Professional Documents

Culture Documents

Metric DIN 965 Spec

Uploaded by

Ray FaiersCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Metric DIN 965 Spec

Uploaded by

Ray FaiersCopyright:

Available Formats

All your fastener needs from a single source

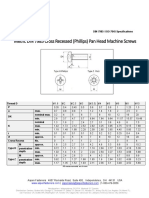

Product Dimensions and Weights DIN 965 ISO 7046 Specifications

Metric DIN 965 Cross Recessed (Phillips) Flat Countersunk Machine Screws

Thread d M1.6 M2 M2.5 M3 (M3.5) M4 M5 M6 M8 M10

P 0.35 0.4 0.45 0.5 0.8 0.7 0.8 1 1.25 1.5

A max. 0.7 0.8 0.9 1 1.2 1.4 1.6 2 2.5 3

B min. 15 16 18 19 20 22 25 28 34 40

nominal max. 3 3.8 4.7 5.6 6.5 7.5 9.2 11 14.5 18

DK

min. 2.75 3.5 4.4 5.3 6.14 7.14 8.84 10.57 14.07 17.57

K max. 0.96 1.2 1.5 1.65 1.93 2.2 2.5 3 4 5

r max. 0.4 0.5 0.7 0.8 0.95 1 1.3 1.6 2 2.5

X max. 0.9 1 1.1 1.25 1.5 1.75 2 2.5 3.2 3.8

no. 0 1 1 1 2 2 2 3 4 4

M approx. 1.7 2.35 2.7 2.9 3.9 4.4 4.6 6.6 8.7 9.6

type H penetration min. 0.66 0.95 1.25 1.5 1.4 1.9 2.1 2.8 3.9 4.8

Cross depth max. 0.91 1.25 1.55 1.8 1.9 2.4 2.6 3.3 4.4 5.3

recess

M approx. 1.8 2.2 2.5 2.8 3.7 4 4.4 6.1 8.5 9.4

type Z penetration min. 0.89 0.92 1.22 1.48 1.34 1.6 2.05 2.46 3.86 4.77

depth max. 1.14 1.17 1.47 1.73 1.8 2.06 2.51 2.92 4.32 5.23

All measurements are in mm

Aspen Fasteners 4807 Rockside Road, Suite 400, Independence, OH 44131 USA

www.aspenfasteners.com | aspensales@aspenfasteners.com | 1-800-479-0056

Headquarters: Independence OH USA; Montreal QC Canada;

Distribution Centers: Boston MA; Chicago IL; Cincinnati KY; Dallas TX; Denver CO; Houston TX; Jersey City NJ; Los Angeles CA; Miami FL;

San Francisco CA; Seattle WA; Washington VA; Toronto ON; Calgary AB; Vancouver BC; Jiutepec (Temixco); Mexico City; Monterrey

All your fastener needs from a single source

Metric DIN 965 is a cross recessed (Phillips) flat countersunk machine screws. Metric machine screws are designed for metal

to metal applications requiring a pre-drilled hole and a mating metric nut or the screw to thread into. These screws are usually

fully threaded with machine threads and blunt point. The recommended pre-drilled hole sizes vary depending on the diameter

of the screw to be used but should be slightly larger in diameter than the major (maximum) thread diameter. These screws are

available in zinc plated steel as well as stainless steel A2 and A4. Metric Flat countersunk heads have a flat top surface and a

cone-shaped bearing surface with a head angle of approximately 90°. They are used for applications where the head must be

flush with the mating surface of the substrate. Aspen Fasteners offers over 500.000 unique fastener products from stock in inch

and metric standard in a variety of materials and finishes. The following sizes metric DIN 965 cross recessed (Phillips) flat

countersunk machine screws are available for immediate shipping from stock: Diameters ranging from M1.6 to M10up to 38mm

long in zinc plated steel and stainless steel A2 and A4. View parts by clicking on the following link: DIN 965 cross recessed

(Phillips) flat countersunk machine screws.

