Professional Documents

Culture Documents

MR3 PDS Basilisk Self-Healing Repair Mortar en v20201003

Uploaded by

KUNBU INVESTMENTOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MR3 PDS Basilisk Self-Healing Repair Mortar en v20201003

Uploaded by

KUNBU INVESTMENTCopyright:

Available Formats

Basilisk-Contracting BV

Product Data Sheet: Molengraaffsingel 10

2629 JD DELFT, The Netherlands

Basilisk Repair Mortar MR3 Tel: +31 15 202 6128

Product Description

Basilisk Repair Mortar MR3 is a one-component ready-mix cementitious based mortar for concrete

repair, meeting the requirements of Class R3 of the European Standard EN 1504-3. In addition to

these requirements Basilisk Repair Mortar MR3 has an integrated autonomous crack healing

capability. Furthermore the mortar is designed to have ductile properties and a strong adhesive

bond.

Basilisk Repair Mortar characteristics

• Strong adhesive bonding

• Ductile behavior (high deformation capacity and low E-modulus)

• Fine-meshed controlled crack behavior

• Self-healing properties

Suitable repair methods (as defined in EN 1504-3)

3.1 Hand applied mortar

3.3 Spraying concrete or mortar

7.1 Increasing cover to reinforcement with additional cementitious mortar or concrete

7.2 Replacing contaminated or carbonated concrete

0063

Basilisk-Contracting BV

Molengraaffsingel 10

2629 JD DELFT

20

063-CPR-101885/01

EN 1504-3

Concrete repair product for technical repair

based on hydraulic cement

Compressive strength Class R3

Chloride ion content ≤ 0,05 %

Adhesive Bond ≥ 1,5 MPa

Carbonation resistance Passes

Thermal compatibility part 1 NPD

Capillary absorption NPD

Dangerous substances Comply with 5.4

Reaction to fire Class A1

MR3_Product Data Sheet www.basiliskconcrete.com Version: 20201003

Replaces: 20200602

Product information

Chemical Base Portland cement, limestone powder, fly ash, biodegradable

polymeric mineral precursor compound, bio-based enzymatic

catalyst and selected aggregates and additives.

Packaging 15 kg bag.

Appearance and color Grey powder.

Shelf life 12 months after production date as specified on packaging.

Storage conditions Store properly in undamaged original sealed packaging in dry

cool conditions.

Mixing Mix Basilisk Repair Mortar MR3 mechanically until a homogenous

mix is obtained. Mixing time depends on type of mixer:

approximately 3 minutes. Never mix less than a full bag.

Water dosage 3.8 - 4.2 L / 15 kg. Use tap water.

Workable time ≥ 30 minutes @ 20 °C. (Workability is effected by temperature if

not addressed accordingly, e.g. heating / cooling)

Technical information

Property Test method Value

Maximum grain size EN 12192-1 2,0 mm

Compressive strength EN 12190 7 days 17,6 MPa

28 days 36,7 MPa

Density EN 12190 7 days 1862 kg/m³

28 days 1867 kg/m³

Flexural strength EN 12190 7 days ~6 MPa

28 days ~7 MPa

Stiffening time EN 13294 1 MPa 120 min

4 MPa 285 min

Workability EN 13395-1 T1 (10±5 min) 149 mm

T2 (30±5 min) 110 mm

Air content EN 12350-7 4,6 %

Chloride ion content EN 1015-17 0,047 %

Adhesive bond EN 1542 2,37 MPa

Carbonation resistance EN 13295 0,5 mm

Elastic Modulus EN 13412 11,9 GPa

Thermal compatibility Part 1 EN 13687-1 NPD MPa

Capillary Absorption EN 13057 NPD

Water dosage 3,8 – 4,2 l/15kg

Layer thickness 40 mm max.

Temperature range Application 5 – 30 °C

Healing 10 – 40 °C

Additional information

For more detailed information regarding safety aspects and application instructions please advise the

MR3 Material Safety Data Sheet and MR3 Application instructions. These are available on our

website or on request.

