Professional Documents

Culture Documents

Jsa Setting Crane and Lifting Generator

Uploaded by

Seppy FajrianiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Jsa Setting Crane and Lifting Generator

Uploaded by

Seppy FajrianiCopyright:

Available Formats

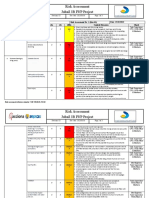

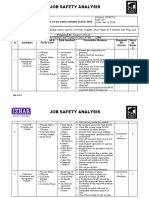

JOB SAFETY ANALYSIS FORM

JOB SAFETY ANALYSIS [TT] Trouble Ticket / [MCM]Change Date :

management Number Ref Number:

27 December 2022

COMPANY : SUBCONTRACTOR: LOCATION OF WORK :

PT. INDOKOMAS BUANA TRAKINDO ROMP02 AREA

PERKASA

DESCRIPTION OF WORK :

SETTING CRANE AND LIFTING GENERATOR

REQUIRED AND/OR RECOMMENDED PERSONAL PROTECTIVE EQUIPMENT: AUTHORISED BY:

HELMET VEST, SAFETY SHOES, SAFETY GLASSES, SAFETY VEST/UNIFORM,

HAND GLOVES.

SEQUENCE OF BASIC JOB POTENTIAL HAZARDS RECOMMENDED ACTION

STEPS OR PROCEDURE

Preparation for work Poor Access/Egress. Supervisor to provide suitable

Slip, trip and falls Access/Egress.

All materials shall be properly

arranged to avoid [S]lip, [T]rips &

[F]alls [STF].

Always Focus During Work

Use PPE according to the work

Preparation access for Crane and Entrance not proper for Crane / Do coordination and joint survey with

Truck coming in to area project Truck come inside Main contractor / user

Limited working area for Crane / Do housekeeping around working

Truck for manuver area specially Crane / truck manuver

area

Use PPE according to the work

Positioning & Installation Crane Finger pinched Avoid pinch point

500 Ton inside areas project Crane collapse Wearing hand gloves when working

Crane swing The foundation crane must be solid

Using plat for crane foundation

Operator certificated must be valid

and proper with Crane unit capacity

Rigger certificated must be valid and

proper

Install baricade around swing radius

area working Crane

Do coordination and joint survey with

Main contractor / user for Unloading

area before working

Use PPE according to the work

Mobilisation Truck come in to Truck are blocked by a car / other Do coordination with Main Contractor

areas Project truck that is loading / unloading for schedule Unloading

Truck are blocked by a material Do housekeeping around working

Hit by the truck area specially truck manuver area and

Truck collapse coordination with Main Contractor for

schedule Unloading

Make sure the access truck come in

are clear

Make sure the access truck come in

are level

Use PPE according to the work

Preparation Unloading Enclosure Hand and Foot are pinched Releasing the straps can only be done

Genset by the driver and helper driver

Position the truck on a flat / level area

/ ground

Avoid the pinch point

Use PPE according to the work

Unloading Enclosure Genset Material Falling down Make sure that wire rope sling and

Hit by material shackle are inspected before used

Wire rope Sling are broken Do communication between rigger

Material Swing and crane operator while doing the

Material damage Unloading

OverLoad Make sure that wire rope sling and

Interfere with worker's access shackle are inspected before used

roads Make sure no one is under the radius

swing / Unloading area

Install baricade and warning sign

around the radius swing area /

Unloading area

Make sure the sling capacity are

proper with lifted material

Make sure that tag line are installed

when loading unloading material

Make sure when the material is swing

does not hit the material or buildings

around the Unloading area.

Crane certificated must be valid

Do calculate the weight of the

material before Unloading in progress

Make sure the material weight

indicator on the crane is working

properly

Do coordination with min Contractor /

User before Unloading activity in

progress

Install baricade for worker access

point when Unloading activity in

progress

Use PPE according to the work

Housekeeping Slip, Trip, Fall Make sure the work access point is

Punctured free and clean when doing cleaning

Eye irritation area

Respiratory disorders Placed the remaining material in the

specified place

Always wearing hand glove when

working

Always wearing safety glasses when

working

Always wearing mask for preventing

respiration from dust

Use PPE according to the work

You might also like

- JSA-Hydraulic Press Testing For PilesDocument6 pagesJSA-Hydraulic Press Testing For PilesUMUTNo ratings yet

