Professional Documents

Culture Documents

Periodic Escalator-Moving Walk Checklist

Uploaded by

Ton marquesCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Periodic Escalator-Moving Walk Checklist

Uploaded by

Ton marquesCopyright:

Available Formats

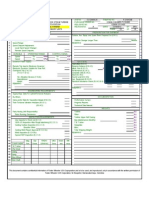

Periodic Escalator/Moving Walk Checklist

Department of Consumer and Business Services

Building Codes Division

1535 Edgewater St. NW, Salem, OR

Mailing address: P.O. Box 14470, Salem, OR 97309-0404

503-378-1298 • Fax: 503-378-4101

oregon.gov/bcd

8.11.4 INSPECTION TEST PERIODS

Maintenance Company: The routine inspection and tests of escalators and moving walks shall be made

at intervals no greater than six months. All references to "Item" are to

Site Name: ASME A17.2-2010 Guide for Inspection of Elevators, Escalators and Moving

Current Year: Walks.

Equipment ID: 8.11.2.1.2 INSPECTIONS MADE IN MACHINE ROOM/SPACE

8.11.4.1 PERIODIC INSPECTION & TEST DATE ASME-

N/A TESTED 2010 Description

REQUIREMENTS

(1st) (2nd) Machine space

N/A JAN-JUN JUL-DEC Description 8.6.8.15.1

(Items 8.1 and 10.1)

Stop switch

PERIODIC INSPECTION AND TESTS SHALL INCLUDE THE FOLLOWING 8.6.8.15.2

(Items 8.2 and 10.2)

General fire protection Controller and wiring

(a) 8.6.8.15.3

(Items 7.1 and 9.1) (Items 8.3 and 10.3)

Geometry Drive machine and brake

(b) 8.6.8.15.4

(Items 7.2 and 9.2) (Items 8.4 and 10.4)

Handrails Speed governor

(c) 8.6.8.15.5

(Items 7.3 and 9.3) (Items 8.5 and 10.5)

Entrance and egress Broken drive chain device

(d) 8.6.8.15.6

(Items 7.4 and 9.4) (Items 8.6 and 10.6)

Lighting Reversal stop switch

(e) 8.6.8.15.7

(Items 7.5 and 9.5) (Items 8.7 and 10.7)

Caution signs Broken step chain or treadway device

(f) 8.6.8.15.8

(Items 7.6 and 9.6) (Items 8.8 and 10.8)

Combplate Step up thrust device

(g) 8.6.8.15.9

(Items 7.7 and 9.7) (Items 7.9 and 8.9)

Deck barricade guard and antislide devices Missing step or pallet device

(h) 8.6.8.15.10

(Items 7.8 and 9.8) (Items 8.10 and 10.10)

Steps and treadway Step and pallet level device

(i) 8.6.8.15.11

(Items 7.9 and 9.9) (Items 8.11 and 10.11)

Operating devices Steps, pallet, step or pallet chain, and trusses

(j) 8.6.8.15.12

(Items 7.10 and 9.10) (Items 8.12 and 10.12)

Skirt obstruction device Handrail safety systems

(k) 8.6.8.15.13

(Item 7.11) (Items 8.13 and 10.13)

Handrail entry device Heaters

(l) 8.6.8.15.14

(Items 8.13 and 10.13) (Items 8.3 and 10.3)

Egress restriction device Permissible stretch in escalator chains

(m) 8.6.8.15.15

(Item 7.13 and 9.13) (Item 7.9)

Speed Disconnected motor safety device

(n) 8.6.8.15.16

(Items 7.14 and 9.14) (Item 8.6 and 10.6)

Balustrades Response to smoke detectors

(o) 8.6.8.15.17

(Items 7.15 and 9.15) (Items 8.15 and 10.15)

Ceiling intersection guards Comb-step or comb-pallet impact device

(p) 8.6.8.15.18

(Items 7.16 and 9.16) (Items 7.7.2 and 9.7.2)

Skirt panels Step/skirt performance index check

(q) 8.6.8.15.19

(Items 7.17 and 9.17) (Item 7.17)

Outdoor protection Clearance between step and skirt (loaded gap)

(r) 8.6.8.15.20

(Items 7.18 and 9.18) (Item 7.17)

Machinery space access, lighting, receptacle, Control devices conformance

(s) 8.6.8.15.21

and condition (Items 2.1 and 4.1) (6.1.6.2.2 or 6.2.6.2.2)