MR3_Product Data Sheet www.basiliskconcrete.com Version: 20201003

Replaces: 20200602

You might also like

- Steel Joists - JMVDocument5 pagesSteel Joists - JMVpelotoNo ratings yet

- Jazz. David P. Brown - Noise Orders - Jazz, Improvisation, and Architecture (2006, Univ of Minnesota Press) PDFDocument193 pagesJazz. David P. Brown - Noise Orders - Jazz, Improvisation, and Architecture (2006, Univ of Minnesota Press) PDFPedro Freitas NetoNo ratings yet

- 7 Verona Place BROOKLYN, NY 11216Document20 pages7 Verona Place BROOKLYN, NY 11216Acxel D. Castillo100% (1)

- Guida Coprax Eng 2015 LightDocument82 pagesGuida Coprax Eng 2015 Lightairsys7projec100% (1)

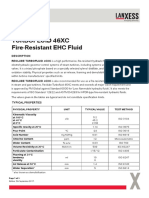

- Reolube Turbofluid 46Xc Fire-Resistant EHC Fluid: Data SheetDocument5 pagesReolube Turbofluid 46Xc Fire-Resistant EHC Fluid: Data SheetJicheng PiaoNo ratings yet

- Malay Traditional House InteriorDocument8 pagesMalay Traditional House InteriorPyqaa Amzah0% (1)

- 450F HsdviDocument2 pages450F HsdviJoJo kNo ratings yet

- Fire Case StudyDocument39 pagesFire Case StudyAkanksha BhakareNo ratings yet

- Intercrete 4820 Formely Monolevel-844SP TDSDocument3 pagesIntercrete 4820 Formely Monolevel-844SP TDSMario DumaineNo ratings yet

- Pds Sika Monotop 4012Document5 pagesPds Sika Monotop 4012arc.medabdelrazekNo ratings yet

- FB 12 STC 048 en 03 - Epoca Calce NHL115 - EngDocument4 pagesFB 12 STC 048 en 03 - Epoca Calce NHL115 - EngrogirosNo ratings yet

- Durocret-Plus: Polymer-Modified, Fiber-Reinforced, Repairing Cement MortarDocument2 pagesDurocret-Plus: Polymer-Modified, Fiber-Reinforced, Repairing Cement Mortarwey5316No ratings yet

- Renderoc FC Dec22Document4 pagesRenderoc FC Dec22NiemNo ratings yet

- FB 12 STC 025 en 03 - Struttura Raso Fino - RF 248 - EngDocument4 pagesFB 12 STC 025 en 03 - Struttura Raso Fino - RF 248 - EngrogirosNo ratings yet

- Sika Monotop 4100protectDocument5 pagesSika Monotop 4100protectJanardhana ReddiNo ratings yet

- Epicon F.S. Mortar: Technical DatasheetDocument3 pagesEpicon F.S. Mortar: Technical DatasheetBogdanBNo ratings yet

- Confil Mortar: Technical DatasheetDocument3 pagesConfil Mortar: Technical DatasheetBogdanBNo ratings yet

- Comprit 137S 0 3Document1 pageComprit 137S 0 3Ahmed AbdelhamidNo ratings yet

- Polycrete®: Three Component Cementitious Polyurethane ScreedDocument2 pagesPolycrete®: Three Component Cementitious Polyurethane ScreedRana Ahmad AamirNo ratings yet

- TDS - Eksmal 4 - ENDocument3 pagesTDS - Eksmal 4 - ENMickijevicNo ratings yet

- Polyethylene Properties - VinidexDocument8 pagesPolyethylene Properties - VinidexalexNo ratings yet

- F1 Model Block: Technical DatasheetDocument2 pagesF1 Model Block: Technical DatasheetRafael ObiciNo ratings yet

- Adingpoks 1: Filed of AplicationDocument3 pagesAdingpoks 1: Filed of AplicationFilip PopordanoskiNo ratings yet

- CNPC CPP W725ef TDSDocument1 pageCNPC CPP W725ef TDScallzrNo ratings yet

- General Description: Coupling: Yellow, Yellow, Orange Pipe Body: Yellow, Yellow, OrangeDocument5 pagesGeneral Description: Coupling: Yellow, Yellow, Orange Pipe Body: Yellow, Yellow, OrangesunnyNo ratings yet

- In House Aggregate Quality ControlDocument6 pagesIn House Aggregate Quality ControlSaber AhmadNo ratings yet

- Pds-Bc-Gard WB OgsDocument2 pagesPds-Bc-Gard WB OgsKenji TanNo ratings yet

- Winpower International Limited: ApplicationDocument2 pagesWinpower International Limited: ApplicationAHMED YOUSEFNo ratings yet

- SikaMonoTop 3020 en CORP 08 2020 1 1Document4 pagesSikaMonoTop 3020 en CORP 08 2020 1 1Mohamed Osama AshmawyNo ratings yet

- FB 12 STC 031 en 05 - Struttura Tixo - TX 259 - EngDocument4 pagesFB 12 STC 031 en 05 - Struttura Tixo - TX 259 - EngrogirosNo ratings yet

- PP h4120 TdsDocument2 pagesPP h4120 TdsengrmfawadazharNo ratings yet

- FC SBU Monile INT 20230526Document2 pagesFC SBU Monile INT 20230526nblinoNo ratings yet

