Professional Documents

Culture Documents

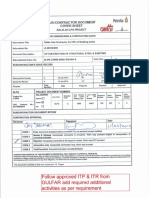

I1912 Ai Opr JC 0070 00 JC For Pelmet Work

Uploaded by

Aiplshubh ChavanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

I1912 Ai Opr JC 0070 00 JC For Pelmet Work

Uploaded by

Aiplshubh ChavanCopyright:

Available Formats

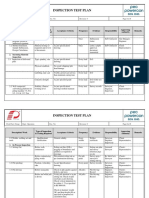

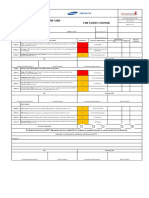

DAIS Extention Project

I1912-AI-OPR-JC-00-00

JOB CARD Rev. No. 00

Pelmet Work

Page 01 of 01

Location Date of Inspection:

Grid and level Time of Inspection:

Measurement

Sr. No Before Starting Construction Importance Tolerance/ Requirements Remarks/ Comments

SUB LIN RIL

Preparation and Approval of method statement/shop drawing (Evaluate and write 0 for non confirming or 1 for 1 GFC Drawing/Method

1

confirming) statement/Shop Drawing

2 Accessibility: Safe access to area visually (Evaluate and write 1 to 5) 4 Take 5 to be completed

3 Safety : Adequate safety precautions being taken place, green tag is in place and valid (Evaluate and write 1 to 5) 4 Take 5, Permits

MEP services are completed as per drawings and clearance taken to proceed further activities . (Evaluate and write 0

4 1 GFC Drawing

for non confirming or 1 for confirming)

AIPL LIN RIL

Activity Owner QA/QC Site Engineer QA/QC Construction Representative QA/QC Engineer

Measurement

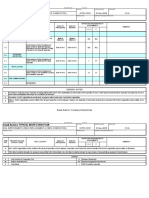

Sr. No Pre-Installation of Aluminium Frame Importance Tolerance/ Requirements Remarks/ Comments

SUB LIN RIL

Ensure all material are inspected before use i.e. aluminum pipe, plywood and Gypsum board.. (Evaluate and write 0 1

1 MIR

for non confirming or 1 for confirming)

AIPL LIN RIL

Activity Owner QA/QC Site Engineer QA/QC Construction Representative QA/QC Engineer

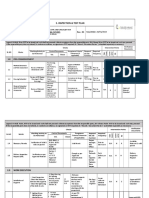

Measurement

Sr. No During Installation- Importance Tolerance/ Requirements Remarks/ Comments

SUB LIN RIL

1 Cutting aluminum pipe as per required length & sizes (Evaluate and write 1 to 5) 4 GFC/Shop Drawings

Shop Drawings / Measuring

2 making pelmet required lenth of size with L angle & screws (Evaluate and write 1 to 5) 4

tape

Check for MEP work chiseling done before frame installation and take confirmation from PMC/Client team for 1

3 Visual

further final fixing of Frame (Evaluate and write 0 for non confirming or 1 for confirming)

Fixing of aluminum framework on ceiling with L angle cleats, screws & hardware

4 Cleats fixing pelmet with ceiling to be fixed as per show in shop drawing (Evaluate and write 1 to 5) 4 GFC/Shop Drawings/Visual

Placing of desired thickness plywood on aluminium work as per actual site dimensions and GFC drawings before

5 4 GFC/Shop Drawings/Visual

final fixtures (Evaluate and write 1 to 5)

Ensure all MEP works are completed and recorded instruction is provided by PMC/ Client before closure of pelmet

6 1 GFC/Shop Drawings/Visual

work with gypsum (Evaluate and write 0 for non confirming or 1 for confirming)

Fixing of ply of desired thickness as per GFC drawing to its respective location with self-drilling zinc plated screw.

7 4 GFC/Shop Drawings/Visual

(Evaluate and write 1 to 5)

8 Fixing of Gypsum board with 25x6 gypsteel screw. (Evaluate and write 1 to 5) 4 GFC/Shop Drawings/Visual

9 Fixing of fiber tape at joints and finishing the same with Approved jointing compound. (Evaluate and write 1 to 5) 4 GFC/Shop Drawings/Visual

AIPL LIN RIL

Activity Owner QA/QC Site Engineer QA/QC Construction Representative QA/QC Engineer

Measurement

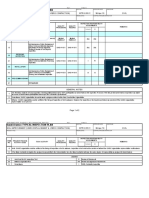

Sr. No Post Construction Importance Tolerance/ Requirements Remarks/ Comments

SUB LIN RIL

Visual/Dimension/Review of

1 All the above checks are found satfisfactory (Evaluate and write 1 to 5) 4 documents

AIPL LIN RIL

Activity Owner QA/QC Site Engineer QA/QC Construction Representative QA/QC Engineer

Overall Workmanship (Quality/General)

Supporting document must be attached above importance level 3 and above.