Additional stop switch(es) Step lateral displacement device

(t) 8.6.8.15.22

(Items 2.2 and 4.2) (6.1.6.3.14)

Controller and wiring Seismic switch

(u) 8.6.8.15.23

(Items 2.3 and 4.3) (Items 7.20.2 and 9.20.2)

Period cleaning - REQUIRED ONCE EVERY 2

Code data plate(2.23.2)

(v) 8.6.8.13 YEARS

(Items 8.14 and 10.14)

Last cleaning date (MM/DD/YY):

8.6.8.3.3 STEP SKIRT INDEX MEASUREMENT

(a) less than or equal to 0.15

6.1.3.6.4 SAFETY ZONE

**The entry and exit zone shall be kept clear of all obstacles**

(b) less than or equal to 0.25 (ASME A17.1a-2002 and later with skirt deflector) _________inches - DISTANCE BETWEEN CENTERLINE OF HANDRAILS

(c) less than or equal to 0.40 (ASME A17.1-2000 and earlier with skirt deflector) + 8 inches equals minimum safety WIDTH:___________inches

Test Date (MM/YY):____________Index Result:_____________ x2 equals minimum safety LENGTH:_________inches

Safety Zone Meets Compliance? Y/N:___

(SEE REVERSE SIDE FOR GENERAL INSTRUCTIONS) Initials:______Date:_____

Minimum maintenance test standards ASME A17.1-2010 Section 8.11

Call 503-373-1298 for information

440-5461 (11/19/COM) Page 1 of 2

General instructions: Example: Routine Checklist Entries

(1st) (2nd)

N/A JAN-JUN JUL-DEC Description

This checklist reflects the minimum routine maintenance (a) Door reopening device

4/25 10/15 (Item 1.1)

and testing standards that apply to your escalator or (f) Car emergency signal

moving walk. 4/17 10/12 (Item 1.6) X

4/25 10/15 (h) Door closing force

Not all of the items that appear on this checklist will be 26 lbs 26 lbs (Item 1.8)

applicable to your equipment. A licensed elevator When measurements are required, they should be entered in

contractor is capable of assisting you in determining those the date box associated with the item. For example, the

items that pertain to your equipment. Check the “N/A” pressure relief reading should be entered as noted in the

box for all items that do not apply. following example:

Item numbers (e.g. Item 1.1, 2.12, etc.) found in the

description column refer to ASME A17.2, Guide for

Inspection of Elevators, Escalators and Moving Walks. Example: Checklist Entry & Measurements

This guide provides information on how to perform routine N/A

DUE DATE ASME-

Description

DATE TESTED 2010

maintenance checks and periodic tests. (Available through 10/2019 8.6.5.14.1 Relief valve setting and system pressure

11/2019

the Tech Bookstore; 800-ASK-BOOK) 550 psi test

The checklist is to be kept in the respective elevator

machine room in clear view and kept up-to-date. You will Additional recordkeeping

need one checklist for each escalator/moving walk per The owner is also required to provide a means to document

year. trouble calls and other information that pertain to the

operational history of the elevator. The documentation must

Who should perform elevator maintenance also describe abnormalities that were discovered or occurred

and testing? during routine maintenance checks and tests and what was

Only properly licensed elevator personnel or owner- done to correct the abnormalities.

authorized personnel are allowed to perform maintenance This log should be kept on site and preferably in the elevator

and tests on elevator equipment. machine room. There is currently no particular format for

Please refer to the shaded items in the description column keeping this information.

on the checklist. The shaded items may be performed by New checklists will be available online at

persons authorized by the building owner. The items not www.bcd.oregon.gov or may be obtained from this office by

shaded can only be performed by licensed elevator calling (503) 373-1298.

personnel.

Any owner-authorized person performing maintenance or

testing must know how to perform the maintenance

evaluation or test and be capable of recognizing incorrect

elevator standards or operation. Corrections in operation or

other repairs must be performed by licensed elevator

personnel employed by a licensed elevator contractor.

Filling out the checklist

The owner is responsible for ensuring the checklist is kept

current. The person or firm performing the required items

must be indicated on the checklist. Where there is

insufficient room to enter all information on the checklist, a

separate sheet or log book may be used.

