Professional Documents

Culture Documents

1 s2.0 S0038080620319995 Main - 2

Uploaded by

mahdOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1 s2.0 S0038080620319995 Main - 2

Uploaded by

mahdCopyright:

Available Formats

SOILS AND FOUNDATIONS Vol. 24, No. 4, 30-48, Dec.

1984

Japanese Society of Soil Mechanics and Foundation Engineering

STRENGTH AND DEFORMATION CHARACTERISTICS

OF SATURATED SAND AT EXTREMELY

LOW PRESSURES

SHINJI FuKUSHIMA* and FuMro TATSUOKA**

ABSTRACT

A senes of drained triaxial compression tests at extremely low pressures was performed

on saturated samples of fine, angular sand to know the dependency of both the angle of

internal friction ¢=arcsin { (a 1 ' -a 3 ')/ (a/ +a 3 ') }max and the deformation characteristics on

the value of a 3 '. Great cares were paid to the stress measurements and the stress corrections

for membrane forces. Also in order to confirm the results with respect to the value of cp,

several analyses based both on the stress-dilatancy relations at failure and on the deformation

·characteristics of sample were performed. It was found that the change of ¢ with the

change of as' is very small when as' is lower than around 0. 5 kgfjcm 2 (50 kN/m 2), especially

lower than around 0. 1 kgf/cm 2 (10 kN/m 2). It was also found that the apparent cohesion

intercept is not needed in using the Mohr-Coulomb failure criterion for the saturated sand

tested. Further, it was found that the change of deformation characteristics of sand with

the change of a 3 ' is rather small when a 3 ' is lower than around 0. 5 kgfjcm 2 as well.

Key words : angle of internal fricti_Q_I!, dilatancy, drained shear, ~~_l1-~:r-~oil2.. shear strength,

triaxial compression test (IGC : D 6)

tests on saturated sand specimens. These

INTRODUCTION are also needed to analyze the results of

The values of the angle of internal friction model tests using sand boxes such as bearing

defined as ¢=arcsin {(at' -a 3 ' ) / (at' +as') }max capacity tests, earth pressure tests or the

of cohesionless soils at low stresses are needed like. However, only a very limited number

for the analyses of for instances shallow of the values of ¢ at low stresses lower

failures of sand slopes and for the determina- than, say, 0. 5 kgfjcm 2 (50 kNjm 2 ) have been

tion of stress-strain relations at extremely reported in literature (Ponce and Bell,

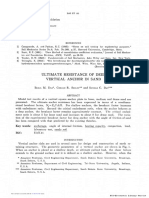

low effective stresses during cyclic undrained 1971, Stroud, 1971). Figs. 1(a) and (b)

* Research Engineer, Fujita Technical Laboratory, Fujita Corp., 74 0-dana-cho, Kohoku-ku,

Yokohama, Kanagawa. Formerly, Graduate Student of University of Tokyo.

** Associate Professor, Institute of Industrial Science, University of Tokyo, 22-1 Roppongi 7,

Minato-ku, Tokyo 106.

Manuscript was received for review on January 6, 1984.

Written discussions on this paper should be submitted before July 1, 1985, to the Japanese Society

of Soil Mechanics and Foundation Engineering, Sugayama Bldg. 4F, Kanda Awaji-cho 2-23,

Chiyoda-ku, Tokyo 101, Japan. Upon request the closing date may be extended one month.

This is an Open Access article under the CC-BY-NC-ND license.

NII-Electronic Library Service

STRENGTH AND DEFORMATION OF SAND 31

results are true there is some amount of the

! i

~ ~

"[ 50 I

DRAINED TRIAXIAL COMPRESSION

SATURATED QUARTZ SAND

AIR-PLUVIATED D 50=0.46mm

emax=0.72, em;n=0.46

apparent cohesion intersept for this sand.

However, it is also true that if the value

ROUNDED TO SUB-ROUNDED of ¢ changes so largely with the change of

-a- ~

a:

45 L

I

FIXED CAP,UNLUBRICATED ENDS

d=7.1cm,h/d=2

YOUNG MODULUS AND

1 as' at low stresses as shown in Fig. 1, it

.;. ~ i { THICKNESS OF MEMBRANE becomes very complicated and also very

g ui~ I :UNREPORTED

~ difficult to analyze the results of model tests

2

a: :om

IJ..<::.

;;_ 40 i

I performed on small model sand grounds. 1

..JCilw

<u.::.

~ 0 a: 35 Also, in such a case, the angle of internal

Wt-0

1-:x;u.

