Professional Documents

Culture Documents

GAT2004-GKP-2015.04 - What's Wrong With HAZOPs and What Can We Do About It

GAT2004-GKP-2015.04 - What's Wrong With HAZOPs and What Can We Do About It

Uploaded by

JacekOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

GAT2004-GKP-2015.04 - What's Wrong With HAZOPs and What Can We Do About It

GAT2004-GKP-2015.04 - What's Wrong With HAZOPs and What Can We Do About It

Uploaded by

JacekCopyright:

Available Formats

APRIL 2015

What’s Wrong With HAZOPs & What We

Can Do About It

A HAZOP is a team-based process hazard analysis (PHA) method. Its purpose is to identify hazards and

operability issues in a process design. HAZOPs are not fun! Maybe that's not a problem, but they also don't Erosion

achieve what they could and that is a problem.

FLOW Vibration

Why Don't We Learn What We Should From HAZOPs?

Etc.

HAZOPs are not as effective as they should be for several reasons, including:

Pressure

• Tunnel Vision - The focus on small nodes obscures the big picture.

• Guideword Excess - Flow, pressure, temperature, and level are not independent.

• HAZOPs are supposed to identify operability issues, but they really don't explicitly address Temperature

operability.

• Risk assessment in HAZOPs is typically difficult, ambiguous and not repeatable. Level

• HAZOP reports are difficult to read and are of limited use.

• Most people don't enjoy HAZOPs and that impacts participation.

Figure 1: Guidewords Are Not Independent

The GATE Stream-based HAZOP process avoids these pitfalls via some novel modifications to the process.

Guideword Excess

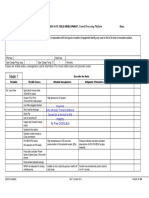

Suggested Flow Deviations

Figure 1 tells the story. Almost all causes of pressure, temperature and level deviation are caused by flow

deviation. If you rigorously do all the flow, pressure, temperature and level deviation discussions you will

perform the HAZOP twice. Often, the solution is to do the flow deviation discussions first and do the others More, Less, No

by exception. That is problematic on a couple of levels.

Different

1. When you get to ‘High Pressure’, there isn’t much to talk about and the record often says Composition

things like “See High Flow”. The conversation that we really need to have is almost an Chemical Injection

afterthought. Solids Precipitation

Phase Change

2. This messes up the HAZOP record. When ‘High Pressure’ scenarios are recorded under ‘High

Flow’ the record is difficult to read and to use. Reaction

Stream-Based Nodes & the ‘Flow’ Discussions Multiple Phases

Our solution to the guideword excess problem is to define a different kind of node for the flow deviation Sampling

discussions, a stream-based node. For this purpose, a stream is a continuous flow of fluid across piping

and equipment items. Any disturbance to the flow anywhere in the stream should impact the stream Startup, Shutdown

throughout (or at least at all points downstream of the disturbance).

5000 psig 1200 psig 300 psig 50 psig Atmos

Commissioning

Out of Service Equipment

HP Sep Corrosion, Erosion

LP Sep Degasser

Dry Oil Tank Process Control

Oil Heater

Crude Cooler

Treater

To Produced

Table 1: Suggested Flow Deviations

To Produced

Water Water

Reservoir

Figure 2: Oil Production Node

APRIL 2015

GAT2004-2015.04

What’s Wrong With HAZOPs & What We Can Do

About It

Some streams are easy to identify. A 2,000 mile equipment-based node. Delay discussion

ethane pipeline with multiple pump stations is of frequency, consequences, and

clearly one stream. Shut off flow at one point and it safeguards until the equipment-based References

stops at all points. node discussion. 1. Duhon, Sutton, (2010), “Why We Don’t

b. Fully discuss other consequences of flow Learn What We Should From HAZOPS”,

Other streams are more abstract. Oil production

deviation (vibration, erosion, slugging, SPE-120735-PA, SPE Projects, Facilities and

from a well that flows through several separators

solids deposition, etc.). Construction, June 2010

where gas is flashed off and water is decanted can

still be considered a ‘stream’ from the reservoir all 2. Duhon (2011), “Stream-based HAZOP, A