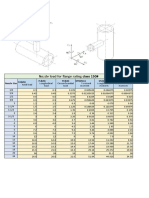

Thread d M1.6 M2 M2.5 M3 (M3.5) M4 M5 M6 M8 M10

L Weight kg/1000pcs

nominal min. max.

3 2.8 3.2 0.058 0.101 0.175

4 3.75 4.25 0.069 0.119 0.206 0.291 0.434

5 4.75 5.25 0.081 0.137 0.236 0.335 0.494 0.676

6 5.75 6.25 0.093 0.152 0.266 0.379 0.554 0.754 1.21

8 7.7 8.3 0.116 0.193 0.326 0.467 0.673 0.9 1.45 2.19

10 9.7 10.3 0.139 0.231 0.386 0.555 0.792 1.06 1.7 2.54 5.03

12 11.65 12.35 0.162 0.268 0.446 0.643 0.911 1.22 1.95 2.89 5.67 9.59

-14 13.65 14.35 0.185 0.306 0.507 0.731 1.03 1.37 2.19 3.25 6.3 10.6

16 15.65 16.35 0.208 0.343 0.567 0.82 1.15 1.53 2.44 3.61 6.94 11.6

-18 17.65 18.35 0.381 0.627 0.908 1.27 1.68 2.69 3.95 7.57 12.6

20 19.6 20.4 0.417 0.687 0.996 1.39 1.84 2.94 4.31 8.21 13.6

-22 21.6 22.4 0.747 1.08 1.51 1.99 3.18 4.66 8.84 14.6

25 24.6 25.4 0.838 1.22 1.69 2.22 3.55 5.19 9.79 16.1

-28 27.6 28.4 1.35 1.87 2.46 3.93 5.72 10.7 17.6

30 29.6 30.4 1.44 1.99 2.61 4.16 6.08 11.7 18.6

35 34.5 35.5 2.29 2.99 4.76 6.96 13 21.1

40 39.5 40.5 3.36 5.39 7.84 14.6 23.6

45 44.5 45.5 6.02 8.73 16.2 26.1

50 49.5 50.5 6.65 9.61 17.8 28.6

55 54 56 19.4 31.1

60 59 61 33.7

Aspen Fasteners 4807 Rockside Road, Suite 400, Independence, OH 44131 USA

www.aspenfasteners.com | aspensales@aspenfasteners.com | 1-800-479-0056

Headquarters: Independence OH USA; Montreal QC Canada;

Distribution Centers: Boston MA; Chicago IL; Cincinnati KY; Dallas TX; Denver CO; Houston TX; Jersey City NJ; Los Angeles CA; Miami FL;

San Francisco CA; Seattle WA; Washington VA; Toronto ON; Calgary AB; Vancouver BC; Jiutepec (Temixco); Mexico City; Monterrey

All your fastener needs from a single source

DIN (Deutsches Institut für Normung - German Institute for Standardization) standards are issued for a variety of

components including industrial fasteners as metric DIN 965 cross recessed (Phillips) flat countersunk machine screws. The

DIN standards remain common in Germany. Europe and globally even though the transition to ISO standards is taking

place. DIN standards continue to be used for parts which do not have ISO equivalents or for which there is no need for

standardization. The ISO equivalent of a metric DIN 965 cross recessed (Phillips) flat countersunk machine screws is ISO

7046.

1) Mechanical properties of stainless steel for metric DIN 965 cross recessed (Phillips) flat countersunk machine

screws

Stainless steels can be divided into three groups of steel - austenitic. ferritic and martensitic. Austenitic steel is by far the most

common type (>90% of commercial fasteners). The steel groups and strength classes are designated by a four-digit sequence

of letters and numbers (eg A2-70) as shown in the following table. DIN EN ISO 3506 governs screws and nuts made from

stainless steel.

