportTAHANo ratings yet

- Ufgs 31 73 00Document27 pagesUfgs 31 73 00NihalNo ratings yet

- 03-09092021-DPR-003-NB-OPV&OPV90M-PT - DRU-TNI AL-M AliDocument5 pages03-09092021-DPR-003-NB-OPV&OPV90M-PT - DRU-TNI AL-M AliQA QCNo ratings yet

- Construction SchedDocument3 pagesConstruction SchedJasmer Lloyd Diaz EspadaNo ratings yet

- Soil ReportDocument23 pagesSoil ReportMarlon Abellanosa BonusNo ratings yet

- Mar 10,2023 Daily Site Report Format Alaba A Gebeya HulbaregDocument1 pageMar 10,2023 Daily Site Report Format Alaba A Gebeya HulbaregAsegidNo ratings yet

- MTO Pipeline Mazalij Civil SubconDocument20 pagesMTO Pipeline Mazalij Civil SubconJonald DagsaNo ratings yet

- Environment Monitoring Monthly Report - Aug'22Document1 pageEnvironment Monitoring Monthly Report - Aug'22Mohit Kumar DasNo ratings yet

- Well Completion Report FOR Addis Ababa Bole International Airport Well (AABIA-01-17)Document49 pagesWell Completion Report FOR Addis Ababa Bole International Airport Well (AABIA-01-17)abraham lemmaNo ratings yet

- Request For InspectionDocument24 pagesRequest For InspectionCampos Silcam SilvioNo ratings yet

- 2 Concrete Works MSDocument7 pages2 Concrete Works MSGaneshNo ratings yet

- Painting of Structure Piping Equipment 22Document5 pagesPainting of Structure Piping Equipment 22Saurabh Kumar VermaNo ratings yet

- Welding Procedure B69AWDocument2 pagesWelding Procedure B69AWMastram HatheshNo ratings yet

- Ufgs 09 90 00Document90 pagesUfgs 09 90 00Amir KhakzadNo ratings yet

- D231327 CenDocument12 pagesD231327 CenFERCHICHI NawelNo ratings yet

- Mar 8,2023 Daily Site Report Format Alaba A Gebeya HulbaregDocument1 pageMar 8,2023 Daily Site Report Format Alaba A Gebeya HulbaregAsegidNo ratings yet

- Journal On Characteristics of Geotechnical Properties of SoilDocument10 pagesJournal On Characteristics of Geotechnical Properties of SoilAderemi AbidemiNo ratings yet

- Test Method: Normalisation Renault Automobiles RE-DS / Service 67250 Section Normes Et Cahiers Des ChargesDocument32 pagesTest Method: Normalisation Renault Automobiles RE-DS / Service 67250 Section Normes Et Cahiers Des ChargesRicardo VitorianoNo ratings yet

- Part-F Soil Investigation Report Boys HostelDocument26 pagesPart-F Soil Investigation Report Boys Hosteldhirajagarwal1989No ratings yet

- ES9-58 Standard Paint Program Tubomachinery Rev WDocument11 pagesES9-58 Standard Paint Program Tubomachinery Rev WganeshNo ratings yet

- Specs-Div 07Document33 pagesSpecs-Div 07Osama KheadryNo ratings yet

- SD05wi1 Structural Inspection WorkpackDocument22 pagesSD05wi1 Structural Inspection WorkpackidrisNo ratings yet

- Castor: Calibration CertificateDocument1 pageCastor: Calibration Certificatevijay narayanNo ratings yet

- Roundness Check Record of 1St Shell CourseDocument1 pageRoundness Check Record of 1St Shell CourseRhannie GarciaNo ratings yet

- Ep Wells Daily Operation ReportDocument5 pagesEp Wells Daily Operation ReportMohammed HamzaaliNo ratings yet

- Weekly Progress Report - No. 06: Sai Gon Binh An Urban AreaDocument15 pagesWeekly Progress Report - No. 06: Sai Gon Binh An Urban AreaMinh Thuận100% (1)

- Petroleum Economy AssignmentDocument58 pagesPetroleum Economy AssignmentTrishan NairNo ratings yet

- Section 033000 Cast-In-Place Concrete PDFDocument42 pagesSection 033000 Cast-In-Place Concrete PDFTargetRockNo ratings yet