4. For each equipment-based node conduct the

the way to the Dry Oil Tank (Figure 2). The flashed More Effective HAZOP Method”, SPE-

pressure, temperature and level deviation

gas and separated water also need to be considered 114982, Presented at SPE Americas E&P

discussions. This is done only after all stream-

as streams in separate stream-based nodes. Health, Safety, Security and Environmental

based nodes that include the equipment item

have been discussed. Note that at this point Conference, Houston, TX, USA, 21-23

A stream-based node is ideal for discussion of flow March 2011

almost all causes of pressure, temperature and

deviations. The flow deviation discussion provides an

level deviation will have been identified via the 3. Duhon, Cronin (2015), “Risk Assessment in

opportunity to evaluate the operability of the

stream-based node discussions. The discussion HAZOPs”, SPE-173544-MS, Presented at the

system. The objective of most operating procedures

now switches to discussion of frequency, SPE Americas E&P Health, Safety, Security

is to establish or change the flow through a system.

consequences and safeguards. Safeguards are and Environmental Conference, Denver, CO,

Operating procedures can be introduced at a high

discussed only once considering the totality of USA, 16-18 March 2015

level. The flow deviation discussions can include

identified deviations for the equipment-based

discussions of startup (initiating flow), shutdown

node. 4. Duhon, “What’s Wrong with HAZOPs and

(stopping flow) and batch operations such as

pigging. Commissioning can also be considered. See What we can do About it”, presented at

5. Evaluate risks and make recommendations American Institute of Chemical Engineers

Table 1 for a more extensive list.

2015 Spring Meeting and 11th Global

Congress on Process Safety, Austin, Texas,

Equipment-Based Nodes for Pressure, Identify the Stream-Based Nodes & April 27-29, 2015

Temperature & Level Discussions Develop Node Schematics

The stream-based node is not an effective vehicle Identify the Equipment-Based

Nodes

for discussion of pressure, temperature and level

safeguarding. Equipment-based nodes (typical FLOW Deviation Discussions for each

HAZOP nodes) are used to conduct the pressure, Stream-Based Node

temperature and level discussion.

Lists of Causes for

An equipment item will generally be part of more PRESSURE

than one stream-based node. An equipment-based Deviations for each

Equip-Based Node

node is evaluated only after all relevant stream-

based nodes have been discussed.

Lists of Causes for

TEMPERATURE

When we begin an equipment-based node Deviations for each

discussion, we will have already identified almost all Equip-Based Node

the causes of pressure, temperature and level

deviation in that equipment item. We discuss the

Lists of Causes for

safeguarding for each node only one time and all the LEVEL Deviations

‘High Pressure’ discussion for a node is contained at for each Equip-

one place in the HAZOP record. Based Node

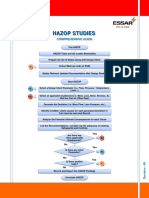

The GATE Stream-Based HAZOP Method PRESSURE Deviation Discussions for

each Equip-Based Node

The method described above is summarized below

and in Figure 3. TEMPERATURE Deviation Discussions

for each Equip-Based Node

1. Identify the stream-based nodes and develop LEVEL Deviation Discussions for

a sketch of each stream-based node. each Equip-Based Node

2. Identify the equipment-based nodes (typical Figure 3: Proposed HAZOP Method

HAZOP nodes).

Conclusions

3. For each stream-based node conduct the flow-

deviation discussions. The purpose of the flow The HAZOP process is probably the most commonly

deviation discussions is largely to develop a applied process hazard analysis process. For a

detailed understanding of the process. number of reasons, we do not learn as much as we

should from HAZOPs. The GATE Stream-based

a. Where a flow deviation causes a

HAZOP Method improves on some of the obvious

temperature, pressure or level deviation,

shortcomings of the standard HAZOP process.

capture the cause in the appropriate

You might also like

- Operator’S Guide to Centrifugal Pumps, Volume 2: What Every Reliability-Minded Operator Needs to KnowFrom EverandOperator’S Guide to Centrifugal Pumps, Volume 2: What Every Reliability-Minded Operator Needs to KnowNo ratings yet

- HAZOP ExerciseDocument12 pagesHAZOP Exerciseshawalina07No ratings yet

- Packaging Prepared Food StuffDocument18 pagesPackaging Prepared Food StuffLeila Madelene Loyola100% (1)

- HAZOPDocument21 pagesHAZOPMalak HindiNo ratings yet

- Hazops Should Be Fun - The Stream-Based HazopDocument77 pagesHazops Should Be Fun - The Stream-Based HazopHector Tejeda100% (1)

- OperationsDocument6 pagesOperationszhangjie100% (1)