~~0 Dr=5%

friction at extremely low pressures should be

~ f~ 30 evaluated for each different kind of sand used

wow

~~~ (a)

for model tests, because the manner of the

z t-0

< < () 25

0.01

'---1.---.1-....------'

0.02 0.05 0.1 0.2 0.5 1 2 5 change of ¢ with the change of as' at low

EFFECTIVE MINOR PRINCIPAL STRESS , o; (kgf/cm

2

)

stresses might be very different among diffe-

;; 55 r - - - - - - - - y - - - - r - - - - · - · · - - - - ,

rent kinds of sand.

J:

0 In view of the above, the authors

wt-

ww performed a senes of drained triaxial

~~50

~ m NOTE: compression tests for a wide range of

!'!: fil

fi_ ~ 45

THE VALUES OF Dr WERE

OBTAINED BEFORE CONSOLIDATION.

confining pressure from 0. 02 kgf/cm 2 (2. 0

;~ kN/m 2 ) to 4 kgf/cm 2 (392 kN/m 2 ) on Toyoura

Q8 sand which has been used extensively in

2 ~-4o D,=94%

a: a.

u.::. model tests at the Institute of Industrial

_,<

<(/) Science, the University of Tokyo (Fuku-

z u. 35

a:o

shima, 1982). In this paper it will be

~~

~(.')

D,=5% shown that the dependency of the value of

l5 ~ 30

wo

I

¢ of Toyoura sand, which is :fine, angular

~:E (b)

~~25L----~---~~--~

sand, on as' at low stresses is much

0.0 1.0 2.0 3.0

smaller than that shown in Fig. 1 and the

EFFECTIVE MINOR PRINCIPAL STRESS ,

o;

(kgf/cm2 ) value of ¢ is almost independent of as' when

Fig. 1. Change of angle of internal friction as' is lower than around 0. 1 kgf/cm 2 (10

by the change of effective minor principal kN/m 2). In addition to this, it will also be

stress in triaxial compression test (repro- shown that to obtain an adequate conclusion

duced from Ponce and Bell, 1971) (1 kgf/ with respect to this problem, great cares

cm2=98kNjm2) should be paid to the stress measurements

and also the membrane forces should be prop-

were reproduced from Ponce and Bell (1971), erly accounted for Furthermore, it will be

in which the value of ¢ has been plotted presented that the deformation characteristics

against the minor principal ~tress as' (a) in of the sand do not change so much with

the logarithmic scale and (b) 1n the the change in a 3 ' when a 3 ' is lower than

arithmetic scale. The membrane forces have around 0. 5 kgf/cm 2 (50 kN/m 2 ), especially

been corrected for these data by Method I lower than around 0. 1 kgf/cm 2 (10kN/m 2 ).

which will be described in detail in the

latter part. These values of ¢ were obtained

by the conventional drained triaxial TEST PROCEDURE

compression tests. It may be seen from In this testing program (Table 1),

these figures that the value of ¢ increases Toyoura sand, uniform sand, having a mean

very sharply with the decrease in as' when grain size of 0. 16 mm, a uniform coefficient

as' is lower than around 0. 2 kgf/cm 2 (20 of 1. 46, a specific gravity G8 =2. 64 and an

kN/m 2). These results suggest that if these angular shape was used. The maxim urn

NII-Electronic Library Service

32 FUKUSHIMA AND T A TSUOKA

Table 1. List of tests

(l) (2) (3) (4) (5) (6) (1) (2) (3) c4) (5)

Te~t / a/ I (as')J eo.a to

eo.a to

No. 1 (kgfjcm2) (kgf/cm2) (mm) (mm)

1

2

3

4

5

'6 0.02

7

8

9

10

11

12 I

13 I

14

15

16

0. 05

25

26

27

0.10

28

29

30

31

32

33

34

35

36

37

38

39 0.20

40

41

42

43

44

and mm1mum void ratio values are 0. 977 samples was accomplished by increasing the

and 0. 605. The nominal values of diameter fall height. The following cares were

and height of specimen were 7 em and 15 em. taken to maintain the accuracy of testing at

Samples were prepared by the air pluviation low stresses.

method; air dry sand was pluviated through· ( 1) Both ends at the cap and at the

air from an nozzle of tube keeping the fall pedestal were made of acryl platens having

height constant. Densification of the very smooth surfaces. These end surfaces.

NII-Electronic Library Service

STRENGTH AND DEFORMATION OF SAND 33

were well lubricated by using the method

of so called Type 2 (Tatsuoka et al, 1984) CAP

where one layer of 50 ,urn-thick Shin-etsu

silicone grease KS 63 G is placed between a

300 ,urn-thick latex disc and an acryl platen

and this lubrication layer is doubled (in total

two grease layers and two latex discs at

each end). The angle of friction between

a mass of Toyoura sand and this lubricated

surface was found by direct shear tests to

be around 0. 4 degree""'O. 5 degree at a normal

stress ranging from around 0. 25 kgfjcm 2 (25

kN/m 2) to around 6. 5 kgf/cm 2 (650 kN/m 2)

(Tatsuoka et al, 1984). Shin-etsu silicone

grease KS 63 G was selected because this kind

of grease had been found very suitable for

tests at relatively low normal stresses.

( 2 ) Both the cap and the pedestal were

enlarged (7. 5 em in diameter compared to a Fig. 2. Schematic diagram showing the

diameter of sample of 7 em) and the cap was condition just before seating of the

fixed to the loading piston in order to have cap on the sample surface

a uniform deformation of sample. Of

course, it was confirmed before each test clamped to the top portion of the bearing

that the surfaces of cap and pedestal be house. (c) The membrane was carefully

parallel to each other. sealed to the top cap in such that no·

( 3) A membrane having an mner- membrane axial strain induced in it. (d)

diameter which was around 2 mm smaller The loading piston was undamped with

than the inner-diameter of split mold was keeping the seating stress to be 3 gf/cm 2 •

used to ensure a good fitting between the (e) The split collar was removed very

membrane and the inside surface of the mold carefully, which had been set on the top of

when a vacuum was applied to the space the split mold in advance as shown in Fig. 2.

between them. It was found from It was considered that while the sample was.

experiences that if these two kinds of not vacuumed yet at this moment most of

diameters are similar, there may be a fold the sand mass located between the bottom

or folds in a membrane when the mem- surface of the top acryl platen and the level

brane is set in a mold and/ or after a of the top edge of the mold was not

sample is consolidated. This arrangement disturbed so much because the free gap was.

induces an initial horizontal tensile strain of only 4 mm and some shear resistances might

an order of 3% in the membrane. A exist between the lubricated surface of the·

membrane was set to a split mold in such cap and the sample surface at a seating stress.

that no initial axial strains induced in the of 3 gfjcm 2 • (f) A vacuum was applied to

membrane. the sample with its value being 0. 02 kgf/cm 2

( 4) After smoothing and flattering the (1. 96 kN/m 2) for the sample which was.

sample surface by scraping with a thin sheared at this value of effective confining

wooden plate, the following procedures were pressure (0. 02 kgf/cm 2). The vacuum value

employed m order not to disturb the was 0. 05 kgfjcm 2 (4. 9 kN/m 2) for the sample

sample: (a) The cap was placed with a sheared at an effective confining pressure of

seating stress of as small as around 3 gfjcm 2 0. 05 kgf/cm 2 or higher. It was confirmed

(0. 3 kN/m 2). (b) The loading piston was that the top cap fell freely when the

NII-Electronic Library Service

34 FUKUSHIMA AND T A TSUOKA

vacuum was applied because of the presence for an effective confining stress ac' of 0. 05

of the free gap made by removing the collar kgfjcm 2 (4. 9 kN/m 2) or higher. When

(Fig. 2). Note that in spite of the presence ac'=O. 02 kgfjcm 2 (1. 96 kN/m 2), no back

of this kind of gap the contact between the pressure was applied in order not to disturb

membrane and the inside surface of the mold a sample during the application of back

may resist to some extent against the pressure. Back pressuring was considered

perfectly free axial deformation of sample necessary to measure accurately the volume

when vacuuming. This kind of contact may change of sample by measuring the water

disappear only after the sample is contracted height in burette. This water height was

to some extent in the radial direction, which measured with a low-capacity differential

will not be the case in the beginning stage pressure transducer (LC-DPT) as shown in

of vacuuming. This is because the mem- Fig. 3 (Tatsuoka, 1981).

brane is compressed radially to some extent ( 6) To obtain the value of effective

even before the application of vacuum. confining pressure or effective mmor

Considering this above, it was decided to principal stress a3' during a triaxial

minimize the vacuum va:lue to the smallest compression test, the differential pressure

·operational value as descr_ibed above. But b_etween the cell water pressure and the pore

this value should be larger than the water pressure was directly measured with a

horizontal stress at the bottom of sample high capacity differential pressure transducer

before the application of vacuum, which is (HC-DPT) (Fuji Electric Co. Ltd, Model

only around 0. 01 kgfjcm 2 (1 kN/m 2). (g) FFF -35) (see Fig. 3). The capacity of

The split brass mold was carefully differential pressure for the HC-DPT was

.disassembled and the dimensions of sample adjusted to an adequate value among 0. 32

were measured. For the sample sheared at kgfjcm 2 (31. 36 kN/m 2 ), 1. 6 kgf/cm 2 (156. 8

an effective confining pressure of 0. 5 kgf/cm 2 kN/m 2) and 3. 2 kgfjcm 2 (313. 6 kN/m 2). The

(49 kN/m 2) or higher, the vacuum was then estimated error in the measured differential

increased to 0. 3 kgfjcm 2 (29. 4kN/m 2) and the pressure was around ±0. 3% for the maxi-

dimensions of sample were measured again. mum differential pressure of 0. 02 kgfjcm 2

( 5) Samples were saturated by circulat- (1. 96 kN/m 2 ), which was mainly caused

ing sufficient amount of carbon-dioxide and during the analog-to-digital conversiOn

de-air water through a specimen and applying procedure in data acquisition. The error in

a back pressure of 2. 0 kgfjcm 2 (196 kNjm 2) percentage decreases with the increase in the

measured differential pressure. Thus the

Pa

value of a 3 ' was calculated as

~PULLEY

(1)

COUNTER WEIGHT

in which DP is the differential pref.sure as

measured with the HC-DPT and Aarm is the

stress correction for the forces working in

membrane which will be described in detail

later. Note that the value of DP is

independent of the level where this Is

measured. Thus, when A arm is independent

of the level, a 3 ' obtained by Eq. (1) is the

same at any level in a sample.

H C-DPT LC-DPT ( 7) While the diameter of the loading

Fig. 3. Schematic diagram of triaxial piston was 20 mm for an effective confining

compression test method for tests pressure of 1 kgfjcm 2 (98 kN/m 2) or higher,

at an effective confining stress of this was reduced to 13 mm for an effective

0.5kgfjcm2 (49kN/m 2) or lower confining pre~sure of 0. 5 kgfjcm 2 ( 49 kNjm 2 )

NII-Electronic Library Service

STRENGTH AND DEFORMA TI.ON OF SAND 35

-or lower to reduce the piston friction. The

loading piston was guided with two low-

"'·~

'+'

-?-;;;--o

I E 1----?-

friction linear motion bearings in a bearing 1 ~I 1

I ~j I

house located at the top plate of triaxial : d! I

.cell (Fig. 3). The sealing against pres- J ;--..... a'c

"-.I i I

surized cell air was achieved by placing a eo.3'-.. A"--., I I

,I I

gap of 0. 01 mm between the inside wall ~'>---L.

·surface of the bearing house and the loading I c

e ISOTROPIC NORMAL

piston along a length of 5 em between two CONSOLIDATION CURVE

bearings. For the tests at an effective Fig. 4. Schematic diagram showing the

<:onfining pressure of 0. 5 kgf/cm 2 (49 kN/m 2 ) change of if> along an identical

or lower, the combined weight of cap, isotropic normal consolidation curve

loading piston and other attachments was

.counter-balanced as illustrated in Fig. 3 from small as 0. 25%/min so that no excess pore

the stage of contacting the cap with the top pressure be accumulated within a sample.

surface of sample in order to keep sample ( 9) All the values of stresses and strains

disturbances to the minimum. The total were automatically recorded, processed and

.amount of friction against the upward or plotted by using a micro-computer in order

down ward movement of the loading piston to reduce the error during these steps.

Fr was carefully evaluated under the actions In most cases, the density of each sample

-of thrusting forces and was found not larger will be represented by the value of void

than 16 gf (0. 16 N) which corresponds to an ratio when the sample is isotropically

.axial stress of as small as 0. 4 gfjcm 2 (0. 039 consolidated at a pressure of 0. 3 kgfjcm 2

kN/m 2 ) for the sample dimension employed (29. 4 kN/m 2 ), e0 • 3 (see Fig. 4). The values

in this study. The effective axial stress u 1 ' of cp and several kinds of strain values will

.at the mid-height of sample was calculated be compared among different samples having

.as an identical value of e0 . 3 • In this sense, the

u/= (Pa+W -Fr)/ As+DP-[(uc+o · rw)a changes of the values of ¢ or strain values

+ il· rw · AcJ! As+ (hs/2) · (Gs-1) rw! (1 with the change of pressure along an

+e)+ilua,. (2) identical isotropic normal consolidation curve

in which P a is the additional axial load will be examined in this paper. The values

measured with a load cell located at the top of e 0 • 3 for samples which were sheared at

of the loading piston, W is the combined stresses lower than 0. 3 kgf/ em 2 such as

weight of cap, loading piston and other Sample A as indicated in Fig. 4 were

.attachments (W =0 when counter-balanced), estimated by using the consolidation curves

Fr is the loading piston friction, A 8 and h 8 up to 0. 3 kgf/cm 2 which were obtained for

.are the cross-sectional area and the height other samples having similar density values. 1

of sample, DP is the differential pressure as

measured, uc is the cell air pressure as

measured with a pressure gage, o is the cell TYPICAL RECORDED S1,RESS AND

water depth above the cap, il and Ac are STRAIN RELATIONS

the thickness and the cross-sectional area of The typical relationships between stress

cap, rw is the unit weight of water, a is ratio u//u 3 ', axial strain ea and volumetric

the cross-sectional area of the loading piston, strain v in a series of drained triaxial

.and il Uam is the stress correction for compression tests on samples having similar

membrane forces which will be described in densities are shown in Figs. 5(a) and (b)

detail later. The load cell was carefully and also in Figs. 5(c) and (d). Figs. 5(a)

calibrated very often by using dead weights. and (b) are on dense samples. Fig. 5(a)

( 8) The axial displacement rate was as are for the samples consolidated to 0. 1 kgf/

NII-Electronic Library Service

36 FUKUSHIMA AND T A TSUOKA

(/) 8 -16

~ DRAINED TRIAXIAL COMPRESSION TEST

a: SATURATED TO YOUR A SAND, AIR-PLUVIATED

5: ISOTROPICALL Y CONSOLIDATED

w

z

< 0.1 0.5 (f)6 .---~--------------~--~--~---,-12

~ 6 -12 f-W

IC> DR AI NED TRIAXIAL COMPRESSION TEST

:2 (.')0: SATURATED TOYOURA SAND, AIR-PLUVIATED

w -o

:2 ~LL. ISOTROPICALL Y CONSOLIDATED

a:

0

~ 'w

ez

LL. :::;<

0:4

-8 z" >-ro

"'::2

(.) < '"' w

w a: tJ:2

-a: f-

(/) .~a:

. "'a: oo

00 ~ LL.

'-.(.) a:

·o-3 f-

lU

2 ~

f-f-

2

uj2 -4 :2 <u

Q~ 3 a:w

f-:2 "0.3 0 (/) ~ 1

~;;,1 > (/)0

(f)u_

(/)0

~~

w 0.1 0.650 (/) ~0

:: !I: O~ft!P"'I"'----<-----+- 0.2 0.658 0 -'-'

-d;CL

(f)l'J 0.658 o..:::;

0.5

_,w 1.0 0,671

u<

z (./)

<I

a_ I

t 0 =0.3mm Ci:LL

ue

z:2

(o) 2.0 0.677

CLO

4.0 0.679

0: f- 0

CL < 0~-~~-~5--~--~--~-~ 4

10 15

AXIAL STRAIN, c.,(%)

.-------------------,-16

~ 8

(.)

DRAINED TRIAXIAL COMPRESSION TEST

a: SATURATED TOYOURA SAND, AIR-PLUVIATED

0

LL. ISOTROPICALL Y CONSOLIDATED

w

z

<

~6 -12

:2

w

:2

a:

0

lJ...

0

~ 4

*

-8> -8

(.) z

w

-a: <

a:

'"'a: f-

oo en

'-.C> 0

.- z a:

~

o::J

-w 2 -4 t;:; -4

O-' :2 a:

-CL ::J f-

>-:::; -' (/)

0

~;;,1 > (.)

(/)lJ... 0:

rzo a· c eo.3 f-

w

g:!I:o (kgf/cm

2

) 0

0 ~

(/)52 ...J

_,w 0.02 0.679 0

<I >

a_ I

t 0 =0.3mm 0.05 0.681

-o

(.)-

(b) 0.1 0.687

~:2

O:f-

O..< 4

0 5 10 15

AXIAL STRAIN, Ea(%)

Fig. 5. Typical relationships between principal stress ratio at the mid-height of sample

uncorrected for membrane forces,· axial strain and volumetric strain for a membrane

thickness of 0. 3mm for (a) dense samples at uc' =0.1.......,4kgfjcm 2, (b) dense samples

at uc' =0. 02.......,0.1kgfjcm 2, (c) loose samples at uc' =0.1.......,4kgfjcm 2 and (d) loose samples

at ac' =0. 02.......,0.1kgfjcm2 (lkgfjcm 2=98kN/m 2)

cm 2 (9. 8 kN/m 2) or higher and Fig. 5(b) are thickness t 0 of 0. 3 mm. The stress values

for those consolidated to 0. 1 kgf/cm 2 or shown in these figures were those at the

lower. Figs. 5(c) and (d) are similar ones mid-height of sample without being cor-

for loose samples. Note that the membranes rected for membrane forces. It may be

used for the data presented in Figs. 5(a) seen in these figures that for both cases,

through (d) are latex rubber membranes dense or loose, the change of the relationship

having a Young's modulus of 15. 2 kgfjcm 2 between axial strain and uncorrected stress

(1. 49 x 10 3 kN/m 2) and an initial averaged ratio at'/a 3 1 with the change of consolidation

NII-Electronic Library Service

STRENGTH AND DEFORMATION OF SAND 37

pressure (Jc' becomes larger as (Jc' decreases any stress corrections for membrane forces

while the change of the relationship between and plotted against the values of e0 • 3 (Fig. 6) .

.axial strain and volumetric strain with the The figures indicated in Fig . 6 mean the

change of (Jc' becomes smaller as (Jc' de- values of mmor principal stress at ((1 1 1/

·Creases. This apparently contradictory (Ja') max• C(Ja') 1 , which have not been

phenomenon will be explained in the corrected for membrane forces either. The

following part by the effects of membrane values of ((1 3 ') 1 were slightly different from

forces on measured stresses. the values of consolidation stress (Jc' at low

Somewhat unsmooth stress and strain stresses because of the unevitable changes

relations seen in Figs. 5(a) through (d) for of the surface levels of both cell water and

extremely lower stresses ((Jc'~O.l kgf/cm 2) water in burette and also because of the

can be considered due to their stick-slip slight changes of both cell air pressure and

behaviors. The angle of internal friction back air pressure during a test. These kinds

was defined for the maximum recorded or of changes were let to occur freely during

calculated stress ratio in any case in the tests because it was considered that the

following part whether stresses were

corrected or uncorrected for membrane

forces.

w

~

~ ::~?O ~

l

TRIAXIAL COMPRESSION TEST, TOYOURA SAND

"''t';;-:3;Ml,UNCORRECTED

~MBRANE FORCES

DEPENDENCY OF ANGLE OF INTER- B-40 ~~

NAL FRICTION ON PRESSURE 5i= =o.ss {

u ~~~~~

The angles of internal friction ¢ obtained a:u.

..J

by using membranes having t 0 =0. 3 mm were <(

z

a:

calculated from the maximum stress ratio at UJ

1-

;;

the mid-height of sample without performing u.

0

w

..1

<!)

z

<(

~50.----~

u DRAINED TRIAXIAL COMPRESSION TEST

a:

0 SATURATED TOYOURA SAND, AIR-PLUVIATED EFFECTIVE MINOR PRINCIPAL STRESS AT <o;;cr:i>max, o; (kgf/cm 2 )

u.

w \

z

<{

o0.038 \FIGURES SHOW THE VALUES Fig. 7. Relationship between angle of

a: OF o3 AT FAILURE,(o'3 ) 1

m

~

+ 0.067 UNCORRECTED FOR internal friction obtained by var-

it MEMBRANE FORCES.

~ 45 ious methods and effective minor

X (

'!\. \

lli~

~~

~'i'\

~~

~oo.ci65

o0033

principal stress at failure in log-

arithmic scale (lkgfjcm 2 =98kNfm2)

~~ ~~ X

"

+

............ 0.11-0 12

~a:

-e-~40 "><, ~

50

X "'

" j_0Trlim) MiMBRANE-FORCES

0. .. .,~.~'-.. "'-.._ '+'-

• UJ

~

.u

5

0.51-

0.52 I"'-.._ ·1>:.~ '-....

,0.051

'-...."-d 5~

13

100.3,

UNCORRECTED }AT MID-

;:: ui (o'3l,(kgf/cm2) {:> -4~+ x-......._ -,;:-.::::__.,~o.o56 i= LEGEND 0.1 , UNCORRECTED

H HEIGHT

~c

~~ \ 1 t> ~"-\, "-......_X "- ~ (j)

45 e 0.1, CORRECTED BY METHOD lOR Ill

E~ "-t>,:~. \ H Q. (j) <!>=42.4 AT BOTTOM,OR CORRECTED

..J (f)

~ ~ 35-

2 -4

4 <>

/

_.._/>

<> ..... ~

... ~ 0.21-0.22

;i

~

e 40

' (a'3=0) DILAT:~6';~~L~fi6~E~~-FAILURE

.

~'I ~~

UJ

~ e 0 . 3 =0.70

~S?

~ ~

"-

1

_ME_MBRANE 0

LATEX, t 0 =0.3mm

w

8~

0

Em= 15.2 kgf/cm

2 a

UJ

eo.3=0.8ti

~ TRIAXIAL COMPRESSION TEST , TOVOURA SAND

:i ~ 30o'-.6:-----o=-".7=------=-o."='s-----:o:'-:.9:------1.0 30

o 1 2 3 4

2

VOID RATIO AT o'c=0.3 kgf/cm , e 0 .3 EFFECTIVE MINOR PRINCIPAL STRESS AT <o;;cr:i )max·o' 3(kgf/cm2

Fig. 6. Angle of internal friction at the Fig. 8. Relationship between angle of

mid-height of sample, uncorrected for internal friction obtained by various

membrane forces for t 0 =0.3mm, plotted methods and effective minor principal

against e 0. 3 (lkgfjcm2 =98kNjm2) stress at failure in arithmetic scale

NII-Electronic Library Service

38 FUKUSHIMA AND T A TSUOKA

adjustments might induce more variations

~ sol-f=~~~R~~~~~~u~~~i~£~~E:~JJIATE-::--- .

1

in a 3 ' than it was in the case of no-

adjustment. It may be seen in this figure ~ ISOTROPICALL y CONSOLIDATED

I :

~ 2 .

that the scattering among the data is very

small even when (a 3 ' ) r is as low as 0. 2 kgf/

~

[Q

i:j

:::;;

4

l

