Professional Documents

Culture Documents

Number: - Full Name: - Duration Is 80 Minutes. Good Luck, Department of Design

Uploaded by

Ömer GezerOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Number: - Full Name: - Duration Is 80 Minutes. Good Luck, Department of Design

Uploaded by

Ömer GezerCopyright:

Available Formats

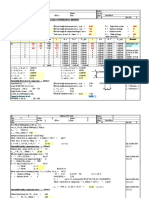

MACHINE ELEMENTS-1

Number: ____________________ Full Name: ____________________

Duration is 80 minutes.

Good luck, Department of Design

Figure 1 Figure 2

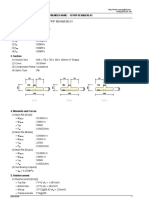

Q-1: In figure 1, the shaft is mounted at “B” and “C”. The torsional moment (Mb=120 Nm) enters from “A”

and exits from “D”. The diameter of the pulley at “D” is Dk= 250 mm, the forces acts from pulley to the shaft

are Fa=8 kN and Fr=10 kN. L1=250 mm; L2=250 mm; Shaft material Fe60; safety factor S=1,8; (Kb.Ky/Kç)=0,35

Note: Ignore the tensile and compressive stresses.

a) Calculate the reactional forces (10P)

b) Draw the bending and torsional moment diagrams. (20P)

c) Calculate the diameter of the shaft for the cross section of “D”. (20P)

Q-2: In figure 2, a welded joint is given in detailed. To the joint; a force as a value of F=10 kN and a bending

moment as a value of Me= 200 Nm are affected. The welded throat is a= 5mm; the welded components Fe50;

the welding quality is III. Quality and safety factor is S= 1,6.

a) Calculate the maximum stresses acts over the welded joint. (15P)

b) Control the strength of the welded joint. (15P)

Q-3: Answer the below questions:

a) Draw the stress-strain diagram for a ductile material. When you need to design a machine element which

is under the static loads, how do you interpret this diagram? (10P)

b) Draw a “B” type parallel key between shaft and hub connection in detailed. (10P)

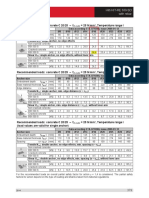

ÇK (N/mm2) ÇAk ÇD eAk eD bAk bD

Fe37 370 240 170 340 190 140 110

Fe 50 500 320 220 450 250 180 150

Fe 60 600 380 260 540 320 220 180

You might also like

- King Fahd University of Petroleum & Minerals: College of Engineering Sciences Mechanical Engineering DepartmentDocument2 pagesKing Fahd University of Petroleum & Minerals: College of Engineering Sciences Mechanical Engineering DepartmentOmar RefeNo ratings yet

- Re AllDocument13 pagesRe AlltsapoutshisNo ratings yet

- Structural ConnectionsDocument26 pagesStructural ConnectionsAlemtsehay ShiferawNo ratings yet

- Birla Institute of Technology and Science, PilaniDocument3 pagesBirla Institute of Technology and Science, PilaniSharad ShrivastavaNo ratings yet

- Column Design Ecp203 VS Aci VS BS8110Document37 pagesColumn Design Ecp203 VS Aci VS BS8110MANo ratings yet

- 2122 MTCC5020 S2 A3 Fa QPDocument8 pages2122 MTCC5020 S2 A3 Fa QPZoay7 I 6No ratings yet

- Moment, Shear and Axial - With Anchor DesignDocument6 pagesMoment, Shear and Axial - With Anchor DesignRuemu Godwin Inikori100% (1)

- S. No Cable Tag No From To Power Cable Description Item Item Motor Rating KW No. of Runs No. of CoreDocument35 pagesS. No Cable Tag No From To Power Cable Description Item Item Motor Rating KW No. of Runs No. of CorejjspenceNo ratings yet

- MS 415 Amen - No - 1Document5 pagesMS 415 Amen - No - 1priyankaprashaanthNo ratings yet

- End Sem PyqDocument5 pagesEnd Sem PyqJaspreet veeraNo ratings yet

- M Af470wDocument56 pagesM Af470wwilliam lozadaNo ratings yet

- Design of Metal Anchors Used in Concrete To ACI318!08!4Document4 pagesDesign of Metal Anchors Used in Concrete To ACI318!08!4tamerragaaNo ratings yet