Screws. Nuts and Bolts

Tensile Tensile

Strength strength strength Dia range Nut Load

Steel group Steel grade N/mm2 PSI

class N/mm2

50 500 70.000 <=M39 500

Austenitic A2 and A4 70 700 100.000 <=M20 700

80 800 118.000 <=M20 800

The tensile stress is calculated with reference to the tensile stress area (see DIN EN ISO 3506-1979). Nuts to be paired with same

grade of stainless steel screws

Steel Property Made From Characteristics

group Strength

class

50 A1. A2 Soft; cold worked. turned and soft pressed fasteners

Austenitic 70 A2. A4 Cold worked. normal70.000

strength formed fasteners

fasteners

<=M39

80 A2. A4 Extreme cold worked. high strength. special applications

70.000

500

fasteners fasteners

<=M39

70.000

500

<=M39

500

Aspen Fasteners 4807 Rockside Road, Suite 400, Independence, OH 44131 USA

www.aspenfasteners.com | aspensales@aspenfasteners.com | 1-800-479-0056

Headquarters: Independence OH USA; Montreal QC Canada;

Distribution Centers: Boston MA; Chicago IL; Cincinnati KY; Dallas TX; Denver CO; Houston TX; Jersey City NJ; Los Angeles CA; Miami FL;

San Francisco CA; Seattle WA; Washington VA; Toronto ON; Calgary AB; Vancouver BC; Jiutepec (Temixco); Mexico City; Monterrey

All your fastener needs from a single source

2) Chemical composition of stainless steel metric DIN 965 cross recessed (Phillips) flat countersunk machine screws

Grade USA Grade Material Material C Si Mn Cr Mo Ni

designation no. % ≤% ≤% % % %

17.5 8.0

≤

X 5Cr Ni 1810 1.4301 1.0 2.0 to - to

0.07

19.5 10.5

18.0 10

≤

A2 304 X 2 Cr Ni 1811 1.4306 1.0 2.0 to - to

0.03

20.0 12.0

17.0 11.0

≤

X 8 Cr Ni 19/10 1.4303 1.0 2.0 to - to

0.07

19.0 13.0

16.5 2.0 10.0

≤

X 5 Cr Ni Mo 1712 1.4401 1.0 2.0 to to to

0.07

18.5 2.5 13.0

A4 316

16.5 2.0 10

≤

X 2 Cr Ni Mo 1712 1.4404 1.0 2.0 to to to

0.03

18.5 2.5 13

3) Chemical composition of steel metric DIN 965 cross recessed (Phillips) flat countersunk machine screws

CHEMICAL COMPOSITION LIMITS %

TEMPERING

PROPERTY

MATERIAL AND TREATMENT C P S TEMP ºC MIN.

CLASS

min. max. max. max.

4.6. 4.8. 5.8. 6.8 Low or medium carbon steel - 0.55 0.05 0.06 -

8.8 Medium carbon steel quenched. tempered 0.25 0.55 0.04 0.05 425

9.8 Medium carbon steel quenched. tempered 0.25 0.55 0.04 0.05 425

Medium carbon steel additives e.g. boron. Mn. Cr or

10.9 0.20 0.55 0.04 0.05 425

Alloy steel - quenched. tempered

12.9 Alloy steel - quenched. tempered 0.20 0.50 0.035 0.035 380

Aspen Fasteners 4807 Rockside Road, Suite 400, Independence, OH 44131 USA

www.aspenfasteners.com | aspensales@aspenfasteners.com | 1-800-479-0056

Headquarters: Independence OH USA; Montreal QC Canada;

Distribution Centers: Boston MA; Chicago IL; Cincinnati KY; Dallas TX; Denver CO; Houston TX; Jersey City NJ; Los Angeles CA; Miami FL;

San Francisco CA; Seattle WA; Washington VA; Toronto ON; Calgary AB; Vancouver BC; Jiutepec (Temixco); Mexico City; Monterrey

All your fastener needs from a single source

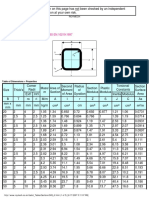

4) Mechanical properties of steel for metric DIN 965 cross recessed (Phillips) flat countersunk machine screws

