Professional Documents

Culture Documents

03b - Annex D - Maintenance Plan - Sheet - Rev.01

Uploaded by

Ndabezitha BukweleOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

03b - Annex D - Maintenance Plan - Sheet - Rev.01

Uploaded by

Ndabezitha BukweleCopyright:

Available Formats

NATO UNCLASSIFIED

Annex D – Documentation Maintenance Plan/Card / Rev.01 to

SOW – AWOS Replacement

CUR-1969 / Serial 2019-1AF27063-00

Dated: 14 May 2020

MAINTENANCE PLAN / CARD

1. Operational-Climatic conditions

The contractor shall clearly identify in the PMP if maintenance routines are required

depending on operational-climatic conditions (i.e.: all conditions, cold below 5 oC, extreme

cold, extreme hot, etc…), if not applicable -> n/a

2. Sorting order of maintenance routines

In the MP, the maintenance routines will be sorted by “Level of Repair” , “Periodicity” and

then by “environmental conditions” (Env. Cond.)

3. Maintenance Sheet/Card

Reference to the maintenance section of the maintenance manual where the task is

described.

MAINTENANCE PLAN (Example)

ANNEX B-Rev.02-Maintenance plan/sheet | AWOS Replacement | 14 May 2020 | P1

NATO UNCLASSIFIED

NATO UNCLASSIFIED

Annex D – Documentation Maintenance Plan/Card / Rev.01 to

SOW – AWOS Replacement

CUR-1969 / Serial 2019-1AF27063-00

Dated: 14 May 2020

PREVENTIVE MAINTENANCE PLAN (EXAMPLE)

Item Level of Periodicity Env. Maintenance Tools required Remarks

Description

1 repair Cond. Card

1 L-1 Daily All Clean the diffusometer #01- page Mop, water, soap

2 L-1 Daily All Check the rain gauge bucket #02- page Tool box

L-1 Daily Snow- Remove snow-ice from under the diffusometer #03- page

3

ice

4 L-1 Bi_weekly All Lubricate #04- page

… Etc…

M#01 L-2/3 Yearly All Visual inspection of sensors #05- page See next page

M#02 L-2/3 Yearly All Verification of bolts tightening #06- page See next page

M#03 L-2/3 Yearly All Verification of external cabinets and enclosures #07- page See next page

M#04 L-2/3 Yearly All (locking, tightness, cables-wires connections, #08- page See next page

M#05 L-2/3 drainage etc…) See next page

M#06 L-2/3 Yearly All Verification of manholes #09- page See next page

Replacement of … See next page

M#07 L-2/3 Etc…

CORRECTIVE MAINTENANCE PLAN (EXAMPLE)

Level of Maintenance Tools required Remarks

Item 1 Description

repair Card

1 L-1 Sensor untighten #C01- page Tool Box

2 L-1 Stickers lost #C02- page BoM Order new sticker and replace

3 L-1 #C03- page

… Etc…

L-2 Sensor cover damaged by projections #C05- page Check initial corrective spares kit and

…

replace as per CMP sheet-card no

… L-2 Cable connection loosen #C06- page Replace the connection

… L-2 Dripping Hydraulic circuit #C07- page

… L-2 Senor calibration #C08- page Refer to the PMP and STTE List / kit

… Etc…

Sensor major calibration Refer to the PMP and STTE List / kit –

… L-3 #C09- page dismount / replace and ship back to

contractor.

ANNEX B-Rev.02-Maintenance plan/sheet | AWOS Replacement | 14 May 2020 P2

NATO UNCLASSIFIED

NATO UNCLASSIFIED

Annex D – Documentation Maintenance Plan/Card / Rev.01 to

SOW – AWOS Replacement

CUR-1969 / Serial 2019-1AF27063-00

Dated: 14 May 2020

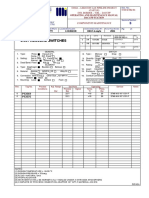

PREVENTIVE MAINTENANCE PLAN (Example)

Description: Electrical Generator, brand, type

Part Number: xxxxx

Env. Periodicity Level Routine Description Time to Skills Consumables Parts Special References Maint.

