Professional Documents

Culture Documents

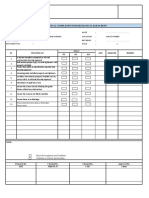

Checklist For Plastering

Checklist For Plastering

Uploaded by

ogbo deinmone0 ratings0% found this document useful (0 votes)

8 views2 pagesThis document is a checklist for plastering that contains standards to check for pre-plastering preparation, cement mortar mixing and application during plastering, and final plastering finishes. It includes items like ensuring sufficient level pegs, protection of installed components, using the correct mortar mix ratio, maintaining thickness and verticality during application, and achieving a visually smooth surface without defects upon completion.

Original Description:

Original Title

CHECKLIST FOR PLASTERING

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document is a checklist for plastering that contains standards to check for pre-plastering preparation, cement mortar mixing and application during plastering, and final plastering finishes. It includes items like ensuring sufficient level pegs, protection of installed components, using the correct mortar mix ratio, maintaining thickness and verticality during application, and achieving a visually smooth surface without defects upon completion.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

8 views2 pagesChecklist For Plastering

Checklist For Plastering

Uploaded by

ogbo deinmoneThis document is a checklist for plastering that contains standards to check for pre-plastering preparation, cement mortar mixing and application during plastering, and final plastering finishes. It includes items like ensuring sufficient level pegs, protection of installed components, using the correct mortar mix ratio, maintaining thickness and verticality during application, and achieving a visually smooth surface without defects upon completion.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 2

PLASTERING

Doc No: LEL-OPD-PLC-001

CHECKLIST

PROCESS: OPERATIONS Rev No: 00

Originator: Doc Type:

Date: Page 1 of 2

ACM CHK

PROJECT…………………………………………………………………………

……………………….

NO STANDARD CHECK REMARK

A PRE-PLASTERING PREPARATION Y☐ N ☐ NA ☐

1 Sufficient level pegs provided Y☐ N ☐ NA ☐

2 All first fixed joinery items are fixed accordingly Y☐ N ☐ NA ☐

3 All concealed M&E services are complete and ready Y☐ N ☐ NA ☐

4 Protection provided to installed components Y☐ N ☐ NA ☐

5 Mortar spread on wall yet to be plastered is cleaned Y☐ N ☐ NA ☐

6 Architectural item such as corner beads, u-groove, Y☐ N ☐ NA ☐

coping, are completed prior to plastering

7 All finished works are well protected prior to Y☐ N ☐ NA ☐

plastering work

B CEMENT MORTAR MIX & DURING

PLASTERING

1 Correct and clean sand material is used with Y☐ N ☐ NA ☐

plastering cement mortar mix ratio as per

specification

2 Adequate lighting provided at work area Y☐ N ☐ NA ☐

3 Verticality and minimum thickness for plastering is Y☐ N ☐ NA ☐

maintained

4 Where applicable cement slurry or lime finish is Y☐ N ☐ NA ☐

done after all minor unevenness is covered by rough

finish in thin layers

5 Plastering is started from the top and gradually Y☐ N ☐ NA ☐

worked downwards

6 Mortar is consumed within the initial setting time for Y☐ N ☐ NA ☐

cement of not more than 30 minutes

7 Plastering is roughened with stick broom/brush for Y☐ N ☐ NA ☐

area where second layer of plastering is specified

8 For joints to be left it is cut straight with edges Y☐ N ☐ NA ☐

chamfered

C FINAL PLASTERING FINISHES

1 Visually acceptable smooth surface with no scratches Y☐ N ☐ NA ☐

2 Checked the evenness Y☐ N ☐ NA ☐

3 Check there is no surface damage or cracks and Y☐ N ☐ NA ☐

surface is free from major defect

PLASTERING

Doc No: LEL-OPD-PLC-001

CHECKLIST

PROCESS: OPERATIONS Rev No: 00

Originator: Doc Type:

Date: Page 2 of 2

ACM CHK

COMPANY REP CLIENT REP

Checked & signed Checked &

signed

You might also like

- Leadership and Self-Deception Study Guide 1.0Document71 pagesLeadership and Self-Deception Study Guide 1.0Lito Dif80% (5)

- Emirates Interview Questions and Answers 20429Document13 pagesEmirates Interview Questions and Answers 20429Jumana Drici100% (1)

- Method Statement For Field Erection Storage TanksDocument29 pagesMethod Statement For Field Erection Storage TanksTee Klong Rung100% (1)