- Soil Test ReportDocument13 pagesSoil Test ReportHanuma KanthetiNo ratings yet

- Peugeot-B53 3220 - 2001 - (HR-CR-Continuously Galvanised) - EnglishDocument7 pagesPeugeot-B53 3220 - 2001 - (HR-CR-Continuously Galvanised) - EnglishdpfloresNo ratings yet

- Work Order RCC WorkDocument4 pagesWork Order RCC Workdeepeshtank56No ratings yet

- 01-07092021-DPR-001-NB-OPV&OPV90M-PT - DRU-TNI AL-M AliDocument3 pages01-07092021-DPR-001-NB-OPV&OPV90M-PT - DRU-TNI AL-M AliQA QCNo ratings yet

- Dogger Bank ADocument11 pagesDogger Bank AGRZEGORZ GNo ratings yet

- Tender8614 2Document425 pagesTender8614 2Vishal SoniNo ratings yet

- Initial Survey LATEST 2022 MARDocument6 pagesInitial Survey LATEST 2022 MARDelta akathehuskyNo ratings yet

- Agl 50 - PIU - Rajkot - Velan, SPT-1 No. - 6Document10 pagesAgl 50 - PIU - Rajkot - Velan, SPT-1 No. - 6jayNo ratings yet

- TSS EECA SOUTH-MoS 404-Touch Up Repair Procedure-MISURATA CCPP Project - Rev02-UnlockedDocument62 pagesTSS EECA SOUTH-MoS 404-Touch Up Repair Procedure-MISURATA CCPP Project - Rev02-UnlockedMehmet AtabayNo ratings yet

- SOP FOR Bored Cast in Situ Pile WorkDocument13 pagesSOP FOR Bored Cast in Situ Pile Workom prakashNo ratings yet

- SPT Report PDFDocument12 pagesSPT Report PDFrahul sumanNo ratings yet

- Phase Cone Penetration Test Reports at Development Area of 2-02-08land LotDocument46 pagesPhase Cone Penetration Test Reports at Development Area of 2-02-08land LotRuwan Sampath WickramathilakaNo ratings yet

- 14-Ufgs 02 32 00Document29 pages14-Ufgs 02 32 00Otceliban SarlNo ratings yet

- Peugeot-B53 3210 - 1997 - (HR-CR-Zinc Electroplated) - EnglishDocument5 pagesPeugeot-B53 3210 - 1997 - (HR-CR-Zinc Electroplated) - EnglishdpfloresNo ratings yet

- Emission Estimation Technique Manual: Non-Metallic Mineral Product ManufactureDocument54 pagesEmission Estimation Technique Manual: Non-Metallic Mineral Product ManufactureSarah Aida SilvianaNo ratings yet

- APT - cc.D.2021.820 (5 Files Merged)Document5 pagesAPT - cc.D.2021.820 (5 Files Merged)umangNo ratings yet

- Technical Specification Canal - 02Document203 pagesTechnical Specification Canal - 02Naveen Nagisetti100% (1)

- Si Report Hebroncourtgeotechnical PDFDocument84 pagesSi Report Hebroncourtgeotechnical PDFazamNo ratings yet

- Screenshot 2021-07-09 at 4.15.18 PMDocument46 pagesScreenshot 2021-07-09 at 4.15.18 PMYOGENDRAN RAJANDARANNo ratings yet

- Concrete Materials: Properties, Specifications, and TestingFrom EverandConcrete Materials: Properties, Specifications, and TestingRating: 4.5 out of 5 stars4.5/5 (5)

- Working Guide to Petroleum and Natural Gas Production EngineeringFrom EverandWorking Guide to Petroleum and Natural Gas Production EngineeringRating: 5 out of 5 stars5/5 (2)

- Classic CV TemplateDocument2 pagesClassic CV TemplateAhmed MohammedNo ratings yet

- Unit 8 WordlistDocument2 pagesUnit 8 WordlistAhmed MohammedNo ratings yet

- Unit 10 WordlistDocument2 pagesUnit 10 WordlistAhmed MohammedNo ratings yet

- SEPARATOR S22 Preliminary Revision 00Document17 pagesSEPARATOR S22 Preliminary Revision 00Ahmed MohammedNo ratings yet

- Daily Report 27-11-2021Document7 pagesDaily Report 27-11-2021Ahmed MohammedNo ratings yet