- CNC Programming and OperationDocument80 pagesCNC Programming and OperationMohammed Habeeb100% (1)

- 5.7 Hazop V1.0Document14 pages5.7 Hazop V1.0abdulmarNo ratings yet

- HAZOP TrainingDocument21 pagesHAZOP TrainingEdmund MaletzkyNo ratings yet

- Human Factors in Process Plant Operation by David A. StrobharDocument66 pagesHuman Factors in Process Plant Operation by David A. StrobharAbdelsalam MahmoudNo ratings yet

- Hazop Worksheet Suggested ScenariosDocument16 pagesHazop Worksheet Suggested ScenariosJagan BoseNo ratings yet

- Hazard Evaluation, HE, Techniques The Following Are Types of HE, TechniquesDocument9 pagesHazard Evaluation, HE, Techniques The Following Are Types of HE, Techniquesyurileonardo27No ratings yet

- 2006 International Sucker Rod Pumping WorkshopDocument33 pages2006 International Sucker Rod Pumping WorkshopRodrigo DacolNo ratings yet

- 5.7 Hazop V1.1Document14 pages5.7 Hazop V1.1scrbdgharaviNo ratings yet

- Hazard and Operability StudiesDocument8 pagesHazard and Operability Studiesangry_granNo ratings yet

- ChE 534 - Module 3Document34 pagesChE 534 - Module 3Precious JamesNo ratings yet

- Lecture HAZOP ExampleDocument29 pagesLecture HAZOP ExampleIbtida SultanaNo ratings yet

- 2 4 Hazop 1Document14 pages2 4 Hazop 1barbarojNo ratings yet

- 2 4 HazopDocument14 pages2 4 HazopwarlindaekaNo ratings yet

- Hazop Study of Cooing TowerrDocument4 pagesHazop Study of Cooing TowerrSania SaeedNo ratings yet

- Assignment # 4: Subject Submitted To Submitted by TopicDocument4 pagesAssignment # 4: Subject Submitted To Submitted by TopicSania SaeedNo ratings yet

- HazopDocument3 pagesHazopVarunNo ratings yet

- 12 HazopDocument6 pages12 HazopNoman AslamNo ratings yet

- HAZOP Tutorial: Figure 1. Select Equipment and Process ParameterDocument9 pagesHAZOP Tutorial: Figure 1. Select Equipment and Process ParameterRangarirai MuswereNo ratings yet

- Early HAZOP Studies Used The Following Set of Guide Words To Systematically Review The ProcessDocument12 pagesEarly HAZOP Studies Used The Following Set of Guide Words To Systematically Review The ProcessH. Muhammad Temter GandaNo ratings yet

- Hazop Hazard & Operability StudiesDocument30 pagesHazop Hazard & Operability StudiesKaitoNo ratings yet

- Hazard and Operability Study - Wikipedia, The Free EncyclopediaDocument6 pagesHazard and Operability Study - Wikipedia, The Free EncyclopediaFernando AlvesNo ratings yet

- Safety and Hazard Analysis: Dr.A.Babu Ponnusami Associate Professor SchemeDocument35 pagesSafety and Hazard Analysis: Dr.A.Babu Ponnusami Associate Professor SchemeAMOL RASTOGI 19BCM0012No ratings yet

- Hazop PDFDocument33 pagesHazop PDFsehunNo ratings yet

- HAZOP Worksheet Adani Wilmar 26.7.2021Document11 pagesHAZOP Worksheet Adani Wilmar 26.7.2021Kailash PandeyNo ratings yet

- Hazard and Operability Studies (HAZOP) 2Document15 pagesHazard and Operability Studies (HAZOP) 2jeevanantham 5846No ratings yet

- Hazard and Operability StudyDocument5 pagesHazard and Operability StudyRoshan RohitNo ratings yet

- Hazard Identification Hazard IdentificationDocument32 pagesHazard Identification Hazard IdentificationTowfiq AhmedNo ratings yet

- Hazard & Operability StudiesDocument54 pagesHazard & Operability StudiesYagnik prajapatiNo ratings yet

- Assess Hazards With Process Flow Failure Modes Analysis: SafetyDocument9 pagesAssess Hazards With Process Flow Failure Modes Analysis: SafetyDiego1980bNo ratings yet

- 11 PDFDocument14 pages11 PDFMuhammadNo ratings yet

- Hazop Study: 11.1.1 BackgroundDocument14 pagesHazop Study: 11.1.1 BackgroundMuhammad100% (1)

