Professional Documents

Culture Documents

Jsa Lifting & Moving Storage Tank 100 KL Pure DC

Uploaded by

Arief WicaksonoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Jsa Lifting & Moving Storage Tank 100 KL Pure DC

Uploaded by

Arief WicaksonoCopyright:

Available Formats

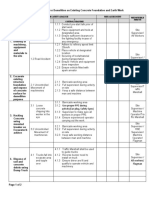

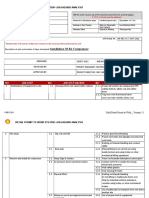

JOB SAFETY ANALYSIS - JSA

PROJECT

JOB NAMENAME : PT. PURE DC - JAKARTA

JOB NAME : LIFTING & MOVING UNDERGROUND STORAGE TANK 100 KL

CONTRACTOR NAME : PT. TRAKINDO UTAMA

NO. WORK ACTIVITIES RISK MITIGASI PPE REQUIRED

Preparation access for Crane and Truck 1.1 Entrance not proper for Crane / Truck come inside 1.1.1 Do coordination and joint survey with Main contractor / user

1

coming in to area project 1.2 Limited working area for Crane / Truck for manuver 1.2.1 Do housekeeping around working area specially Crane / truck manuver area 1. Safety Helmet

2. Safety Googles

2.1 Finger pinched 2.1.1 Avoid pinch point 3. Safety shoes

2.1.2 Wearing hand gloves when working 4. Handgloves

2.2 Crane collapse 2.2.1 The foundation crane must be solid 5. Mask

2.2.2 Using plat for crane foundation

2 Positioning & Installation Crane 360 Ton 2.2.3 Operator certificated must be valid and proper with Crane unit capacity

inside areas project

2.2.4 Rigger certificated must be valid and proper

2.3 Crane swing 2.3.1 Install baricade around swing radius area working Crane OTHERS

2.3.2 Install Safety Sign " CRANE IN OPERATION" 1. Handly Talkie - HT

2.3.3 Do coordination and joint survey with Main contractor / user for swing area before working 2. Traffic cone

3. Safety line tape

3.1 Truck are blocked by a car / other truck that is loading / 3.1.1 Do coordination with Main Contractor for schedule Unloading Storage Tank 100 KL 4. Safety Take Line

unloading

3.2 Truck are blocked by a material 3.2.1 Do housekeeping around working area specially truck manuver area and coordination with Main

3 Mobilisation Truck come in to areas Project Contractor for schedule Unloading

3.3 Hit by the truck 3.3.1 Make sure the access truck come in are clear

3.4 Truck collapse 3.4.1 Make sure the access truck come in are level

4.1 Hand and Foot are pinched 4.1.1 Releasing the straps can only be done by the driver and helper driver

4 Preparation Unloading Storage Tank 100 KL 4.1.2 Position the truck on a flat / level area / ground

4.1.3 Avoid the pinch point

5.1 Material Falling down 5.1.1 Make sure that wire rope sling and shackle are inspected before used

5.1.2 Do communication between rigger and crane operator while doing the lifting

5.2 Hit by material 5.2.1 Make sure that wire rope sling and shackle are inspected before used

5.2.2 Make sure no one is under the radius swing / lifting area

5.2.3 Install baricade and warning sign around the radius swing area / lifting area

5.3 Wire rope Sling are broken 5.3.1 Make sure that wire rope sling and shackle are inspected before used

5.3.2 Make sure the sling capacity are proper with lifted material

5 Lifting Storage Tank 100 KL 5.4 Material Swing 5.4.1 Make sure that tag line are installed when loading unloading material

5.5 Material damage 5.5.1 Make sure when the material is swing does not hit the material or buildings around the lifting area.

