Professional Documents

Culture Documents

Electric Cars: The Battery Challenge: Feature

Uploaded by

rohan sebastianOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Electric Cars: The Battery Challenge: Feature

Uploaded by

rohan sebastianCopyright:

Available Formats

Feature

AUDI AG

T

Batteries for an electric car are assembled at the Audi production plant in Brussels.

ELECTRIC CARS:

he age of the electric car is upon us.

Earlier this year, the US automobile

giant General Motors announced that

THE BATTERY

it aims to stop selling petrol-powered

and diesel models by 2035. Audi,

based in Germany, plans to stop pro-

ducing such vehicles by 2033. Many

other automotive multinationals

CHALLENGE

have issued similar road maps. Suddenly, major

carmakers’ foot-dragging on electrifying their

fleets is turning into a rush for the exit.

The electrification of personal mobility is

picking up speed in a way that even its most

ardent proponents might not have dreamt of

just a few years ago. In many countries, gov-

Recycling batteries and reducing the use ernment mandates will accelerate change. But

even without new policies or regulations, half

of scarce metals will be key to the world’s of global passenger-vehicle sales in 2035 will

be electric, according to the BloombergNEF

transition to electric vehicles. (BNEF) consultancy in London.

By Davide Castelvecchi This massive industrial conversion

marks a “shift from a fuel-intensive to a

material-intensive energy system”, declared

the International Energy Agency (IEA) in May1.

In the coming decades, hundreds of millions

336 | Nature | Vol 596 | 19 August 2021

©

2

0

2

1

S

p

r

i

n

g

e

r

N

a

t

u

r

e

L

i

m

i

t

e

d

.

A

l

l

r

i

g

h

t

s

r

e

s

e

r

v

e

d

.

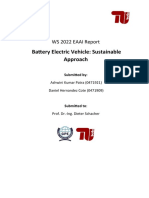

of vehicles will hit the roads, carrying massive GOING ELECTRIC hiccups will not change the picture in the long

batteries inside them (see ‘Going electric’). And A forecast suggests that by 2035, more than half term. “As more processing capacity is built,

each of those batteries will contain tens of kilo- of new passenger vehicles sold worldwide will these shortages are likely to work themselves

be electric, even without further policies to

grams of materials that have yet to be mined. promote switching. out,” says Haresh Kamath, a specialist in energy

Anticipating a world dominated by electric storage at the Electric Power Research Institute

Internal Hybrid Fuel Plug-in Battery

vehicles, materials scientists are working on combustion cell hybrid electric in Palo Alto, California.

two big challenges. One is how to cut down on The increase in lithium mining carries its

100

the metals in batteries that are scarce, expen- own environmental concerns: current forms of

sive, or problematic because their mining extraction require copious amounts of energy

New vehicle sales (millions)

carries harsh environmental and social costs. 80 (for lithium extracted from rock) or water (for

Another is to improve battery recycling, so extraction from brines). But more-modern

that the valuable metals in spent car batter- 60 techniques that extract lithium from geother-

ies can be efficiently reused. “Recycling will mal water, using geothermal energy to drive

play a key role in the mix,” says Kwasi Ampofo, 40 the process, are considered more benign. And

a mining engineer who is the lead analyst on despite this environmental toll, mining lith-

metals and mining at BNEF. ium will help to displace destructive fossil-fuel

20

Battery- and carmakers are already spend- extraction.

ing billions of dollars on reducing the costs of Researchers are more worried about cobalt,

0

manufacturing and recycling electric-vehicle which is the most valuable ingredient of cur-

REF. 2

2015 2020 2025 2030 2035 2040

(EV) batteries — spurred in part by government rent EV batteries. Two-thirds of global supply

incentives and the expectation of forthcoming called the anode, to another, the cathode. The are mined in the Democratic Republic of the

regulations. National research funders have two are separated by yet another layer, the Congo. Human-rights activists have raised

also founded centres to study better ways to electrolyte. Cathodes are the main limiting concerns over conditions there, in particular

make and recycle batteries. Because it is still factor in battery performance — and they are over child labour and harm to workers’ health;

less expensive, in most instances, to mine where the most valuable metals lie. like other heavy metals, cobalt is toxic if not

metals than to recycle them, a key goal is to The cathode of a typical lithium-ion battery handled properly. Alternative sources could

develop processes to recover valuable metals cell is a thin layer of goo containing micro-scale be exploited, such as the metal-rich ‘nodules’

cheaply enough to compete with freshly crystals, which are often similar in structure to found on the sea floor, but they present their

mined ones. “The biggest talker is money,” says minerals that occur naturally in Earth’s crust own environmental hazards. And nickel,

Jeffrey Spangenberger, a chemical engineer or mantle, such as olivines or spinels. The crys- another major component of EV batteries,

at Argonne National Laboratory in Lemont, tals pair up negatively charged oxygen with could also face shortages3.