~~~~)

510

,.------.-'----~

0.117

s:;-::--~0.060

i

.

em 2 or lower. o: i 0.52 " 0.038 _t_o=0.1 mm

l:lJ

0: 0

~ ~· --··;~ \ 0.070

'';d!-.061

J -v- - -

(a',)t (kgf/cm'J /

I

Since the relationships between </> and e0 . a C!l uJ

W I 2~c

l:i. .__o_• 05 7'.0.048 o o.026-0.038 1

could be well defined for each stress level, ~ § I ll'-"'0:033 . I "'0.048-0.060

-:.o: ,

egl

4 J<o.115 ; · [co.061-0.070

the values of </> for e0 . 3 =0. 70 or eo.a=O. 85 0: 40'- ' 0 034

o~ xo.1o3-o.111

were read for each stress level and plotted 3

~- """·:-ro.064

against (a 3 ') r both in the logarithmic scale 2w

2o::::;;c: I

~coo.o3o

~63

'

(Fig. 7) and in the arithmetic scale (Fig. 8). ~ ;;j \ I "'~Oo2~58

At least two important points may be seen ;i)) 35;- to=0.3mm _/ 0.103"-._

from these figures. First, the true values ~ 1- ! ·u·~.Tc-ofi'REcTED

FoR ~

~ G MEMBRANE FORCES

of ¢ at lower stresses should be smaller u..W

o:r:

than those indicated by the hollow circles wb

6~ 1

especially at a3 ' lower than 0. 1 kgf/cm 2 ~ ~ 3 ~~- - --o.s----------o.-9------,-~0

(9. 8 kN/m 2) because the errors due to the vo·m RATIO AT a~ =0.3 kgf/cm2 , e 0 . 3

effects of membrane forces for a rather thick Fig. 9. Angle of internal friction at the mid-

membrane of t 0 =0. 3 mm involved in these height of sample, uncorrected for membrane

da~a always increase the calculated values forces for t 0 =0.1 mm, plotted against e 0 • 3.

of i,¢. In spite of this fact, it may be seen (1 kgf jcm 2 = 98 kN jm 2 )

th~t ·the rate of the change of </> with the

change of a 3 ' in this case is much smaller pressure ac' of 0. 1 kgf/cm 2 (9. 8 kN/m 2) or

than that indicated in Figs. 1(a) and (b). lower were performed using thinner latex

The reason for this apparent differe~ce can membranes having t 0 =0. 1 mm or 0. 12 mm.