Comments :

Good observation (if any)

LIN RIL

Construction Representative QA/QC Engineer Site In-Charge & (OR) QA/QC Engineer

DAIS-QAP-F14 Rev. 00

You might also like

- ITP For Installation For PVC Perforated Pipes of Underdrain SystemDocument3 pagesITP For Installation For PVC Perforated Pipes of Underdrain SystemImho Tep75% (4)

- Inspection Test Plan Piling WorkDocument4 pagesInspection Test Plan Piling WorkAhmad AfeeqNo ratings yet

- (Painting Works) : Inspection and Test PlanDocument2 pages(Painting Works) : Inspection and Test Planrize1159No ratings yet

- Itp For Painting - FDocument5 pagesItp For Painting - FMudabbir HussainNo ratings yet

- Inspection and Test Plan (Reinforced Concrete Slab Construction)Document2 pagesInspection and Test Plan (Reinforced Concrete Slab Construction)ray100% (2)

- 16-Itp CCTV SystemDocument2 pages16-Itp CCTV Systemkash30100% (4)

- Bored Pile QC Flow ChartDocument1 pageBored Pile QC Flow ChartChung Yiung YungNo ratings yet

- Inspection and Test Plan 2Document3 pagesInspection and Test Plan 2EdNo ratings yet

- ISRO EOT Crane QAPDocument17 pagesISRO EOT Crane QAPSuleman Khan100% (1)

- Otis LineDocument2 pagesOtis LineKesav ViswanathNo ratings yet

- 6.ITP For RebarDocument1 page6.ITP For RebarDaniel Sinaga100% (1)

- Itp For Ug PipelineDocument3 pagesItp For Ug PipelineJustin Alwar100% (1)

- ITP For Mass Concrete Filling Over Rock Near Tunnel WallDocument2 pagesITP For Mass Concrete Filling Over Rock Near Tunnel WallrayNo ratings yet

- Itp For Fitp For Hdpe Pipes InstallationDocument3 pagesItp For Fitp For Hdpe Pipes InstallationBleep NewsNo ratings yet

- Inspection and Test Plan (Reinforced Concrete Column Construction)Document2 pagesInspection and Test Plan (Reinforced Concrete Column Construction)rayNo ratings yet

- Itp - Electrical Second FixDocument4 pagesItp - Electrical Second Fixirfan vpNo ratings yet

- +construction Contracts PDFDocument11 pages+construction Contracts PDFSheila DomalantaNo ratings yet

- Project Details: Conductor Pulling, Sagging & Spacer InstallationDocument3 pagesProject Details: Conductor Pulling, Sagging & Spacer InstallationPrabhakar SvNo ratings yet

- Saudi Aramco Typical Inspection Plan: Soil Improvement (Vibro Replacement & Vibro Compaction) 30-Oct-17 CivilDocument10 pagesSaudi Aramco Typical Inspection Plan: Soil Improvement (Vibro Replacement & Vibro Compaction) 30-Oct-17 CivilJagdishNo ratings yet

- QAP FinalDocument6 pagesQAP FinalANSHUMAN KUMARNo ratings yet

- HydrocarbonEngineering October 2015 PreviewDocument22 pagesHydrocarbonEngineering October 2015 PreviewmnasiroleslamiNo ratings yet

- Irshad CVDocument2 pagesIrshad CVPraveen Pathak100% (1)

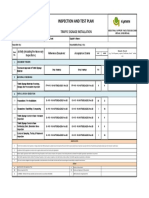

- Traffic Signage - Installation - ItpDocument1 pageTraffic Signage - Installation - Itpmoytabura96No ratings yet

- ITP Inspection and Testing Plan For Above Ground Water Supply PipesDocument1 pageITP Inspection and Testing Plan For Above Ground Water Supply Pipessarmad spectrumNo ratings yet

- ITP Steel Structure Rev.01Document2 pagesITP Steel Structure Rev.01Imam SyarifudinNo ratings yet

- ET - CONCRTE GENERIC ITP - 001 - Rev0 (Prelim) 1Document2 pagesET - CONCRTE GENERIC ITP - 001 - Rev0 (Prelim) 1Sagar Aliasjackey100% (1)

- Itp STR Slpg-Q-0000-24001-032-001-4-ADocument11 pagesItp STR Slpg-Q-0000-24001-032-001-4-AsivagnanamNo ratings yet

- Itp For Formworks (Ringlock System)Document3 pagesItp For Formworks (Ringlock System)damianNo ratings yet