Illinois, who manages a US federally funded positively charged lithium and various other

lithium-ion battery-recycling initiative, called metals — in most electric cars, a mix of nickel, Managing metals

ReCell. manganese and cobalt. Recharging a battery To address the issues with raw materials, a

rips lithium ions out of these oxide crystals number of laboratories have been experi-

Lithium future and pulls the ions to a graphite-based anode menting with low-cobalt or cobalt-free cath-

The first challenge for researchers is to reduce where they are stored, sandwiched between odes. But cathode materials must be carefully

the amounts of metals that need to be mined designed so that their crystal structures don’t

for EV batteries. Amounts vary depending on break up, even if more than half the lithium

the battery type and model of vehicle, but a ions are removed during charging. And

single car lithium-ion battery pack (of a type

known as NMC532) could contain around 8 kg

Recycling will abandoning cobalt altogether often lowers

a battery’s energy density, says materials

of lithium, 35 kg of nickel, 20 kg of manganese play a key role scientist Arumugam Manthiram at the Uni-

and 14 kg of cobalt, according to figures from

Argonne National Laboratory.

in the mix.” versity of Texas in Austin, because it alters the

cathode’s crystal structure and how tightly it

Analysts don’t anticipate a move away from can bind lithium.

lithium-ion batteries any time soon: their cost Manthiram is among the researchers who

has plummeted so dramatically that they are layers of carbon atoms (see ‘Electric heart’). have solved that problem — at least in the lab

likely to be the dominant technology for the Lithium itself is not scarce. A June report by — by showing that cobalt can be eliminated

foreseeable future. They are now 30 times BNEF2 estimated that the current reserves of from cathodes without compromising perfor-

cheaper than when they first entered the market the metal — 21 million tonnes, according to the mance4. “The cobalt-free material we reported

as small, portable batteries in the early 1990s, US Geological Survey — are enough to carry the has the same crystal structure as lithium cobalt

even as their performance has improved. BNEF conversion to EVs through to the mid-century. oxide, and therefore the same energy density,”

projects that the cost of a lithium-ion EV battery And reserves are a malleable concept, because or even better, says Manthiram. His team did

pack will fall below US$100 per kilowatt-hour they represent the amount of a resource that this by fine-tuning the way in which cathodes

by 2023, or roughly 20% lower than today (see can be economically extracted at current are produced and adding small quantities of

‘Plummeting costs of batteries’). As a result, prices and given current technology and reg- other metals — while retaining the cathode’s

electric cars — which are still more expensive ulatory requirements. For most materials, if cobalt-oxide crystal structure. Manthiram says

than conventional ones — should reach price demand goes up, reserves eventually do, too. it should be straightforward to adopt this pro-

parity by the mid-2020s. (By some estimates, As cars electrify, the challenge lies in scaling cess in existing factories, and has founded a

electric cars are already cheaper than petrol up lithium production to meet demand, start-up firm called TexPower to try to bring

vehicles over their lifetimes, thanks to being Ampofo says. “It’s going to grow by about it to market within the next two years. Other

less expensive to power and maintain.) seven times between 2020 and 2030.” labs around the world are working on cobalt-

To produce electricity, lithium-ion batteries This could result in temporary shortages free batteries: in particular, the pioneering EV

shuttle lithium ions internally from one layer, and dramatic price swings, he says. But market maker Tesla, based in Palo Alto, California, has

Nature | Vol 596 | 19 August 2021 | 337

©

2

0

2

1

S

p

r

i

n

g

e

r

N

a

t

u

r

e

L

i

m

i

t

e

d

.

A

l

l

r

i

g

h

t

s

r

e

s

e

r

v

e

d

.

Feature

ELECTRIC HEART

The battery packs in electric vehicles are built from

said it plans to eliminate the metal from its

batteries in the next few years.

