Professional Documents

Culture Documents

Za 55835

Uploaded by

garrettCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Za 55835

Uploaded by

garrettCopyright:

Available Formats

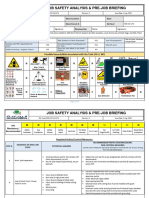

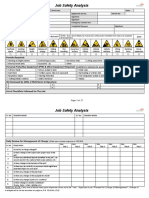

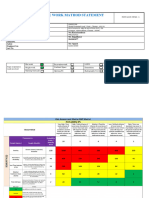

JSA (Job Safety Analysis)

Start Date of Work Order: Work Order Number: Job/Task Description:

7/11/2023 za55835 change fuel pump

Name of Service Technician(s): Job Location:

g167 1b

Ye

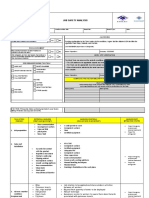

Do I understand the scope and steps required to perform the job/task?

No If the answer is “NO” to any of these questions

✘

Have I read and/or understand the required procedure (ex. SIS)?

s

✘

NoDO NOT PROCEED. Contact your supervisor

Have I read and understand the safety policies that relate to the job/task? ✘

No

Identify and assess the risk of current job/task. Determine what control measures and PPE that must be in place to eliminate and protect yourself from the potential hazards.

1. Physical Hazards: Control Measures: PPE:

Yes No✘ Do cut hazards exist from exposed sharp edges? Sharp edges have been padded, covered, or access to area is limited Gloves:

Yes No Do pinch points/crush hazards exist?

✘

✘ Machine/parts have been blocked against motion, cribbed or chocked Cut Resistant Gloves – ANSI level 2 cut resistance

✘

Yes No✘ Do slip/trip/ hazards exist? General housekeeping; ice/mud/debris cleaned or mitigated

✘ Cut Resistant/Impact Gloves-ANSI level 4 cut resistance

Yes No✘ Do fall hazards exist? Ladders; stairs; handrails; 3 points of contact Chemical Resistant Gloves

Yes No✘ Do welding flash/radiation hazards exist? Proper screening is in place; hot work procedures are being followed Welding Gloves

Yes No✘ Are any fire hazards created by hot work? Access to fire extinguishers; hot work procedures are being followed

Yes No✘ Do any flying particle hazards exist? (Grinding, cutting etc.)

✘ Machine guarding is in place and working properly Eye/Face Protection:

Yes No✘Do electrical hazards exist? Arc flash procedure and equipment Safety Glasses–ANSI Z87.1

✘

2. Ergonomic Hazards: Control Measures: Prescription Safety Glasses with side shields

Yes No✘ Does this job/task require work in prolonged awkward positions? Changing of position and stretching Face shield

✘

No Does this job/task require bending, twisting over-reaching excessively? Changing of position and stretching

Yes

✘ ✘

✘

Yes No✘ Does this job/task require the use of excessive force or heavy lifting? Appropriate lifting device; Assistance with moving/lifting Other:

3. Chemical Hazards: Control Measures: Respirator – must be approved and fit tested

Yes No✘ Does over exposure to liquids, vapors, or dust exist? SDS are readily available and have been reviewed Hearing Protection

4. Control of Hazardous Energy (Lockout/Tagout): Control Measures: High Visibility

Yes No Are all energy sources identified and controlled? Review Lockout/Tagout procedures and implement controls Fall Protection/Fall Restraint

✘

No✘ Can equipment move unexpectedly? Proper blocking against motion procedures has been implemented

Yes

✘ Foot Protection (composite protection/slip management/shoe tread)

5. Environmental Hazards: Control Measures: Welding PPE (shaded eye protection, garments, etc.)

Yes No✘ Does severe weather create additional exposures to injury/illness? (Tornadoes, Lighting etc.) Weather conditions are being monitored; emergency plans are in place Arc Flash PPE Kits

No Do slip/trip/fall hazards exist do to ice, water, or snow? Surface ice, water, or snow have been cleared/salted

Yes

✘

✘

Yes No✘ Do spill hazards or exposures to hazardous/infectious waste exist? Controls are in place to prevent contact with chemical or waste

6. Work Condition Hazards: Control Measures:

Yes No✘ Is there a need to warn or limit access? Warning signs, caution tape, barricades, or guardrails

7. Other Hazards (List): Control Measures (List):

✘

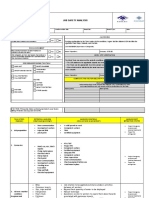

8. Have Employees in Adjacent Work Areas Been Made Aware of and Understand Potential Hazards in Your Work Area? (Check Yes or No and Have the Employee Insert Name and Date