PROPERTY CLASS

8.8

MECHANICAL PROPERTY

4.8 5.6 5.8 6.8 Up to M Over M 9.8 10.9 12.9

16 16

Tensile Strength nom. 400 500 600 800 900 1000 1200

(Rm. N/mm²) min. 420 500 520 600 800 830 900 1040 1220

min. 130 155 160 190 250 255 290 320 385

Vickers Hardness

max 250 320 336 360 380 435

min. 124 147 152 181 319 242 266 295 353

Brinell Hardness

max. 238 385 319 342 363 412

min. HR 71 79 82 89 -

HRC - - - - 20 23 28 32 39

Rockwell Hardness

HR 95 99 -

max. HRC - - - - 32 34 37 39 44

Yield Stress ReL. nom. 320 300 400 480 -

N/mm² min. 340 300 420 480 -

Stress at permanent nom. - 640 720 900 1080

set limit N/mm² min. - 640 660 720 940 1100

Disclaimer

Dimensional data and technical information for metric DIN 965 cross recessed (Phillips) flat countersunk machine screws was

obtained from publicly available sources and not acquired through standards agencies. It has been completed and compiled for

reference purposes only; where discrepancies are found they are subject to change without notice. Aspen Fasteners makes no

warranties or representations regarding the accuracy and validity of the compiled information and data. Contact the relevant

standards authorities for accurate and detailed information.

Aspen Fasteners 4807 Rockside Road, Suite 400, Independence, OH 44131 USA

www.aspenfasteners.com | aspensales@aspenfasteners.com | 1-800-479-0056

Headquarters: Independence OH USA; Montreal QC Canada;

Distribution Centers: Boston MA; Chicago IL; Cincinnati KY; Dallas TX; Denver CO; Houston TX; Jersey City NJ; Los Angeles CA; Miami FL;

San Francisco CA; Seattle WA; Washington VA; Toronto ON; Calgary AB; Vancouver BC; Jiutepec (Temixco); Mexico City; Monterrey

You might also like

- Math Practice Simplified: Decimals & Percents (Book H): Practicing the Concepts of Decimals and PercentagesFrom EverandMath Practice Simplified: Decimals & Percents (Book H): Practicing the Concepts of Decimals and PercentagesRating: 5 out of 5 stars5/5 (3)

- Metric DIN 965 Cross Recessed (Phillips) Flat Countersunk Machine ScrewsDocument5 pagesMetric DIN 965 Cross Recessed (Phillips) Flat Countersunk Machine ScrewsDHEERAJ413No ratings yet

- Metric DIN 963 SpecDocument5 pagesMetric DIN 963 SpecKI FastenersNo ratings yet

- Metric DIN SpecDocument1 pageMetric DIN SpecErnestNo ratings yet

- Metric DIN 916 SpecDocument5 pagesMetric DIN 916 SpecJUAN CARDONANo ratings yet

- CSK Screw DiamensionsDocument2 pagesCSK Screw DiamensionsSenthil Thandavan CA DuraiNo ratings yet

- Metric DIN 7981 SpecDocument5 pagesMetric DIN 7981 SpecSudhanshu JainNo ratings yet

- Wing - Updated Dimensions - Jan 23 2017Document5 pagesWing - Updated Dimensions - Jan 23 2017Karteek RaghuNo ratings yet

- Sections - SHS - Hot Formed (BS EN 10219-1997)Document8 pagesSections - SHS - Hot Formed (BS EN 10219-1997)Bradley GoldenNo ratings yet

- Nozzle Load For Flange Rating Class 150#: Nozzle Size Fa (KN) FL (KN) FC (KN) MT (KNM) ML (KNM) MC (KNM)Document6 pagesNozzle Load For Flange Rating Class 150#: Nozzle Size Fa (KN) FL (KN) FC (KN) MT (KNM) ML (KNM) MC (KNM)olekNo ratings yet

- DIN 85 - Slotted Pan Head ScrewsDocument2 pagesDIN 85 - Slotted Pan Head Screwssachin pukaleNo ratings yet