The log book entry should clearly reference the checklist

item number found after each maintenance and test

description entry. In all cases, the date (mm/dd or mm/yyyy

as applicable) must be entered on the checklist.

The checkbox following the item description is to be

checked only if the task was performed by owner-

authorized personnel. Leave the box unchecked if the item

was performed by licensed elevator personnel.

Minimum maintenance test standards ASME A17.1-2010 Section 8.11

Call 503-373-1298 for information

440-5461 (11/19/COM) Page 2 of 2

You might also like

- DSM-IV Adult ADHD Symptom Checklist-Self Report Version # 6182Document1 pageDSM-IV Adult ADHD Symptom Checklist-Self Report Version # 6182Chris0% (1)

- ACSEW Cast Control Centers Appleton en 7439390 PDFDocument8 pagesACSEW Cast Control Centers Appleton en 7439390 PDFGERARDO DIAZNo ratings yet

- World Whisky - A Nation-By-Nation Guide To The Best Distillery Secrets Over 650 Whiskies - Charles Maclean - DK Dorling Kindersley (C) PDFDocument354 pagesWorld Whisky - A Nation-By-Nation Guide To The Best Distillery Secrets Over 650 Whiskies - Charles Maclean - DK Dorling Kindersley (C) PDFCarlos E. Ramírez100% (8)

- Redutor GFTDocument4 pagesRedutor GFTIkaro MatosNo ratings yet

- PECOMADocument25 pagesPECOMAAnan JaiswalNo ratings yet

- Stream of NectarDocument4 pagesStream of NectarderekmendozaNo ratings yet

- Sample Written Oversight Agreement For SupervisionDocument1 pageSample Written Oversight Agreement For SupervisionSayan SarkarNo ratings yet

- RTTS Safety JointDocument3 pagesRTTS Safety JointHamid Reza BabaeiNo ratings yet

- Periodic Escalator Moving Walk Test (6-Month)Document2 pagesPeriodic Escalator Moving Walk Test (6-Month)ajsioco.oboNo ratings yet

- Insp Guide For EscalatorsDocument1 pageInsp Guide For EscalatorsYousef ShishaniNo ratings yet

- China HST: Vol Tahun Section Sub-Sect Sub2-Sect HSR Trial 1-Dec-09Document2 pagesChina HST: Vol Tahun Section Sub-Sect Sub2-Sect HSR Trial 1-Dec-09Lasmini AmbarwatiNo ratings yet

- Ehs160 ServoDocument143 pagesEhs160 ServoClaudiu MorarNo ratings yet

- CHECKLISTforescalatorswalks June 2016Document1 pageCHECKLISTforescalatorswalks June 2016vikrant987No ratings yet

- Type GTF Type GLF Type PTF Type SCF: Gate, Globe & Check Valves Class 150 - 600, 800 As Per ASME B16.34, API 602Document12 pagesType GTF Type GLF Type PTF Type SCF: Gate, Globe & Check Valves Class 150 - 600, 800 As Per ASME B16.34, API 602Qaswa Imran KhanNo ratings yet

- PVQ-1310 PV-C1320 PV-C1330W VV-1300 VV-1310W PV-C1340 PV-C1350W PV-C2010 PV-C2020 PV-C2030W VV-2000 PV-C2060 PDFDocument129 pagesPVQ-1310 PV-C1320 PV-C1330W VV-1300 VV-1310W PV-C1340 PV-C1350W PV-C2010 PV-C2020 PV-C2030W VV-2000 PV-C2060 PDFRobson RodriguesNo ratings yet

- EDPCDocument110 pagesEDPCThamotharanNo ratings yet

- Preliminary Design Considerations For Variable Geometry Radial Turbines With Multi-Points SpecificationsDocument13 pagesPreliminary Design Considerations For Variable Geometry Radial Turbines With Multi-Points SpecificationsSyed Jiaul HoqueNo ratings yet

- Welding Consumable Calculation (WCC) : Doc. No Project Client Project Details Technical Requirement ConsumablesDocument8 pagesWelding Consumable Calculation (WCC) : Doc. No Project Client Project Details Technical Requirement Consumableskeymal9195No ratings yet

- WSPTableof ContentsDocument5 pagesWSPTableof Contentsodette_gbrNo ratings yet

- Kavr159 en M G11Document118 pagesKavr159 en M G11Indra AryanaNo ratings yet

- Api 611 5Th Edition General " Purpose Steam Turbine Existing TurbineDocument1 pageApi 611 5Th Edition General " Purpose Steam Turbine Existing TurbineAlejandro GilNo ratings yet