- Job Safety Analysis - Cone ErectionDocument7 pagesJob Safety Analysis - Cone ErectionMohammed MinhajNo ratings yet

- JSA Hot Work and ModificationDocument19 pagesJSA Hot Work and ModificationBrings MotoVlogNo ratings yet

- JSA Column Errection, Shuttering, Casting, Deshuttering Raw Material Ware HouseDocument9 pagesJSA Column Errection, Shuttering, Casting, Deshuttering Raw Material Ware Houseradeep100% (1)

- Deep Excavation Risk AssessmentDocument12 pagesDeep Excavation Risk Assessmentdonfrancis639No ratings yet

- JSA For Road BarrierDocument3 pagesJSA For Road BarrierMohammed MinhajNo ratings yet

- 4.assembly & Erection of StructureDocument3 pages4.assembly & Erection of StructureFrancis Vinoj100% (1)

- Risk Assessment-Concrete Casting by Using PumpsDocument3 pagesRisk Assessment-Concrete Casting by Using PumpsSarfraz Randhawa100% (2)

- Risk Assessment Ubderground Electric Power SupplyDocument4 pagesRisk Assessment Ubderground Electric Power SupplySameer Abdul RaufNo ratings yet

- 50 MW Artistic Wind Power Project: Job Safety Analysis Worksheet (Equipment Lifting)Document3 pages50 MW Artistic Wind Power Project: Job Safety Analysis Worksheet (Equipment Lifting)Raza Muhammad SoomroNo ratings yet

- Maeda-Onaka, Joint Venture: Generic Lifting PlanDocument4 pagesMaeda-Onaka, Joint Venture: Generic Lifting PlanJaycee Pagador100% (2)

- JHA - Civil Work - Excavation (Manual & Mechanical), Form Work & Concreting For Marlin ProjectDocument9 pagesJHA - Civil Work - Excavation (Manual & Mechanical), Form Work & Concreting For Marlin ProjectKelvin TanNo ratings yet

- Awning Install JhaDocument2 pagesAwning Install JhafatimahNo ratings yet

- Concrete Work - Truck PumpingDocument1 pageConcrete Work - Truck PumpingPrakash PavuralaNo ratings yet

- Risk Assessment - Use of Mobile Crane & Boom TruckDocument3 pagesRisk Assessment - Use of Mobile Crane & Boom TruckSarfraz Randhawa100% (3)

- JSA-Confined Space Activity - 05Document4 pagesJSA-Confined Space Activity - 05babjihanumanthuNo ratings yet

- Sequence of StepDocument2 pagesSequence of StepVelociity SR NagarNo ratings yet

- Job Safety Analysis Sheet: KOC Emergency-160 90030980 (PIL)Document3 pagesJob Safety Analysis Sheet: KOC Emergency-160 90030980 (PIL)Sreeraj Reghunathan Nair Vanmazhy100% (1)

- Generic Lifting PlanDocument4 pagesGeneric Lifting Planayman coreNo ratings yet

- 50 MW Artistic Wind Power Project: Job Safety Analysis Worksheet (Equipment Lifting)Document3 pages50 MW Artistic Wind Power Project: Job Safety Analysis Worksheet (Equipment Lifting)Raza Muhammad SoomroNo ratings yet

- Attachment 8 RA LiftingDocument5 pagesAttachment 8 RA Liftingathul subash100% (2)

- JSA #19 - Heavy Lifting in Hazardous AreaDocument1 pageJSA #19 - Heavy Lifting in Hazardous AreaMock ProjectNo ratings yet

- Jsa Cooling TowerDocument5 pagesJsa Cooling TowerRavi thokalNo ratings yet

- Job Safety Analysis (JSA) - CONCRETE WORKS - DateDocument2 pagesJob Safety Analysis (JSA) - CONCRETE WORKS - DatenabeelNo ratings yet

- PJHA Form - Compi (Ash Bin) Piling of CHBDocument3 pagesPJHA Form - Compi (Ash Bin) Piling of CHBPaul TamayoNo ratings yet

- PCW Pipe Installation JhaDocument2 pagesPCW Pipe Installation Jhafatimah100% (1)

- Sunmow Jha 001Document3 pagesSunmow Jha 001Douglas DellyNo ratings yet

- 2..loading Unloading and Installation of PipingDocument3 pages2..loading Unloading and Installation of PipingFrancis VinojNo ratings yet