Name of Employee: Date:

Yes No

Yes No

Yes No

Yes No

Yes No

9. Additional Hazards Created as Work Order Progressed (List Date and Added Hazard): Added Control Measures:

Date: Hazard: Control:

You might also like

- Infrastructure Safety AssessmentDocument2 pagesInfrastructure Safety AssessmentSteveNo ratings yet

- Safety Check List ShortDocument6 pagesSafety Check List Shortdaniel antonio arica pajaresNo ratings yet

- Sect. 4 TSTI Rev. 8Document2 pagesSect. 4 TSTI Rev. 8RetselisitsoeNo ratings yet

- JSA - Repair-Coating and Finition WorkDocument3 pagesJSA - Repair-Coating and Finition WorkAMIN100% (1)

- RG04-KPC1901-JHA-DOC-004-16 - Epoxy Mixing - Chemical HandlingDocument8 pagesRG04-KPC1901-JHA-DOC-004-16 - Epoxy Mixing - Chemical Handlingsaravana prabuNo ratings yet

- "Red" High (1) "Yellow" Medium (2) "Green" Low (3) : IllnessDocument2 pages"Red" High (1) "Yellow" Medium (2) "Green" Low (3) : IllnessBarb O'NeillNo ratings yet

- JSEA Job Safety and Environmental Analysis Format SWMS 2 Oct 2020Document6 pagesJSEA Job Safety and Environmental Analysis Format SWMS 2 Oct 2020sarge18No ratings yet

- JSA ELETRICAL MaintenanceDocument17 pagesJSA ELETRICAL MaintenanceWeru MorrisNo ratings yet

- Diesel RefuelingDocument3 pagesDiesel RefuelingAMINNo ratings yet

- Transportation Construction Safety Checklist: PersonnelDocument10 pagesTransportation Construction Safety Checklist: Personneldaniel antonio arica pajaresNo ratings yet

- FCMC - Pre-Task Plan - PTP Form - TemplateDocument3 pagesFCMC - Pre-Task Plan - PTP Form - TemplateS. Corey LezamaNo ratings yet

- Health, Safety & Environmental Program Jsa (Job Safety Analysis)Document5 pagesHealth, Safety & Environmental Program Jsa (Job Safety Analysis)Osiobe EwomazinoNo ratings yet

- CONFINED SPACES JSADocument7 pagesCONFINED SPACES JSAWeru MorrisNo ratings yet

- Loading and Unloading Pile Pipes SafelyDocument4 pagesLoading and Unloading Pile Pipes SafelyOsiobe Ewomazino100% (1)

- Health and Safety Internal Audit FormDocument5 pagesHealth and Safety Internal Audit FormFahad ChugtaiNo ratings yet

- Health, Safety & Environmental Program Jsa (Job Safety Analysis)Document3 pagesHealth, Safety & Environmental Program Jsa (Job Safety Analysis)Wealth OSIOBENo ratings yet

- Job Safety Analysis for Scaffolding ErectionDocument3 pagesJob Safety Analysis for Scaffolding Erectionaioudi100% (2)

- Daily plant inspectionDocument5 pagesDaily plant inspectionSteve O'DonoghueNo ratings yet

- Pickling and Passivation Activity For Bucket ElevatorDocument6 pagesPickling and Passivation Activity For Bucket ElevatorVIctor OdususiNo ratings yet

- JSA - Repair-Coating and Finition Work THDocument3 pagesJSA - Repair-Coating and Finition Work THKhorbi AbdeltifNo ratings yet

- LMRA Checklist PDFDocument2 pagesLMRA Checklist PDFMarcelo Costa100% (2)

- Jsa Lifitng Gantry FabricationDocument3 pagesJsa Lifitng Gantry FabricationOsiobe EwomazinoNo ratings yet

- Reactive Repair Job Ticket C1034Document5 pagesReactive Repair Job Ticket C1034MukeshLagadhirNo ratings yet

- JSA-Use of Temporary Energization (Power Generator)Document4 pagesJSA-Use of Temporary Energization (Power Generator)MajdiSahnoun100% (1)

- Job Safety Analysis FormDocument9 pagesJob Safety Analysis FormBhagat DeepakNo ratings yet

- Job Safety Analysis Pre-Task Briefing: Reviewed / Approved By: Safety PersonnelDocument2 pagesJob Safety Analysis Pre-Task Briefing: Reviewed / Approved By: Safety Personnelmahammed saleemNo ratings yet

- Health, Safety & Environmental Program Jsa (Job Safety Analysis)Document7 pagesHealth, Safety & Environmental Program Jsa (Job Safety Analysis)Osiobe Ewomazino50% (2)