- Welding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement ConsumablesDocument10 pagesWelding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement Consumableskeymal9195No ratings yet

- Updates For Furniture Test Standards (2) - EN 581-2:2009Document2 pagesUpdates For Furniture Test Standards (2) - EN 581-2:2009cosmpiroNo ratings yet

- CF34 10eDocument9 pagesCF34 10eJulia GarciaNo ratings yet

- P 40 k2 2 en - QD55x QE55x Motor Drive Instruction Manual - Pfaff Electronic Stop - FreeDocument32 pagesP 40 k2 2 en - QD55x QE55x Motor Drive Instruction Manual - Pfaff Electronic Stop - FreealeXak Noe100% (1)

- RTTS Circulating ValveDocument2 pagesRTTS Circulating ValveHamid Reza BabaeiNo ratings yet

- Periodic Hydraulic Elevator ChecklistDocument4 pagesPeriodic Hydraulic Elevator ChecklistAbdullah TahsinNo ratings yet

- Kbu8j - 600v, 8a Bridg RectifierDocument2 pagesKbu8j - 600v, 8a Bridg RectifierLangllyNo ratings yet

- Alr Table eDocument18 pagesAlr Table eachoudar2016No ratings yet

- Saudi Aramco Test ReportDocument7 pagesSaudi Aramco Test Reportkarthi51289No ratings yet

- CP832Document2 pagesCP832caf02No ratings yet

- EDC-DTS-MV006 - 35 KV and 22 KV Pole Mounted Auto ReclosersDocument27 pagesEDC-DTS-MV006 - 35 KV and 22 KV Pole Mounted Auto ReclosersJoe bilouteNo ratings yet

- AASHTO Pile SpecsDocument37 pagesAASHTO Pile SpecsVignesh RamalingamNo ratings yet

- CH 8.7Document28 pagesCH 8.7rammirisNo ratings yet

- Tegangan Dan Regangan TollsDocument8 pagesTegangan Dan Regangan TollsJuli FirmanNo ratings yet

- 09-8 Electric and Pneumatic ActuatorsDocument7 pages09-8 Electric and Pneumatic ActuatorsAbderrahmaneTemhachetNo ratings yet

- Diagrama Electrico de Una Amoladora-Ingles-OriginalDocument6 pagesDiagrama Electrico de Una Amoladora-Ingles-OriginalErick Contreras QuispeNo ratings yet

- Welding Consumable Calculation (WCC) : Doc. No Project Client Project Details Technical Requirement ConsumablesDocument8 pagesWelding Consumable Calculation (WCC) : Doc. No Project Client Project Details Technical Requirement Consumableskeymal9195No ratings yet

- Trening Bagera 7 I 7aDocument134 pagesTrening Bagera 7 I 7aDraganNo ratings yet

- ACSEW Cast Control Centers: Explosionproof, Dust-IgnitionproofDocument24 pagesACSEW Cast Control Centers: Explosionproof, Dust-IgnitionproofDennis MendozaNo ratings yet

- MandateDocument2 pagesMandateGanesh KashinathNo ratings yet

- Book 1Document2 pagesBook 1adz200No ratings yet

- Konsep Terjadi Angkutan SedimenDocument56 pagesKonsep Terjadi Angkutan SedimenFasdarsyah FasNo ratings yet

- Missouri Division of Fire Safety Elevator Safety UnitDocument4 pagesMissouri Division of Fire Safety Elevator Safety UnitMMMOH200No ratings yet

- Standard Specification: Section 8: Traffic Signal SystemDocument7 pagesStandard Specification: Section 8: Traffic Signal SystemMohd Izzuddin ZainiNo ratings yet

- SB 10054865 6305Document15 pagesSB 10054865 6305Ralph WamaeNo ratings yet

- Caja RTXDocument92 pagesCaja RTXLuis Alberto Gutierrez LeyvaNo ratings yet

- Section 8 Design of Scour ProtectionDocument32 pagesSection 8 Design of Scour Protectionyared makonnenNo ratings yet

- Mitigation Stick SlipDocument6 pagesMitigation Stick SlipCarlos SensanoNo ratings yet

