Professional Documents

Culture Documents

Epcmd 2 Qm00 FMT PP 013 - 00

Uploaded by

Muthu AlaguRajOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Epcmd 2 Qm00 FMT PP 013 - 00

Uploaded by

Muthu AlaguRajCopyright:

Available Formats

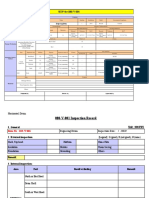

Inspection and Preparation For Epoxy

Lining

Reliance

Project: Plant: Unit: Report No: Date:

System Name: System Number: Test Package No.: Date:

Extent of weld Coating

Location Distance

Repairs Feathered Cleaning by

Salt between

Sr. Nature of Joint Category 5cm away Water

Line Number Contamination Corroded area &

No. Defect No. of Defect Smooth from Jetting/

From To Welding Check Protection

Grinding Damaged Splash

Anode

Area

Remarks:

Legends: RH: Relative Humidity, DFT: Dry Film Thickness, Category – A: Weld joints are not coated, Category – B: Coating failure due to Poor

Surface Preparation resulting in epoxy coating starts pealing off, Category – C: Coating damaged due to inadequate dressing of the weld and weld repairs,

Category – D: Coating damaged due to mechanical damages, Category – E: Coating damaged due to deposit of foreign material on the coated surface,

Category – F: Coating damaged due to Lumps and excessive coating, Sagging, dripping etc. Category – G: Coating damaged due to softening observed due

to improper mixing of (Base and Activator) Coating, Category – H: Coating damaged due to hot work.

Coating Contractor Piping Contractor Reliance Execution Reliance QMD Reliance O&M / TPI

Signature

Name

Date

Format No.: EPCMD-2QM00FMTPP013, Rev.-00, Date: 25.05.2011 Page 1 of 1

You might also like

- HONDA D2021 E Coating SpecificationDocument5 pagesHONDA D2021 E Coating SpecificationDavid Martínez100% (1)

- Automotive Painting Processes - Today and Tomorrow - Dr. Michael Hilt, Fraunhofer Institute, Germany PDFDocument21 pagesAutomotive Painting Processes - Today and Tomorrow - Dr. Michael Hilt, Fraunhofer Institute, Germany PDFfatahkaryadiNo ratings yet

- Construction Progress PaymentDocument4 pagesConstruction Progress PaymentrajaNo ratings yet

- Form bbs2563Document3 pagesForm bbs2563Julián Tiburcio GonzálezNo ratings yet

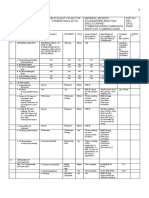

- SEIP For 080-V-001: Degassing DrumDocument6 pagesSEIP For 080-V-001: Degassing DrumThinh NguyenNo ratings yet

- CoatingsDocument8 pagesCoatingsMy Dad My WorldNo ratings yet

- Practical Guidelines For The Inspection and Repair of Hot Dip Galvanized CoatingsDocument8 pagesPractical Guidelines For The Inspection and Repair of Hot Dip Galvanized CoatingsIan FletcherNo ratings yet

- Galvanizing Defects RectificationsDocument28 pagesGalvanizing Defects RectificationslakshanNo ratings yet

- Galvanizing Defects RectificationsDocument19 pagesGalvanizing Defects RectificationskumarNo ratings yet

- SEIP For 089-H-001Document7 pagesSEIP For 089-H-001Thinh NguyenNo ratings yet

- SEIP For 089-H-002Document7 pagesSEIP For 089-H-002Thinh NguyenNo ratings yet

- PR-025-F-11 Surface Preparation & Painting ReportDocument1 pagePR-025-F-11 Surface Preparation & Painting ReportkumaraguruNo ratings yet

- Incoming Report Report Vertical Pump (VS6)Document16 pagesIncoming Report Report Vertical Pump (VS6)Firdaus Syifaan PratamaNo ratings yet

- PreliminaryReport 02026.4Document5 pagesPreliminaryReport 02026.4Green MichaelsNo ratings yet

- CCI Radome Whitepaper 190813Document9 pagesCCI Radome Whitepaper 190813bardaris100% (1)

- Sheth Corrosion & Coating Pvt. LTD.: Surface Preparation & Painting Inspection ReportDocument2 pagesSheth Corrosion & Coating Pvt. LTD.: Surface Preparation & Painting Inspection ReportTejas MohanNo ratings yet