5.6 OverLoad 5.6.1 Make sure that Crane has been inspected before doing the lifiting activity

5.6.2 Crane certificated must be valid

5.6.3 Do calculate the weight of the material before lifting in progress

5.6.4 Make sure the material weight indicator on the crane is working properly

5.7 Interfere with worker's access roads 5.7.2 Do coordination with min Contractor / User before lifting activity in progress

5.7.3 Install baricade for worker access point when lifting activity in progress

6.1 Hand and Foot are pinched 6.1.1 Releasing the straps can only be done by the driver and helper driver

6 Preparation Unloading Extension Mainhole 6.1.2 Position the truck on a flat / level area / ground

6.1.3 Avoid the pinch point

7.1 Material Falling down 7.1.1 Make sure that wire rope sling and shackle are inspected before used

7.1.2 Do communication between rigger and crane operator while doing the lifting

7.2 Hit by material 7.2.1 Make sure that wire rope sling and shackle are inspected before used

7.2.2 Make sure no one is under the radius swing / lifting area

7.2.3 Install baricade and warning sign around the radius swing area / lifting area

7.3 Wire rope Sling are broken 7.3.1 Make sure that wire rope sling and shackle are inspected before used

7.3.2 Make sure the sling capacity are proper with lifted material

7 Lifting Extension Mainhole 7.4 Material Swing 7.4.1 Make sure that tag line are installed when loading unloading material

7.5 Material damage 7.5.1 Make sure when the material is swing does not hit the material or buildings around the lifting area.

7.6 OverLoad 7.6.1 Make sure that Crane has been inspected before doing the lifiting activity

7.6.2 Crane certificated must be valid

7.6.3 Do calculate the weight of the material before lifting in progress

7.6.4 Make sure the material weight indicator on the crane is working properly

7.7 Interfere with worker's access roads 7.7.2 Do coordination with min Contractor / User before lifting activity in progress

7.7.3 Install baricade for worker access point when lifting activity in progress

8.1 Slip, Trip, Fall 8.1.1 Make sure the work access point is free and clean when doing cleaning area

8.2 Punctured 8.2.1 Placed the remaining material in the specified place

8 cleaning of the work area 8.2.2 Always wearing hand glove when working

8.3 Eye irritation 8.3.1 Always wearing safety glasses when working

8.4 Respiratory disorders 8.4.1 Always wearing mask for preventing respiration from dust

9.1 Lack of lighting / Dark 9.1.1 Make sure the work area has lighting.

9 Activities at night

9.1.2 Make sure the lights used can illuminate the entire work area.

Prepared by Acknowledged by revisi/approve with comment/approve

PT.TRAKINDO UTAMA PT.TRAKINDO UTAMA PURE DC

( HSE ) ( PROJECT MANAGER ) (_____________________________) (_____________________________) (_____________________________)

You might also like

- Risk AssessmentDocument6 pagesRisk AssessmentMohammed Shiful0% (1)

- Pc228us Uslc-3#30001 Sebm030501 U0303Document579 pagesPc228us Uslc-3#30001 Sebm030501 U0303Сергей Москвин100% (2)

- Macramee For Jewelry ZZZDocument174 pagesMacramee For Jewelry ZZZVlatko Goljevacki100% (3)

- Fit To Be Tied PDFDocument24 pagesFit To Be Tied PDFancsisan100% (3)

- JSA Working at HeightDocument2 pagesJSA Working at HeightFadzira Syahira Fadzaleh100% (7)

- JSA For Electrical ActivitiesDocument14 pagesJSA For Electrical Activitiesdrparihary100% (2)

- WORK at HEIGHT Job Hazard AnalysisDocument3 pagesWORK at HEIGHT Job Hazard Analysistosin babayomi0% (1)

- 011 - JSA (Tower Crane)Document9 pages011 - JSA (Tower Crane)satti80% (5)

- Jsa For Sand Filling of SwampDocument5 pagesJsa For Sand Filling of SwampOgunwa Emmanuel0% (1)

- Step No Sequence of Basic Job Steps Potential Hazards Controll Measures Action byDocument6 pagesStep No Sequence of Basic Job Steps Potential Hazards Controll Measures Action byrahul tk100% (1)

- Kta Alliance Spray /touch Up Painting of Project Materials: Job Safety Analysis (JSA)Document3 pagesKta Alliance Spray /touch Up Painting of Project Materials: Job Safety Analysis (JSA)Ogunwa EmmanuelNo ratings yet

