Professional Documents

Culture Documents

1.1 Garment Industry Preproduction Works 01

Uploaded by

maya_muth0 ratings0% found this document useful (0 votes)

274 views6 pagesGarment Industry Preproduction Works 01

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentGarment Industry Preproduction Works 01

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

274 views6 pages1.1 Garment Industry Preproduction Works 01

Uploaded by

maya_muthGarment Industry Preproduction Works 01

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 6

Pre-Production Processes in Garment Manufacturing

When we talk about garment manufacturing, we mostly cover bulk

production processes. To know about the complete garment

manufacturing process one should also learn about the pre-production

process.

What is a pre-production process?

The processes that are done prior to the start of bulk garment

production are known as pre-production process. From sample

development, approvals, research and development work for orders,

testing of raw material to pre-production meeting are pre-production

process. Pre-production processes are very important for the efficient

production.

A typical garment export house generally has following pre-

production processes:

Meeting with buyers

In this stage, the designer of a manufacturing house shows their

creations, latest designs to buyers. On the other hand, if the buyer

already had fixed design of a style and need few changes on it related

to fit, fabrics or trims they discuss those things with the merchandiser

of the manufacturing unit.

Development of initial samples for the buyer

In this stage after receiving buyer’s concept or instructions on the new

style, samples are made with available fabrics and trims

Development of fabric sample, bit loom, print and embroidery

artwork

The fabric is developed as per the buyer requirement. Fabric

development means sourcing of customer specific fabric with

matching properties, dyed and finished for solid colours. For the solid

colour lap dip approval is a very important process. Until lap dip

sample is approved merchants re-submit lap dips. In case of yarn dyed

fabrics merchants develop fabric sample with specified design, stripes

or checks. These fabric samples called as Bit Loom. Other approvals

such as print and embroidery artwork approval and colour approval

are done. It may be done a later stage at the time of pre-production.

Costing of a garment (complete cost as well as manufacturing

cost)

Merchants prepare cost sheet with details cost break up such as raw

material cost, manufacturing cost, overheads and margin. Costing is

very a critical stage. Because whether a company will get order or not

depends on their costing. If the garment cost is very high then the

manufacturer may lose the order and on the other hand, if the factory

keeps their cost low, they will not earn profit from the order.

Estimation of the garment cost should be done on data based.

Pattern making, correction of pattern, pattern grading

In a factory, a pattern master prepares the first fit pattern. Then re-

develop pattern adding buyer comments and rectification on a fit

sample. After fit approval, pattern master grade pattern for size set

samples only for specified sizes. Once the order is ready for

production they grade pattern for whole size range.

Fit sample, size set sample making and approval from buyer

Each sample has a certain purpose. Samples are made in the sampling

department and sent to the buyer for approvals.

Correction of fit samples according to buyer comments

If the sample is not approved or further work is recommended by the

buyer. Correction is done and re-submitted to the buyer.

Approval process

Approval of fabric swatches, print colours, embroidery design,

beadworks

Production planning, Material planning and line planning

To start production on time and ship the order on time planning is a

must. Planning is needed for material sourcing, production capacity,

line planning. Scheduling of jobs and responsibility is defined at this

stage.

Placing an order for fabrics, trims, accessories and packing

materials

Sourcing of raw material. Raw materials include fabrics, all kind of

trims and accessories.

Testing of fabrics and other raw materials

Physical properties are being tested for bulk fabric. This test can be

done in in-house testing labs.

Study of approved sample

For operation break down, work content, critical operation and line

setting. Also finding the best ways for producing the garment most

efficiently in the production stage.

Pre-production meeting

Once pre-production (PP) sample is approved (also called sealer

sample) and most of the trims are sourced, merchants or production

planning department conduct pre-production meeting with the

production team, quality team and sourcing team. All important

comments, procedures to be followed, dos and don’ts are discussed.

Scheduling of PCD (planned cut date) and shipment date is

announced to all teams.

A garment export house procures raw materials for garments, cut-

make-finishes garments in production facilities and ships packed

garments to the destination countries. To make garments ready to ship

with desired quality and on-time delivery, garment manufacturers

need to establish various department based on the activities.

A typical export house has the following departments. Each

department performs a number of activities. There is no fixed number

of activities and activities of department depend on the organization

size and major processes involved in export order processing. Primary

activities are shown in the following infographic.