not be explained by the present authors The uncorrected values of ¢ at the mid-

mainly because several experimental details height of samples when t 0 =0.1 mm were

for the data shown in Figs. l(a) and (b) are plotted against e0 . 3 (Fig. 9). The figures

not presented in the literature. indicated in Fig. 9 are the values of effective

Second, it may be seen from Fig. 7 that minor principal stress at (a//aa')max' (aa') r'

in the case of e0• 3 = 0. 85 the manner of the which have not been corrected for membrane

change of </> with the change of a 3 ' when forces either. Since no clear effects of

a 3 ' is between 0. 5 kgf/cm 2 ( 49 kN/m 2) and (a 3 ') r on the values of </> could be seen

0. 2 kgf/cm 2 (19. 2 kN/m 2 ) is not smooth, but among the data, the values of </> for e0 . 3 =

is rather unnatural. This may be due to 0. 7Q and 0. 85 were read from these data

thatI at aa' lower than 0. 5 kgf/cm 2 the effects and: indicated in Fig. 7 by two horizontal

of membrane forces are especially larger for broken lines, which were determined as

the~e looser samples having e0 , 3 =0. 85 than </> =43 degrees for(aa') r=O. 038"'0. 117kgf/cm 2

for ·.denser samples because the maximum (3. 7 "'11. 5 kN/m 2) and </> =37 degrees for

value of a//a 3 ' is attained at a larger strain (a 3 ' ) r=O. 026"'0. 103 kgf/cm 2 (2. 5"'10. 1 kN/

value for a looser sample, resulting m m 2 ). It may be seen from Fig. 7 that

larger membrane forces. This trend may when stresses are not corrected for membrane

also indicate the necessity of stress correc- forces the calculated values of~ : </> are

tions for membrane forces at least for the smaller for t 0 =0. 1 mm than for tc)=O. 3 mm,

cas.e of t 0 =0. 3 mm. with the difference increasing with the

In view of the above, additional drained decrease in a 3 ' or (a 3 ' ) 1 .. This is also

triaxial compression tests on specimens another evidence for the effects of membrane

consolidated to an effective consolidation forces on the measured value of cp.

NII-Electronic Library Service

STRENGTH AND DEFORMATION OF SAND 39

If the effects of membrane forces are not

negligible in obtaining the true values of DRAINED TRIAXIAL COMPRESSION TEST K=

¢ at <Ja' lower than around 0. 1 kgfjcm 2 even SATURATED TOYOURA SAND,

AIR-PLUVIATED //

-"3.1

when thin membranes having an initial / ;Z3,0

thickness t 0 =0. 1 mm are used, another !/ IN

+

important conclusion may be derived from

the data shown in Fig. 9. If the values of <o'3)t

¢ indicated in Fig. 9 are properly corrected

+ ~~;~;:;~i2

l

for membrane forces, the corrected values 01

of ¢ will decrease. The amount of decrease • 2

A4

will increase as (<J 3 ') 1 decreases because the

effects of membrane forces on the values of

¢ are larger for lower values of (<J 3 ' ) r·

Then, the corrected values of ¢ become

smaller with the decrease in a/ when as' is

~ww~

7

r;RAINEornAXIALCOMPRESSION TEST w

lower than around 0.1 kgfjcm 2 (10 kNm 2 ) . SATURATED TOYOURA SAND ~

This conclusion seems rather unnatural. %gj AIR-PLUVIATED

1

1 ~

:E ~ t 0 (mm) z_,./ ~

However, it is to be noted that the stress 1- z 6 " {• .... o.3 1 ~ANGE FoR e

<(_;;: o o A o 1 I )I t 0 =0.3mm

145

condition within a sample becomes very

non-uniform at extremely low pressures.

The values of ¢ indicated in Fig. 9 were

~co

...t'_:::;

'b' ~

·0'-a:o

I.

•

.

(0'3lt{kgf/cm2) I "' __

0 0.026-0.05 7 • 1 II

I I / V'

o o.o58-o.o?o 1 • ) l v

I "-1

-~---/'

ll /_

I

calculated from the maximum stress ratio

~ u. 5 -

Oo

;::w

<( 1-

0

• A0.103-

I I /0-' :)''

0.122/"'; j1/ u/''

/ '~-

•/ 140

value (<J// a 3 ') max at the mid-height of sample. 0:

w~ /•

I /)',}

~o

For example, suppose that at the mid-height ~0: o~ /~ ,/

-o RANGE FOR

of sample the true stress values are (<J/) 1 = ~ 34- {o' 3) 1=0.51-4.0kgf/cm 2

~ w· 35

0. 045 kgf/cm 2 (4. 41 kN/m 2) and (<J 1')max= ~ 0: RANGE FOR t 0 =0.1 mm

2

~~ (b) AND (0'3lt=0.026-0.122kgf/cm

0. 227 kgfjcm 2 (22. 2 kN/m 2), resulting in

(<J//<J 3 ')max =5. 045 or ¢ =42. 0 degrees. When ri:-'0 3

o.8 1.0 1.2 1.4 1.6 1.8 2.0 2.2

Dt=DILATANCY RATE, (-2i: 31i: 1 ),AT {C;I0'3lmax

the void ratio value e is 0. 7, the value of

Fig. 10. Stress-dilatancy plottings at failure

(a 1 ')max at the bottom becomes 0.,2342 kgf/

at (a) q 3 ' =0. 51.......,4kgfjcm 2 and (b) q 3 ' =

cm 2 (22. 95 kN/m 2). When the _effects of

0.026.......,0.122kgfjcm 2 , with stress values

membrane forces on the value of (a 3 ' ) r are as follows being uncorrected for memb-

the same at any level in the sample and rane forces (lkgfjcm 2 =98lkNfm 2 )

also the horizontal shear stress working on

the bottom surface of sample can be forces. Therefore, it seems that the trend

neglected, the value of (<J 3 ') 1 at the bottom indicated in Fig. 9 be quite possible. This

of sample- is also 0. 045 kgfjcm 2 • Then, the point will be discussed again later.

value of (<J/ 1<Ja') max at the bottom of In an attempt to know the extent of the

sample becomes 5. 20, giving ¢ =42. 7 degrees, effects of membrane forces on measured

which is 0. 7 degrees larger than the value of values of ¢, another kind of analysis was

¢ calculated from the stress values at the performed as follows. In Fig. lO(a) are

mid-height of sample. Therefore, it can shown the stress-dilatancy plottings at

be said that if thej failure of sample Is failure for (<J 3 1) r=O. 51"""4. 0 kgf/cm 2 (50. 0""'

controlled by the maximum value of 392 kN/m 2) where the membrane forces have

(<J 1 '/<J 3 ')max within a sample, the values of only negligible effects on measured values of

¢ obtained from the stresses at the mid- (<J 1 '/ <J 3 ') max· While a small scattering· can

height of sample are underestimated ones be seen among the data, the relations can

especially at lower stresses even if stresses be· considered quite independent of the value

have been properly corrected for membrane of (<J 3 ') 1 . - In Fig. 10(b) are · shown the

NII-Electronic Library Service

40 FUKUSHIMA AND T A TSUOKA

similar stress-dilatancy plottings at failure in which Llaa,. and Liar,. are the corrections

for (a 3') 1 =0. 026"-'0. 122 kgf/cm 2 (2. 5""'12. 0 to the axial and radial stresses (refer to

kN/m 2) for two membrane thickness values, Eqs. (1) and (2)), Em and t are the Young's

t 0 =0. 1 mm and 0. 3 mm. The range for modulus and the present averaged thickness

(a 3 ' ) r=O. 51""'4 kgf/cm is also indicated in

2

of membrane, d is the present diameter of

Fig. 10(b). Note that the values of (a 1 '/ sample and ea,. and c: 0 ,. are the averaged axial

a 3 ') max and (a 3 ' ) 1 indicated in Fig. 10(a) and and circumferential strains in membrane

(b) are the ones uncorrected for membrane which were assumed equal to the averaged

forces, measured at the mid-height of axial and radial strains in a sample in this

sample. It may be clearly seen in Fig. 10(b) study. Of course the values of ea"' and com

that the data points for t 0 =0. 3 mm are were obtained accounting for initial strains

located quite higher than those for t 0 =0. 1 in membranes. Note that a Poisson's ratio

mm which are in turn located slightly of 0. 5 is used to derive Eq. (3) and will also

higher than those for (as') r=O. 51'"'"'4 kgf/ be used in the following two methods.

em 2 • If the stress-dilatancy relation at Eq. (3) or similar ones with slight modifica-

failure is independent of the value of (a 3 ') 1 tions has been used by many researchers ;

for the range of a 3 ' between 0. 026 kgf/cm 2 for clay samples by Henkel and Gilbert

(2. 5 kNJm 2 ) and 4. 0 kgfjcm 2 (392 kN/m 2 ) , we (1952), Duncan and Seed (1967) and Berre

can conclude from the data shown in Fig. 10 (1982) and for sand samples by Ponce and

(b) that for both t 0 =0. 3 mm and 0. 1 mm the Bell (1971) and Molenkamp and Luger

effects of membrane forces should be (1981).

accounted for to obtain the true values of Method II : It IS assumed that m a

¢, with the correction being larger for t 0 = membrane the axial deformation occurs

0. 3 mm than for t 0 = 0. 1 mm. independently of the radial and circumferen-

tial deformations. The equations for stress

corrections are

STRESS CORRECTION FOR MEMBRANE Llaam = - ( 4Em · t · eam)Jd

(4)

FORCES Liar,.=- (2Em · t · eom)/d

The shape of membrane during a triaxial Method III : In this method it is assumed

compression test at low stresses is rather that the resistance of membrane against

complicated because of very rough surfaces axial deformation is negligible due to such

of sand samples and also because the buckling a buckling phenomenon as schematically

of membrane can occur at a larger axial illustrated in Fig. 11 which is assumed to

strain especially at extremely low pressures. occur over the whole area of membrane.

By these reasons, it is very difficult to find This method was called "Hoop tension

an exact method of stress corrections for theory" by Henkel and Gilbert (1952). The

membrane forces for sand specimens.

Therefore, the following three methods

were compared.