- Maeda-Onaka, Joint Venture: Generic Lifting PlanDocument4 pagesMaeda-Onaka, Joint Venture: Generic Lifting PlanJaycee Pagador100% (2)

- WSHi - Vehicular Safety at Work in SingaporeDocument17 pagesWSHi - Vehicular Safety at Work in SingaporeThupten Gedun Kelvin Ong100% (1)

- ULSADO-JSA-Demolation Existing Concrete FoundationDocument2 pagesULSADO-JSA-Demolation Existing Concrete FoundationKelvin Tan75% (4)

- JSA Demolition Wall B#3Document2 pagesJSA Demolition Wall B#3tit somm100% (3)

- ULSADO-JSA - Installation of Temporary Fence GateDocument2 pagesULSADO-JSA - Installation of Temporary Fence GateKelvin TanNo ratings yet

- JSA For Ship Repairing Welding Cutting and Grinding Activity 21.08.2023Document7 pagesJSA For Ship Repairing Welding Cutting and Grinding Activity 21.08.2023Sebin VargheseNo ratings yet

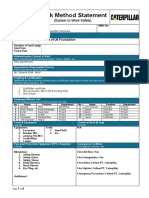

- Work Method StatamentDocument4 pagesWork Method StatamentAmril Al RizaNo ratings yet

- 3 (1) Leea Advice On Eyebolts PDFDocument2 pages3 (1) Leea Advice On Eyebolts PDFReda MashalNo ratings yet

- 11 - JSA (Tower Crane) 12-9-06Document11 pages11 - JSA (Tower Crane) 12-9-06sattiNo ratings yet

- Iso 10325 2018Document9 pagesIso 10325 2018Julio Andrés Casal Ramos0% (1)

- Hoisting & Rigging Handbook - AEDC PDFDocument341 pagesHoisting & Rigging Handbook - AEDC PDFLim100% (1)

- K604169E Training Eurolift PDFDocument34 pagesK604169E Training Eurolift PDFBenjamin Gonzalez0% (1)

- Suspended Scaffold Inspection ChecklistDocument3 pagesSuspended Scaffold Inspection ChecklistSamantha Meril PandithaNo ratings yet

- JSA - 015 - Concrete Breaking With Hydraulic BreakerDocument2 pagesJSA - 015 - Concrete Breaking With Hydraulic BreakerAhmed AlderbiNo ratings yet

- Falih Falih SDN SDN BHD BHD JOB Job Safety Safety Analysis Analysis Jsa/Piling Jsa/Piling 1 1 of OF5 5 Doc. Doc. No. NO. Page No. NODocument9 pagesFalih Falih SDN SDN BHD BHD JOB Job Safety Safety Analysis Analysis Jsa/Piling Jsa/Piling 1 1 of OF5 5 Doc. Doc. No. NO. Page No. NOSreejith SureshNo ratings yet

- PowerPoint Safe Mooring Operations With All Speakers Slides Rev B PDFDocument92 pagesPowerPoint Safe Mooring Operations With All Speakers Slides Rev B PDFNeli Ruiz100% (2)

- Wire Rope InspectionDocument34 pagesWire Rope InspectionCristian Hugo100% (3)

- JACK IN Piling WorkDocument9 pagesJACK IN Piling WorkShaheed AzharNo ratings yet

- West of England - Loss Prevention Bulletin - Gangways and Accomodation Ladders PDFDocument6 pagesWest of England - Loss Prevention Bulletin - Gangways and Accomodation Ladders PDFDave Moreno100% (1)

- Safety Guidelines For Design, Construction & Operation of TugsDocument50 pagesSafety Guidelines For Design, Construction & Operation of TugsTomash Verbitsky100% (2)

- Refueling JSA 4 08 2019 Rev.03 Near WaterDocument9 pagesRefueling JSA 4 08 2019 Rev.03 Near Waterrisky indra antariNo ratings yet

- Sheaves InspectionDocument9 pagesSheaves InspectionGrenoite Grenoite100% (1)