- Mtcna - Training - materials-JAN 2023Document353 pagesMtcna - Training - materials-JAN 2023Giovanni Kuncara100% (1)

- FM-1184-202-13A REV 002 Inspection Record For Painting SystemDocument1 pageFM-1184-202-13A REV 002 Inspection Record For Painting SystemWalidNo ratings yet

- Method Statement For Piping InstallationDocument9 pagesMethod Statement For Piping Installationคุณพ่อน้อง บิ๊กบอส100% (12)

- 1) JOB PROCEDURE For Tank Fabrication and Erection of HPCLDocument15 pages1) JOB PROCEDURE For Tank Fabrication and Erection of HPCLsenthilkumarsk88% (8)

- Job Procedure For Eriction of TankDocument13 pagesJob Procedure For Eriction of TankAnonymous i3lI9M100% (2)

- Blasting and Painting ProcedureDocument9 pagesBlasting and Painting Procedureisukuru67% (12)

- Epic For Upgrade of Port Control Tower and Systems at Rlic: Inspection Checklist For Painting WorksDocument4 pagesEpic For Upgrade of Port Control Tower and Systems at Rlic: Inspection Checklist For Painting Workssree100% (1)

- Ex ServicemenDocument3 pagesEx Servicemensriprak100% (4)

- Checklist For Concrete PlacementDocument2 pagesChecklist For Concrete Placementogbo deinmoneNo ratings yet

- Tank Fabrication ProcedureDocument11 pagesTank Fabrication ProcedureNurul100% (2)

- Mechanical Check List Pumps.R5Document2 pagesMechanical Check List Pumps.R5Armando BiringkanaeNo ratings yet

- Inspection Check List For Rectification of Defect No. E398Document2 pagesInspection Check List For Rectification of Defect No. E398Aous H100% (1)

- Cocrete Pour Card 3Document1 pageCocrete Pour Card 3Anil UdaleNo ratings yet

- Checklist For PCCDocument2 pagesChecklist For PCCShyam SutharNo ratings yet

- Procedure Fabrikasi TankiDocument10 pagesProcedure Fabrikasi TankiMuhammad Yunus NurdinNo ratings yet

- Shop Fabrication Procedure (Supply of Tank Option#3) PDFDocument7 pagesShop Fabrication Procedure (Supply of Tank Option#3) PDFGATOTNo ratings yet

- VD-LINE-WP57-SUB-ATM-0001-017 - ERECTION AND INSTALLATION PROCEDURE ATM TANK - Rev.1Document18 pagesVD-LINE-WP57-SUB-ATM-0001-017 - ERECTION AND INSTALLATION PROCEDURE ATM TANK - Rev.1tomy.jipNo ratings yet

- Cube Format1Document2 pagesCube Format1jyothis_joy8315No ratings yet

- New Bottom PlateDocument9 pagesNew Bottom PlateEmmanuel kusimo100% (1)

- TRN-0203 Approval-BDocument8 pagesTRN-0203 Approval-BrayNo ratings yet

- Concrete Finishing and CuringDocument13 pagesConcrete Finishing and CuringrayNo ratings yet

- LS - prt.TUB.067 Stabilizer InspectionDocument4 pagesLS - prt.TUB.067 Stabilizer InspectionAlphonse YACKAMAMBO DIBACKANo ratings yet

- Final Inspection Release Note: Rawae Al Amal Industrial ServicesDocument1 pageFinal Inspection Release Note: Rawae Al Amal Industrial ServicesJamal Mohamed RahamathullahNo ratings yet

- Blasting Painting ProcedureDocument4 pagesBlasting Painting ProcedureRyanNo ratings yet

- Checklist1301 - Plastering WorkDocument1 pageChecklist1301 - Plastering WorkAdlanAbushibaNo ratings yet

- Installation & Testing of Above Ground Sewer& Storm PipingDocument11 pagesInstallation & Testing of Above Ground Sewer& Storm Pipinghamoda mansourNo ratings yet

- SOC Alerada H13-6 MSI+MTI Logging Procedure TGT 03.11.2022 Rev2Document11 pagesSOC Alerada H13-6 MSI+MTI Logging Procedure TGT 03.11.2022 Rev2mohanedNo ratings yet

- 4.repairing For Concrete Structure MethodologyDocument4 pages4.repairing For Concrete Structure MethodologyEyutt Hghgh100% (1)

- 1.PNRI - System Startup & Shutdown - Rev.0.0Document16 pages1.PNRI - System Startup & Shutdown - Rev.0.0Lê Xuân Cương100% (1)