Sun Yang-Kook at Hanyang University in

thousands of cells, with electronics to manage charging

and discharging. To prevent overheating, some units Seoul, South Korea, is another materials sci-

include an active cooling system. A battery pack holds entist who has achieved similar performance

tens of kilograms of valuable metals; researchers hope

to make recycling them easier and to reduce the

in cobalt-free cathodes. Sun says that some

amounts needed in future designs. technical problems might remain in creat-

ing the new cathodes, because the process

Battery packs

relies on refining nickel-rich ores, which can

Battery cells come in cylindrical, prismatic and pouch varieties, and are require expensive pure-oxygen atmospheres.

arranged into modules that are assembled into packs. These packs are But many researchers now consider the cobalt

typically welded and glued together, which makes them hard to take

apart at the end of their life cycle.

problem essentially solved. Manthiram and

Sun “have shown that you can make really

good materials without cobalt and [that] per-

Pack form really well”, says Jeff Dahn, a chemist at

Dalhousie University in Halifax, Canada.

Nickel, although not as expensive as cobalt,

isn’t cheap, either. Researchers want to remove

it as well. “We have addressed the cobalt

scarcity, but because we’re scaling so rapidly,

we are heading straight for a nickel problem,”

says Gerbrand Ceder, a materials scientist at

Module the Lawrence Berkeley National Laboratory in

Berkeley, California. But removing both cobalt

and nickel will require switching to radically dif-

ferent crystal structures for cathode materials.

Cylindrical Prismatic Pouch One approach is to adopt materials called

disordered rock salts. They get their name

Cell

because of their cubic crystal structure, which

is similar to that of sodium chloride, with oxy-

gen playing the part of chlorine and a mix of

heavy metals replacing the sodium. Over the

Cell structure past decade, Ceder’s team and other groups

Inside cells, sheet-like electrodes (anodes and cathodes) are curled up or have shown that certain lithium-rich rock salts

sandwiched together, with an electrolyte taking up the space in between. allow the lithium to easily slip in and out — a

crucial property to enable repeated charging5.

Housing Aluminium/ But, unlike conventional cathode materials,

polymer pouch disordered rock salts do not require cobalt or

Electrodes

nickel to remain stable during that process. In

particular, they can be made with manganese,

SOURCE: ADAPTED FROM G. HARPER ET AL. NATURE 575, 75–86 (2019) AND G. OFFER ET AL. NATURE 582, 485–487 (2020).

which is cheap and plentiful, Ceder says.

Electrolyte

Recycle better

Electrolyte

If batteries are to be made without cobalt,

Electrodes researchers will face an unintended conse-

quence. The metal is the main factor that

makes recycling batteries economical,

because other materials, especially lithium,

are currently cheaper to mine than to recycle.

In a typical recycling plant, batteries are first

Cell chemistry

Circuit

shredded, which turns cells into a powdered

Lithium-ion cells generate

electricity when lithium ions Electron mixture of all the materials used. That mix

flow from the anode through an is then broken down into its elemental con-

electrolyte to the cathode, – Anode Cathode +

forcing electrons to flow around

stituents, either by liquefying it in a smelter

an outside circuit. Charging Lithium ion (pyrometallurgy) or by dissolving it in acid

reverses that process. (hydrometallurgy). Finally, metals are pre-

Copper foil Aluminium foil cipitated out of solution as salts.

(current (current Research efforts have focused on improving

collector) collector)

the process to make recycled lithium economi-

cally attractive. The vast majority of lithium-ion

Crystals of metal batteries are produced in China, Japan and

Typically

oxides, including

graphite

elements such as South Korea; accordingly, recycling capabil-

manganese, cobalt ities are growing fastest there. For example,

and nickel Foshan-based Guangdong Brunp — a subsidiary

Electrolyte of CATL, China’s largest maker of lithium-ion

338 | Nature | Vol 596 | 19 August 2021

©

2

0

2

1

S

p

r

i

n

g

e

r

N

a

t

u

r

e

L

i

m

i

t

e

d

.

A

l

l

r

i

g

h

t

s

r

e

s

e

r

v

e

d

.

cells — can recycle 120,000 tonnes of batteries PLUMMETING COSTS OF BATTERIES batteries — the ones that start petrol-powered

per year, according to a spokesperson. That’s The price of lithium-ion cells has fallen by cars — gives reason for optimism. Because

the equivalent of what would be used in more more than 97% since 1991. lead is toxic, those batteries are classified as

than 200,000 cars, and the firm is able to 8,000 hazardous waste and have to be disposed of

recover most of the lithium, cobalt and nickel. safely. But an efficient industry has developed

SOURCE: M. S. ZIEGLER & J. E. TRANCIK ENERGY ENVIRON. SCI.