You might also like

- Apparel Merchandising 2020Document101 pagesApparel Merchandising 2020Nidhi ChadhaNo ratings yet

- Apparel Manufacturing ProcessDocument46 pagesApparel Manufacturing Processroselyn ayensa100% (1)

- Role of MerchandiserDocument16 pagesRole of MerchandiserStutiGoenkaNo ratings yet

- Role of Different Samples in The Export Oriented Apparel IndustryDocument7 pagesRole of Different Samples in The Export Oriented Apparel Industrymehedi_mollah50% (2)

- Smeda-Jica Industry Support Program: Small and Medium Enterprises Development AuthorityDocument65 pagesSmeda-Jica Industry Support Program: Small and Medium Enterprises Development AuthoritySAILAYS100% (2)

- Merchandising Process Product Development TADocument24 pagesMerchandising Process Product Development TANah-bel EhmedNo ratings yet

- Production Planning and Control in the Garments IndustryDocument2 pagesProduction Planning and Control in the Garments Industrykbalabala100% (1)

- Cutting Room Planning: ATDC, BhubaneswarDocument37 pagesCutting Room Planning: ATDC, BhubaneswarBinoy MundaNo ratings yet

- QC Tools in Apparel Industry Submitted by Priyanka KumariDocument22 pagesQC Tools in Apparel Industry Submitted by Priyanka Kumaripriyanka royNo ratings yet

- Marker MakingDocument12 pagesMarker MakingsachipalNo ratings yet

- FASHION EXPORT MERCHANDISINGDocument19 pagesFASHION EXPORT MERCHANDISINGRishi KumarNo ratings yet

- Roles and Responsibilities of A FASHION DESIGNERDocument10 pagesRoles and Responsibilities of A FASHION DESIGNERFatimah TabassumNo ratings yet

- Industry Visit Report of Sai Baba Garments: BY - Ashish Bhuwania BFT/17/381Document8 pagesIndustry Visit Report of Sai Baba Garments: BY - Ashish Bhuwania BFT/17/381ravikantNo ratings yet

- Cutting and Spreading Fabric EfficientlyDocument7 pagesCutting and Spreading Fabric EfficientlyAlemu HaileNo ratings yet

- Quality Control in Garment IndustryDocument4 pagesQuality Control in Garment IndustryOnlineClothing Study100% (1)

- Standardization of Apparel Manufacturing Industry Focusing On "Cutting Section"Document8 pagesStandardization of Apparel Manufacturing Industry Focusing On "Cutting Section"Anish RajNo ratings yet

- Rationalizing Sampling Efficiency of An Export House Through Effective Inventory ManagementDocument57 pagesRationalizing Sampling Efficiency of An Export House Through Effective Inventory ManagementanishaNo ratings yet

- Advanced Apparel Manufacturing ManagementDocument27 pagesAdvanced Apparel Manufacturing ManagementPrachi YashNo ratings yet

- Cost Control Apparel IndustryDocument20 pagesCost Control Apparel IndustryjitinsharmanewNo ratings yet

- Pre-production process overviewDocument7 pagesPre-production process overviewsanyaNo ratings yet

- Dnls MMDocument19 pagesDnls MMpriyal100% (1)

- Trims and Accessories InspectionDocument4 pagesTrims and Accessories Inspectionsok daraNo ratings yet

- Carr and Latham's Technology of Clothing ManufactureFrom EverandCarr and Latham's Technology of Clothing ManufactureDavid J. TylerRating: 4 out of 5 stars4/5 (1)

- 20 Ways To Improve Productivity in Garment Production and Planning CapacityDocument8 pages20 Ways To Improve Productivity in Garment Production and Planning CapacityCucak RowoNo ratings yet

- Traffic Light System For Quality Inspection in Garment ManufacturingDocument9 pagesTraffic Light System For Quality Inspection in Garment Manufacturingrajivranjan3490100% (1)

- Raw Material Consumption Calculation in Apparel Industry - Clothing IndustryDocument5 pagesRaw Material Consumption Calculation in Apparel Industry - Clothing IndustryQad BestmplNo ratings yet

- IE SOP - Standard Operating Procedure of Industrial Engineering Department - Garments-InfoDocument3 pagesIE SOP - Standard Operating Procedure of Industrial Engineering Department - Garments-InfoSayed Aasim JawaidNo ratings yet

- Sample Section:It Is The First Section Of: Garment Manufacturing ProcessDocument6 pagesSample Section:It Is The First Section Of: Garment Manufacturing ProcesssantumysoreNo ratings yet