- Corrosion Resistance CoatingDocument2 pagesCorrosion Resistance CoatingSaeed HassaniNo ratings yet

- Ce Thermal and Moisture Emulsion Solvent RC-815 Inivest Haider Saleh Al-Haider & Partner CoDocument1 pageCe Thermal and Moisture Emulsion Solvent RC-815 Inivest Haider Saleh Al-Haider & Partner Cosudeep karunNo ratings yet

- 4 - 02 - 07 - Eng - Corrosion Resistance CoatingsDocument10 pages4 - 02 - 07 - Eng - Corrosion Resistance CoatingsRafa Lopez PuigdollersNo ratings yet

- Work Stage and Code Potential Defects How Determined Likely Cause Suggestions For ActionDocument9 pagesWork Stage and Code Potential Defects How Determined Likely Cause Suggestions For ActionIniyavanHajiMohamedNo ratings yet

- SEIP For 089-WHB-001: Claus Waste Heat BoilerDocument6 pagesSEIP For 089-WHB-001: Claus Waste Heat BoilerThinh NguyenNo ratings yet

- Serva-Pak™: Extended Surface High Capacity Bag FilterDocument4 pagesServa-Pak™: Extended Surface High Capacity Bag FilterLuis E SánchezNo ratings yet

- SEIP For 080-V-101: Slop Oil DrumDocument6 pagesSEIP For 080-V-101: Slop Oil DrumThinh NguyenNo ratings yet

- Method Statement For Rectify Earth Cleat at SiteDocument2 pagesMethod Statement For Rectify Earth Cleat at Sitezulkaif abbasiNo ratings yet

- Application of Coating To Metallic Structure: Construcciones Industriales Tapia S.A. de C.VDocument12 pagesApplication of Coating To Metallic Structure: Construcciones Industriales Tapia S.A. de C.VJorge I Lara RamosNo ratings yet

- Evaluating Degree of Rusting On Painted Steel Surfaces: Standard Practice ForDocument6 pagesEvaluating Degree of Rusting On Painted Steel Surfaces: Standard Practice Forharpreet singhNo ratings yet

- 107.WI - Anodizing - EC 004 - Lower ReceiverDocument7 pages107.WI - Anodizing - EC 004 - Lower ReceiverRknight BNo ratings yet

- Galvanizing Thickness MeasurementsDocument10 pagesGalvanizing Thickness Measurementswaleed yehiaNo ratings yet

- Method Statement For HDG and PC - RevaisedDocument2 pagesMethod Statement For HDG and PC - Revaisedzulkaif abbasiNo ratings yet

- Plastering ChecklistDocument1 pagePlastering Checklistshankarmandal567No ratings yet

- TRW 23925036 02Document9 pagesTRW 23925036 02Eddy GuerreroNo ratings yet

- 3c - Bill BroughtonDocument24 pages3c - Bill BroughtonVenkateswaran Ananthu krishnamoorthyNo ratings yet

- PreliminaryReport 02026.3Document4 pagesPreliminaryReport 02026.3Green MichaelsNo ratings yet

- For Information: The Israel Electric CorporationDocument8 pagesFor Information: The Israel Electric CorporationRushirajNo ratings yet

- QAQC Forms - Cocrete & FormworksDocument1 pageQAQC Forms - Cocrete & FormworksShahbaz KhanNo ratings yet

- Edc Abo RuduisDocument5 pagesEdc Abo Ruduislemuel bacsaNo ratings yet

- Kingdom of Saudi Arabia: Soils and AggregatesDocument1 pageKingdom of Saudi Arabia: Soils and AggregatesHamza AldaeefNo ratings yet

- SEIP For 080-C-001: Sour Water StripperDocument8 pagesSEIP For 080-C-001: Sour Water StripperThinh NguyenNo ratings yet

- TR 1a Glycol Overhead Piping East SideDocument11 pagesTR 1a Glycol Overhead Piping East SideShamsul AffendiNo ratings yet

- Pallet Racks/Shelves Survey: Sema VISP-154-0420 SITE Area GSK Pakistan LimitedDocument1 pagePallet Racks/Shelves Survey: Sema VISP-154-0420 SITE Area GSK Pakistan LimitedJawad RafiqNo ratings yet