- 3M™ Scotch-Weld™ Multi-Material & Composite Urethane Adhesives DP6330NS - 20230807Document8 pages3M™ Scotch-Weld™ Multi-Material & Composite Urethane Adhesives DP6330NS - 20230807shreyanshNo ratings yet

- 3M 232 12 5mm 0 5 36yrd DatasheetDocument4 pages3M 232 12 5mm 0 5 36yrd Datasheetfelixnord19No ratings yet

- EPAPROOF FPCS 08.EN - Rev.11.060917Document8 pagesEPAPROOF FPCS 08.EN - Rev.11.060917Ali HashemiNo ratings yet

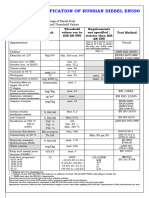

- 2 Specification Russian EN590Document1 page2 Specification Russian EN590Sephiwe MafilikaNo ratings yet

- TECNOLEN 25 Bs1d0 - 42234 - 42344 - V5 - ENDocument2 pagesTECNOLEN 25 Bs1d0 - 42234 - 42344 - V5 - ENKarima ABOUALINo ratings yet

- Jarvis 1096 - EN 13501. B s2 d0Document5 pagesJarvis 1096 - EN 13501. B s2 d0Calin SimionNo ratings yet

- 101foam MingkoDocument1 page101foam MingkoJaime PeñabrañaNo ratings yet

- NEXT TFD Elder (1) 1Document13 pagesNEXT TFD Elder (1) 1Ruffabbey06No ratings yet

- TL - 03 - Reparatur Glet - 01 - 2016 - enDocument1 pageTL - 03 - Reparatur Glet - 01 - 2016 - enNevena IlicNo ratings yet

- FB 12 STC 047 en 01 - Epoca Calce NHL110 - EngDocument4 pagesFB 12 STC 047 en 01 - Epoca Calce NHL110 - EngrogirosNo ratings yet

- Isostud Geo P-EngDocument1 pageIsostud Geo P-EngPiulitza88No ratings yet

- Sikagard 720 EpocemDocument5 pagesSikagard 720 EpocemMohamed Osama AshmawyNo ratings yet

- Emcekrete EP: High Performance Self-Leveling Epoxy GroutDocument2 pagesEmcekrete EP: High Performance Self-Leveling Epoxy Groutwilian liNo ratings yet

- Quality Product Certification ReinforcementDocument3 pagesQuality Product Certification ReinforcementsamiNo ratings yet

- Ldpe Film 2004TX37 - 2004TC37Document2 pagesLdpe Film 2004TX37 - 2004TC37Phuoc TranNo ratings yet

- Technical Data Polyfloor MortarDocument3 pagesTechnical Data Polyfloor MortarMeliany SariNo ratings yet

- Renderoc S: Constructive SolutionsDocument4 pagesRenderoc S: Constructive SolutionstalatzahoorNo ratings yet

- PLUMBING PPR-Pipe DesoDocument11 pagesPLUMBING PPR-Pipe DesoOwen Francis Arles MaongatNo ratings yet

- Surat Jastifikasi - (SANFAB PE - ST)Document5 pagesSurat Jastifikasi - (SANFAB PE - ST)arungrifqy putraaditNo ratings yet

- Cempatch S - TDS - 3Document2 pagesCempatch S - TDS - 3Ahmed MohsinNo ratings yet

- Transformer Data Sheet (IFC) (Approved)Document8 pagesTransformer Data Sheet (IFC) (Approved)bambang sugitoNo ratings yet

- DSMTS 0017.3 - AlSi HBNDocument3 pagesDSMTS 0017.3 - AlSi HBNfaustoleo123No ratings yet

- Pds I 7 BC Gard SBDocument2 pagesPds I 7 BC Gard SBMohamadLutfiNo ratings yet

- Fosroc Nitocote EP405: Solvent-Free Epoxy Resin Coating For Water Retaining and Water Excluding Structures UsesDocument3 pagesFosroc Nitocote EP405: Solvent-Free Epoxy Resin Coating For Water Retaining and Water Excluding Structures UsesGer ShorttNo ratings yet

- Ep 331 TX (Qatar) : Non Shrink Thixotropic Repair Mortar With FiberDocument2 pagesEp 331 TX (Qatar) : Non Shrink Thixotropic Repair Mortar With Fiberabb100% (1)

- PP Trilene He2.0tfDocument2 pagesPP Trilene He2.0tfLaili AzkiyahNo ratings yet

- Renderoc LA 1011Document4 pagesRenderoc LA 1011Bijaya RaulaNo ratings yet

- LDPE L2102TX00: ApplicationDocument2 pagesLDPE L2102TX00: ApplicationAmir masoud MoezziNo ratings yet