- Documentation On TNA PlanDocument2 pagesDocumentation On TNA PlanTanushree BaghelNo ratings yet

- Knitwear Technology (Cutting & Sewing) - APM 7402 - Note Book-1Document25 pagesKnitwear Technology (Cutting & Sewing) - APM 7402 - Note Book-1shahinrezaNo ratings yet

- L-5 (Marker Making)Document17 pagesL-5 (Marker Making)Kashfmm100% (1)

- Implementing Industrial Engineering As A Tool in The IndustryDocument37 pagesImplementing Industrial Engineering As A Tool in The IndustryMeenal GraceNo ratings yet

- AQLDocument4 pagesAQLAnonymous wA6NGuyklDNo ratings yet

- Fast React Evolve Case Study MaduraDocument2 pagesFast React Evolve Case Study MaduraNt93100% (1)

- Apparel Industrial EngineeringDocument4 pagesApparel Industrial EngineeringkbalabalaNo ratings yet

- QCM - Quality Control in Garments IndustryDocument21 pagesQCM - Quality Control in Garments IndustrysatexNo ratings yet

- Bon-Ton Qa Inspection ManualDocument41 pagesBon-Ton Qa Inspection ManualYogesh KadianNo ratings yet

- Sample Room DepartmentDocument5 pagesSample Room DepartmentRajib DasNo ratings yet

- Cost Sheet GarmentDocument9 pagesCost Sheet GarmentAnonymous uHT7dDNo ratings yet

- Care LabelDocument21 pagesCare Labelmonisha100% (1)

- Final InspectionDocument20 pagesFinal InspectionP. Lakshmanakanth100% (2)

- SpreadingDocument39 pagesSpreadingPratik MinjNo ratings yet

- Planning Process and Capacity Calculations in Clothing ManufactureDocument11 pagesPlanning Process and Capacity Calculations in Clothing ManufactureSivakumar KNo ratings yet

- 3 Apparel Production Systems ComparedDocument8 pages3 Apparel Production Systems Comparedghosh7171No ratings yet

- Responsibilities of an Apparel MerchandiserDocument2 pagesResponsibilities of an Apparel MerchandiserSayed Aasim JawaidNo ratings yet

- Factory Report 2Document6 pagesFactory Report 2Chen Wei Sassei-KetsuNo ratings yet

- Quality Control in Garment Manufacturing Process-Textile LearnerDocument17 pagesQuality Control in Garment Manufacturing Process-Textile LearnerMayaNo ratings yet

- Policy for Sewing Floor ManagementDocument3 pagesPolicy for Sewing Floor ManagementAmit hasanNo ratings yet

- Garment Manufacturing and Quality AssuranceDocument9 pagesGarment Manufacturing and Quality AssuranceGaurav BharadwajNo ratings yet

- Cost Saving in Cutting Section of Apparel IndustryDocument4 pagesCost Saving in Cutting Section of Apparel IndustryMazed IslamNo ratings yet

- Marker EfficiencyDocument8 pagesMarker EfficiencyMeeta Arora100% (1)

- SopDocument23 pagesSopAl Arafat RummanNo ratings yet

- Process Flow of Cutting and Cutting EquipmentDocument8 pagesProcess Flow of Cutting and Cutting EquipmentarunkadveNo ratings yet

- Apparel Quality Management: Assignment Ii Total Quality Management Practices in Opex Group, BangladeshDocument11 pagesApparel Quality Management: Assignment Ii Total Quality Management Practices in Opex Group, BangladeshShivani JayanthNo ratings yet

- Candidate Self Assesment 6th EditionDocument3 pagesCandidate Self Assesment 6th EditionNuhan Khan100% (1)

- Sewing Defects in Apparel IndustryDocument3 pagesSewing Defects in Apparel IndustryMadhavi Ajay NagarNo ratings yet

- Improving Productivity of Garment Industry With Time Study October 2017Document6 pagesImproving Productivity of Garment Industry With Time Study October 2017rasel miahNo ratings yet

- Plant Layout - IDocument16 pagesPlant Layout - ITanya rajNo ratings yet

- Quality Control of Lee JeansDocument17 pagesQuality Control of Lee JeansLalit ChaudharyNo ratings yet

- Apparel Manufacturing PDF FreeDocument16 pagesApparel Manufacturing PDF Freeole.msfashionNo ratings yet

- 2.2 - Fashion CentersDocument10 pages2.2 - Fashion Centersmaya_muth100% (1)