- MTP 5Document4 pagesMTP 5tinku singhNo ratings yet

- Design of Reinforced Concrete Elements: UsingDocument62 pagesDesign of Reinforced Concrete Elements: UsingISsa Qafa'itiNo ratings yet

- 9) Design Col. and Rafter 002Document4 pages9) Design Col. and Rafter 002Er navneet jassiNo ratings yet

- L-2/T-1/CE Date: 31/01/2012: Section - ADocument17 pagesL-2/T-1/CE Date: 31/01/2012: Section - AMahmudul Hasan PathikNo ratings yet

- U Beam PDFDocument114 pagesU Beam PDFKS&TAN sdn bhdNo ratings yet

- Wsa Adbta7055ind NCRPB DFR Vol II-c Hapur Sewer DPR EstimatDocument85 pagesWsa Adbta7055ind NCRPB DFR Vol II-c Hapur Sewer DPR EstimatTanveer PathanNo ratings yet

- Quiz 1 2.008 Design and Manufacturing II: SolutionDocument12 pagesQuiz 1 2.008 Design and Manufacturing II: SolutionLa Casita de TonyNo ratings yet

- Mech 260-Final ExamDocument3 pagesMech 260-Final ExamwerewaroNo ratings yet

- Jis e 2101-1990Document7 pagesJis e 2101-1990F.S.No ratings yet

- Assignment CivilDocument1 pageAssignment CivilVAIBHAV KASHYAP U ce16b062No ratings yet

- End Sem 2019aDocument35 pagesEnd Sem 2019a1paper 1penNo ratings yet

- Plate ColumnsDocument3 pagesPlate ColumnsK SrikanthNo ratings yet

- MECH 325 - Midterm Book 1: InstructionsDocument17 pagesMECH 325 - Midterm Book 1: InstructionsRohan ThaparNo ratings yet

- Slender Web I Section Design - Staad Verification ProblemDocument14 pagesSlender Web I Section Design - Staad Verification ProblemGuessss..........!!!!!100% (1)

- Year2015Volume15 02 20Document6 pagesYear2015Volume15 02 20ankushwreNo ratings yet

- Retrofitting of Denford TRIAC CNC Milling MachineDocument25 pagesRetrofitting of Denford TRIAC CNC Milling MachineDivyanshNo ratings yet

- Parts Catalog: 0CD50-M05530ENDocument28 pagesParts Catalog: 0CD50-M05530ENVladis0710100% (1)

- Chap 1c PDFDocument18 pagesChap 1c PDF안혜영No ratings yet

- BOOK Ugural 15 Mechanical Design of Machine ComponentsDocument95 pagesBOOK Ugural 15 Mechanical Design of Machine ComponentsLeonel Bejar VelardeNo ratings yet

- HS FSW01 00000088aec - CDocument5 pagesHS FSW01 00000088aec - CMarcoNo ratings yet

- Meng501L - Project - Spring 2020-2021Document7 pagesMeng501L - Project - Spring 2020-2021Mohammad HasanNo ratings yet

- Meng501L - Project - Spring 2020-2021Document7 pagesMeng501L - Project - Spring 2020-2021Mohammad HasanNo ratings yet

- A Study of The Grouped Arrangements of Stud Connectors On Shear StrengthDocument15 pagesA Study of The Grouped Arrangements of Stud Connectors On Shear Strengthfs jiNo ratings yet

- DE5302 Strength of Materials 1 - Semester 2 2020 - Exam - FinalDocument21 pagesDE5302 Strength of Materials 1 - Semester 2 2020 - Exam - FinalGopal KrishanNo ratings yet

- R 161214112017Document2 pagesR 161214112017srinivasallam1986_87No ratings yet

- FES MTG Welding Fixture F7222910Document11 pagesFES MTG Welding Fixture F7222910Sekar NaikNo ratings yet

- Post-Tensioning Format For Pc-Girder General InformationDocument1 pagePost-Tensioning Format For Pc-Girder General InformationTirthajit RoyNo ratings yet

- DsdsDocument15 pagesDsdsbasum matNo ratings yet

- Hilti D16Document1 pageHilti D16Ina RoseNo ratings yet

- Time: 3 Hours Total Marks: 100: B.Tech (Sem-V) Theory Examination 2019-20 Machine Design-IDocument3 pagesTime: 3 Hours Total Marks: 100: B.Tech (Sem-V) Theory Examination 2019-20 Machine Design-IAnup KashyapNo ratings yet