- STA ElectricalDocument3 pagesSTA ElectricalimranNo ratings yet

- JSA FormDocument4 pagesJSA Formandrew rachmanNo ratings yet

- Annex I - SWP Application CriteriaDocument1 pageAnnex I - SWP Application CriteriaPutri aulia akramNo ratings yet

- Emt445 Curriculum Method 1 NowDocument7 pagesEmt445 Curriculum Method 1 Nowapi-354631612No ratings yet

- JSA-Visual Inspection and Ultrasonic Thickness Measurement On Pressure VesselsDocument2 pagesJSA-Visual Inspection and Ultrasonic Thickness Measurement On Pressure VesselsMajdiSahnoun100% (1)

- JSA 173 - CRT RIG UP - Updated 21.10.2019Document11 pagesJSA 173 - CRT RIG UP - Updated 21.10.2019tafhim rashidNo ratings yet

- JSA-174.Confined Space EntryDocument3 pagesJSA-174.Confined Space Entryghazi4u100% (1)

- Job Safety Analysis: Required References Jsa ReviewDocument3 pagesJob Safety Analysis: Required References Jsa ReviewWalid KhelfaNo ratings yet

- Connexion de Cable MT Avec Boite JonctionDocument3 pagesConnexion de Cable MT Avec Boite JonctionWalid KhelfaNo ratings yet

- Job Safety Analysis: Required References Jsa ReviewDocument3 pagesJob Safety Analysis: Required References Jsa ReviewWalid KhelfaNo ratings yet

- Job Safety Analysis (Jsa) : Mast InspectionDocument1 pageJob Safety Analysis (Jsa) : Mast Inspectionmadjid bobNo ratings yet

- AML - Job Safety Analysis Form - LiftingDocument12 pagesAML - Job Safety Analysis Form - LiftingBhagat DeepakNo ratings yet

- JSA-020-Safety Watch-Hot WorkDocument2 pagesJSA-020-Safety Watch-Hot WorkNishad MuhammedNo ratings yet

- Cutting ActivitiesDocument3 pagesCutting ActivitiesWalid KhelfaNo ratings yet

- 053 Jsa Quay Wall Superstructure RV 02Document10 pages053 Jsa Quay Wall Superstructure RV 02Wealth OSIOBENo ratings yet

- Diesel RefuelingDocument3 pagesDiesel RefuelingAMINNo ratings yet

- "Danger Floor Opening 100% Tie-Off Required" or "Danger Hole - Do Not Remove Cover"Document2 pages"Danger Floor Opening 100% Tie-Off Required" or "Danger Hole - Do Not Remove Cover"MyolwinooNo ratings yet

- P12 - CHEAC - New Camp - STA - Installation of Fence - 23 Mar 2023Document3 pagesP12 - CHEAC - New Camp - STA - Installation of Fence - 23 Mar 2023imranNo ratings yet

- Job Safety Analysis Form: CSCCB Hole WatchDocument4 pagesJob Safety Analysis Form: CSCCB Hole WatchFrank ElizardoNo ratings yet

- SWMS No 6 Threaded Rod InstallingDocument6 pagesSWMS No 6 Threaded Rod InstallingMokka SamaiyalNo ratings yet

- Permit Work at HeightDocument2 pagesPermit Work at HeightIwan Setiawan100% (1)

- Winterset Health and Safety AuditDocument2 pagesWinterset Health and Safety AuditEngr Abdul Shakoor ShaikhNo ratings yet

- Gorbel Fall Arrest Insights Ideas For Workplace ComplianceDocument16 pagesGorbel Fall Arrest Insights Ideas For Workplace ComplianceIsrael AguilarNo ratings yet

- Hot Work SafetyDocument3 pagesHot Work SafetyNasir Mehmood Aryani100% (1)

- AML - Job Safety Analysis MaintenanceDocument23 pagesAML - Job Safety Analysis Maintenancedeepak bhagatNo ratings yet

- Workplace Audit Checklist 2019Document7 pagesWorkplace Audit Checklist 2019Prashanth JeerNo ratings yet

- HSE Site Instruction For Contractor FormDocument2 pagesHSE Site Instruction For Contractor Formابو محمد علي100% (1)

- Grating Decking and Floor Removal FormDocument2 pagesGrating Decking and Floor Removal FormMohamed Abd ElhaleemNo ratings yet

- Travaux Genie Civil MTR JSADocument5 pagesTravaux Genie Civil MTR JSAAMINNo ratings yet

- Permit To Work Kone E1 Lift Repair July 2023Document1 pagePermit To Work Kone E1 Lift Repair July 2023Prajin KundoorNo ratings yet