- 1.5 - Textile Fibers Yarns and Fabrics - 03Document5 pages1.5 - Textile Fibers Yarns and Fabrics - 03maya_muth100% (1)

- 1.5 - Classification of FabricsDocument3 pages1.5 - Classification of Fabricsmaya_muth100% (1)

- 1.5 - Trims and AccessoriesDocument7 pages1.5 - Trims and Accessoriesmaya_muth100% (1)

- Fashion TermsDocument5 pagesFashion Termsmaya_muthNo ratings yet

- Unit 4 - Health and Saftey Related Practices Applicable at WorkplaceDocument2 pagesUnit 4 - Health and Saftey Related Practices Applicable at Workplacemaya_muthNo ratings yet

- 2.6 - Flat Sketches and Technical Drawings - Teachers ReferenceDocument12 pages2.6 - Flat Sketches and Technical Drawings - Teachers Referencemaya_muth100% (2)

- 03 - Pattern MakingDocument40 pages03 - Pattern Makingmaya_muthNo ratings yet

- 02 - Flat SketchingDocument17 pages02 - Flat Sketchingmaya_muth100% (2)

- Garment Industry ProcessesDocument30 pagesGarment Industry Processesmaya_muth100% (1)

- Workplace Hazards and Safety PoliciesDocument4 pagesWorkplace Hazards and Safety Policiesmaya_muthNo ratings yet

- Unit 3 - Design Development, Techpack & SamplesDocument8 pagesUnit 3 - Design Development, Techpack & Samplesmaya_muthNo ratings yet

- SESSION 2.1: DESIGN CONCEPTS INTRODUCTIONDocument47 pagesSESSION 2.1: DESIGN CONCEPTS INTRODUCTIONmaya_muth100% (1)

- Unit 1 - Planning and Designing Garment Collection For A SeasonDocument32 pagesUnit 1 - Planning and Designing Garment Collection For A Seasonmaya_muthNo ratings yet

- Unit 3 - Design Development, Techpack & SamplesDocument8 pagesUnit 3 - Design Development, Techpack & Samplesmaya_muthNo ratings yet

- Workplace Hazards and Safety PoliciesDocument4 pagesWorkplace Hazards and Safety Policiesmaya_muthNo ratings yet

- Unit 2 - Design Principles and MethodsDocument45 pagesUnit 2 - Design Principles and Methodsmaya_muthNo ratings yet

- Women Entrepreneurship Need Aand ImportanceDocument4 pagesWomen Entrepreneurship Need Aand Importancemaya_muthNo ratings yet

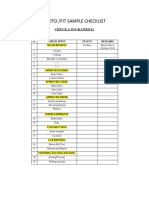

- Proto Sample ChecklistDocument2 pagesProto Sample Checklistmaya_muthNo ratings yet

- AFD I Year - Practical WorksDocument1 pageAFD I Year - Practical Worksmaya_muthNo ratings yet

- Identify The Given Pattern Making Tools and Write Their Uses.Document2 pagesIdentify The Given Pattern Making Tools and Write Their Uses.maya_muthNo ratings yet

- Identify The Given Pattern Making Tools and Write Their Uses.Document2 pagesIdentify The Given Pattern Making Tools and Write Their Uses.maya_muthNo ratings yet

- AFD - Focus Area - Vocational SkillDocument1 pageAFD - Focus Area - Vocational Skillmaya_muthNo ratings yet

- Employabilty Skills Focus AreaDocument10 pagesEmployabilty Skills Focus Areamaya_muthNo ratings yet

- Fashion Design Entrepreneurship Skills and SolutioDocument10 pagesFashion Design Entrepreneurship Skills and Solutiomaya_muthNo ratings yet

- AFD - Focus Area - Vocational Skill - NotesDocument50 pagesAFD - Focus Area - Vocational Skill - Notesmaya_muthNo ratings yet

- Fashion Design Entrepreneurship Skills and SolutioDocument10 pagesFashion Design Entrepreneurship Skills and Solutiomaya_muthNo ratings yet

- Women Entrepreneur in AFDDocument4 pagesWomen Entrepreneur in AFDmaya_muthNo ratings yet

- Tucks: No: 9 Date: . .Document5 pagesTucks: No: 9 Date: . .maya_muthNo ratings yet

- Minimum Inspection Programme AeroplanesDocument7 pagesMinimum Inspection Programme AeroplanesAndreNo ratings yet

- Adamson, Almodóvar - All About My MotheDocument87 pagesAdamson, Almodóvar - All About My MotheMário DrgoňaNo ratings yet