- Corrosion Mapping by Mohd SirajDocument4 pagesCorrosion Mapping by Mohd SirajIrfankhan Yunuskhan PathanNo ratings yet

- Sheth Corrosion & Coating Pvt. LTD.: Surface Preparation & Painting Inspection ReportDocument2 pagesSheth Corrosion & Coating Pvt. LTD.: Surface Preparation & Painting Inspection ReportTejas MohanNo ratings yet

- RESPONSIBILITY: G - Galvanized D - Designer B - Builder/Fabricator S - Steel Type/SurfaceDocument11 pagesRESPONSIBILITY: G - Galvanized D - Designer B - Builder/Fabricator S - Steel Type/SurfaceLaxit100% (1)

- Qa/Qc Form: Shop: Field: Technical InspectionDocument1 pageQa/Qc Form: Shop: Field: Technical Inspectionعبداللة العبداللةNo ratings yet

- Nawin Singh - McdermottDocument22 pagesNawin Singh - McdermottdakidofdaboomNo ratings yet

- HDG Practical GuidelinesDocument7 pagesHDG Practical GuidelinesMantasNo ratings yet

- JMC Projects India Limited Water Business Unit FormworkDocument4 pagesJMC Projects India Limited Water Business Unit FormworkKumar AbhishekNo ratings yet

- Format PileDocument1 pageFormat PileVijay KumarNo ratings yet

- SNO Instrument Class Remark SDocument2 pagesSNO Instrument Class Remark SxiaozNo ratings yet

- Eximius 3Document1 pageEximius 3Fardeen KhanNo ratings yet

- Effect of Abrasive Particle Size On Friction and Wear Behaviour of HVOFDocument20 pagesEffect of Abrasive Particle Size On Friction and Wear Behaviour of HVOFMouna KallelNo ratings yet

- Root Cause AnalysisDocument21 pagesRoot Cause AnalysisXavier JosephNo ratings yet

- Presentation On IU (Group B - 14 - 11 - 23)Document41 pagesPresentation On IU (Group B - 14 - 11 - 23)Nazat AfrinNo ratings yet

- MS-DD-3000-HSE-FRM-0020 - Harness Inspection RegisterDocument1 pageMS-DD-3000-HSE-FRM-0020 - Harness Inspection RegisterMuhammad Hamzah HabbiburrahmanNo ratings yet

- Format 11 - Appearance Approval ReportDocument1 pageFormat 11 - Appearance Approval ReportvijayNo ratings yet

- SEIP For 086-V-001: Amine Acid Gas KO DrumDocument6 pagesSEIP For 086-V-001: Amine Acid Gas KO DrumThinh NguyenNo ratings yet

- Nitobond ArDocument46 pagesNitobond ArGavriel NgNo ratings yet

- Likhitha Infrastructure PVT - LTD Line History Sheet For Station PipingDocument4 pagesLikhitha Infrastructure PVT - LTD Line History Sheet For Station PipingShivam TiwariNo ratings yet

- JSA For Pressure Test 2ND REVISIONDocument10 pagesJSA For Pressure Test 2ND REVISIONMuthu AlaguRaj100% (1)

- JSA For Earth Work & ExcavationDocument4 pagesJSA For Earth Work & ExcavationMuthu AlaguRajNo ratings yet

- 6684-PIP-101-MB-0001 - 000 - 02 - Piping List For Indmax UnitDocument17 pages6684-PIP-101-MB-0001 - 000 - 02 - Piping List For Indmax UnitMuthu AlaguRajNo ratings yet

- Ins Summary Epcmd 2 Qm00 FMT PP 016 - 00Document1 pageIns Summary Epcmd 2 Qm00 FMT PP 016 - 00Muthu AlaguRajNo ratings yet

- 6684-PIP-G00-EB-0006 - 000 - 02 - Technical Specification For Coating $ WRDocument8 pages6684-PIP-G00-EB-0006 - 000 - 02 - Technical Specification For Coating $ WRMuthu AlaguRajNo ratings yet

- Protective Painting SystemDocument45 pagesProtective Painting SystemMuthu AlaguRajNo ratings yet

- Ug PipingDocument51 pagesUg PipingMuthu AlaguRaj100% (1)

- Presentation On NDT For UG & AG Piping of J3 Projects-Rev-00Document41 pagesPresentation On NDT For UG & AG Piping of J3 Projects-Rev-00Muthu AlaguRajNo ratings yet