- Tabel Profile L InegalDocument2 pagesTabel Profile L InegalPal BarniNo ratings yet

- High Tensile C Purlin: Steel Grade Equivalent To ASTM 446 Grade DDocument2 pagesHigh Tensile C Purlin: Steel Grade Equivalent To ASTM 446 Grade DRodolfo ZazuetaNo ratings yet

- Consteel Hot Finished Hollow SectionsDocument13 pagesConsteel Hot Finished Hollow SectionsAnonymous dWa1xtpKmfNo ratings yet

- Incoloy 800 Thread Flange 300LB 300# ASME B16.5Document2 pagesIncoloy 800 Thread Flange 300LB 300# ASME B16.5Yilia WangNo ratings yet

- HPV Hydrostatics Run2Document6 pagesHPV Hydrostatics Run2maaathanNo ratings yet

- Book 1Document4 pagesBook 1aneeshp_4No ratings yet

- Metric, Socket Head Shoulder Screws, (Stripper Bolt), Class 12.9, Black Oxide (Unground Surfaces)Document2 pagesMetric, Socket Head Shoulder Screws, (Stripper Bolt), Class 12.9, Black Oxide (Unground Surfaces)khairulyuslizarNo ratings yet

- Mechanical Thread TablesDocument38 pagesMechanical Thread TablesbarcristianNo ratings yet

- Shank Area SpecificationsDocument3 pagesShank Area SpecificationsychodnekerNo ratings yet

- Ac Resistance and Reactance 50 HZDocument6 pagesAc Resistance and Reactance 50 HZJoseph B Delos ReyesNo ratings yet

- Rectangular TankDocument4 pagesRectangular TankKevin John PaglinawanNo ratings yet

- Square Hollow Sections - Hot FormedDocument5 pagesSquare Hollow Sections - Hot FormedAristotle MedinaNo ratings yet

- Resistencia Tension Pernos ASTM F1554Document4 pagesResistencia Tension Pernos ASTM F1554mrnicusNo ratings yet

- Square Hollow Sections - Cold FormedDocument5 pagesSquare Hollow Sections - Cold FormedAristotle MedinaNo ratings yet

- BS 5950, Structural Hollow Sections, Celsius, RHS, Section Properties - Dimensions and Properties - Blue Book - Tata Steel TubesDocument9 pagesBS 5950, Structural Hollow Sections, Celsius, RHS, Section Properties - Dimensions and Properties - Blue Book - Tata Steel TubesEng Hinji RudgeNo ratings yet

- SHS Tabel (Steel Designers Manual)Document1 pageSHS Tabel (Steel Designers Manual)Endot Junior100% (1)

- Chart Title Chart Title: Axis Title Axis TitleDocument2 pagesChart Title Chart Title: Axis Title Axis TitleabhinabNo ratings yet

- DATA SetDocument5 pagesDATA SetFer MabNo ratings yet

- BetonDocument2 pagesBetonsafiradaryamandiri jogjaNo ratings yet

- Astm A500 SHS 1Document4 pagesAstm A500 SHS 1Wong JowoNo ratings yet

- Grosime PereteDocument1 pageGrosime Peretebogd32000No ratings yet

- Bar Area CalculationDocument5 pagesBar Area CalculationPranay WaghmareNo ratings yet

- PropertiesDocument5 pagesPropertiesskumarsrNo ratings yet

- Metric DIN 7984 Low Profile Head Hexagon Socket Cap Screws: Visit Our For Product AvailabilityDocument5 pagesMetric DIN 7984 Low Profile Head Hexagon Socket Cap Screws: Visit Our For Product AvailabilityTugay ArıçNo ratings yet

- Steel Pipes Standard SizesDocument2 pagesSteel Pipes Standard SizesCarolie BacatanoNo ratings yet

- Metric DIN 404 Slotted Capstan Screws: Visit Our For Product AvailabilityDocument5 pagesMetric DIN 404 Slotted Capstan Screws: Visit Our For Product AvailabilityPaulo Henrique NascimentoNo ratings yet