Method I : In this method, it is assumed

that a membrane has a shape of perfect

thin-wall cylindrical shell. Thus this

method was called "Compression shell

theory" by Henkel and Gilbert (1952). The

stress corrections for membrane forces are

expressed on the theory of elasticity as

Llaa,. = - (8/3) [Em· t(2 ea,. +eo,.) ]jd Fig. 11. Schematic diagram of

3

Liar,.=- ( 4/3) [Em· t(ea,. +2 eo,.)]/d ( ) buckling of membrane

NII-Electronic Library Service

STRENGTH AND DEFORMATION. OF SAND 41

9r-------------~------~~--~ c

DRAINED TRIAXIAL COMPRESSION TEST ~45 -.----

SATURATED TOYOURA SAND, AIR-PLUVIATED tu DRAINED TRIAXIAL COMPRESSION TEST /

w 8 ISOTROPICALL Y CONSOLIDATED

w ::=; SATURATED TOYOURA SAND ;

..J w >- AIR-PLUVIATED

0.· 0:111

<

~

((J

~5l

01-

/

;!" //

u. 7

0

1-

J:

~

iii 6

~~

J:

I

0

~

a:::=; /+ t 0 {mm) CD ® @

~~ 1 ,f' {01 OA X

< u.

~ 0 35"

! / / o:12

0.3 0

-&

A

0

+

WI-

1-J: I

METHOD Ill :: ~ ~ 2

i_o'3l1 c BY METHOD Ill (kgf/cm )

a" CORRECTED BY 0 t :a> 0.030-0.060 (0.045+)

j: METHOD II ~ S! i@ 0.061-0.075 (0.068+)

<

a: 3 VOID RATIO AT START OF SHEAR=0.682

~ ~ +AVERAGED l@ 0.107-0.132 (0.119+)

< < 30 -~- -----~----____j

~ o'c =0.02kgf/cm

2

30 35 40 45

~ t 0 =0.3mm ANGLE OF INTERNAL FRICTION, cp, IN DEGREE

lii 2 Em= 15.2kgflcm2 AT MID-HEIGHT OF SAMPLE, CORRECTED BY METHOD Ill

INITIAL MEMBRANE STRAIN;

Fig. 13. if> corrected by Method I versus if>

1~--------~------------~---J

0 5 10 15

corrected by Method III for a c' equal

AXIAL STRAIN, & 3 (%) to or less than O.lkgfjcm 2 (9.8kN/m 2 )

Fig. 12. Stress-strain relationships for

stresses corrected or uncorrected for while in these methods quite different modes

membrane forces (lkgfjcm 2 =98kN/

of deformation of membrane are considered.

m2)

In Fig. 13 are plotted the corrected values

of ¢ at the mid-height of sample obtained

equations for stress corrections, which are

by Method I against those by Method III

slightly different from the equations shown

for all the tests performed at (Jc'=O. 1 kgfjcm 2

by Henkel and Gilbert, are

(9. 8 kN/m 2 ) or lower. It may be seen that

Llaa,.=O, Llar,.=-(2Em·t·el1,.)/d (5) the difference of ¢ between these two

In Fig. 12 are shown the relationships methods are very small. In particular, the

between axial strain and principal stress ratio difference is not larger than around 0. 1

at the mid-height of sample which are either degree when t 0 =0. 1 mm, which is of a

uncorrected or corrected for membrane similar order of the estimated error in this

forces by these three methods for a sample study. This result seems only to be

consolidated to (Jc' =0. 02 kgf/cm 2 (1. 96 kN/ fortuitous, because Method I and Method

m 2). Of course, the initial strains of III may provide different results, for example,

the membrane were accounted for, which in constant-volume tests on sands or in

are (sa,.)i=O. 0% and (eo,.)i= -2. 7%. It drained tests on non-dilative soils such as

may be seen in Fig. 12 that the stress normally consolidated clay. This is because

corrections for membrane forces are quite in these tests the volumetric strains can be

large when the confining stress is extremely much less than the radial strains, resulting

low and a thick membrane (t 0 =0. 3 mm) is in different corrections to radial stress

used. It may also be seen that the corrected between Methods I and III.

stress values are different between Method II In Fig. 14 (a) are shown the angles of

and the other correction methods (Methods internal friction ¢ calculated by using the

I and III). Since Method II is rather stresses at the mid-height of sample, which

unrealistic from the viewpoint of the are either uncorrected or corrected for

elasticity theory, this method will not be membrane forces by two methods (Methods

considered anymore in this paper. I and III), obtained for the samples conso-

It may also be seen in Fig. 12 that Methods lidated to (Jc'=O. 02 kgf/cm 2 , using two kinds

II and III provide very similar stress values, of membrane thickness, t 0 =0.1 mm and 0. 3

NII-Electronic Library Service

42 FUKUSHIMA AND T ATSUOKA

w

i5o~------,~------

~ DRAINED TRIAXIAL COMPRESSION TEST

U> SATUR~ TEO TOYOURA SAND, AIR-PLUVIATEO

u. '\ O'c=0.02kgl/cm2 t 0 =0.1mm

0 2

I •\ (o' 3 l 1=0.026-0.057kgf/cm

~ t 0 (mm)

!

~

e'"'

45~1

\

\,~---- •

'•//~ ~·

O.

0.3,

1'

·UNCORRECTED

VOID RATIO AT START

OF SHEAR:0.838

Ea=11.5%

~ \, "a, 2

:(w I -<!(' '\ \ a' c=0.02 kgf/cm

\ 't, 2

(a' 3 ) =0.03 kgf/cm

~ I \."' \ 1

cw 40 l >.> ""·

\ '• ·,

~-I

~ i

~~

~ ~

\ •,

I~ ~)

BY~~~

~-~.

v.""

CORRECTED

35 METI-'OD I METHOD '-

~ o. 1 + 0 1

ffi

t-

' 03

'

X A , 'il~ Photo. 1. Shape of sample vacuumed after

~ 1 (a) test which stopped at ea =11. 5%

w 30 1

<5 0.6 0. 7 0.8 0.9 1,0

~ VOID RATIO AT o'c=0.02kgl/cm2

priate for the membrane force correction

w

-'50,-------

c. I I

at peak stress conditions for the test condition

::< DRAINED TRIAXIAL COMPRESSION TEST

employed in this study or for similar

~ SATURATED TOYOURA SAND, AIR-PLUVIATED

...0 a~ =0.05kgl/cm2

conditions .

2

~ \ <o~ l1 =o.058-0.070kg!lcm It was observed m the tests at extremely

~45r \ lg(mm) low pressures that membranes did not buckle

Q ~ \ \ \ /--' • 0, 1

;i ~\ ,, / : : - - • 0 _3 ; UNCORRECTED ,

1

at small axial strains, where dense samples

:( \\.--x:..----- ! had their peak stress values, while most

§

ttl ~~""'

\ \ \ '·,~-

membranes buckled at larger axial strains,

~ 40- \\ where loose samples had their peak stress

! ~~~ values as typically shown in Photo. 1. Many

~ ' ~ horizon tal lines seen on the surface of

~

'

t- I

I """· '

'\,

. " " -

sample in Photo. 1 are the results of

~ [ CORRECTED BY 4>-.... ""

:;:

1

t 0 (mm) METHOD I METHOD Ill '- ~ bucklings of membrane. In physical terms,

-' 35- o. 1 + - -- o ~A

~

a: 0.3 X A

- -~ 4>...._ it seems that Method I is more reasonable

w i

t- than Method III at smaller axial strains,

~ i

...0 ~) I while Method III is more reasonable than

~ 30~--~- --- __ J.___________ _ _ j Method I at larger axial strains. Since any

-o.s

' _ _ _ __.___ _ _

Cl o.s o.1 o.s 1.0

z

< VOID RATIO AT o'c =0.05kgl/cm2 clear difference in the corrected values of 9

Fig. 14. Angles of internal friction, uncorrected between these two methods was not seen in

or corrected for membrane forces for samples this study for both dense and loose samples,

consolidated to (a) qc' =0. 02kgffcm 2 and both methods will be used together in the

(b) qc' =0. 05kgffcm 2 (lkgffcm 2 =98kN/in 2 ) following part. Of course, it is likely that

both Method I and III are still not the

mm. Also in Fig. 14(b) are shown the angles perfect ones due to many reasons as described

of internal friction for the samples consoli- later.

dated to ac' =0. 05 kgf/cm 2 • It may be seen In Figs. 15(a) and (b) are shown the

in Figs. 14 (a) and (b) that the values of 9 summaries of the angles of internal friction

corrected by either Method I or Method III 9 corrected by (a) Method I and (b) Method

are very similar between for t 0 =0. 1 mm and III obtained for three kinds of membrane

for t 0 =0. 3 mm. Accordingly, both Method thickness, t 0 =0. 1 mm, 0. 12 mm and 0. 3 mm

I and Method III can be considered appro- for three ranges of stress, (a 3 ') r.c• which is

NII-Electronic Library Service

STRENGTH AND . DEFORMATION OF SAND 43

50..------,------r-----,------, 0

DRAINED TRIAXIAL COMPRESSION TES.T

SATURATED TOYOURA SAND, AIR-PLUVIATED

~

t;'j

DRAINED TRIAXIAL COMPRESSION TEST

SATURATED TOYOURA SAND, AIR··PLUVIATED1

I

0

~ 6

t 0 (mm)

0

J:

OJ {• • • 0.3 •

1 0.1 0 X

1-

UJ (>

. ~ 0 0 D. 0.1 '

0.12

~ t;

UJ :::;:45

UJ>-

+~ 1 0.3

• + ....

<a' 3 >1•0 ,CORRECTED

~ lBY..M.S.TH9_l:!_l_!l<.gflgm:2J

1

l;OJ -;a: 5 0. 0.029-0.060

- 0 DB 0.061-0.072

ow

0~

~UJO~ ~

!>A 0.106-0.125

' 03 AT FAILURE CORRECTED· ~w

~ . Cl.

e- ~ '\~ _!'!_'( METHOD _1._~>1 >.!,.c:S_kgf/cm22_ I 0

i= ~

g 2 40

s-a.~ ""'

0

1'lh-~§·0.106-0.125(0.115+)

~ o.o61-o.o72<o.o6a+>

1 ~(I)

(I)u. 4

(1)0

RANGE FOR

ca· 3 >1=o.o51-

4.0kgf/cm21'

fl: ~ 0 1 Q.Q29-Q.Q6Q(0.043,(.) I

Wt-

a::x;

RANGE FOR (O'clf.c=

~~ ti52UJ

< u.