- Ballscrew Product Specifications 9 10Document2 pagesBallscrew Product Specifications 9 10harryNo ratings yet

- Csec (U) LTD.: Member Name: - 1strip Beam (638) - 01Document40 pagesCsec (U) LTD.: Member Name: - 1strip Beam (638) - 01CSEC Uganda Ltd.No ratings yet

- Measure Against E280-000x E302-000x E315-0xxx E732-0010 and E270-000 - en - 7.00Document11 pagesMeasure Against E280-000x E302-000x E315-0xxx E732-0010 and E270-000 - en - 7.00Антон ОсадчукNo ratings yet

- Yeditepe University Department of Civil Engineering Ce 483 - Design of Structural Steel Members 2021 - 2022 FALL Tension Members ExamplesDocument4 pagesYeditepe University Department of Civil Engineering Ce 483 - Design of Structural Steel Members 2021 - 2022 FALL Tension Members ExamplesAlya TekinNo ratings yet

- Design of Machine Elements: B.E. (Mechanical Engineering / Power Engineering) Fifth Semester (C.B.S.)Document4 pagesDesign of Machine Elements: B.E. (Mechanical Engineering / Power Engineering) Fifth Semester (C.B.S.)Chandani KannakeNo ratings yet

- E-Hld Shea PDFDocument2 pagesE-Hld Shea PDFJose Luis Soto PetralandaNo ratings yet

- Al+ - :::F::L: BS EN 1992-1-1:2004 EN 1992-1-1:2004 (E)Document4 pagesAl+ - :::F::L: BS EN 1992-1-1:2004 EN 1992-1-1:2004 (E)alexNo ratings yet

- AUTODESK STRUCTURAL BRIDGE DESIGN PROGRAM VerificationDocument12 pagesAUTODESK STRUCTURAL BRIDGE DESIGN PROGRAM VerificationMohammed Haitham ElShafieNo ratings yet

- Prestressed ConcDocument11 pagesPrestressed ConcKurt CargoNo ratings yet

- Coral M2 DatasheetDocument12 pagesCoral M2 DatasheetdanydwarNo ratings yet

- Continuous BeamDocument29 pagesContinuous BeamZakwan ZakariaNo ratings yet

- 13 Rev 1Document22 pages13 Rev 1kbgainsanNo ratings yet

- Service Bulletin: SubjectDocument15 pagesService Bulletin: Subjecttoni pequodNo ratings yet

- Cat. EJB - A - Series - 2018Document6 pagesCat. EJB - A - Series - 2018fikiawekNo ratings yet

- Spot Weld Parameters HLSDocument10 pagesSpot Weld Parameters HLSHemantNo ratings yet

- Time: 1:30 Hrs Max. Marks: 20: B. Tech. (PE) Fourth Semester Class Test-2 (March - 2021) Me-262 Machine Design - IDocument2 pagesTime: 1:30 Hrs Max. Marks: 20: B. Tech. (PE) Fourth Semester Class Test-2 (March - 2021) Me-262 Machine Design - Ionline onlineNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Physics and Technology of Crystalline Oxide Semiconductor CAAC-IGZO: Application to LSIFrom EverandPhysics and Technology of Crystalline Oxide Semiconductor CAAC-IGZO: Application to LSINo ratings yet

- SV - DA200 Series AC Servo Drive - V2.2Document1 pageSV - DA200 Series AC Servo Drive - V2.2Ömer GezerNo ratings yet

- Godox Continuous Lighting 2nd en 20220919-1Document60 pagesGodox Continuous Lighting 2nd en 20220919-1Ömer GezerNo ratings yet

- PFU8 0903 enDocument89 pagesPFU8 0903 enÖmer GezerNo ratings yet

- MODBUS RTU in DARWIN Controllers: 1-IntroductionDocument6 pagesMODBUS RTU in DARWIN Controllers: 1-IntroductionÖmer GezerNo ratings yet

- Body 1 - Shooting SettingsDocument2 pagesBody 1 - Shooting SettingsÖmer GezerNo ratings yet

- Quick QuideDocument16 pagesQuick QuideÖmer GezerNo ratings yet