- Conveyor Belt StandardsDocument7 pagesConveyor Belt Standardssuraia100% (1)

- MCD - JHA - 014 - Repainting McDonalds PylonDocument3 pagesMCD - JHA - 014 - Repainting McDonalds Pylondini lalalaNo ratings yet

- Lizof Jsa For ExcavationDocument2 pagesLizof Jsa For ExcavationOgunwa EmmanuelNo ratings yet

- JSA - 003 - Tripod Rig Erection, Operation and DismantlingDocument2 pagesJSA - 003 - Tripod Rig Erection, Operation and DismantlingAbhijit JanaNo ratings yet

- E 503 JsaDocument3 pagesE 503 Jsarizal azizanNo ratings yet

- Octopus Jsa For ExcavationDocument1 pageOctopus Jsa For ExcavationOgunwa EmmanuelNo ratings yet

- 13.concrete PouringDocument3 pages13.concrete PouringAyaz AhmadNo ratings yet

- Jsa Setting Crane and Lifting GeneratorDocument2 pagesJsa Setting Crane and Lifting GeneratorSeppy FajrianiNo ratings yet

- Job Safety Analisys - HSBC WTC 1 - 2Document3 pagesJob Safety Analisys - HSBC WTC 1 - 2Ismi Ambar SariNo ratings yet

- JHRA StructuralDocument55 pagesJHRA StructuralArnold AlamaniNo ratings yet

- MSHEM-02.11-C Level 2 JSA - Veolia - RO Units Vehicle Forklift Use For Loading & Unloading Material.Document5 pagesMSHEM-02.11-C Level 2 JSA - Veolia - RO Units Vehicle Forklift Use For Loading & Unloading Material.Abdullah AbedNo ratings yet

- Rsa 3 Project: Title Job Safety Analysis FormDocument3 pagesRsa 3 Project: Title Job Safety Analysis FormKashif RehmanNo ratings yet

- C063 JSA For Installaiton of I Beam at Laundry AreaDocument7 pagesC063 JSA For Installaiton of I Beam at Laundry Areaiftikhar ahmadNo ratings yet

- Fire Line Modification JSADocument124 pagesFire Line Modification JSARaj Engineering ServicesNo ratings yet

- JSA 003 Hacking of Damaged Thickening at Underdeck - Jetty HeadDocument1 pageJSA 003 Hacking of Damaged Thickening at Underdeck - Jetty HeadRyanNo ratings yet

- Hicararc WpaDocument19 pagesHicararc WpaNickIrwingNo ratings yet

- Method Statement Coring Pit of ElevatorDocument7 pagesMethod Statement Coring Pit of ElevatorsochealaoNo ratings yet

- JSA 001 Tug Boat Positioning and Crew TransferDocument1 pageJSA 001 Tug Boat Positioning and Crew TransferRyanNo ratings yet

- Jsa For Receiving and Loading of Aggregates Onto Material BargeDocument2 pagesJsa For Receiving and Loading of Aggregates Onto Material BargeOgunwa EmmanuelNo ratings yet

- JHA - Installation of Air CompressorDocument4 pagesJHA - Installation of Air CompressorFikri HidayatNo ratings yet

- Jha - PW - 22 - Plumbing WorkDocument3 pagesJha - PW - 22 - Plumbing WorkFikri HidayatNo ratings yet

- Loading Stones in Dumper Tractor - Transportation Near Pit JSA HSE ProfessionalsDocument1 pageLoading Stones in Dumper Tractor - Transportation Near Pit JSA HSE ProfessionalsSamadov 13No ratings yet

- 02-1. Risk Assessment Guide LineDocument67 pages02-1. Risk Assessment Guide LinePEng. Tech. Alvince KoreroNo ratings yet

- Jha - SW - 22 - Spandex Wall ReplacementDocument5 pagesJha - SW - 22 - Spandex Wall ReplacementFikri HidayatNo ratings yet

- Inland Transportation and Handling ProcedureDocument4 pagesInland Transportation and Handling Procedureismail karmanaNo ratings yet