~0

+

""+ +AVERAGED

I

I ::i::x:

::II ~a)

0.029-0.060kgf/cm 2 ,

~ !i: , t =0.3mm 0 ~~

"""' J :::;: 0 3

x ~ o.8

'----'::--,---,-'-;---'-:-----''=----'----'_

1.0 1.2 1.4 1.6 1.8 2.0 2.2

; ~ "r co·,>,="'"'•' ~ ~ !:( DILATANCY RATE, (-2& 1& 1 ) AT (0'1

3

10~ >max

eli 1 0 ~RAJNED~;~~PRES;I-;~~-l

~~

0

I (a)

,1

:r:

1-

SATURATED TOYOURA SAND, AIR-PLUVIATED i

UJ 6

3

~~.6~---0~.~7-----~0~.8~---~0.~9------1~.0

:::;:

>- •• & ~~~

0.3 -1

;OJ {

VOID RATIO AT a'0 ::::0.3kgf/cm2 , e 0 . 3 "0

0 0 ~ 0.1

~~-

Ew

(a'3>t.c•CORRECTED

'b~ 2

BY METHOD Ill (kgf/cm )

!

I

50-----.----------..--------, "-0: 5

DRAINED TRIAXIAL COMPRESSION TEST '§ ~ {. 0 0.030-0.060

SATURATED TOYOURA SAND, AIR-PLUVIATED 0 • c 0.061-0.075

-~ ,& ~ 0.107-0.132 &

Oa.

0 i=::;: RANGE FOR

_ t 0bm._m_l_:;!~-T-~~

1

1

0

I

m; ·r~· :.,

1-

ww

l:i! :2 45- 0.12 -4- <>

<!J)- +

UJCO 0.3 • & + a: :r: / RANGE FOR

00

zw ~~ (b) <a'c\c::;0.030-0.060

2

-~- ::J 1 kgf/cm

·o ::;: 9 3 __L _ __J_I-:----,"

e-:!i x:::;: 0.8 1.0 1.2 1.4 1.6 1.8 2.0 2.2

.a:

~~ DILATANCY RATE, (-2i; 3 /i: 1 ) AT (O;/O"almax

6 8 40.

i=u.i

0-'

Fig. 16. Stress-dilatancy plottings at failure

a:~ for stress ratio at the mid-height of

u.<

...J(j)

<

zu. sample corrected for membrane forces by

o:O

LUI- (a) Method I and (b) Method III at

I-I

~ ':::! 351 extremely low pressures as compared

o~ I

with that at (0' 3 ') 1 =0. 51_...._,4, Okgfjcm 2

~e

(!):2 II

(1 kgfjcm 2 =98kNjcm 2 )

~~ I. (b)

3 ~'-.:.6----o=-'.-=-7---

0.8 0.9 1.0

Figs. 15(a) and (b) and plotted in Fig. 7

VOID RATIO AT a'0 ::::0.3kgf/cm

2

, e0 .3 using the averaged value of cr 3 =(a 3 ' ) 1 .c for

Fig. 15. Angles of internal friction corrected each stress range indicated in Figs. 15(a)

for membrane forces by (a) Method I and and (b), without distinguishing these two

(b) Method III for t 0 =0.1mm, 0.12mm methods. Solid circles shown in Fig. 7

and 0. 3mm for oc' equal to or less than represent the values of <P for t 0 =0. 3 mm

0.1l<gfjcm 2 corrected by either Method I or Method III

obtained for the samples consolidated to ac' =

the minor principal stress at failure corrected 0. 2 kgf/cm 2 and 0. 5 kgf/cm 2 • It may be seen

for membrane forces. It may be :seen that 1n Figs. 7 and 15 that the values of <P

for any stress range the membrane thickne::..,· obtained from the s1:ress values at the mid-

t 0 has no clear dfects on the value of <P height of sample corrected by either Method

when stresses are corrected for membrane I or J\1ethod III becomes ~mailer as as'

forces. The values of <P for e 0 , 3 = 0. 70 and decreases when a 3 ' is lower than .:round

0. 85 were read from the relations shown in 0. 1 kgfjcm 2 • This trend may be due tc an

NII-Electronic Library Service

44 FUKUSHIMA AND T ATSUOKA

underestimation of ifJ at lower values of not perfectly zero due to both imperfect

a a'. lubrication and the forces working in the

To confirm this point, the stress-dilatancy end latex discs. In adition to these, m

relations at failure were plotted in Figs. 16(a) Method I, since the shape of the membrane

and (b) where stress values were the ones even before buckling is not of perfect thin

at the mid-height of sample, corrected by wall cylinder shell as assumed, Eq. (3) may

(a) Method I and (b) Method III, obtained not be an exact one. Also in Method III,

at (as') 1 .c equal to (a) 0.125 kgfjcm 2 (12. 3 since the manner of buckling of membrane

kN/m 2) or lower or (b) 0. 132 kgf/cm 2 (12. 9 when it occures is not as perfect as assumed,

kgfjcm 2 ) or lower. It may be seen in both the resistance of membrane against axial

Figs. 16(a) and (b) that while there is a deformation may not be perfectly zero. It

scattering among the data, the data points was considered not capable for the present

for (as') 1 .c less than 0.060kgf/cm 2 (5.9 authors to obtain the truly exact stress

kN/m 2 ) are located slightly below the range condition within a sample which is needed

for (as') 1 =0. 51~4. 0 kgf/cm 2 (50~392 kN/ to obtain the true value of ifJ at extremely

m 2). This may indicate that when the low stresses. Further researches will be

effects of Cas') ron the true stress-dilatancy necessary to clarify this point.

relations at failure are negligible for the Another independent attempt was made to

range of (as') r between 0. 029 kgfjcm 2 (2. 8 correct the stress values for membrane

kN/m 2 ) and 4. 0 kgf/cm 2 (392 kN/m 2 ), at forces. It was assumed that the differences

least the values of (a//as')max for (as') f.c in the locations of the stress-dilatancy

less than 0. 060 kgfjcm 2 (5. 9 kNjm 2) indicated plottings among the data for different stress

in Figs. 16 (a) and (b) are slightly underes- ranges presented in Fig. IO(b) are caused

timated ones in obtaining the true angle of only by the errors in measured stress values.

internal friction. The stress ratio values (a 1 '/a 3 ')max for t 0 =

In view of the above, the value of 0. 1 mm and at (as') r=O. 026~0. 122 kgfjcm 2

(a//as')max at the bottom of sample were (2. 5~12. 0 kN/m 2 ) were reduced in such that

calculated accounting for the self-weight of the range of these data overlapped the range

sample assuming that the value of a 3 ' is the for (as') r=O. 51~4 kgfjcm 2 • The values of

same at any level in a sample as described ifJ at e0 .s=0. 70 and 0. 85 for t 0 =0.1 mm were

before. Then, the angles of internal obtained from the values of (a//aa')max

friction were calculated from these values of corrected as above and these reduced values

(a//as')max· These values are indicated by of ifJ were indicated by two solid horizon tal

hollow triangles in Fig. 7 and solid circles lines in Fig. 7 and two solid circles in Fig. 8.

in Fig. 8. The relationships between ifJ and The ranges of as' for these lines shown in

a 3 ' thus obtained look smoother and more Fig. 7 were taken to be the same with the

natural than the others. Probably, these ranges for the broken lines expediently. It

relations are very close to the true relations. may be seen in Fig. 7 that the values of ifJ

However, these relations may still involve thus obtained are quite similar to those

some, probably very small, errors due to values of ifJ obtained from the values of

the following causes. First, when a sample (a 1 '/as')max at the bottom of sample with

is long with the initial height to diameter being corrected for membrane forces by

ratio of 2. 1 as in this study it does not either Method I or Method III.

deform as a right cylinder even with the In summary, it may be concluded that

well lubricated ends, while the shape is more the true value of ifJ at extremely low

closer to a right cylinder than that in the values of as' lower than around 0. 1 kgf/cm 2

case of tests using regular or non-1 ubricated (10kN/m 2 ) may be very close to either the

ends. Furthermore, the horizontal shear values obtained from the values of (a 1 '/

stress at the top and bottom of sample is as') max at the bottom of sample corrected

NII-Electronic Library Service

STRENGTH AND DEFORMATION OF SAND 45

w 45~---,------,--~ different depths. Of course, due to the

w I DRAINED TRIAXIAL COMPRESSION TEST

a:

(.!) anisotropic nature of strength of sand the

-'UJ e 0 _3 =0.70

<c

zz 40- value of p may change with depth if the

ffi -_

~& I directions of principal stresses changes with

l); 35 depth. This point is beyond the scope of

w2

-lf-

(.!)U

SATURATED TOYOURA SAND, AIR-PLUVIATED this paper. The reason for very small or

e 0 _3 =VOID RATIO AT a' 0 =0_;__3_kgf/cm2

za:

<u.. 300.01 0.02 0.05 0.1 0.2 --0::"-:.5::-----'-1--2':--------!5

negligible dependency of p on the value of

EFFECTIVE MINOR PRINCIPAL STRESS AT(o;;o3>max,Oa (kgf/cm )

2

a 3 ' at extremely low pressures for Toyoura

Fig. 17. Summarized relationships between~

sand is not clarified yet. Further researches

and a 3 ' for e 0 • 3 =0.70 and 0.85 (lkgf/ will be needed.

cm 2 =98kNjm 2 )

for membrane forces by either Eq. (3) DEFORMATION CHARACTERISTICS

(Method I) or Eq. (5) (Method III) or the AT EXTREMELY LOW PRESSURES

values obtained by the correction method It may be seen from Figs. 5(a) through

based on the stress-dilatancy relations at

-6,-----r------r-------r----~

failure. The curves shown in Fig. 17 were DRAINED TRIAXIAL COMPRESSION TEST

obtained by averaging two relations obtained -5

SATURATED TOYOURA SAND, AIR-PLUVIATED

by these two methods above. It may be ;Jl" (a) c 8 =5% ____,CD"--®

_,.t0"-(m_m'-) @

l()

seen that the change of p with the change II" -4

to) {

0.1

0.12

0

t- 0.3.

of a 3 ' is quite small when a 3 ' is lower than <

...; -3

around 0. 5 kgf/cm 2 (49 kN/m 2). In particu- ~

>

a'3 AT Ca=5%, CORRECTED

BY METHOD Ill (kgf/cm2 )

lar, there is almost no change in the value ~ -2

a:

of p when a 3 ' is lower than around 0. 1 t-

en

u

kgfjcm 2 (10 kNjm 2). cc

t-

w

::E

Another important conclusion may be 3 0

0

·----:_J

obtained from Fig. 8. The relationships >

between p and a 3 ' represented by two solid

curves shown in Fig. 8 correspond to those 2

o~.6-----o-'-.7---------0-'---.8------0.9 1.0

shown in Fig. 17. From these curves, the 2

VOID RATIO AT a'c=0.3kgf/cm ,eo.3

values of p at a 3 ' =0. 0 can be reasonably

obtained by extrapolating these curves to

t 0 (mm) G) ® @

the points of a 3 ' =0. 0, which are p =42. 4

l 0.1 0 .~.

degrees for e0 . 3 =0. 70 and p =36. 1 degrees for

.