- Daily Report 26-11-2021Document7 pagesDaily Report 26-11-2021Ahmed MohammedNo ratings yet

- Daily Report 25-11-2021Document7 pagesDaily Report 25-11-2021Ahmed MohammedNo ratings yet

- MMF 10 2021Document3 pagesMMF 10 2021Ahmed MohammedNo ratings yet

- Boiler3 (B)Document1 pageBoiler3 (B)Ahmed MohammedNo ratings yet

- Operation Principal of Screw CompressorDocument1 pageOperation Principal of Screw Compressornarayan46No ratings yet

- E Series Service Manual 83177 - 1Document56 pagesE Series Service Manual 83177 - 1Okan TaktakoğluNo ratings yet

- MediaDocument10 pagesMediaVusale MirzeyevaNo ratings yet

- ADDRESS1Document12 pagesADDRESS1*IretexNo ratings yet

- Basic Instructions To Use These Spreadsheets For T-PRO Differential Three Phase Slope TestDocument9 pagesBasic Instructions To Use These Spreadsheets For T-PRO Differential Three Phase Slope TestMeghavahinaNo ratings yet

- Maldague - Applications of Infrared Thermography in Nondestructive Evaluation PDFDocument23 pagesMaldague - Applications of Infrared Thermography in Nondestructive Evaluation PDFFilipehenriqueNo ratings yet

- Pradeep Indrakanti PresentationDocument12 pagesPradeep Indrakanti Presentationrecsco2No ratings yet

- Q4-PhilPol ST1Document3 pagesQ4-PhilPol ST1Franjhielyn GolvinNo ratings yet

- Bearings: Purpose of Bearings - Loads - Types of Bearings - Materials - Construction - ApplicationDocument15 pagesBearings: Purpose of Bearings - Loads - Types of Bearings - Materials - Construction - ApplicationSeanRiniFernando100% (1)

- Internet of Things-Final Project Smart Cities : Ghofrane Ferchichi Stic L2 SR BDocument12 pagesInternet of Things-Final Project Smart Cities : Ghofrane Ferchichi Stic L2 SR BGhofrane FerchichiNo ratings yet

- WInd Turbine Research ProposalDocument4 pagesWInd Turbine Research ProposalAbeed AbeerNo ratings yet

- Testing and Commissioning, Termination CablesDocument2 pagesTesting and Commissioning, Termination CablesJhuneheart MontalesNo ratings yet

- ProCurve and Cisco STP InteroperabilityDocument86 pagesProCurve and Cisco STP InteroperabilityrahizNo ratings yet

- CB2402 Week 3 Part 2Document4 pagesCB2402 Week 3 Part 2RoyChungNo ratings yet

- Salesforce Lightning Application Development Essentials by Mike Topalovich B01lxkog36 PDFDocument6 pagesSalesforce Lightning Application Development Essentials by Mike Topalovich B01lxkog36 PDFpankaj kumarNo ratings yet

- Research Paper On Flywheel PDFDocument4 pagesResearch Paper On Flywheel PDFAadityaNo ratings yet

- I 3031Document222 pagesI 3031Daniel Venancio VieiraNo ratings yet

- Financial Statements and Ratio Analysis NEWDocument108 pagesFinancial Statements and Ratio Analysis NEWDina Adel DawoodNo ratings yet

- Nasa Sitcthed Sandwich PanelDocument166 pagesNasa Sitcthed Sandwich PanelRakesh BabuNo ratings yet

- Dbms Lab ManualsDocument13 pagesDbms Lab ManualsRohit M NNo ratings yet

- Data LoggerDocument77 pagesData LoggerCooll DuudeNo ratings yet

- TM 325C Prelim ProjectDocument18 pagesTM 325C Prelim ProjectAl Booc CatipayNo ratings yet

- Hydraulics Review ProblemsDocument9 pagesHydraulics Review ProblemsrojethtrinidadNo ratings yet

- Capital Expenditures:: Definition and ExplanationDocument1 pageCapital Expenditures:: Definition and ExplanationBryent GawNo ratings yet

- RMM SyllabusDocument3 pagesRMM Syllabusgayathri saravananNo ratings yet

- Anu 2Document3 pagesAnu 2anuNo ratings yet

- Berkeley Solar DroneDocument1 pageBerkeley Solar DroneAviation/Space History LibraryNo ratings yet