Cond. of Complete Required Required Required Tools, Test (instruction #, Sheet/Card

Repair (hrs) (and qty when (and qty) & Support manual, paragraph,

relevant) Equipment page)

Required

DURING STORAGE (short term storage and long term storage shall be clearly differentiated when appropriate)

If any – unless delete

POST STORAGE (PREPARATION FOR TRANSPORT)

If any – unless delete

DURING TRANSPORTATION (if appropriate, differentiate operations base on the transportation duration and conditions)

If any – unless delete

DURING OPERATION

All Weekly 1st Oil Analysis, Apply VA test, extract oil 2 Elec/Mech. Rags, lubricant, Plug and 11-D-EG-00-000- Card no 5 +

Vibration for OA, submit oil to Tech. cleaning agent washer kit - 000 Maintenance page 125

Analysis Vendor's Factory for 980-frsc-01 4590-23 Instructions for

analysis. HVAC System

All Monthly 1st Lubrication Change Oil in motor 0.5 Elec/Mech. Rags, lubricant, Plug and 11-D-EG-00-000- See OEM

Service Tech. cleaning agent washer kit - 000 Maintenance document

980-frsc-01, 4590-23 Instructions for page 85

20W30 Oil 89054- HVAC System

All Quarterly 2nd Open & Open up the unit, inspect 80 FSR & Rags, lubricant, Seal 9076- 11-D-EG-00-000- Card no 10 +

Inspect all parts, clean and Elec/Mech cleaning agent 3, others as 000 Maintenance page 150

lubricate, replace Tech. 980-frsc-01 A/R Instructions for

damaged parts, HVAC System

reassembly, test.

All 60 monthly/ xx 3rd Complete Ship unit to Vendor's 300 A&E Heavy A/R A/R 11-D-EG-07-000- Card no 12 +

operating Overhaul plant, dismantle unit, Electric 000, Overhaul page 165

hours replace all worn parts, Equipment Instructions for

test upon completion, Inc. AEHEE 100 KW

return test certif.. sheet. (Vendor) Generators

ANNEX B-Rev.02-Maintenance plan/sheet | AWOS Replacement | 14 May 2020 P3

NATO UNCLASSIFIED

NATO UNCLASSIFIED

Annex D – Documentation Maintenance Plan/Card / Rev.01 to

SOW – AWOS Replacement

CUR-1969 / Serial 2019-1AF27063-00

Dated: 14 May 2020

MAINTENANCE SHEET / CARD (Example)

ANNEX B-Rev.02-Maintenance plan/sheet | AWOS Replacement | 14 May 2020 |P4

NATO UNCLASSIFIED

NATO UNCLASSIFIED

Annex D – Documentation Maintenance Plan/Card / Rev.01 to

SOW – AWOS Replacement

CUR-1969 / Serial 2019-1AF27063-00

Dated: 14 May 2020

ANNEX B-Rev.02-Maintenance plan/sheet | AWOS Replacement | 14 May 2020 |P5

NATO UNCLASSIFIED

You might also like

- Preventive Maintenance Schedule Formats For Substation Equipments Sep 17 01-08Document105 pagesPreventive Maintenance Schedule Formats For Substation Equipments Sep 17 01-08Ramesh Epili100% (1)

- Toyota Tacoma 2012 - Tvip V5 Part Number: PT398-35121: PreparationDocument22 pagesToyota Tacoma 2012 - Tvip V5 Part Number: PT398-35121: PreparationTomas OrozcoNo ratings yet

- 6.3 MVA Trasformer User Manual, M020118F, XABD078+Document134 pages6.3 MVA Trasformer User Manual, M020118F, XABD078+vassindou100% (1)

- Using SSPC Coating Material Standards 1Document18 pagesUsing SSPC Coating Material Standards 1achusanachu100% (1)

- Manufacturing Process of Plastic BottlesDocument19 pagesManufacturing Process of Plastic BottlesAparna Samuel87% (23)

- Employee Safety Training Matrix Template ExcelDocument79 pagesEmployee Safety Training Matrix Template Excelشاز إياسNo ratings yet

- Evidence For Evolution: How Are DNA and Comparative Anatomy Used To Show Relatedness?Document5 pagesEvidence For Evolution: How Are DNA and Comparative Anatomy Used To Show Relatedness?Brionna SmithNo ratings yet

- MSN 33501 - SRDL - 19.10.2021Document39 pagesMSN 33501 - SRDL - 19.10.2021hadir.sob7yNo ratings yet