- Fabrication and Erection ProcedureDocument13 pagesFabrication and Erection ProcedureshivanshsovNo ratings yet

- Jacking Procedure PDFDocument14 pagesJacking Procedure PDFmanish pathrabeNo ratings yet

- Quality Management System: Work Instruction For Roll Inspection and Turning A. New Rolls: InspectionDocument2 pagesQuality Management System: Work Instruction For Roll Inspection and Turning A. New Rolls: InspectionsourajpatelNo ratings yet

- LS - prt.TUB.069 Shop Inspection of Surface Safety Valve Kelly Valve, and Inside Blowout PreventersDocument6 pagesLS - prt.TUB.069 Shop Inspection of Surface Safety Valve Kelly Valve, and Inside Blowout PreventersAlphonse YACKAMAMBO DIBACKANo ratings yet

- Checklist For Setting OutDocument2 pagesChecklist For Setting Outogbo deinmoneNo ratings yet

- Jms Site Preparation - RGTP p20220019 Esb Con Jms 9243 0001Document11 pagesJms Site Preparation - RGTP p20220019 Esb Con Jms 9243 0001amir hakimNo ratings yet

- Internal Plastering 16Document1 pageInternal Plastering 16manish260320No ratings yet

- Method Statement For Roof Lifting by Jacks (REV0) FINAL M13Document13 pagesMethod Statement For Roof Lifting by Jacks (REV0) FINAL M13مصطفى هشامNo ratings yet

- Ppi Convert Loading Test Plate BearingDocument12 pagesPpi Convert Loading Test Plate BearingFrans ManurungNo ratings yet

- IMSB-AR-CL-003 SkimcoatDocument1 pageIMSB-AR-CL-003 SkimcoatShan THALANo ratings yet

- Bluskies Engineering PVT LTD: Acp Panel Inpection ReportDocument7 pagesBluskies Engineering PVT LTD: Acp Panel Inpection ReportRavi Shankar KolluruNo ratings yet

- ASSEMBLY Rev00Document48 pagesASSEMBLY Rev00kumar.arunk6784No ratings yet

- Installation Manual - GISDocument28 pagesInstallation Manual - GISTheerawut Wongyai100% (1)

- 11-KU-TWK-50-QA-PRO-2173 - 0 - Wrapping ProcedureDocument8 pages11-KU-TWK-50-QA-PRO-2173 - 0 - Wrapping ProcedureAvak NishanNo ratings yet

- Construction Method by Jack UpDocument23 pagesConstruction Method by Jack UpMikiRoniWijaya100% (1)

- WMS Concrete Repair WorkDocument8 pagesWMS Concrete Repair WorkRepl microsoft, PuneNo ratings yet

- Cco-Ng1810100032c-Gen-Cx7753-00001-A01-Cs Installation WorksDocument19 pagesCco-Ng1810100032c-Gen-Cx7753-00001-A01-Cs Installation WorksToreson OfuafoNo ratings yet

- F 321 Inspection Request For Back FillingDocument1 pageF 321 Inspection Request For Back FillingSaad Al Deen HashemNo ratings yet

- Method Statement For In-Situ Pull Off Test On MarbleDocument15 pagesMethod Statement For In-Situ Pull Off Test On MarbleGary Lo67% (3)

- LS - prt.TUB.066 Shop Inspection Underreamer, Hole Opner, and RollerDocument5 pagesLS - prt.TUB.066 Shop Inspection Underreamer, Hole Opner, and RollerAlphonse YACKAMAMBO DIBACKANo ratings yet

- Checklist 16 Blasting and Painting Including Use of EtcDocument3 pagesChecklist 16 Blasting and Painting Including Use of EtcFatin ZulkifliNo ratings yet

- LS - prt.TUB.064 Shop Inspection of LWD - MWDDocument4 pagesLS - prt.TUB.064 Shop Inspection of LWD - MWDAlphonse YACKAMAMBO DIBACKANo ratings yet

- NIBprime Failed Due To Deactivation Bottle Buffer 25 Aug 21Document4 pagesNIBprime Failed Due To Deactivation Bottle Buffer 25 Aug 21Shweta YadavNo ratings yet

- 05 Checklist C&S RC Work (General)Document6 pages05 Checklist C&S RC Work (General)Aldi mubaroq100% (1)