-b-

0.12

e0 . 3 =0. 85. This indicates that it is not 0.3 ..

necessary to introduce the apparent cohesion

intercept when the Mohr-Coulomb theory is

used for the data obtained by this investiga-

tion. Furthermore, it may be seen in Fig. 8

that when a 3 ' is represented in the arithmetic

scale the rate of the change of p with the

change of a/ does not change so much as

a 3 ' changes.

It seems that these conclusions can simplify

the analyses of model test results, because

these results suggest that the angle of VOID RATIO AT 0'0 =0.3kgf/cm 2 ,e 0_3

internal friction within a uniform model Fig. 18. Volumetric strain values at (a)

sand ground or slope is not needed to change ea=5% and (b) ea=lO% versus void

or is needed to change only slightly at ratio e 0 , 3 (lkgffcm 2 =98kN/m 2)

NII-Electronic Library Service

46 FUKUSHIMA AND TATSUOKA

§ -8 ,-~--.---- . ' compression be negligible. It may be seen

a: I DRAINED TRIAXIAL COMPRESSION TEST

~ _ .. SATURATED TOYOURA SAND, AIR-PLUVIA TED that for the data when (a 3 ') r equals 0. 1

6

II, I ----- e 0 .3=0.70, ta=10% kgffcm 2 or lower the effects of membrane

(.) I

1-

..: -4:·

I thickness on the values of v are negligible.

~> •

In Fig. 19 are plotted the values of v at

z -21-

ca=5% or 10% for e0 . 3 =0. 70 and 0. 85

<:

a:

:

1-

<J) O'

obtained from the relations indicated in

()

a:

1-

Figs. 18(a) and (b). It may be seen that

w

::;:

:::> 0.5

the trends of the change of v with the

g 0""3 CORRECTED BY METHOD Ill, MEASURED AT

!:a=5 OR 10% (kgf/cm 2 )

change of a 3 ' are very similar to those for

¢ shown in Fig. 17. Furthermore, in Fig. 1

Fig. 19. Volumetric strain values at ea=

20 are shown the relationship between axial

5% or 10% versus a 3' for e 0 • 3 =0. 70

and 0. 85 (lkgfjcm 2=98kN/m 2) strain values observed at a 1 '/a 3 '=3 or 4 and

a 3 ' which were obtained by the procedure

similar to that used to make Fig. 19. In

@~ 4

[ SATURATED TOYOURA SAND, AIR-PLUVIATED.

Fig.20, the value of a1'/aa' and a3 ' are

~ ~ !

II t-

~ ~ ·i

I

those at the mid-height of sample corrected

for membrane forces by Method III. It may

(.) I,

...,. ~ 10 3

; eo.3=0.70

g ~ ~- I 'eo;;o:i =4 be seen in Fig. 20 that the changes of the

"' ~ ~ 'j + eo.3=0.85 ~ 0-;;--~~

11 u.. o 2- 0 -10 ·= 3 ! __u'2~~ , value of ta thus defined with the change of

•t;O ~- I 1 3 ' "'-

.;,~ ~ I

a 3 ' are virtually smaller when a/ is less

0 - a:

r \

-+

~-~~1r- -~--+- .J than around 0. 5 kgf/cm 2 (50 kN/m 2),

< b

~-.::;:1

LlJ I

- ~0

____..o--1

~'2 ~ a: I I especially when a 3 ' is less than around 0. 1

:J ~ f2 QL

I, ':::::.J=-o---'

...J..__---...J. ' _]

I

kgf/cm 2 (10 kN/m 2 ). This trend seems to

0.01 0.02 0.05 0.1 0.2 0.5 2 5

<J '3 AT c;; 0 3 = 3 OR 4 CORRECTED BY METHOD Ill (kgf I cm 2 ) correspond very well to that seen in both

Fig. 20. Axial strain values at 0'1 '/q3 ' =3 or Figs. 17 and 19. These results shown in

4 versus a a' for e 0 . 3 =0. 70 and 0. 85 with Figs. 19 and 20 may support the conclusions

stresses being corrected for membrane with respect to ¢ obtained by this

forces by Method III(lkgfjcm2=98kN/m2) investigation, because the deformation

characteristics of normally consolidated sand

(d) that the volumetric strain-axial strain samples are in general closely related to their

curves show small differences at different strength characteristics.

confining pressures when ac' is around 0. 1 It may be seen in Fig. 19 that the tendency

kgf/cm 2 or lower, while at higher stresses of volume expansion when aa' is lower than

this difference increases with the increase around 0. 1 kgf/cm 2 is slightly larger than as

in confining pressure. In Figs. 18(a) and (b) expected from the smooth change of volume

are plotted the values of volumetric strain change with the change of a 3 ' which are

v at an axial strain ca of 5% or 10% indicated by broken lines. This tendency

against the values of e0 . 3 • Any corrections may be attributed to the strain hardening

to measured values of ca and v were not caused before the start of shearing. It is

made for bedding errors for the data shown very likely that this kind of strain hardening

in Figs. 18(a) and (b) and the following induced some amount of volume decrease

:figures. Since rather large strain values are due to shear deformation, which is larger

presented in these :figures, it can be for a looser sample. This kind of extra

considered that the effects of bedding error volume decrease can be induced under the

on the relationships shown in these :figures anisotropic stress conditions during the

be rather small. Also it was considered that stages of the setting of cap and membrane

the volume change due to the change of and the saturation of sample. When triaxial

effective confining pressure during triaxial compression tests are performed at a pressure

NII-Electronic Library Service

STRENGTH AND DEF.ORMATION OF SAND 47

of .as low as 0. 02~0. 05 kgf/cm 2, the effects things being equal. In particular, the

of this kind of strain hardening may still change of ¢> with the change of a 3 ' was

be preserved in the deformation properties found to be very small at a 3 ~' lower than

of the sample in the beginning of triaxial around 0. 1 kgf/cm 2 C9. 8 kN/m 2 ). In using

compression, resulting in decreasing the the Mohr-Coulomb failure criterion for

tendency of volume decrease or increasing the saturated Toyoura sand, it is not needed to

tendency of volume expansion. Therefore, introduce the apparent cohesion intercept,

it seems that if the strain hardening using reasonable values of ¢> which decreases

described above were not caused before the slightly at a rather constant rate as a 3 '

start of triaxial compression, the volume increases.

change characteristics at a 3 ' less than around ( 3) The deformation characteristics at

0. 1 kgfjcri:1 2 would have been such ones as large strains of saturated Toyoura sand

indicated by broken lines shown in Fig. 19. change only slightly with the change of

Further researches will be needed to answer a 3 ' when as' is lower than around 0. 5 kg£/

this question· after improving the testing cm 2 (50 kN/m 2 ), especially when 0" 3 ' is lower

method more. than around 0. 1 kgfjcm 2 (10 kN/m 2). This

Furthermore, it may be seen in Fig. 20 phenomenon corresponds well to such a

that the axial strain values are larger for trend in ¢> as described above.

smaller values of a 3 ' when a 3 ' is less than

around 0. 05 kgf/cm 2• This may correspond

to the fact that the value of stress ratio ACKNOWLEDGEMENTS

a 1 '/a 3 ' or ¢> obtained at the mid-height of The major part of this investigation was

sample are underestimated ones as the performed as a part of the Doctor of

maximum values of a//a 3 ' within a sample Engineering thesis work of the first author

at an extremely low stress. Further at the Institute of Industrial Science, the

researches will also be needed m this University of Tokyo, with the cooperations

respect. provided by Mr. 0. Tadokoro, undergraduate

student of the University of Nihon. The

authors gratefully acknowledge the helpful

CONCLUSIONS discussions of Dr. F. Molenkamp, Delft Soil

The angle of internal friction ¢>=arcsin Mechanics Laboratory, the Netherlands,

{Ca1'- a3 ')/ Ca 1 ' +a 3 ') }max of saturated Toyoura which were very useful to increase the

sand and its deformation characteristics at accuracy of our testing methods. The staff

extremely low pressures were measured by members of the central workshop of the

the conventional drained triaxial compression Institute fabricated the major parts of the

tests while paying great cautions to stress apparatuses with the cooperations provided

measurements. On the basis of the limited by Messrs. T. Sato and S. Yamada, colleagues

number of tests reported in this paper, the of the authors. Miss M. Torimitsu helped

following were found : the authors with preparing the draft. The

( 1) To obtain accurate values of ¢> at authors are indebted to their colleagues

extremely low pressures, the effects of both above. Financial support provided by the

membrane forces and self-weight of sample Ministry of Education IS also greatly

should be properly accounted for in calculat- acknowledged.

ing stresses within a sample.

C2 ) The angle of internal friction of

saturated Toyoura sand does not change so REFERENCES

much with the change of the minor l)Berre, T. (1982) : "Triaxial testing at the Nor-

principal stress a 3 ' when a 3 ' is lower than wegian Geotechnical Institute," Geotechnical

around 0. 5 kgfjcm 2 (50 kN/m 2 ) , all other Testing Journal, ASTM, Vol. 5, No.l/2,

NII-Electronic Library Service

48 FUKUSHIMA AND T A TSUOKA

March/June, pp. 3-17. 6)Ponce, V. M. and Bell, J. M. (1971) : "Shear

2)Duncan, J. M. and Seed, H. B. (1967) : "Correc- strength of sand at extremely low pressures,"

tions for strength test data," Jour. SM Div., Jour. of SMF Div., Proc. of ASCE, Vol. 97,

Proc. ASCE, Vol. 93, No. SM 5, pp.121-137. No. SM 4, April, pp. 625-638.