- 5a JS T4 Air DrillDocument48 pages5a JS T4 Air DrillFredy SierraNo ratings yet

- Sea 2007Document21 pagesSea 2007juan zamoraNo ratings yet

- 8940168386-1 Air HammerDocument36 pages8940168386-1 Air HammerWillian Tavares de CarvalhoNo ratings yet

- M87X en M IDocument146 pagesM87X en M ISINU0607IITEEENo ratings yet

- Implementation of Automatic Phase Change Over Using Micro-Controller A Project ReportDocument12 pagesImplementation of Automatic Phase Change Over Using Micro-Controller A Project ReportArun BalaNo ratings yet

- 12 PM 102a (CTMM58)Document2 pages12 PM 102a (CTMM58)Loki LcuNo ratings yet

- 47 - Main Tranformer 7775 Kva STRDocument10 pages47 - Main Tranformer 7775 Kva STRRishik SainiNo ratings yet

- 6ra7025 6DV62 0 Simoreg DC Converter Siemens ManualDocument235 pages6ra7025 6DV62 0 Simoreg DC Converter Siemens ManualrenatoNo ratings yet

- k500 Service ManualDocument28 pagesk500 Service ManualHector LopezNo ratings yet

- Repair and Reconditioning Specification For AC Squirrel-Cage Motors With Voltage Ratings of 2.3 KV To 13.2 KVDocument132 pagesRepair and Reconditioning Specification For AC Squirrel-Cage Motors With Voltage Ratings of 2.3 KV To 13.2 KVzulham100% (1)

- Design of Heo Gates (23!11!12)Document39 pagesDesign of Heo Gates (23!11!12)Deepak SharmaNo ratings yet

- RT300-1 & RT345XL - Parts Manual - Draft10 - 09-14-12Document276 pagesRT300-1 & RT345XL - Parts Manual - Draft10 - 09-14-12Daniel Castillo Peña100% (3)

- Wheel Dozers, Landfill Compactors, Soil Compactors PDFDocument60 pagesWheel Dozers, Landfill Compactors, Soil Compactors PDFwilson claveriaNo ratings yet

- Low-Voltage Switchgear and Controlgear - Part 2: Circuit-BreakersDocument71 pagesLow-Voltage Switchgear and Controlgear - Part 2: Circuit-BreakersTirantha BandaraNo ratings yet

- Waterside Plaza Technical Investigation Report (English Version)Document14 pagesWaterside Plaza Technical Investigation Report (English Version)Ton marquesNo ratings yet

- I.B.9560 Westinghouse RototrolDocument37 pagesI.B.9560 Westinghouse RototrolTon marquesNo ratings yet

- MFDElevatorAccidentReportDocument1 pageMFDElevatorAccidentReportTon marquesNo ratings yet

- 01CA009Document7 pages01CA009Ton marquesNo ratings yet

- BVL00000011 - Exhibit IL - 2 - Procedure Mech - LIF - Proc - 001 - Inspection or Testing Document Electric Traction Lifts (February 2017)Document19 pagesBVL00000011 - Exhibit IL - 2 - Procedure Mech - LIF - Proc - 001 - Inspection or Testing Document Electric Traction Lifts (February 2017)Ton marquesNo ratings yet

- In-Depth Investigation of Escalator Riding Accidents in Heavy Capacity MRT StationsDocument10 pagesIn-Depth Investigation of Escalator Riding Accidents in Heavy Capacity MRT StationsTon marquesNo ratings yet

- RideWatcher EngDocument12 pagesRideWatcher EngTon marquesNo ratings yet

- Analysis of VibroacousticDocument9 pagesAnalysis of VibroacousticTon marquesNo ratings yet

- DINACELL CÉLULA DE CARGA 1262-04 (En - Web)Document33 pagesDINACELL CÉLULA DE CARGA 1262-04 (En - Web)Ton marquesNo ratings yet

- Ed 5622240Document9 pagesEd 5622240Ton marquesNo ratings yet

- BPMG EMED F1 v1 (Jul2016)Document2 pagesBPMG EMED F1 v1 (Jul2016)Ton marquesNo ratings yet

- Release LiftEscalator Regulations 080716Document11 pagesRelease LiftEscalator Regulations 080716Ton marquesNo ratings yet