Government policies are helping to encour- 7,000 to recycle them instead, even though lead is

Price (US$ per kilowatt-hour)

age this: China already has financial and reg- 6,000 cheap. “Over 98% of lead-acid batteries are

ulatory incentives for battery companies that recovered and recycled,” Kamath says. “The

source materials from recycling firms instead 5,000 value of a lead-acid battery is even lower than

of importing freshly mined ones, says Hans Eric 4,000 a lithium-ion battery. But because of volume,

Melin, managing director of Circular Energy it makes sense to recycle anyway,” Melin says.

HTTPS://DOI.ORG/GRHX (2021).

Storage, a consulting company in London. 3,000 It might take a while until the market for lith-

The European Commission has proposed 2,000 ium-ion batteries reaches its full size, in part

strict battery-recycling requirements which because these batteries have become excep-

could be phased in from 2023 — although 1,000 tionally durable: present car batteries might

prospects for the bloc to develop a domestic 0

last up to 20 years, Kamath says. In a typical

recycling industry are uncertain6. The admin- 1991 1996 2001 2006 2011 2016 electric car sold today, the battery pack will

istration of US President Joe Biden, meanwhile, outlive the vehicle it was built into, says Melin.

wants to spend billions of dollars to foster a Another potential hurdle is that the chem- That means that when old EVs are sent to

domestic EV battery-manufacturing industry istry of cathodes is constantly evolving. The scrap, the batteries are often neither thrown

and support recycling, but hasn’t yet proposed cathodes that manufacturers will use 10–15 away nor recycled. Instead, they are taken out

regulations beyond existing legislation class- years from now — at the end of the life cycle of and reused for less-demanding applications,

ing batteries as hazardous waste that must present-day cars — could very well be different such as stationary energy storage or power-

be safely disposed of. Some North American from today’s. The most efficient way to get the ing boats. After ten years of use, a car battery

start-up firms say they can already recover materials out could be for the manufacturer to such as the Nissan Leaf’s, which originally held

the majority of a battery’s metals, including collect its own batteries at the end of the life 50 kilowatt-hours, will have lost at most 20%

lithium, at costs that are competitive with cycle. And batteries should be designed from of its capacity.

those of mining them, although analysts say the ground up in a way that makes them easier Another May report from the IEA, an organ-

that, at this stage, the overall economics are to take apart, Gaines adds. ization noted for its historically cautious fore-

only advantageous because of the cobalt. Materials scientist Andrew Abbott at the casts, included a road map8 to achieve global

A more radical approach is to reuse the cath- University of Leicester, UK, argues that recy- net-zero emissions by mid-century, which

ode crystals, rather than break down their struc- cling will be much more profitable if it skips includes conversion to electric transport

ture, as hydro- and pyrometallurgy do. ReCell, the shredding stage and takes the cells apart as a cornerstone. The confidence that this

the US$15-million collaboration managed by directly. He and his collaborators have devel- is achievable reflects a growing consensus

Spangenberger, includes three national labs, among policymakers, researchers and man-

three universities and numerous industry play- ufacturers that challenges to electrifying cars

ers. It is developing techniques that will enable are now entirely solvable — and that if we want

recyclers to extract the cathode crystals and to have any hope of keeping climate change to

resell them. One crucial step, after the batteries Over 98% of lead-acid a manageable level, there is no time to lose.

have been shredded, is to separate the cathode batteries are recovered But some researchers complain that elec-

materials from the rest using heat, chemicals or tric vehicles seem to be held to an impossible

other methods. “The reason we’re so enthusias-

and recycled.” standard in terms of the environmental impact

tic about retaining the crystal structure is that of their batteries. “It would be unfortunate and

it took a lot of energy and know-how to put that counterproductive to discard a good solu-

together. That’s where a lot of the value is,” says oped a technique for separating out cathode tion by insisting on a perfect solution,” says

Linda Gaines, a physical chemist at Argonne and materials using ultrasound7. This works best Kamath. “That does not mean, of course, that

the principal analyst for ReCell. in battery cells that are packed flat rather than we should not work aggressively on the battery

These reprocessing techniques work with a rolled up (as common ‘cylindrical’ cells are), disposal question.”

range of crystal structures and compositions, and, Abbott adds, can make recycled materials

Gaines says. But if a recycling centre receives much cheaper than virgin mined metals. He Davide Castelvecchi reports for Nature from

a waste stream that includes many types of is involved in a £14-million (US$19-million) London.