- ISO 50001 Implementation Guide LR - IndiaDocument7 pagesISO 50001 Implementation Guide LR - IndiaDebabrata PanigrahiNo ratings yet

- Manual Grua GROVE TM S870Document90 pagesManual Grua GROVE TM S870rogerNo ratings yet

- I1912-AI-OPR-JC-0066-00 JC For Acrylic Emulsion Paint WorksDocument3 pagesI1912-AI-OPR-JC-0066-00 JC For Acrylic Emulsion Paint WorksAiplshubh ChavanNo ratings yet

- JC For Vanity CounterDocument1 pageJC For Vanity CounterGrace tpplNo ratings yet

- Inspection and Test Plan 2 PDF FreeDocument3 pagesInspection and Test Plan 2 PDF FreeaefNo ratings yet

- Saudi Aramco Typical Inspection Plan: Soil Improvement (Vibro Replacement & Vibro Compaction) 31-Nov-2018 CivilDocument10 pagesSaudi Aramco Typical Inspection Plan: Soil Improvement (Vibro Replacement & Vibro Compaction) 31-Nov-2018 CivilTariqMalik0% (1)

- Rev. Description Date Prepared by Checked by Checked by Approved byDocument5 pagesRev. Description Date Prepared by Checked by Checked by Approved byYasser FathiNo ratings yet

- Satip A 000 01Document10 pagesSatip A 000 01Akansha SharmaNo ratings yet

- Satip A 000 01 Rev 7 (Final)Document2 pagesSatip A 000 01 Rev 7 (Final)faisalNo ratings yet

- Inspection and Test Plan: Linolium Sheet InstallationDocument1 pageInspection and Test Plan: Linolium Sheet Installationmoytabura96No ratings yet

- Malod Kheralia RoadDocument12 pagesMalod Kheralia RoadartiNo ratings yet

- Shic A 0009Document1 pageShic A 000901095902062ahmedNo ratings yet

- ITP - Miscellaneous Metal WorksDocument2 pagesITP - Miscellaneous Metal Worksmohsin.meizaNo ratings yet

- Inspection Test Plan For Welding and FabricationDocument4 pagesInspection Test Plan For Welding and FabricationFlint RiderNo ratings yet

- Satip-A-000-01 Rev 8 Soil Improvement (Vibro Replacement - Vibro Compaction FinalDocument2 pagesSatip-A-000-01 Rev 8 Soil Improvement (Vibro Replacement - Vibro Compaction FinalTarek YehiaNo ratings yet

- Ray Itp For PaitingDocument18 pagesRay Itp For PaitingVinayaga MoorthiNo ratings yet

- TWJO-ITP-PRC-0005 Reva2 ITP For PC BoxCul in LBDPTDocument6 pagesTWJO-ITP-PRC-0005 Reva2 ITP For PC BoxCul in LBDPTBangkit SamosirNo ratings yet

- SATIP-A-000-01 Rev 7Document1 pageSATIP-A-000-01 Rev 7Zuhaib KhanNo ratings yet

- Lucky Tower 001 - Quality-Incoming Inspection and Test Plan 001 - 250912Document2 pagesLucky Tower 001 - Quality-Incoming Inspection and Test Plan 001 - 250912mohNo ratings yet

- N0579-TJN-ET-SI0008 - R02 ITP For AIS InstallationDocument7 pagesN0579-TJN-ET-SI0008 - R02 ITP For AIS InstallationAbat SayekeyevNo ratings yet

- I2114-OPR-ITP-CHK-007A (01) Pour Inspection Checklist - RCCDocument3 pagesI2114-OPR-ITP-CHK-007A (01) Pour Inspection Checklist - RCCPrasant Kumar SahooNo ratings yet

- ITP - ErectionDocument2 pagesITP - ErectionTech 5No ratings yet

- QIP of Boiler For ErectionDocument6 pagesQIP of Boiler For ErectionUmair Awan100% (2)

- Rajpar Wadhvan RoadDocument12 pagesRajpar Wadhvan RoadartiNo ratings yet

- Format For Information For Inspection of Ongoing /completed WordDocument13 pagesFormat For Information For Inspection of Ongoing /completed WordARTI PALEKARNo ratings yet

- ITP Installation of Containments QC REV 2Document4 pagesITP Installation of Containments QC REV 2irfan vpNo ratings yet

- TWJO-ITP-GEN-0009 Reva0 ITP For Precast Box Culvert in L B Depot AreaDocument5 pagesTWJO-ITP-GEN-0009 Reva0 ITP For Precast Box Culvert in L B Depot AreaBangkit SamosirNo ratings yet

- Itp Repair Works 79Document2 pagesItp Repair Works 79Mohamed GamalNo ratings yet