- Sunmow Jha 002Document3 pagesSunmow Jha 002Douglas DellyNo ratings yet

- JHA - LiftingDocument3 pagesJHA - Liftingmark jayson yabesNo ratings yet

- DB Termination JhaDocument2 pagesDB Termination JhafatimahNo ratings yet

- 1..loading Unloading and Erection of Steel StructuresDocument2 pages1..loading Unloading and Erection of Steel StructuresFrancis VinojNo ratings yet

- Loading Stones in Dumper Tractor - Transportation Near Pit JSA HSE ProfessionalsDocument1 pageLoading Stones in Dumper Tractor - Transportation Near Pit JSA HSE ProfessionalsSamadov 13No ratings yet

- Cable Puling JhaDocument2 pagesCable Puling JhafatimahNo ratings yet

- Pole Unit Install JhaDocument2 pagesPole Unit Install JhafatimahNo ratings yet

- JSA For SURGE VESSEL WorkDocument6 pagesJSA For SURGE VESSEL Workathul subashNo ratings yet

- JSA - Porta Cabin Shifting For GODREJDocument3 pagesJSA - Porta Cabin Shifting For GODREJshamshad ahamedNo ratings yet

- GOSP-5 (60) Placing Red Tile &caution Tape Inside The TrenchDocument6 pagesGOSP-5 (60) Placing Red Tile &caution Tape Inside The TrenchShahid BhattiNo ratings yet

- Mechanical Demolish JhaDocument2 pagesMechanical Demolish JhafatimahNo ratings yet

- Job Safety Practices Erection of Precast Columns, Beams, TT Slab, Hollow Core Slab, Insulated Wall Panels & Cladding and StairsDocument4 pagesJob Safety Practices Erection of Precast Columns, Beams, TT Slab, Hollow Core Slab, Insulated Wall Panels & Cladding and StairsBarkat UllahNo ratings yet

- Job Safety Analysis - Clinker StorageDocument4 pagesJob Safety Analysis - Clinker StorageMohammed MinhajNo ratings yet

- Adr Jsa 1711 002Document7 pagesAdr Jsa 1711 002Dada KhalandarNo ratings yet

- Job Safety Analysis - Cone ErectionDocument6 pagesJob Safety Analysis - Cone ErectionEslam lotfy- Eslam elsadatNo ratings yet

- Excavator JSA - 001Document2 pagesExcavator JSA - 001Mamar ZraryNo ratings yet

- 29 HIRA Annexure HDocument328 pages29 HIRA Annexure HpradeepyellurNo ratings yet

- JSA Mobile Crane Pipe Installation Tandem LiftDocument3 pagesJSA Mobile Crane Pipe Installation Tandem LiftSyed HarisNo ratings yet

- WMS Summary EnglishDocument1 pageWMS Summary EnglishKarthik babuNo ratings yet

- HydrotestingDocument4 pagesHydrotestingDarwin De ChavezNo ratings yet

- Safety: JOB AnalysisDocument4 pagesSafety: JOB AnalysisAjay kumar100% (1)

- Naf 2020 Ra 012 00Document12 pagesNaf 2020 Ra 012 00vinayNo ratings yet

- Ahu Unit Install JhaDocument3 pagesAhu Unit Install JhafatimahNo ratings yet

- Jsa For Cable LayingDocument2 pagesJsa For Cable LayingSabari VtNo ratings yet

- Activity Hazards Analysis: MD485B Tower Assembly AHADocument6 pagesActivity Hazards Analysis: MD485B Tower Assembly AHAJaycee PagadorNo ratings yet

- JSA For Scaffolding Erection Dismantling and Modification WorkDocument17 pagesJSA For Scaffolding Erection Dismantling and Modification Workshane.ramirez1980No ratings yet

- Jsa (Ercction of Tower Crane) G-11Document4 pagesJsa (Ercction of Tower Crane) G-11khurram shahzadNo ratings yet

- Jsa Lifting & Moving Storage Tank 100 KL Pure DCDocument1 pageJsa Lifting & Moving Storage Tank 100 KL Pure DCArief WicaksonoNo ratings yet

- X.9.b Job Hazard AnalysisDocument8 pagesX.9.b Job Hazard AnalysisChris Kenneth ManansalaNo ratings yet

- SEOT JSA For Vehicle EntryDocument3 pagesSEOT JSA For Vehicle EntryArchana SoorajNo ratings yet

- Jsa For Plaster WorkDocument4 pagesJsa For Plaster Workumar KhitabNo ratings yet