battery, various types of cathode material will UK government research scheme on battery

1. International Energy Agency. The Role of Critical Minerals

end up in the recycling cauldron. This could sustainability, called ReLiB.

in Clean Energy Transitions (IEA, 2021); available at https://

complicate efforts to separate out the differ- www.iea.org/reports/the-role-of-critical-minerals-in-

ent cathode-crystal types. Although processes Crank up the volume clean-energy-transitions

2. BloombergNEF. Electric Vehicle Outlook 2021 (BNEF,

developed by ReCell can easily separate nickel, Whichever recycling processes become stand-

2021); available at https://about.bnef.com/electric-

manganese and cobalt from other kinds ard, scale will help. Although media reports vehicle-outlook

of cells, such as those that use lithium iron tend to describe the coming deluge of spent 3. Baars, J., Domenech, T., Bleischwitz, R., Melin, H. E. &

phosphate, for example, they will have a hard batteries as a looming crisis, analysts see it as Heidrich, O. Nature Sustain. 4, 71–79 (2021).

4. Li, W., Lee, S. & Manthiram, A. Adv. Mater. 32, 2002718

time separating two types that both contain a big opportunity, says Melin. Once millions of (2020).

cobalt and nickel, but in different proportions. large batteries begin to reach the end of their 5. Yang, J. H., Kim, H. & Ceder, G. Molecules 26, 3173 (2021).

For this and other reasons, it will be crucial for lives, economies of scale will kick in and make 6. Melin, H. E. et al. Science 373, 384–387 (2021).

7. Lei, C. et al. Green Chem. 23, 4710–4715 (2021).

batteries to carry some kind of standardized recycling more efficient — and the business

8. International Energy Agency. Net Zero by 2050: A

barcode that tells recyclers what’s inside, case for it more attractive. Roadmap for the Global Energy Sector (IEA, 2021);

Spangenberger says. Analysts say the example of lead-acid available at https://www.iea.org/reports/net-zero-by-2050

Nature | Vol 596 | 19 August 2021 | 339

©

2

0

2

1

S

p

r

i

n

g

e

r

N

a

t

u

r

e

L

i

m

i

t

e

d

.

A

l

l

r

i

g

h

t

s

r

e

s

e

r

v

e

d

.

You might also like

- PADI Rescue Diver - Blank Knowledge ReviewDocument13 pagesPADI Rescue Diver - Blank Knowledge ReviewAj Quek67% (3)

- Bottled Lightning: Superbatteries, Electric Cars, and the New Lithium EconomyFrom EverandBottled Lightning: Superbatteries, Electric Cars, and the New Lithium EconomyRating: 4 out of 5 stars4/5 (6)

- 974-0753 Onan RDJC RDJF Diesel Engine Service Manual (09-1984)Document64 pages974-0753 Onan RDJC RDJF Diesel Engine Service Manual (09-1984)Leo BurnsNo ratings yet

- OVE - Everything You Need To Know About Electric Car-11Document52 pagesOVE - Everything You Need To Know About Electric Car-11Giaccone A.No ratings yet

- AMORC What Constitutes A High Degree Member in AMORC 2Document3 pagesAMORC What Constitutes A High Degree Member in AMORC 2Francis EjikeNo ratings yet

- Ancient Skies of Northern Europe: Stars, Constellations, and The Moon in Nordic MythologyDocument12 pagesAncient Skies of Northern Europe: Stars, Constellations, and The Moon in Nordic MythologyoldenglishblogNo ratings yet

- State of Stealth FINAL 121317Document41 pagesState of Stealth FINAL 121317Muhammad Afzaal100% (2)

- Training Sinal PDFDocument15 pagesTraining Sinal PDFlobitoferoz81No ratings yet

- Observed: A Complete RethinkDocument3 pagesObserved: A Complete Rethinkapi-25933302No ratings yet

- Sameer PresentationDocument17 pagesSameer PresentationMuhammad Asif KhanNo ratings yet

- Impact of Electric VehicleDocument5 pagesImpact of Electric VehicleHamizan IsroNo ratings yet

- Disruptor Automotive EcosystemDocument8 pagesDisruptor Automotive EcosystemTushar BallabhNo ratings yet

- Electricity Market Design in The Prosumer EraDocument6 pagesElectricity Market Design in The Prosumer EraGustavoNo ratings yet