- Documentación Del Sistema de PaletizadoDocument1,184 pagesDocumentación Del Sistema de PaletizadoAnalista Control de CalidadNo ratings yet

- Comments Response SheetDocument2 pagesComments Response SheethusamNo ratings yet

- 4-PU101-PR-DI-029 14 SheetsDocument16 pages4-PU101-PR-DI-029 14 SheetsBurhan Ayub100% (1)

- 7 A Lesson Plan EMD KtuDocument4 pages7 A Lesson Plan EMD KtumaniNo ratings yet

- UntitledDocument200 pagesUntitledHung NguyenNo ratings yet

- Seaquest Shipmanagement Engine Manual Engine Instructions: Engine Filing System File No. File NameDocument1 pageSeaquest Shipmanagement Engine Manual Engine Instructions: Engine Filing System File No. File NameFilip NikolevskiNo ratings yet

- Mb-0301-4e DX07 PlugDocument4 pagesMb-0301-4e DX07 PlugSHYAM THILLAINATHANNo ratings yet

- CM-04&05 Flow MeterDocument10 pagesCM-04&05 Flow MeterPortfolio TrackerNo ratings yet

- IONE-VP-02-H-001-075 - Rv11 - C - INSTRUMENT ALARM AND TRIP LIST - R11Document3 pagesIONE-VP-02-H-001-075 - Rv11 - C - INSTRUMENT ALARM AND TRIP LIST - R11dhiaa mohammedNo ratings yet

- Data PDFDocument30 pagesData PDFBernardo Ramos RojasNo ratings yet

- HighlightDocument8 pagesHighlightAlexNo ratings yet

- l2cm 4 0202 RQ Tsos Rev BDocument16 pagesl2cm 4 0202 RQ Tsos Rev BidilfitriNo ratings yet

- SB 10058823 5431Document3 pagesSB 10058823 5431tgreen27602No ratings yet

- DCDT Shekkel Syam Monthly Report - SEP 2020Document29 pagesDCDT Shekkel Syam Monthly Report - SEP 2020Sachin SebastianNo ratings yet

- Electrical Pull Chamber DrawingsDocument1 pageElectrical Pull Chamber DrawingsmaldushNo ratings yet

- Mitec Redundant C Band 213265-001MA - Rev - 0 - (WRK-340420RX-485-ES-00) 1 - 1 Down Redundant System)Document51 pagesMitec Redundant C Band 213265-001MA - Rev - 0 - (WRK-340420RX-485-ES-00) 1 - 1 Down Redundant System)Danny NjomanNo ratings yet

- EASBAS355620036ENR2Document14 pagesEASBAS355620036ENR2Raymond ZamoraNo ratings yet

- Method Statement FOR Installation of Electrical Earthing System SP-2Document10 pagesMethod Statement FOR Installation of Electrical Earthing System SP-2Mohammad Fazal KhanNo ratings yet

- Mmt-Gro-11-Pp-Li-0006 - A (Ems Comments)Document6 pagesMmt-Gro-11-Pp-Li-0006 - A (Ems Comments)Rodger SenaNo ratings yet

- Document Review Sheet: (Refer To Transmittal For Return Date)Document4 pagesDocument Review Sheet: (Refer To Transmittal For Return Date)BalasubramanianNo ratings yet

- HighlightDocument5 pagesHighlightAlexNo ratings yet

- Listado de PiezasDocument154 pagesListado de PiezasrdzptecNo ratings yet

- EDI Guideline INVOIC RomaniaDocument80 pagesEDI Guideline INVOIC RomaniaDorin CretescuNo ratings yet

- Ampm2602d-01 Rev KDocument29 pagesAmpm2602d-01 Rev KBrad CooperNo ratings yet

- NG50!3!200-EnG-RP-AB-00-2235 Spools & Jumpers Basis of DesignDocument67 pagesNG50!3!200-EnG-RP-AB-00-2235 Spools & Jumpers Basis of DesignsurNo ratings yet

- CHM 1 2044Document15 pagesCHM 1 2044hulaneNo ratings yet

- QMF 424-Drawing List-FP-WATCHTOWER - 24MAY2021Document1 pageQMF 424-Drawing List-FP-WATCHTOWER - 24MAY2021JuvyNo ratings yet