- Climate Zones & Traditional Shelter of UAEDocument7 pagesClimate Zones & Traditional Shelter of UAEJITHIN JAYARAMNo ratings yet

- Unturned Item CodesDocument11 pagesUnturned Item CodesEray KırcaNo ratings yet

- Ctid 314 Lesson IDocument16 pagesCtid 314 Lesson IMary CitizenNo ratings yet

- Hair - Analysts Can Tell Investigators If Individual Hairs Are Human or Animal, and in The Case of Human Hair, Where OnDocument2 pagesHair - Analysts Can Tell Investigators If Individual Hairs Are Human or Animal, and in The Case of Human Hair, Where OnSalvari VitasNo ratings yet

- Rainwater Goods 18-09-2008Document22 pagesRainwater Goods 18-09-2008Sha Mas ShaNo ratings yet

- Retail Store Manager in Atlanta GA Resume Margaret (Maggie) WixDocument3 pagesRetail Store Manager in Atlanta GA Resume Margaret (Maggie) WixMargaretWixNo ratings yet

- Charlotte The Cat: by NvkatherineDocument4 pagesCharlotte The Cat: by NvkatherineDebra EdelmannNo ratings yet

- Woolf Virginia The Duchess and The JewellerDocument8 pagesWoolf Virginia The Duchess and The Jewellerია თურმანიძეNo ratings yet

- Univolt N61B (MSDS)Document11 pagesUnivolt N61B (MSDS)Anonymous F2TxS3YoaNo ratings yet

- © Ncert Not To Be Republished: The Rattrap 44444Document14 pages© Ncert Not To Be Republished: The Rattrap 44444Abhanshu PandeyNo ratings yet

- Safety NetsDocument13 pagesSafety NetsGanga DaranNo ratings yet

- Burlington Free Press 15-16Document36 pagesBurlington Free Press 15-16Young Writers ProjectNo ratings yet

- VS200.V2 SealeyDocument2 pagesVS200.V2 SealeyaudioimagenNo ratings yet

- Crafty Tibbles Legolas IngDocument14 pagesCrafty Tibbles Legolas IngKARINA ANDREA TAPIA CONTRERAS100% (2)

- Phantom by Jo Nesbo Sample ChapterDocument18 pagesPhantom by Jo Nesbo Sample ChapterRandomHouseAU50% (2)

- 860 I Don't Like Ron Gonzales PDFDocument10 pages860 I Don't Like Ron Gonzales PDFtechnovNo ratings yet

- 2018 Kawasaki Ninja 400 Abs 73405Document170 pages2018 Kawasaki Ninja 400 Abs 73405Saulo HenriqueNo ratings yet

- Linesheet Lookbook - Colcci Rev 2Document8 pagesLinesheet Lookbook - Colcci Rev 2Denis PaixãoNo ratings yet

- Bella Doll Full PatternDocument44 pagesBella Doll Full PatternKata Lakatos75% (4)

- 5972 Present Simple Tense Part 4 Interrogative Sentences 3 Pages 9 Tasks With KeyDocument5 pages5972 Present Simple Tense Part 4 Interrogative Sentences 3 Pages 9 Tasks With KeyDonu Cristina100% (1)

- Margot Malpote - Assignment Week 3Document4 pagesMargot Malpote - Assignment Week 3margotNo ratings yet

- Translations of Eastern Poetry & Prose 1922Document236 pagesTranslations of Eastern Poetry & Prose 1922ahmad_fahmyalfar75_6100% (1)

- Queue EdictDocument2 pagesQueue EdictOliver Harley BergNo ratings yet

- Runway Magazine Emerging Designer 2012Document132 pagesRunway Magazine Emerging Designer 2012James BuccelliNo ratings yet

- Giordano Case Questions Case 4 in BookDocument6 pagesGiordano Case Questions Case 4 in Bookakpe1234No ratings yet

- OzCharge 12V Automatic Battery Charger User GuideDocument8 pagesOzCharge 12V Automatic Battery Charger User GuideEdu Cernadas MíguezNo ratings yet

- Lux Series, Homecoming Daemons PovDocument3 pagesLux Series, Homecoming Daemons PovLucy Byrne100% (2)

- Castlegar/Slocan Valley Pennywise Oct. 25, 2016Document48 pagesCastlegar/Slocan Valley Pennywise Oct. 25, 2016Pennywise PublishingNo ratings yet