- Gel Sop GBP 02Document8 pagesGel Sop GBP 02Rehman FaisalNo ratings yet

- 18.yohkorei-Mos-Installsmokeducting Work 20231027Document36 pages18.yohkorei-Mos-Installsmokeducting Work 20231027dad dadNo ratings yet

- Final Report - 1721-V-0905 BDocument5 pagesFinal Report - 1721-V-0905 BvivekNo ratings yet

- BX Test Spec TSEL0066Document12 pagesBX Test Spec TSEL0066Jim SharpNo ratings yet

- Design Guidelines for Surface Mount TechnologyFrom EverandDesign Guidelines for Surface Mount TechnologyRating: 5 out of 5 stars5/5 (1)

- Pressuremeter Testing: Methods and InterpretationFrom EverandPressuremeter Testing: Methods and InterpretationRating: 5 out of 5 stars5/5 (2)

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

- CE 441 Foundation Engineering 05 07 2019Document216 pagesCE 441 Foundation Engineering 05 07 2019Md. Azizul Hakim100% (1)

- Svga DatabaseDocument220 pagesSvga DatabaseJigs2009No ratings yet

- Skype B2B Business ModelDocument6 pagesSkype B2B Business ModelAjay YadavNo ratings yet

- HID ReaderDocument3 pagesHID ReaderLogan FlintNo ratings yet

- COMSATS University Islamabad Lahore Campus: Midterm Terminal Examination - Fall 2021Document9 pagesCOMSATS University Islamabad Lahore Campus: Midterm Terminal Examination - Fall 2021NABEEL AHMADNo ratings yet

- Rutter VDR and SVDR Spares ListDocument4 pagesRutter VDR and SVDR Spares ListAkhil ViswanathanNo ratings yet

- Code First Migrations With The Entity Framework in An ASPDocument11 pagesCode First Migrations With The Entity Framework in An ASPmetro gNo ratings yet

- Go Fin 126 07 pg323Document1 pageGo Fin 126 07 pg323Varuna VandanaNo ratings yet

- Stem Opt - 2016-04828Document300 pagesStem Opt - 2016-04828satkabeer654No ratings yet

- Takashima Ekidan PDFDocument347 pagesTakashima Ekidan PDFtranszen100% (1)

- Gar-Dur UHMW Profile ExtrusionsDocument2 pagesGar-Dur UHMW Profile ExtrusionsGarlandMfg100% (1)

- V-2154-101-A-111 - 0A Method Statement Stairway Tank InstallationDocument24 pagesV-2154-101-A-111 - 0A Method Statement Stairway Tank InstallationWidya PrasetyaNo ratings yet

- Class 9 History CH 4Document6 pagesClass 9 History CH 4Yash PlayNo ratings yet

- Dublin Core Metadata Element SetDocument6 pagesDublin Core Metadata Element SetCursoBD2008No ratings yet

- Sharp r-5970Document20 pagesSharp r-5970Unu DecebalNo ratings yet

- Preparing Conduct An Observation and InterviewDocument10 pagesPreparing Conduct An Observation and InterviewRatu GarethaNo ratings yet

- Inventive Pricing of Urban Public TransportDocument19 pagesInventive Pricing of Urban Public TransportSean100% (1)

- PBL20 Project Compal Confidential: LA-6772P Schematic REV 1.0Document45 pagesPBL20 Project Compal Confidential: LA-6772P Schematic REV 1.0Ramdas KambleNo ratings yet

- Content: Your First Web Application With VFPDocument23 pagesContent: Your First Web Application With VFPFlavio FalcãoNo ratings yet

- User Manual Reports FINGate PortalDocument103 pagesUser Manual Reports FINGate PortalAbhinav BharadwajNo ratings yet

- MRP - Scenario User Guide: December, 2006Document22 pagesMRP - Scenario User Guide: December, 2006Sameh RadwanNo ratings yet

- Osurnia Epar Product Information - en PDFDocument19 pagesOsurnia Epar Product Information - en PDFVicentiu PredescuNo ratings yet

- Corporate Social Responsibility and Creating Shared Value: Case of LatviaDocument7 pagesCorporate Social Responsibility and Creating Shared Value: Case of LatviaDhiya UlhaqNo ratings yet

- Hvac Resume SkillsDocument6 pagesHvac Resume Skillsg1hulikewes2100% (2)

- 2.2 Ca 21mca3001Document8 pages2.2 Ca 21mca3001Humanshi JangraNo ratings yet

- Foxit PDF Editor ManualDocument204 pagesFoxit PDF Editor ManualRochmat Dwi Karwanto50% (2)