- Heavy Hex Bolt DimensionsDocument6 pagesHeavy Hex Bolt DimensionsSUJIT PATEL100% (1)

- Galvanized Pipe Friction LossDocument5 pagesGalvanized Pipe Friction Lossdaud heruNo ratings yet

- Metric DIN 127 SpecDocument5 pagesMetric DIN 127 SpecmahfuzNo ratings yet

- Book 1Document11 pagesBook 1PARMAR ANJALINo ratings yet

- Advantage FYI166Document1 pageAdvantage FYI166mohanadsamaraNo ratings yet

- M.S. Sq. Pipe Wts.Document2 pagesM.S. Sq. Pipe Wts.HimTex /JaswinderNo ratings yet

- PasadorDocument6 pagesPasadorAndres Byke SepulvedaNo ratings yet

- Tata SHSDocument7 pagesTata SHSakshay pawarNo ratings yet

- Product Hollow Sections 1Document2 pagesProduct Hollow Sections 1smvisuNo ratings yet

- ProjectDocument8 pagesProjectsamrawit aysheshimNo ratings yet

- Book1-Cameroon DataDocument5 pagesBook1-Cameroon DatahanshanantaNo ratings yet

- Correlations & Efficient FrontierDocument4 pagesCorrelations & Efficient FrontierkirsurkulkarniNo ratings yet

- Flowserve CV TablesDocument36 pagesFlowserve CV TableschikubadgujarNo ratings yet

- Structural Applications: IS 1161 AS1163 EN10219Document1 pageStructural Applications: IS 1161 AS1163 EN10219NitinNo ratings yet

- Nominal Wall Thickness For Schedule Sizes.: 5 10 20 30 40 60 STD 80 XS 100 120 140 160 XXSDocument2 pagesNominal Wall Thickness For Schedule Sizes.: 5 10 20 30 40 60 STD 80 XS 100 120 140 160 XXSChano HanokNo ratings yet

- Tools TipsExtensionsDocument4 pagesTools TipsExtensionsSolina AlunorteNo ratings yet

- Tubos para Intercambiadores. Principales Medidas BWG.: ASTM Heat Exchanger Tube - Principal BWG SizesDocument1 pageTubos para Intercambiadores. Principales Medidas BWG.: ASTM Heat Exchanger Tube - Principal BWG SizesSaraMendozaNo ratings yet

- NFPA System CapacityDocument4 pagesNFPA System CapacitynomarblesNo ratings yet

- Length Width Thickness Self Weight of Slab Live Load/m2 M M M kN/m2 kN/m2Document2 pagesLength Width Thickness Self Weight of Slab Live Load/m2 M M M kN/m2 kN/m2sudhirNo ratings yet

- BlendDocument5 pagesBlendkwameNo ratings yet

- Lot SizesDocument2 pagesLot SizesAhmedNo ratings yet

- Schedule ChartDocument1 pageSchedule ChartSubash Gold KingNo ratings yet

- STRESS STRAIN MODEL V2 - AluminumDocument11 pagesSTRESS STRAIN MODEL V2 - AluminumRay FaiersNo ratings yet

- Guide To AnnealingDocument3 pagesGuide To AnnealingRay FaiersNo ratings yet

- Novel Coronavirus ManualDocument53 pagesNovel Coronavirus ManualXuân Giang NguyễnNo ratings yet

- Tube Pressure CalculatorDocument4 pagesTube Pressure CalculatorRay FaiersNo ratings yet

- Material Data Sheet: Tufnol WhaleDocument3 pagesMaterial Data Sheet: Tufnol WhaleRay FaiersNo ratings yet

- Annealing - Chemical TestDocument6 pagesAnnealing - Chemical TestRay FaiersNo ratings yet

- The Materials Analyst, Part 23 - Stress Cracking - How To Avoid This KillDocument4 pagesThe Materials Analyst, Part 23 - Stress Cracking - How To Avoid This KillRay FaiersNo ratings yet