- Green Transportation The Outlook For Electric Vehicles in Latin AmericaDocument16 pagesGreen Transportation The Outlook For Electric Vehicles in Latin AmericaShazmaniaNo ratings yet

- Building The Electric-Vehicle-Charging-Infrastructure-America-Needs-VfDocument10 pagesBuilding The Electric-Vehicle-Charging-Infrastructure-America-Needs-VfDavid MiguelNo ratings yet

- Electric Vehicle Outlook 2019 - Bloomberg NEFDocument1 pageElectric Vehicle Outlook 2019 - Bloomberg NEFYann ElhamNo ratings yet

- Ptmail - m1021 - Ss - Ev Ultimate Market Intelligence ReportDocument23 pagesPtmail - m1021 - Ss - Ev Ultimate Market Intelligence ReportPIYUSH GOPALNo ratings yet

- Lithium-Ion Battery For Hevs, Phevs, and Evs: Hitachi Review Vol. 63 (2014), No. 2Document6 pagesLithium-Ion Battery For Hevs, Phevs, and Evs: Hitachi Review Vol. 63 (2014), No. 2RAMPRASATH EEENo ratings yet

- Study - Id134904 - Electric Vehicles A Global OverviewDocument46 pagesStudy - Id134904 - Electric Vehicles A Global OverviewPalash AroraNo ratings yet

- IJTech - E 6465 - Progressing The Sustainable Mobility View of ElectDocument5 pagesIJTech - E 6465 - Progressing The Sustainable Mobility View of ElectAhmad HafizNo ratings yet

- Overview of Electric and Hybrid VehiclesDocument8 pagesOverview of Electric and Hybrid VehiclesdanielyismawNo ratings yet

- Will Electric Vehicles Really Create A Cleaner Planet - Thomson ReutersDocument27 pagesWill Electric Vehicles Really Create A Cleaner Planet - Thomson ReutersbsvseyNo ratings yet

- The Potential of Domestic Electric Vehicles To Con-Tribute To Power System Operation Through Vehicle To Grid TechnologyDocument5 pagesThe Potential of Domestic Electric Vehicles To Con-Tribute To Power System Operation Through Vehicle To Grid TechnologyAlim HuseynovNo ratings yet

- Automotive Powertrain Suppliers Face A Rapidly Electrifying Future v2Document9 pagesAutomotive Powertrain Suppliers Face A Rapidly Electrifying Future v2Ananchai UkaewNo ratings yet

- Powering The Electric Car: AmpsDocument4 pagesPowering The Electric Car: AmpsAditya AgarwalNo ratings yet

- The Future Lies With Electric Vehicles - The Economist PDFDocument5 pagesThe Future Lies With Electric Vehicles - The Economist PDFAgus ColonnaNo ratings yet

- Mahindra Electric Mobility Limited: The Electric Vehicles DilemmaDocument12 pagesMahindra Electric Mobility Limited: The Electric Vehicles DilemmaViren JoshiNo ratings yet

- EV Cost 2020 2030 20190401Document12 pagesEV Cost 2020 2030 20190401aahhhiiiitttttNo ratings yet

- Artigo 07 ADocument10 pagesArtigo 07 ALucas BerraNo ratings yet

- Hybrid Electric Cars Combustion Engine Driven CarsDocument6 pagesHybrid Electric Cars Combustion Engine Driven Carskiennguyen102203.ptNo ratings yet

- Tüv Rheinland 170111 - TR Ev ServicesDocument9 pagesTüv Rheinland 170111 - TR Ev ServicesHaroon ShaikhNo ratings yet

- Study Id103895 Electric Vehicles ReportDocument68 pagesStudy Id103895 Electric Vehicles ReportsplitfireflyNo ratings yet

- SubtitleDocument2 pagesSubtitleqhasabueroNo ratings yet

- A Study of Different Energy Storage Devices Used in Electric VehiclesDocument14 pagesA Study of Different Energy Storage Devices Used in Electric VehiclesJeerigi DeepikaNo ratings yet

- Application Roadmap For Battery Powered Electric Mobility: Daniel Holz, Thomas FuhrmannDocument4 pagesApplication Roadmap For Battery Powered Electric Mobility: Daniel Holz, Thomas FuhrmannerpublicationNo ratings yet

- Electric Cars Disruptive Innovation in The Indian Auto IndustryDocument3 pagesElectric Cars Disruptive Innovation in The Indian Auto IndustryEditor IJTSRDNo ratings yet

- Electric and Fuelcell VehiclesDocument14 pagesElectric and Fuelcell VehiclesChinthaka Nayana Kumara RajapakshaNo ratings yet