- Cosmos Products: Technical Service Data SheetDocument1 pageCosmos Products: Technical Service Data Sheetgowtham_venkat_4No ratings yet

- PDS Gyproc CoreBoard PDFDocument2 pagesPDS Gyproc CoreBoard PDFSunil YadavNo ratings yet

- Test - API 577 - Quizlet 145qDocument38 pagesTest - API 577 - Quizlet 145qAnonymous Q4YUvRNo ratings yet

- Lakhauri BricksDocument6 pagesLakhauri BricksPankaj SainiNo ratings yet

- Blowdown Valves 6DB Series Rev 2 (MS-02-118)Document2 pagesBlowdown Valves 6DB Series Rev 2 (MS-02-118)herysyam1980No ratings yet

- SmartLine Pressure Accessories - Manifold CatalogueDocument36 pagesSmartLine Pressure Accessories - Manifold CatalogueManuel GerardoNo ratings yet

- Electrical General NotesDocument5 pagesElectrical General NotesjustineNo ratings yet

- Site Book Gyplyner UniversalDocument16 pagesSite Book Gyplyner UniversalmcnortyNo ratings yet

- Specification of Pipe Fittings:: 90 Angle Elbow For General ProcessDocument6 pagesSpecification of Pipe Fittings:: 90 Angle Elbow For General ProcesstanviryNo ratings yet

- Experimental Investigation For Welding Aspects of AISI 304 & 316 by Taguchi Technique For The Process of TIG & MIG WeldingDocument6 pagesExperimental Investigation For Welding Aspects of AISI 304 & 316 by Taguchi Technique For The Process of TIG & MIG Weldingsurendiran123No ratings yet

- Scofield Stamped SpecDocument7 pagesScofield Stamped SpecJamiu LateefNo ratings yet

- Community MasihiDocument10 pagesCommunity Masihilove meNo ratings yet

- Structural Analysis Report Residential Building at Kavrepalanchowk, NepalDocument65 pagesStructural Analysis Report Residential Building at Kavrepalanchowk, NepalSopan GochheNo ratings yet

- Concrete Masonry Cantilever Retaining WallsDocument4 pagesConcrete Masonry Cantilever Retaining Wallsing_fernandogalvez2015No ratings yet

- Inspection and Test PlanDocument42 pagesInspection and Test Planmurtada kamilNo ratings yet

- Se 1025Document7 pagesSe 1025Roohian AliNo ratings yet

- GF Clara A BoqDocument12 pagesGF Clara A BoqJake MonteroNo ratings yet

- Boundary Wall NIT 3-1Document2 pagesBoundary Wall NIT 3-1Er Soumen Dey KhanNo ratings yet

- HOSHIZAKI KM-151BWH - Parts - ListDocument28 pagesHOSHIZAKI KM-151BWH - Parts - ListRomankoNo ratings yet

- Hep2O Price ListDocument20 pagesHep2O Price Listpmusgrove123No ratings yet

- Smartcare Tile Adhesive For Tile On Tile ApplicationDocument2 pagesSmartcare Tile Adhesive For Tile On Tile ApplicationDesign Group India IndiaNo ratings yet

- Polycab Price List 21st May 18Document22 pagesPolycab Price List 21st May 18Sreegith Chelatt0% (1)

- Bullet Proof Glass: BY Divya Mathew Kavyashri S Savitha BalajiDocument6 pagesBullet Proof Glass: BY Divya Mathew Kavyashri S Savitha Balajiraj kNo ratings yet

- Casting Material WCB PDFDocument9 pagesCasting Material WCB PDFChinmoyee SharmaNo ratings yet

- Phenolic Resins Chemistry, Applications PDFDocument584 pagesPhenolic Resins Chemistry, Applications PDFHernan MartNo ratings yet

- Bill of QuantitiesDocument3 pagesBill of QuantitiesJuys GuerreroNo ratings yet

- A 1 KDocument5 pagesA 1 KSumantrra ChattopadhyayNo ratings yet

- Cement Chemistry Notation and Mineral NamesDocument2 pagesCement Chemistry Notation and Mineral NamesAfqan B-vNo ratings yet

- M-121 Aluminium Structural Material Rev1Document17 pagesM-121 Aluminium Structural Material Rev1vlong3003100% (1)