- Momi Table PDFDocument1 pageMomi Table PDFEbru Önlü DuralNo ratings yet

- Analysis of Polycarbonate Stress Cracking and Cleaning Solvent Compatibility With Telephone Components Such As Terminal Blocks and ConnectionsDocument3 pagesAnalysis of Polycarbonate Stress Cracking and Cleaning Solvent Compatibility With Telephone Components Such As Terminal Blocks and ConnectionsRay FaiersNo ratings yet

- Hallstar Stresscracking Resistance of PolycarbonateDocument9 pagesHallstar Stresscracking Resistance of PolycarbonateRay FaiersNo ratings yet

- Solidworks Non Linear Tips and TricksDocument1 pageSolidworks Non Linear Tips and TricksRay FaiersNo ratings yet

- Zyg Anodic Index PDFDocument3 pagesZyg Anodic Index PDFRay FaiersNo ratings yet

- vs2 Speciality Products Catalogue Lo Res PDFDocument71 pagesvs2 Speciality Products Catalogue Lo Res PDFRay FaiersNo ratings yet

- ORING Hand Book Handbook PDFDocument229 pagesORING Hand Book Handbook PDFBandarSWCC100% (1)

- Circlip Data PDFDocument6 pagesCirclip Data PDFRay FaiersNo ratings yet

- 19 Rack DesignGuideDocument12 pages19 Rack DesignGuideRay FaiersNo ratings yet

- CMI Level 7 ExamplesDocument8 pagesCMI Level 7 ExamplesRay FaiersNo ratings yet

- Parker O-Ring HandbookDocument287 pagesParker O-Ring Handbookhlusk9neogas100% (4)

- Ta Elastomer Cure DatesDocument3 pagesTa Elastomer Cure DatesRay FaiersNo ratings yet

- SolidWorks Simulation - Avoiding SingularitiesDocument6 pagesSolidWorks Simulation - Avoiding SingularitiesAnonymous P8Bt46mk5INo ratings yet

- LM6Document55 pagesLM6Kaio Dos Santos SilvaNo ratings yet

- BucklingDocument6 pagesBucklingZiyad12No ratings yet

- Galvanic Corrosion ChartDocument1 pageGalvanic Corrosion Chartakalp1005No ratings yet

- ANSYS ConvergenceDocument24 pagesANSYS ConvergenceRay FaiersNo ratings yet

- Mesh ControlsDocument51 pagesMesh ControlsFernando MarquezNo ratings yet

- Galvanic Relationship of MetalsDocument2 pagesGalvanic Relationship of MetalsRay FaiersNo ratings yet

- Torque SettingsDocument1 pageTorque SettingsRay FaiersNo ratings yet

- DNV Bolts Failure Analisys Marine ApplicationDocument34 pagesDNV Bolts Failure Analisys Marine ApplicationBrian Chmeisse100% (2)

- Screw TorqueDocument1 pageScrew TorqueRay FaiersNo ratings yet

- Euler S BucklingDocument6 pagesEuler S BucklingRay FaiersNo ratings yet

- Dsge ModelsDocument42 pagesDsge ModelsLuis FelipeNo ratings yet

- Take It From NT:-Cash Book Plays Role of Both Journal As Well As LedgerDocument17 pagesTake It From NT:-Cash Book Plays Role of Both Journal As Well As LedgerAnonymous b4qyneNo ratings yet

- 1 23ba PDFDocument997 pages1 23ba PDFKoosha SaghariNo ratings yet

- Environmental Economics Research Paper SampleDocument8 pagesEnvironmental Economics Research Paper Samplempymspvkg100% (1)

- MJ's Home and Commercial Cleaning Services Comparative Statement of Financial Performance As of December 31, 2021 - 2025 (In Philippine Peso)Document16 pagesMJ's Home and Commercial Cleaning Services Comparative Statement of Financial Performance As of December 31, 2021 - 2025 (In Philippine Peso)Jasmine ActaNo ratings yet

- Unified Directives 2076 Amendment1 PDFDocument74 pagesUnified Directives 2076 Amendment1 PDFRupEshNo ratings yet