- Tagro Catalog 2022Document32 pagesTagro Catalog 2022Lilian AzerNo ratings yet

- Epibear: Technical DatasheetDocument3 pagesEpibear: Technical DatasheetBogdanBNo ratings yet

- FB 12 STC 049 en 01 - Epoca Calce NHL 093 - EngDocument3 pagesFB 12 STC 049 en 01 - Epoca Calce NHL 093 - EngrogirosNo ratings yet

- FD-860 Specification SheetDocument1 pageFD-860 Specification SheetWattsNo ratings yet

- List of Largest HotelsDocument2 pagesList of Largest HotelsmaryamsaifNo ratings yet

- Unit3 Late Medival English GothicDocument13 pagesUnit3 Late Medival English Gothicsarath sarathNo ratings yet

- Saudi Aramco Inspection Checklist: Post-Application Inspection of Fireclay Brick Installation SAIC-N-2041 15-Dec-09 MechDocument5 pagesSaudi Aramco Inspection Checklist: Post-Application Inspection of Fireclay Brick Installation SAIC-N-2041 15-Dec-09 MechaamirapiNo ratings yet

- 1702 High Rise Buildings in The Netherlands Hybrid Structures and Precast Concrete PDFDocument9 pages1702 High Rise Buildings in The Netherlands Hybrid Structures and Precast Concrete PDFNithiya SmileeNo ratings yet

- Study On Effect of Blast Furnace Slag and Waste Fillers On Performance of Warm Mix Asphalt'Document25 pagesStudy On Effect of Blast Furnace Slag and Waste Fillers On Performance of Warm Mix Asphalt'Varun ChennigarNo ratings yet

- Posi Struts DetailsDocument15 pagesPosi Struts DetailsSuciul E ViuNo ratings yet

- White Collar FactoryDocument14 pagesWhite Collar FactoryAnder AndersenNo ratings yet

- DCC3113 - Chapter 5 PDFDocument24 pagesDCC3113 - Chapter 5 PDFXkarr Rasta100% (1)

- NCMA TEK 10-02B - Control Joints Empirical MethodDocument4 pagesNCMA TEK 10-02B - Control Joints Empirical MethodJeff HedmanNo ratings yet

- NYC PARKS - Astoria Park Pool DrawingsDocument73 pagesNYC PARKS - Astoria Park Pool DrawingsColin PearceNo ratings yet

- SUOS2011 (2021 Edition) W MarkupDocument448 pagesSUOS2011 (2021 Edition) W MarkupChan XavierNo ratings yet

- Ac Centeno BsuDocument8 pagesAc Centeno Bsuhr3341720No ratings yet

- AISC Design Example 1Document4 pagesAISC Design Example 1vibishnanNo ratings yet

- Git Mod 4Document122 pagesGit Mod 4Adil SayedNo ratings yet

- Beam Schedule PDFDocument1 pageBeam Schedule PDFStructure departmentNo ratings yet

- QS Report Example 5Document18 pagesQS Report Example 5Hedi ZarkounaNo ratings yet

- ML - Spaces - Brochure Commercial Vile Parle WDocument8 pagesML - Spaces - Brochure Commercial Vile Parle WPrashant JadhavNo ratings yet

- QSEV - Detailed Estimate Abstract Sheet - 2119022 - Yash PawarDocument23 pagesQSEV - Detailed Estimate Abstract Sheet - 2119022 - Yash PawarYash pawarNo ratings yet

- Aman Article PDFDocument6 pagesAman Article PDFGabriel Moyer-PerezNo ratings yet

- 2020 02 11.10.00.44 Ce8022 Prefabricated StructuresDocument1 page2020 02 11.10.00.44 Ce8022 Prefabricated StructuresBALAKRISHNANNo ratings yet

- 1970 Fitch, The Architecture of The Well Tempered Environment (Review)Document4 pages1970 Fitch, The Architecture of The Well Tempered Environment (Review)nachosollaNo ratings yet

- MOSLEY BUNGEY HULSE Reinforced Concrete Design To Eurocode 2 1Document420 pagesMOSLEY BUNGEY HULSE Reinforced Concrete Design To Eurocode 2 1Leonard C. Iancu95% (20)

- Seismic Isolation For ArchitectsDocument9 pagesSeismic Isolation For ArchitectsHilal GünayNo ratings yet

- Key Plan Type-1 01: Muscat International AirportDocument1 pageKey Plan Type-1 01: Muscat International AirportTanveer PatilNo ratings yet