- 3.2 Maintenance Parts: 3.2.1 Replacement Parts A. Main BodyDocument1 page3.2 Maintenance Parts: 3.2.1 Replacement Parts A. Main BodywoozykatNo ratings yet

- PT Tank 002Document4 pagesPT Tank 002Ahmad FawazyNo ratings yet

- PO 44403 EE2 003 - Redline - 3Document29 pagesPO 44403 EE2 003 - Redline - 3Max Antonio AllccacoNo ratings yet

- MK12D Repair From 12.2004Document1 pageMK12D Repair From 12.2004leacmagnoNo ratings yet

- Cover of Comment Sheet: Bandar-Abbas Phosphoric Acid Plant ProjectDocument2 pagesCover of Comment Sheet: Bandar-Abbas Phosphoric Acid Plant ProjectrezaNo ratings yet

- Work Inspection Request: Contract Number: MDC/2471374 - 2 Wir Reference: Revision: 0 Date & Time of InspectionDocument11 pagesWork Inspection Request: Contract Number: MDC/2471374 - 2 Wir Reference: Revision: 0 Date & Time of Inspectionamith_kmNo ratings yet

- A318/A319/A320/A321: Service BulletinDocument35 pagesA318/A319/A320/A321: Service BulletinGiraldo CardenasNo ratings yet

- Com PW Mr03 0008 001 04 Js1227 Itt Starter Panel Ga Drawing CrsDocument1 pageCom PW Mr03 0008 001 04 Js1227 Itt Starter Panel Ga Drawing CrsMohammed BrashdiNo ratings yet

- Service Manual: Digital Video Camera RecorderDocument46 pagesService Manual: Digital Video Camera RecorderDamian AlcantarNo ratings yet

- Pressure Switch DatasheetDocument1 pagePressure Switch DatasheetMohamed El MaadawyNo ratings yet

- Relief and Blowdown Report: Page 1 of 21Document21 pagesRelief and Blowdown Report: Page 1 of 21TarekNo ratings yet

- Nghi Son 2 BOT Thermal Power Plant Project Design Query SheetDocument3 pagesNghi Son 2 BOT Thermal Power Plant Project Design Query SheetMr NgocNo ratings yet

- BOM For Transformer at Playa LaiyaDocument3 pagesBOM For Transformer at Playa LaiyaHarold de MesaNo ratings yet

- 16522969-MAN - Rev. 01Document128 pages16522969-MAN - Rev. 01FSTNo ratings yet

- Pepperl+Fuchs 3094848-0.2Document13 pagesPepperl+Fuchs 3094848-0.2Mukund IndianNo ratings yet

- Irn 01 BSS Technologies 28-10-22Document2 pagesIrn 01 BSS Technologies 28-10-22vishnudasNo ratings yet

- Document Title: Revision: Vendor Rev.: Facility Identifier: Discipline: Document Type: Project Doc. Number: Vendor Doc. NumberDocument34 pagesDocument Title: Revision: Vendor Rev.: Facility Identifier: Discipline: Document Type: Project Doc. Number: Vendor Doc. Numberrajindo1No ratings yet

- CN Scrubber Dn3500 Rev04Document58 pagesCN Scrubber Dn3500 Rev04becemNo ratings yet

- Daily Progress Report: Al Fanar CompanyDocument3 pagesDaily Progress Report: Al Fanar CompanyrajmohanNo ratings yet

- GS95024-2-12 MAGNA Supplement 24.11.20 Ast D3Document30 pagesGS95024-2-12 MAGNA Supplement 24.11.20 Ast D3664bbdfvxnNo ratings yet

- Ricoh DF 3010 Service BulletinDocument16 pagesRicoh DF 3010 Service Bulletinwilliam lozadaNo ratings yet

- LG CJT30000002 Rewriter Service Bulletin LG Sofware UpdatedDocument16 pagesLG CJT30000002 Rewriter Service Bulletin LG Sofware UpdatedEdison EspinalNo ratings yet

- OM Manual For Kitchen EquipmentDocument151 pagesOM Manual For Kitchen Equipmentmukilanarul12No ratings yet

- A318/A319/A320/A321: Service BulletinDocument29 pagesA318/A319/A320/A321: Service BulletinPradeep K sNo ratings yet

- REQUEST FORM Tambahan Material WorkshopDocument4 pagesREQUEST FORM Tambahan Material WorkshopwidyaNo ratings yet