- HAZOP Study of HXDocument3 pagesHAZOP Study of HXHadia SAULATNo ratings yet

- Hazard Evaluation, HE, Techniques The Following HE, Techniques Have Been Used in Chronological OrderDocument14 pagesHazard Evaluation, HE, Techniques The Following HE, Techniques Have Been Used in Chronological OrderŘëhmàñ ÀĺîNo ratings yet

- MSC Hazard Evaluation Lecture 3-November 2017Document38 pagesMSC Hazard Evaluation Lecture 3-November 2017Mir Hasib Ul LatifNo ratings yet

- A Knowledge-Based Framework For Automating HAZOP Analysis: A A A or A ADocument10 pagesA Knowledge-Based Framework For Automating HAZOP Analysis: A A A or A Aadrian haimNo ratings yet

- Hazards and Operability Analysis (HAZOP) : Saeid AhmadiDocument27 pagesHazards and Operability Analysis (HAZOP) : Saeid AhmadimahradNo ratings yet

- Hazard and Operability Study (Hazop)Document22 pagesHazard and Operability Study (Hazop)Aun AbbasNo ratings yet

- 5.7 Hazop V1.0Document25 pages5.7 Hazop V1.0marius_brkt6284No ratings yet

- Practice Causes HazDocument9 pagesPractice Causes Haz2b9vwelwxNo ratings yet

- Chapter 6 Supplemental M StudentDocument20 pagesChapter 6 Supplemental M StudentjhonsotoNo ratings yet

- HAZOP Studies GuideDocument4 pagesHAZOP Studies GuideMRITYUNJOY GUPTANo ratings yet

- Hazard and Operability Study (Hazop)Document16 pagesHazard and Operability Study (Hazop)Usman KhalidNo ratings yet

- Hazard and Operability StudyDocument21 pagesHazard and Operability StudyBubbleNo ratings yet

- Loss Prevention and HAZOPDocument39 pagesLoss Prevention and HAZOPIyer VasundharaNo ratings yet

- Jump RopingDocument6 pagesJump RopingjunNo ratings yet

- Hazop PDFDocument7 pagesHazop PDFsheik hussainNo ratings yet

- Hazop Study PrintDocument11 pagesHazop Study PrintKetan PatelNo ratings yet

- Hazard Operability Analysis (Hazop) : Annex I.6Document7 pagesHazard Operability Analysis (Hazop) : Annex I.6TAhseen UsmanNo ratings yet

- Presentation 2 26 FebDocument27 pagesPresentation 2 26 FebMohamed ElabbasyNo ratings yet

- Vol V Esia Vol 3 Part 2a-2g HazopDocument15 pagesVol V Esia Vol 3 Part 2a-2g HazopSalahBouzianeNo ratings yet

- Q9 HazopDocument7 pagesQ9 HazophemendraNo ratings yet

- 5.7 Hazop V1.0Document14 pages5.7 Hazop V1.0Soda PopNo ratings yet

- About This File: ObjectivesDocument5 pagesAbout This File: ObjectivesMinhAnhNo ratings yet

- Hyd RO Dose User ManualDocument114 pagesHyd RO Dose User ManualMohammed HassanNo ratings yet

- Ad 19 NPSHDocument14 pagesAd 19 NPSHkevinNo ratings yet

- HAZOP Validation Questionaire Post TrainingDocument3 pagesHAZOP Validation Questionaire Post TrainingakaashNo ratings yet

- (Safety Science Vol. 76) Ale, B.J.M. - Hartford, D.N.D. - Slater, D. - ALARP and CBA All in The Same Game (2015) (10.1016 - J 1Document11 pages(Safety Science Vol. 76) Ale, B.J.M. - Hartford, D.N.D. - Slater, D. - ALARP and CBA All in The Same Game (2015) (10.1016 - J 1JacekNo ratings yet

- Nuclear Technologies p1c, Chadwick House, Birchwood, Warrington, WA 3 6AE, United Kingdom Tel 44 1925 855421 Russell. Bowdenknuclear Co. UkDocument6 pagesNuclear Technologies p1c, Chadwick House, Birchwood, Warrington, WA 3 6AE, United Kingdom Tel 44 1925 855421 Russell. Bowdenknuclear Co. UkJacekNo ratings yet

- JLNG RolloverDocument3 pagesJLNG RolloverJacekNo ratings yet

- Journal of Loss Prevention in The Process Industries: Paul BaybuttDocument3 pagesJournal of Loss Prevention in The Process Industries: Paul BaybuttJacekNo ratings yet