- HIRA For Concrete Pouring of Diaphragm WallDocument4 pagesHIRA For Concrete Pouring of Diaphragm WallLoc Nguyen0% (1)

- Install StairwayDocument4 pagesInstall StairwayAgung Juni KurniawanNo ratings yet

- Fire Line Modification JSA StepsDocument2 pagesFire Line Modification JSA StepsRaj Engineering ServicesNo ratings yet

- Jha Mob Demob MaterialsDocument1 pageJha Mob Demob MaterialsMOHD REZUANNo ratings yet

- MAB For JHADocument8 pagesMAB For JHARohit TharseNo ratings yet

- Swing Grinding JhaDocument6 pagesSwing Grinding JhaDwitikrushna RoutNo ratings yet

- Internal Cleaning in WSW N2 SeparatorDocument4 pagesInternal Cleaning in WSW N2 SeparatorWALIDNo ratings yet

- Crane Specification DocumentDocument9 pagesCrane Specification DocumentP Venkata SureshNo ratings yet

- Safety Target For July 2018Document1 pageSafety Target For July 2018Jun Rey MoralesNo ratings yet

- Jsa Roof Sheeting & Wall CladdingDocument23 pagesJsa Roof Sheeting & Wall Claddingsamir ranjan dhalNo ratings yet

- 4-JSA - Unloading Under Inert - F9030 B NewDocument6 pages4-JSA - Unloading Under Inert - F9030 B NewAde RahmadiNo ratings yet

- Guía Operaciones Helicóptero BarcoDocument38 pagesGuía Operaciones Helicóptero Barcovanmorrison69No ratings yet

- Octopus Jsa For Fusion WeldingDocument2 pagesOctopus Jsa For Fusion WeldingOgunwa EmmanuelNo ratings yet

- JSA Fuel Transfer From Tug Boat To BargeDocument2 pagesJSA Fuel Transfer From Tug Boat To BargeRyanNo ratings yet

- MM PracticalDocument5 pagesMM PracticalSilent TornadoNo ratings yet

- BS en 12385-1-2002 (2004)Document22 pagesBS en 12385-1-2002 (2004)Leon MarcoNo ratings yet

- Ropeway Ropes Technical GuideDocument13 pagesRopeway Ropes Technical GuideNelson Andres Moreno AriasNo ratings yet

- Steel Mesh System For Reinforced FillDocument25 pagesSteel Mesh System For Reinforced FillThameem SharaafNo ratings yet

- Spiral Rope Chain - Beading Techniques - Fusion BeadsDocument5 pagesSpiral Rope Chain - Beading Techniques - Fusion BeadsShawn BrownNo ratings yet

- Wilo Crononorm NLDocument55 pagesWilo Crononorm NLAlexandreCaironiNo ratings yet

- ISO 2408 2017 (E) - Character PDF DocumentDocument60 pagesISO 2408 2017 (E) - Character PDF DocumentNelly DavedNo ratings yet

- Big Question Mark Scheme and Teacher NotesDocument4 pagesBig Question Mark Scheme and Teacher NotesSahar AhmedNo ratings yet

- Taglineuse PEERREVIEWDOCDocument56 pagesTaglineuse PEERREVIEWDOCMohamed Said0% (1)

- Nautical Science Syllabus PDFDocument77 pagesNautical Science Syllabus PDFDevansh TyagiNo ratings yet

- Suspension TherapyDocument35 pagesSuspension TherapySubhankar GiriNo ratings yet

- Phoenix - Visit - 25 08 2017Document22 pagesPhoenix - Visit - 25 08 2017Adeeb RizviNo ratings yet

- Rigging Types and ConceptsDocument24 pagesRigging Types and ConceptsBoom DizzleNo ratings yet

- 2012 Petzl CatalogueDocument114 pages2012 Petzl CataloguealanrinNo ratings yet

- MDG-33 TotDocument205 pagesMDG-33 TotSteve PennNo ratings yet

- Mobile Gantries SI 20.3Document2 pagesMobile Gantries SI 20.3reda mesbahNo ratings yet

- Slings FinalDocument16 pagesSlings FinalAmaka NwakobiNo ratings yet