3)Fukushima, S. (1982) : "Experimental study on 7)Stroud, M.A. (1971) : "The behaviour of sand at

deformation and strength characteristics of sand low stress levels in the simple-shear apparatus, "

by torsional shear tests," Doctor of Eng. The- A dessertation submitted for the degree of Ph.

sis, University of Tokyo (in Japanese). D. at Cambridge Univ.

4)Henkel, D. J. and Gilbert, G. C. (1952) : "The ef- 8)Tatsuoka, F. (1981) : "A simple method for auto-

fect of rubber on the measured triaxial compres- matic measurement of volume change in labora-

sion strength of clay samples, " Geotechnique, tory tests," Soils and Foundations, Vol. 21, No.

Vol. 3, pp. 20-29. 3, pp. 104-105.

5)Molenkamp, F. and Luger, H. J. (1981) : "Model- 9)Tatsuoka, F., Molenkamp, F., Torii, T. and

ling and minimization of membrane penetration Hino, T. (1984) : "Behavior of lubrication layers

effects in tests on granular soils," Geotechnique, of platens in element tests," Soils and Founda·

Vol. 31, No.4, pp. 471-486. tions, Vol. 24, No.1, pp. 113-128.

NII-Electronic Library Service

You might also like

- 2D 1 Tutorial (090 190)Document101 pages2D 1 Tutorial (090 190)Kate MartinezNo ratings yet

- Ship Magnetism and the Magnetic Compass: The Commonwealth and International Library of Science, Technology, Engineering and Liberal Studies: Navigation and Nautical CoursesFrom EverandShip Magnetism and the Magnetic Compass: The Commonwealth and International Library of Science, Technology, Engineering and Liberal Studies: Navigation and Nautical CoursesRating: 5 out of 5 stars5/5 (3)

- 2D 1 Tutorial (090 206)Document117 pages2D 1 Tutorial (090 206)Kate MartinezNo ratings yet

- PLAXIS 2D 2017-Tutorial-Lesson06Document9 pagesPLAXIS 2D 2017-Tutorial-Lesson06Ibrahim AlemNo ratings yet

- 919 002Document5 pages919 002Bell drumNo ratings yet

- 1 s2.0 S0038080620320205 MainDocument15 pages1 s2.0 S0038080620320205 MainJORGE ANTONIO ANAYA QUISPENo ratings yet

- TN010 - Raft FootingDocument2 pagesTN010 - Raft FootingStar HONo ratings yet

- A Method For Calculating The Undrained Strength Ratio Cu P - 1981 - Soils andDocument7 pagesA Method For Calculating The Undrained Strength Ratio Cu P - 1981 - Soils andfabian valenciaNo ratings yet

- Direct-Tensile Stress and Strain of A Cement-Stabilized SoilDocument6 pagesDirect-Tensile Stress and Strain of A Cement-Stabilized Soilgodfrey kiyinjaNo ratings yet

- On The Size of Drops in Pulsed and VibratingDocument4 pagesOn The Size of Drops in Pulsed and VibratingArunNo ratings yet

- PLAXIS 2D 2018 Tutorial Lesson07Document9 pagesPLAXIS 2D 2018 Tutorial Lesson07Vu Thuygiang100% (1)

- '$fi O&M: Fig. 8-Evolution Ofjield Stresses and Slumps Versus Time. Concrete B4 (CF: Table 4)Document6 pages'$fi O&M: Fig. 8-Evolution Ofjield Stresses and Slumps Versus Time. Concrete B4 (CF: Table 4)Moezselmi.12 SelmiNo ratings yet

- Figure 2.1 Top View of The Excavation Pit: 5.0 M 5.0 M 5.0 M 5.0 MDocument13 pagesFigure 2.1 Top View of The Excavation Pit: 5.0 M 5.0 M 5.0 M 5.0 MM Shourav hasanNo ratings yet

- PLAXIS - 3D2017 Tutorial Lesson 02 Excavation - in - SandDocument13 pagesPLAXIS - 3D2017 Tutorial Lesson 02 Excavation - in - SandAndrew WinnerNo ratings yet

- 09 Site Investigations IIIDocument13 pages09 Site Investigations IIIAlvaro B. Galarce JerezNo ratings yet

- Stress StrainDocument18 pagesStress StrainpkNo ratings yet

- 1 s2.0 S0038080620323106 MainDocument17 pages1 s2.0 S0038080620323106 MainUdo SantosNo ratings yet

- Sunneset & Al (1989) - Evaluation of Soil Parameters FromDocument14 pagesSunneset & Al (1989) - Evaluation of Soil Parameters FromJennifer MillerNo ratings yet

- Compression and Consolidation of Powder SolidsDocument40 pagesCompression and Consolidation of Powder Solidspayal_patil_4100% (3)

- 32 Pile Desing Clay Soils PDFDocument23 pages32 Pile Desing Clay Soils PDFSebastian TrescureNo ratings yet

- Skempton - Standard Penetration Test Procedures and Effects in Sands of Overburden, Relative Density, Ageing and OverconsolidationDocument23 pagesSkempton - Standard Penetration Test Procedures and Effects in Sands of Overburden, Relative Density, Ageing and OverconsolidationDEBASIS100% (3)

- Bearing Capacity CalculationDocument7 pagesBearing Capacity CalculationPrince QuimnoNo ratings yet

- NormalLightWeigthConcrete PDFDocument12 pagesNormalLightWeigthConcrete PDFPabloNo ratings yet

- Corrosion Fatigue Behaviour of B R A S S in Aqueous SolutionsDocument9 pagesCorrosion Fatigue Behaviour of B R A S S in Aqueous SolutionsVaishnavi SinghNo ratings yet

- Rohini 63373629893Document15 pagesRohini 63373629893Samer elkhederNo ratings yet

- CTC SITE INVESTIGATION and Geotechnical DesignDocument30 pagesCTC SITE INVESTIGATION and Geotechnical DesignAmr SamyNo ratings yet

- Soil Exploration Part 2 and 3Document38 pagesSoil Exploration Part 2 and 3naman.h.cogniNo ratings yet

- LLLLLL,, TP: 9lROE NE MDocument21 pagesLLLLLL,, TP: 9lROE NE MLarvalNo ratings yet

- Design of FoundationDocument53 pagesDesign of FoundationYaselaNo ratings yet

- Triple-Fluid Evaluations Using Density, Neutron, and Electromagnetic Propagation LogsDocument12 pagesTriple-Fluid Evaluations Using Density, Neutron, and Electromagnetic Propagation Logsdebashis22mNo ratings yet

- Forum: Estimating Flow Efficiency From Afterflow..Distorted Pressure Buildup DataDocument2 pagesForum: Estimating Flow Efficiency From Afterflow..Distorted Pressure Buildup DataGermania ManchenoNo ratings yet

- TE H Ical Notes: (A) AftDocument5 pagesTE H Ical Notes: (A) AftCustódio MiguensNo ratings yet

- Design of Monopile Foundations For Offshore Wind eDocument11 pagesDesign of Monopile Foundations For Offshore Wind eThanh Đạt NguyễnNo ratings yet

- Quay Walls - Combined - Wall - Buckling - TubesDocument12 pagesQuay Walls - Combined - Wall - Buckling - TubesHugo LeiteNo ratings yet

- 3583.PLAXIS - 2D - CEV22.01 - Tutorial - 05 - Excavation of An NATM TunnelDocument14 pages3583.PLAXIS - 2D - CEV22.01 - Tutorial - 05 - Excavation of An NATM TunnelPhalgun MoturuNo ratings yet

- Uplift Resistrance of Deep Vertical Anchor in Sand - Braja, SeeleyDocument5 pagesUplift Resistrance of Deep Vertical Anchor in Sand - Braja, SeeleyHarry MohamedNo ratings yet

- Geotechnical Investigation Advanced ReportDocument7 pagesGeotechnical Investigation Advanced ReportGicco CastorNo ratings yet

- 1 s2.0 S0038080620323799 MainDocument6 pages1 s2.0 S0038080620323799 Maingodfrey kiyinjaNo ratings yet

- Case Studies of Cptu Exploration Techniques in Investigating Challenging Ground Conditions in MalaysiaDocument6 pagesCase Studies of Cptu Exploration Techniques in Investigating Challenging Ground Conditions in Malaysiajinwook75No ratings yet

- Effects of Plasticity and Sample Disturbance On Statistical Properties of UndrainedDocument11 pagesEffects of Plasticity and Sample Disturbance On Statistical Properties of UndrainedthalesgmaiaNo ratings yet

- T Sting Swede : Be Ore AtigueDocument2 pagesT Sting Swede : Be Ore AtiguecmkohNo ratings yet

- PED I Book Part 1Document27 pagesPED I Book Part 1RADHE GRAPHICSNo ratings yet

- Undrained Deformation and Liquefaction of Sand Under Cyclic StressesDocument16 pagesUndrained Deformation and Liquefaction of Sand Under Cyclic StressesAVIK SAHANo ratings yet

- Damgaard - Anderson - 2012 - Natural Frequcmy and Damping Estimation of An OWT StructureDocument8 pagesDamgaard - Anderson - 2012 - Natural Frequcmy and Damping Estimation of An OWT StructureIWINOSA AGHEDONo ratings yet

- 61 The Struc Eng Vol74 3Document1 page61 The Struc Eng Vol74 3daylight888No ratings yet

- Stability of Cubes, Tetrapods and Accropode: January 1988Document11 pagesStability of Cubes, Tetrapods and Accropode: January 1988romeoremoNo ratings yet

- PLAXIS - 3D2018 Tutorial Lesson 07Document12 pagesPLAXIS - 3D2018 Tutorial Lesson 07Brahan SevillanoNo ratings yet

- Cam Clay PDFDocument9 pagesCam Clay PDFAUSTIN ZHANGNo ratings yet

- N) - The Blow Count Is: 5.5 Drained and Undrained Loading Conditions Via FemDocument9 pagesN) - The Blow Count Is: 5.5 Drained and Undrained Loading Conditions Via FemAUSTIN ZHANGNo ratings yet