- 3 Drivers of China's Booming EV MarketDocument9 pages3 Drivers of China's Booming EV Markettrang.duong180162No ratings yet

- TLT - Electric Vehicle Grease - Sander - 05-19Document6 pagesTLT - Electric Vehicle Grease - Sander - 05-19gilar herliana putraNo ratings yet

- The Electric Car 2005Document14 pagesThe Electric Car 2005aumkota271811No ratings yet

- Electric Vehicles Will Kill Global Oil Industry by 2030, Says Stanford Economist Tony Seba - The American Energy NewsDocument5 pagesElectric Vehicles Will Kill Global Oil Industry by 2030, Says Stanford Economist Tony Seba - The American Energy NewsAdi Danu SaputraNo ratings yet

- Overview of Electric and Hybrid VehiclesDocument8 pagesOverview of Electric and Hybrid Vehiclesmonish balaNo ratings yet

- Directions in Internal Combustion Engine ResearchDocument8 pagesDirections in Internal Combustion Engine ResearchJosé Fco. VillegasNo ratings yet

- Taiwan Industries HV ComponentDocument25 pagesTaiwan Industries HV ComponentKawaljeet SinghNo ratings yet

- Solar Electric Vehicle: Need, Working, Advantages and ChallengesDocument6 pagesSolar Electric Vehicle: Need, Working, Advantages and ChallengesIJRASETPublicationsNo ratings yet

- Fferent Scenarios of Electric Mobility: CurrentDocument22 pagesFferent Scenarios of Electric Mobility: CurrentNicolai Ascue CortesNo ratings yet

- CS-2 Standards Battle - Which Automotive Technology Will WinDocument2 pagesCS-2 Standards Battle - Which Automotive Technology Will Winemail bukaNo ratings yet

- A Grid-Friendly Electric Vehicle Infrastructure The Korean ApproachDocument10 pagesA Grid-Friendly Electric Vehicle Infrastructure The Korean Approachbhasker sharmaNo ratings yet

- ScienceDocument37 pagesScienceaidanNo ratings yet

- Electric Vehicle BatteryDocument14 pagesElectric Vehicle BatteryDaniel CoteNo ratings yet

- Cool Metric For Lithium-Ion Batteries Could Spur ProgressDocument3 pagesCool Metric For Lithium-Ion Batteries Could Spur ProgressAlhussein Mohammed Abd ElhafeezNo ratings yet

- Art 20181202Document14 pagesArt 20181202abhik DasNo ratings yet

- The Business Opportunities in Electric Motor IndustryDocument12 pagesThe Business Opportunities in Electric Motor IndustryOsen GaoNo ratings yet

- TOYOTADocument12 pagesTOYOTAZhasmin ElmuratovaNo ratings yet

- A Review On Plug-In Electric Vehicles: Introduction, Current Status, and Load Modeling TechniquesDocument14 pagesA Review On Plug-In Electric Vehicles: Introduction, Current Status, and Load Modeling TechniquesRAJANNo ratings yet

- Using Renewables For TrucksDocument30 pagesUsing Renewables For TrucksamolrNo ratings yet

- Thán Khí-D41586-021-02606-3Document4 pagesThán Khí-D41586-021-02606-3banNo ratings yet

- 10 GB Etf Ev LRDocument20 pages10 GB Etf Ev LRJurgen HietbrinkNo ratings yet

- Global Perspective On Electric Vehicle 2020Document4 pagesGlobal Perspective On Electric Vehicle 2020NabinNo ratings yet

- E-Vehicle Manufacturing IndustryDocument24 pagesE-Vehicle Manufacturing IndustryManasa NistalaNo ratings yet

- ZETA Fact Sheet 11 2020Document1 pageZETA Fact Sheet 11 2020Maria MeranoNo ratings yet

- WWW Iea Org Reports Electric Vehicles Fbclid IwAR2Hb0q3VT2zirqdJPECZntpL6UOdldZNbojqzuKVJ7qqH45Jfkn0X9Lu oDocument7 pagesWWW Iea Org Reports Electric Vehicles Fbclid IwAR2Hb0q3VT2zirqdJPECZntpL6UOdldZNbojqzuKVJ7qqH45Jfkn0X9Lu ohahaNo ratings yet

- E-Mobility Overview PDFDocument48 pagesE-Mobility Overview PDFRizki Fajar NovantoNo ratings yet