- 001.17033.000230 - Da001 - Rev 01 - CDocument70 pages001.17033.000230 - Da001 - Rev 01 - CSérgio RibeiroNo ratings yet

- Inergen System Operation and Maintenance InstructionDocument16 pagesInergen System Operation and Maintenance InstructionchuminhNo ratings yet

- T NG Ôn 2-HandoutDocument14 pagesT NG Ôn 2-HandoutHà HườngNo ratings yet

- Icp-Aes S1Document57 pagesIcp-Aes S1fitriana dewi kurniawatiNo ratings yet

- Nitrox Tablice!Document6 pagesNitrox Tablice!Frane AsanovićNo ratings yet

- "MacFarlane and Another V Tayside Health Board (2000) 2 AC 59Document8 pages"MacFarlane and Another V Tayside Health Board (2000) 2 AC 59LAW MANTRA100% (1)

- Types of CompressorsDocument44 pagesTypes of Compressorsjezreeleda.limNo ratings yet

- Current AffairsDocument20 pagesCurrent AffairsugoobiokaforNo ratings yet

- Motor Disturbance in ChildrenDocument84 pagesMotor Disturbance in ChildrenYuri BrosgolNo ratings yet

- The Complete Aqueous Hydrochloric Acid Solutions Density-Concentration CalculatorDocument2 pagesThe Complete Aqueous Hydrochloric Acid Solutions Density-Concentration CalculatorEngr. Md. Tipu SultanNo ratings yet

- Bkf1243-Analytical Chemistry 21314 PDFDocument9 pagesBkf1243-Analytical Chemistry 21314 PDFrushdiNo ratings yet

- MSDS Hemolok GelDocument5 pagesMSDS Hemolok GelReniNo ratings yet

- Qualitaetsmanagement ISO9001 enDocument0 pagesQualitaetsmanagement ISO9001 ennufrwhotNo ratings yet

- ASME B56-8 InterpretationsDocument3 pagesASME B56-8 InterpretationsING HARRINSON FERREBUSNo ratings yet

- Community Health Nursing Post Test 1Document18 pagesCommunity Health Nursing Post Test 1quidditch07No ratings yet

- Module Tests: Expert PTEA Testmaster B2 Answer KeyDocument5 pagesModule Tests: Expert PTEA Testmaster B2 Answer KeyRyan MathProNo ratings yet

- Lymph Node - Any of The Small, Oval or Round Bodies, Located Along The Lymphatic VesselsDocument2 pagesLymph Node - Any of The Small, Oval or Round Bodies, Located Along The Lymphatic VesselsKaren ParraNo ratings yet

- Notes Piping Symbols Pipe Components Cont. Pipe Components Pipe ComponentsDocument1 pageNotes Piping Symbols Pipe Components Cont. Pipe Components Pipe ComponentsMohd KhaidirNo ratings yet

- Simply Put - ENT NOSE LECTURESDocument38 pagesSimply Put - ENT NOSE LECTURESCedric KyekyeNo ratings yet

- Death Claim Form Early - English - Hindi - 05112019Document9 pagesDeath Claim Form Early - English - Hindi - 05112019CHATTU HALDERNo ratings yet

- Appointment RecieptDocument1 pageAppointment Recieptaqil faizanNo ratings yet

- 300 SS TigDocument10 pages300 SS TigSameer KhanNo ratings yet

- Fire Protection MethodsDocument3 pagesFire Protection MethodsEquilibrium EngineersNo ratings yet

- IPM Indore 2022 Original Paper With Answer KeyDocument19 pagesIPM Indore 2022 Original Paper With Answer KeyGod Plan100% (1)

- MSDS NaOH 48% FDocument6 pagesMSDS NaOH 48% FGerry HandoyoNo ratings yet

- Sulfato de Zinc MsdsDocument5 pagesSulfato de Zinc MsdsTomas Gaviria MartinezNo ratings yet

- Kunft KDW4752N DishwasherDocument59 pagesKunft KDW4752N Dishwashermike_sanNo ratings yet

- S5Q2MOD5 WK5 Modes of Reproduction in Flowering and Non Flowering PlantsDocument26 pagesS5Q2MOD5 WK5 Modes of Reproduction in Flowering and Non Flowering PlantsShie PanteNo ratings yet