- Be Alert For Common Cause FailuresDocument1 pageBe Alert For Common Cause FailuresJacekNo ratings yet

- Baybutt, Paul - Treatment of Multiple Failures in Process Hazard AnalysisDocument4 pagesBaybutt, Paul - Treatment of Multiple Failures in Process Hazard AnalysisJacekNo ratings yet

- Iso 6691 en PDFDocument11 pagesIso 6691 en PDFPAWAN KNo ratings yet

- Acd Si 005Document13 pagesAcd Si 005Massimo FumarolaNo ratings yet

- Redesign of CastingDocument35 pagesRedesign of Casting20MP62 - GOWTHAM BNo ratings yet

- High Energy Ball Milling Process For Nanomaterial SynthesisDocument4 pagesHigh Energy Ball Milling Process For Nanomaterial SynthesisKajal MIshraNo ratings yet

- 5.2. CVG5150. Mix-Design (Ex. 2 Solution)Document23 pages5.2. CVG5150. Mix-Design (Ex. 2 Solution)Anish valmikiNo ratings yet

- 360 Degree Final ReportDocument22 pages360 Degree Final ReportVishalNo ratings yet

- Stock Count SheetDocument8 pagesStock Count Sheetmalomostephen2No ratings yet

- 12 WeldingDocument14 pages12 WeldingCarl CrawfordNo ratings yet

- OSI Floortek Anti-Static Vinyl Installation MethodologyDocument10 pagesOSI Floortek Anti-Static Vinyl Installation MethodologyBernanRolandCelisNo ratings yet

- Company Profile Ata MarketingDocument18 pagesCompany Profile Ata MarketingAdhitiya Rizki PratamaNo ratings yet

- Foundary Lecutures NotesDocument257 pagesFoundary Lecutures NotesSUYASH GATKALNo ratings yet

- HW2 Fall 2022Document3 pagesHW2 Fall 2022hamza balNo ratings yet

- Lean Chapter 4Document15 pagesLean Chapter 4WinterMist11No ratings yet

- Sundow Polymers Co., LTD.: Surpren SN232Document2 pagesSundow Polymers Co., LTD.: Surpren SN232Phuong The NguyenNo ratings yet

- Sps His Honeywell Perfect Fit Datasheet Letter 0222Document2 pagesSps His Honeywell Perfect Fit Datasheet Letter 0222Lê Anh MinhNo ratings yet

- Tds Az 1500 SeriesDocument7 pagesTds Az 1500 SeriesIgor_uhuNo ratings yet

- 772-CURA 3.5.1 AssemblyDocument4 pages772-CURA 3.5.1 AssemblyPhoto LibrelonNo ratings yet

- Printed Circuit Board FabricationDocument20 pagesPrinted Circuit Board FabricationLakshmi C100% (7)

- 2022 May Refresher V5 SOLUTIONDocument3 pages2022 May Refresher V5 SOLUTIONKenneth AndayaNo ratings yet

- Extrusion Method of Tube With Spiral InnerDocument3 pagesExtrusion Method of Tube With Spiral InnerTHE SEZARNo ratings yet

- SWMS Fabrication Works On Pipe With Cutting, Grinding, Welding, Fitting-UpDocument2 pagesSWMS Fabrication Works On Pipe With Cutting, Grinding, Welding, Fitting-UpCao Anh HuyenNo ratings yet

- Die Cutting TolerancesDocument4 pagesDie Cutting TolerancesNeil LeonNo ratings yet

- Blueprint - Your Pulverizer For Improved PerformanceDocument65 pagesBlueprint - Your Pulverizer For Improved PerformancesvvsnrajuNo ratings yet

- Mesh To Micron Conversion Chart Ecologix SystemsDocument3 pagesMesh To Micron Conversion Chart Ecologix SystemsPitipong SunkhongNo ratings yet

- Surface Preparation and Painting Shop: Group 5Document33 pagesSurface Preparation and Painting Shop: Group 5Yumul RenceNo ratings yet

- FAS Brochure API PDFDocument41 pagesFAS Brochure API PDFVictor Flores ResendizNo ratings yet

- Minerals 11 00894Document15 pagesMinerals 11 00894Victor Alfonso RodriguezNo ratings yet

- The Toyota Production SystemDocument14 pagesThe Toyota Production SystemmichaelNo ratings yet