- الأسرة وتربية الطفل ، الدكتورة هدى محمود الناشفDocument1 pageالأسرة وتربية الطفل ، الدكتورة هدى محمود الناشفanon_545606833No ratings yet

- Ceiling Works - Gypsum Plaster BoardDocument5 pagesCeiling Works - Gypsum Plaster Boardparesh.ahirNo ratings yet

- F02. Weekly Quality Observation Report - LTCDWSW&CWSBGQMQISF02 REV-0Document4 pagesF02. Weekly Quality Observation Report - LTCDWSW&CWSBGQMQISF02 REV-0RamBinodSharmaNo ratings yet

- Integrated Management System: Contractor: UCC Infraroad JV Infraroad JV Project Quality ControlDocument2 pagesIntegrated Management System: Contractor: UCC Infraroad JV Infraroad JV Project Quality ControlBleep NewsNo ratings yet

- RA MashDocument30 pagesRA Mash2830093188No ratings yet

- Navsari Div - Box Culvert On Hansapore Flag Station RoadDocument14 pagesNavsari Div - Box Culvert On Hansapore Flag Station RoadartiNo ratings yet

- Valvada Desai Wad RoadDocument13 pagesValvada Desai Wad RoadARTI PALEKARNo ratings yet

- ITIL 2011 - The Big Picture v.2.0 - CFN PeopleDocument1 pageITIL 2011 - The Big Picture v.2.0 - CFN PeopleChristian Feldbech NissenNo ratings yet

- Tech SpecDocument228 pagesTech Spectanumay.geminiNo ratings yet

- HMI-Detachable Active Array Head, A Proposed Solution-Final - 1Document9 pagesHMI-Detachable Active Array Head, A Proposed Solution-Final - 1scarrion80No ratings yet

- MTG General PresentationDocument18 pagesMTG General PresentationVasil DosevNo ratings yet

- Abhijit GowariDocument3 pagesAbhijit Gowarikapil35No ratings yet

- Istcofr01 4854Document2 pagesIstcofr01 4854Supuran RichardoNo ratings yet

- AMKTech ProfileDocument31 pagesAMKTech ProfileArun ReddyNo ratings yet

- Gaur City Price List W.E.F. 11.01.2021 Except - 7th AvenueDocument1 pageGaur City Price List W.E.F. 11.01.2021 Except - 7th AvenueZama KazmiNo ratings yet

- IsgDocument18 pagesIsgashibekNo ratings yet

- Superflex CatalogueDocument24 pagesSuperflex CatalogueJusthyTaquiriNo ratings yet

- Paint Film Quality of Plastic Parts and Chrome Plated Parts: M5081 - 2018-N Nissan Engineering StandardDocument14 pagesPaint Film Quality of Plastic Parts and Chrome Plated Parts: M5081 - 2018-N Nissan Engineering StandardCARLOS A.N. LANZILLOTTONo ratings yet

- High Friction Surfacing: About Ennis-FlintDocument2 pagesHigh Friction Surfacing: About Ennis-FlintZaheer DoomahNo ratings yet

- K4212 PDFDocument9 pagesK4212 PDFJonathan MolinaNo ratings yet

- ABF - Payment Milestone - PNGDocument1 pageABF - Payment Milestone - PNGTakrimi IsmailNo ratings yet

- Zara - Bif CaseDocument25 pagesZara - Bif CaseAnjana CarriNo ratings yet

- Interim Project Presentation On Coconut DehuskerDocument17 pagesInterim Project Presentation On Coconut DehuskerMithun Mohan0% (1)

- Srs GasketsDocument7 pagesSrs GasketsRanganathan SekarNo ratings yet

- Introduction To ITILDocument7 pagesIntroduction To ITILShahnoor HaiderNo ratings yet

- Unlocking Cities: The Impact of Ridesharing Across IndiaDocument44 pagesUnlocking Cities: The Impact of Ridesharing Across IndiaLearning EngineerNo ratings yet

- Hyundai FB MachiningcenterDocument28 pagesHyundai FB MachiningcenterJonathan PalaciosNo ratings yet

- Free and Open Source Desktop GIS Projects and Software: An AnalysisDocument62 pagesFree and Open Source Desktop GIS Projects and Software: An Analysissiddhant jenaNo ratings yet

- Basic Guide To Fire Alarm InstallationDocument5 pagesBasic Guide To Fire Alarm InstallationisbtanwirNo ratings yet

- Clariant Corporate Presentation EnglishDocument31 pagesClariant Corporate Presentation Englishzolo54No ratings yet

- Glossario OffshoreDocument48 pagesGlossario OffshoreHenrique NogueiraNo ratings yet