- Topography SurveyDocument2 pagesTopography SurveyAMIN100% (2)

- Analisa Keselamatan Kerja: Job Safety AnalysisDocument3 pagesAnalisa Keselamatan Kerja: Job Safety AnalysisEthos SeptiansyahNo ratings yet

- C.B.S.E Study Material 2 (Unit-1)Document71 pagesC.B.S.E Study Material 2 (Unit-1)vikramkhatri4100% (2)

- OpenStage Provisioning Interface Developer's GuideDocument182 pagesOpenStage Provisioning Interface Developer's GuideEstêvão Samuel Procópio AmaralNo ratings yet

- Husqvarna/Viking Designer Topaz Sewing Machine Instruction ManualDocument80 pagesHusqvarna/Viking Designer Topaz Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- Turbine Clearance ControlDocument135 pagesTurbine Clearance ControlAnu Partha100% (1)

- Frank GehryDocument12 pagesFrank Gehrya to z CHANNELNo ratings yet

- CSC 551: Web Programming Spring 2004: Basic HTMLDocument18 pagesCSC 551: Web Programming Spring 2004: Basic HTMLprasad150686100% (1)

- Oracle Fixed AssetsDocument1,204 pagesOracle Fixed AssetsYudha Prayoga100% (1)

- Project Pegasus Andy Contextualizes Contemporary Time Travel Research 3-18-10Document2 pagesProject Pegasus Andy Contextualizes Contemporary Time Travel Research 3-18-10Lawrence JonesNo ratings yet

- ESA322 Dynamic Vibration Absorber ProjectDocument15 pagesESA322 Dynamic Vibration Absorber ProjectAhmad ShaqeerNo ratings yet

- BHA PROPOSAL FOR SERD-N2 ST WELLDocument1 pageBHA PROPOSAL FOR SERD-N2 ST WELLPinggir KaliNo ratings yet

- Wind Loads On Buildings - Mwfrs (Envelope Procedure) : Chapter C28Document5 pagesWind Loads On Buildings - Mwfrs (Envelope Procedure) : Chapter C28Van Len TranNo ratings yet

- PTFE Cartridges LPF SereisDocument1 pagePTFE Cartridges LPF SereisPavan AvulaNo ratings yet

- SatyadevAhlawat-CV 0Document6 pagesSatyadevAhlawat-CV 0True CallerNo ratings yet

- EurokinDocument14 pagesEurokinapitbhuNo ratings yet

- EmulsionDocument22 pagesEmulsionLasromauli SagalaNo ratings yet

- 10.03.2020-CeramicMicrospheres 410 TechPaper 9842346 PDFDocument4 pages10.03.2020-CeramicMicrospheres 410 TechPaper 9842346 PDFhomeros76No ratings yet

- Dr. Leach's Filter Potpourri: Transfer FunctionsDocument33 pagesDr. Leach's Filter Potpourri: Transfer FunctionsAhmad FauziNo ratings yet

- Load Combination IRCDocument2 pagesLoad Combination IRCmgr4.designNo ratings yet

- Manual Tong GuideDocument6 pagesManual Tong Guidefatehul alamNo ratings yet

- EE 499, Lecture 03 Frequency ReuseDocument6 pagesEE 499, Lecture 03 Frequency ReuselakshmiNo ratings yet

- Synopsis (Fingerprint Reg)Document5 pagesSynopsis (Fingerprint Reg)Smiju SukumarNo ratings yet

- 615 Series Quick Start Guide 757435 ENa. Relay ABBDocument4 pages615 Series Quick Start Guide 757435 ENa. Relay ABBTung NguyenNo ratings yet

- FRP Technology by WeatherheadDocument20 pagesFRP Technology by WeatherheadSagarNo ratings yet

- RESUME TITLEDocument2 pagesRESUME TITLEYogesh ChaudhariNo ratings yet

- Slip casting step-by-step galleryDocument3 pagesSlip casting step-by-step galleryKy Trung0% (1)

- Industrial Training ReportDocument19 pagesIndustrial Training ReportRam PandeyNo ratings yet

- ISO 3834 2 - Rev. 1.0 - ENG - Final 20201016 1Document2 pagesISO 3834 2 - Rev. 1.0 - ENG - Final 20201016 1musthafaNo ratings yet

- Circular PierDocument48 pagesCircular PierAbhijeet Sahu100% (2)

- CTPC Chapter 2 MCQDocument12 pagesCTPC Chapter 2 MCQNUR AZNAN PATWARY 45 Batch DCENo ratings yet

- Determining Footing Sizes IrcDocument2 pagesDetermining Footing Sizes IrcAiline TriciaNo ratings yet