- 2022-2023 Lecture 1 - Additional Reading MaterialDocument12 pages2022-2023 Lecture 1 - Additional Reading MaterialMats VersmissenNo ratings yet

- Fundamentals of Electric Vehicles (Evs) : Prateek Joshi and Carishma Gokhale-WelchDocument30 pagesFundamentals of Electric Vehicles (Evs) : Prateek Joshi and Carishma Gokhale-WelchHüseyin CemNo ratings yet

- EU China Energy Magazine 2022 April Issue: 2022, #3From EverandEU China Energy Magazine 2022 April Issue: 2022, #3No ratings yet

- Littelfuse EVI EV Charging Infrastructure Presentation PDFDocument19 pagesLittelfuse EVI EV Charging Infrastructure Presentation PDFRaka Pratindy100% (1)

- AE240 Notes Early-Airfoil-Development-Handout-1Document5 pagesAE240 Notes Early-Airfoil-Development-Handout-1mohamedNo ratings yet

- s1160 Jorvet Infusion PumpDocument4 pagess1160 Jorvet Infusion PumpGhulam HyderNo ratings yet

- Hemiplegia Case 18.12.21Document5 pagesHemiplegia Case 18.12.21Beedhan KandelNo ratings yet

- Recognizing and Classifying Daily Human Activities: Group-22Document23 pagesRecognizing and Classifying Daily Human Activities: Group-22Divyam GuptaNo ratings yet

- Biomedical Uses and Applications of Inorganic Chemistry. An OverviewDocument4 pagesBiomedical Uses and Applications of Inorganic Chemistry. An OverviewHiram CruzNo ratings yet

- Livro Vertex MACIOCIADocument62 pagesLivro Vertex MACIOCIAxandinhag100% (5)

- J-20 Stealth Fighter Design Balances Speed and Agility - Defense Content From Aviation WeekDocument9 pagesJ-20 Stealth Fighter Design Balances Speed and Agility - Defense Content From Aviation WeekMahesNo ratings yet

- Chapter 34 - The Influence of Monetary and Fiscal Policy On Aggregate Demand (Compatibility Mode) PDFDocument19 pagesChapter 34 - The Influence of Monetary and Fiscal Policy On Aggregate Demand (Compatibility Mode) PDFthanhvu78No ratings yet

- BITEBUDZ COMPANY EME Kemerut 1Document31 pagesBITEBUDZ COMPANY EME Kemerut 1Mark LightNo ratings yet

- LUXEON Altilon SMDDocument25 pagesLUXEON Altilon SMDBertram PredikNo ratings yet

- Unit 2Document9 pagesUnit 2Quinn LilithNo ratings yet

- 4K Resolution: The Future of ResolutionsDocument15 pages4K Resolution: The Future of ResolutionsRavi JoshiNo ratings yet

- Case Report - Anemia Ec Cervical Cancer Stages 2bDocument71 pagesCase Report - Anemia Ec Cervical Cancer Stages 2bAnna ListianaNo ratings yet

- Quarter3 English ModuleDocument6 pagesQuarter3 English ModuleIan Daquipil100% (2)

- Compteur 7757 - A PDFDocument16 pagesCompteur 7757 - A PDFbromartNo ratings yet

- January 2005 6677 Mechanics M1: Mark SchemeDocument7 pagesJanuary 2005 6677 Mechanics M1: Mark SchemeWael TareqNo ratings yet

- Bubble Slabs Burned at 800 °C With Different Periods: IOP Conference Series: Materials Science and EngineeringDocument10 pagesBubble Slabs Burned at 800 °C With Different Periods: IOP Conference Series: Materials Science and Engineeringshilpa jacobNo ratings yet

- Herpes Simplex KeratitisDocument20 pagesHerpes Simplex KeratitisriskhapangestikaNo ratings yet

- QuizBowl QuestionsDocument84 pagesQuizBowl QuestionsJowel MercadoNo ratings yet

- RfI SB Listening ScriptsDocument18 pagesRfI SB Listening ScriptsKate PolissyaNo ratings yet

- Lonza ManualsProductInstructions Determination of Protein Concentration 31460Document2 pagesLonza ManualsProductInstructions Determination of Protein Concentration 31460sydneypadillioNo ratings yet

- International StandardDocument8 pagesInternational Standardnazrul islamNo ratings yet

- Língua Inglesa: Reported SpeechDocument3 pagesLíngua Inglesa: Reported SpeechPatrick AlmeidaNo ratings yet