- Siti 2018 IOP Conf. Ser. Earth Environ. Sci. 117 012025Document9 pagesSiti 2018 IOP Conf. Ser. Earth Environ. Sci. 117 012025Ton marquesNo ratings yet

- CoP Le Works With Appendices EngDocument218 pagesCoP Le Works With Appendices EngTon marquesNo ratings yet

- Modelo InformativoDocument1 pageModelo InformativoTon marquesNo ratings yet

- Periodicity of Metals - TeacherDocument6 pagesPeriodicity of Metals - TeacherTruong AnhNo ratings yet

- CCNA Cyber Ops (Version 1.1) - Chapter 6 Exam Answers FullDocument20 pagesCCNA Cyber Ops (Version 1.1) - Chapter 6 Exam Answers FullRawan AlharbiNo ratings yet

- Pumps Senator .LibyaDocument40 pagesPumps Senator .Libyasenator.libyaNo ratings yet

- SLEEPING BEAUTY - Narrative TextDocument6 pagesSLEEPING BEAUTY - Narrative TextPande AdnyanaNo ratings yet

- Manual de Partes Thmig 500Document3 pagesManual de Partes Thmig 500Alexander HernandezNo ratings yet

- Phototransduction Occurs at The RetinaDocument13 pagesPhototransduction Occurs at The RetinaKathleen RussellNo ratings yet

- Surgical Face Masks in The Operating Theatre: Re-Examining The EvidenceDocument6 pagesSurgical Face Masks in The Operating Theatre: Re-Examining The EvidenceepNo ratings yet

- mkbn211 Pkjun16Document5 pagesmkbn211 Pkjun16Nicholus Opincai JercilioNo ratings yet

- Nrscgfreqconfig - Scgdlarfcn and Nrscgfreqconfig - Scgdlarfcnpriority Parameters Specify The Arfcn and PriorityDocument5 pagesNrscgfreqconfig - Scgdlarfcn and Nrscgfreqconfig - Scgdlarfcnpriority Parameters Specify The Arfcn and PriorityCesarNunesNo ratings yet

- SummaryDocument2 pagesSummaryAmit ParouhaNo ratings yet

- Translation and Cultural Adaptation of The States of Consciousness Questionnaire (SOCQ) and Statistical Validation of The Mystical Experience Questionnaire (MEQ30)Document5 pagesTranslation and Cultural Adaptation of The States of Consciousness Questionnaire (SOCQ) and Statistical Validation of The Mystical Experience Questionnaire (MEQ30)Douglas SouzaNo ratings yet

- Healing Flowers of The ZodiacDocument25 pagesHealing Flowers of The Zodiacedgarabraham100% (6)

- Greenlandic Inuit Show Genetic Signatures of Diet and Climate AdaptationDocument1 pageGreenlandic Inuit Show Genetic Signatures of Diet and Climate AdaptationCates MandinNo ratings yet

- NyDocument5 pagesNyKim SindahlNo ratings yet

- GASBRAYTONDocument16 pagesGASBRAYTONJohnCris B. FornilosNo ratings yet

- Series: Dual Rod CylinderDocument22 pagesSeries: Dual Rod CylinderAnonymous A55PY1bNo ratings yet

- Edwards 7025 Barocel Gauge Instruction Manual - 2Document32 pagesEdwards 7025 Barocel Gauge Instruction Manual - 2dbhansali57No ratings yet

- Ishrae 365 2009 PDFDocument16 pagesIshrae 365 2009 PDFZeeshan HasanNo ratings yet

- Basic Interior Design RulesDocument25 pagesBasic Interior Design RulesMadalina-Irina Tanaselea100% (2)

- Fatty Alcohol Production ProcessDocument9 pagesFatty Alcohol Production ProcessZevaniNo ratings yet

- LMENIM1401Document106 pagesLMENIM1401Parameswararao BillaNo ratings yet

- Hodgkin-Huxley Model and Fitzhugh-Nagumo ModelDocument15 pagesHodgkin-Huxley Model and Fitzhugh-Nagumo ModelGobiNo ratings yet

- Ripening of FruitsDocument24 pagesRipening of Fruitsnishi@sainiNo ratings yet

- Final Friends Book 2 - The Dance - Christopher PikeDocument282 pagesFinal Friends Book 2 - The Dance - Christopher PikeNikie5100% (4)

- Earth RoadDocument6 pagesEarth Roaddemoz asfawNo ratings yet