- Tugas CH 7 - Amelia Zulaikha PDocument3 pagesTugas CH 7 - Amelia Zulaikha Pamelia zulaikha100% (1)

- Laporan Strategic Planning PT Ultrajaya TBK (FINAL)Document201 pagesLaporan Strategic Planning PT Ultrajaya TBK (FINAL)Maharani MustikaNo ratings yet

- You Are Hoping To Buy A House in The Future and Recently Received An Inheritance ofDocument2 pagesYou Are Hoping To Buy A House in The Future and Recently Received An Inheritance ofJael CanedoNo ratings yet

- LSBF - Acca - f9 Study Notes June 2015Document216 pagesLSBF - Acca - f9 Study Notes June 2015Nausheen Ahmed Noba100% (1)

- Development Economics-Module 2Document15 pagesDevelopment Economics-Module 2maleeha shahzadNo ratings yet

- IKEA - Global Sourcing Challenge - Case Analysis - SuryarajanS - EPGPKC06077Document2 pagesIKEA - Global Sourcing Challenge - Case Analysis - SuryarajanS - EPGPKC06077surya rajanNo ratings yet

- Friday: Dhaka Electric Supply Company Limited (DESCO) Load Shedding Schedule On 11 KV FeedersDocument15 pagesFriday: Dhaka Electric Supply Company Limited (DESCO) Load Shedding Schedule On 11 KV Feedersisti1No ratings yet

- Financial Functions and CalculationsDocument6 pagesFinancial Functions and CalculationsbertinNo ratings yet

- Quantity Estimate of 600 SS RCC GumbaDocument10 pagesQuantity Estimate of 600 SS RCC GumbaKale DaiNo ratings yet

- Brief Intro of IsraelDocument28 pagesBrief Intro of Israel王郁妘No ratings yet

- 516-70 DiffDocument8 pages516-70 DiffMohammad HassanNo ratings yet

- PTGAC - Written AssessmentDocument10 pagesPTGAC - Written AssessmentEsme AlcarazNo ratings yet

- Bill No.3 - Building Works Summary: Intermediate END: Element No. Description Amount AmountDocument105 pagesBill No.3 - Building Works Summary: Intermediate END: Element No. Description Amount AmountKelvin KongNo ratings yet

- Site Diary Work TemplateDocument15 pagesSite Diary Work Templateblaqhaqar0% (1)

- Subject: GEC 8 The Contemporary World Chapter 1: Introduction To Globalization (3 Hours)Document6 pagesSubject: GEC 8 The Contemporary World Chapter 1: Introduction To Globalization (3 Hours)Cj DasallaNo ratings yet

- WTP Trading NotesDocument3 pagesWTP Trading NotesLi Zing ShieNo ratings yet

- Multi Gas Meter - Gas Alret - HoneywellDocument6 pagesMulti Gas Meter - Gas Alret - Honeywellmohamed saadNo ratings yet

- Burke IndictmentDocument59 pagesBurke Indictmentjroneill100% (2)

- Empirical Tools of Public Finance: Solutions and ActivitiesDocument7 pagesEmpirical Tools of Public Finance: Solutions and ActivitiesAKÇA ELGİNNo ratings yet

- Home Office and Branch Accounting-Exercise PDFDocument2 pagesHome Office and Branch Accounting-Exercise PDFChristine Joy LanabanNo ratings yet

- Unit 1. Fundamentals of Managerial Economics (Chapter 1)Document42 pagesUnit 1. Fundamentals of Managerial Economics (Chapter 1)Tripti Khosla0% (1)

- Final Year Project ProposalDocument4 pagesFinal Year Project ProposalZELALEMNo ratings yet

- Alicia StitchDocument1 pageAlicia StitchJoelito CalunodNo ratings yet

- 2 Does HSBC's Most Recent Campaign Resonate With Its Target Audience? Why or Why Not?Document10 pages2 Does HSBC's Most Recent Campaign Resonate With Its Target Audience? Why or Why Not?Trang HaNo ratings yet