Professional Documents

Culture Documents

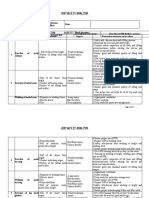

Fire Line Modification JSA Steps

Uploaded by

Raj Engineering ServicesCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fire Line Modification JSA Steps

Uploaded by

Raj Engineering ServicesCopyright:

Available Formats

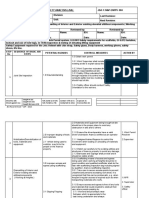

Job Safety Analysis JSA N0.

:- 01

JOB DECRIPTION :- HOT WORK ACTIVITY LOCATION :- Admin Front side

Prepared By :- Review By :- Prepared Date :- 13/10/2021

Approved By :- Date :- Next Review Date :-

PPE's Required to perform the Job- Safety Helmet , Safety Shoes , Hand gloves ,Safety clear view googles , Reflector Jacket , Nose Mask , Leathor gloves, Welding FaceShield /

Clear view face shield

sr.no. Describe Job Step Potential Hazards Recommended (Hazard Controls)

1.1.1) Before shifting make sure pathway area is clear from of slip ,trip hazards.

1.1) Slip, trip hazard 1.1.2) The material should be taken by

craftsman in proper manner for proper stacking On pallet For Shifting.

1.2.1) Remove the all Sharp Edge From the Site if not removed then covered it

1.2) Physical injury while Shifting ( Pinch, Cut 1.2.2) Use all required PPE'S during Material shifting time.

injury), 1.2.3) Use shoulder pad During Material Shifting On shoulder.

1.2.4) Do Not Put The Hand Below Material

1.3.1) Check The all Tools & Equipment's Before Take The Any tool & Equipment.

1.3.2) Check The HOPT Visually & through Checklist.

1.3) Damage Tools & Equipment's

1.3.3) Check The Gas Trolley & Check the Cylinder Cap.

1.3.4) They will not be carried by laying on the Cylinder , They Will be Carried In Trolley.

1.4.1) Only vehicle operator are allowed to operate the vehicle.

SHIFTING OF MATERIAL & EQUIPMENT’S 1.4.2) No worker allowed in the vehicle movement area .

1) ( AT JOB LOCATION MANUALLY & WITH

THE HELP OF HOPT & PALLET. 1.4.3) Pathway must be free from obstacle.

1.4) Property damage( Material Can Hit With

Worker & Other Objects) 1.4.4) Use stoppers/chokes to avoid movement of vehicle.

1.4.5) Mobile Phone Not Allowed During operating of vehicle.

1.4.6) Signal man Must be available During material unloading Work For Giving the signal &

also give the whistle.

1.5.1) only 25 kg Any Material allow For Lifting per person .

1.5) Fall of material 1.5.2). Proper Man Power According to Weight Shifting Work.

1.5.3) Material Will be Tie Properly With The Help Of PP Rope.

1.6.2) Use Proper PPE'S During Work.

1.6.2) Give the Proper Work Place For Working.

1.6) Ergonomic hazard. 1.6.3) Use Proper Body Position During Work.

1.6.4) Use Proper Man Power According To weight & One Worker Allow to lift Only 25 kg.

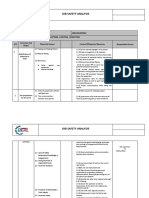

2.1.1) Check the Area before Start the Work.

2.1) Slip, trip hazard 2.1.2) Insure Start the Work The Working area free From Slip Trip Hazard Through Daily

Housekeeping Checklist.

2.2.1) Remove the all Sharp Edge From the Site if not removed then covered it

2.2) Physical injury ( Pinch, Cut injury),

2.2.2) Use all required PPE'S during Material shifting time.

AREA BARRICADE & PROPER MATERIAL

2) STACKING

2.3.1) Material Will Be Stacking Properly.

2.3) Fall Of Material From Pallet 2.3.2) We Will Not Store The material Too Much Height

2.3.3) If Possible Then Tie With PP Rope.

2.4.1) Only Store The material On Mention Location.

2.4) Placed Wrong Location

2.4.2) No Any material Store & Stacking In Front Of Emergency Door & Emergency equipment.

3.1) Personnel starting the work 3.1.1) Job Specific Training will be conducted prior to Start the Work & wearing the required

uninducted/protected PPE

3.2) Welding machine could fail to lead 3.2.1) Welding work must not be performed in bad weather like rain.

accident. 3.2.2) Check machine before starting the work and maintain checklist with construction tag

3.3) Electrical shock 3.3.1) All portable power tools & extension board must be inspected by Gillette electrical

department and tag off before starting the work.

3.3.2) Ensure no loose connection or cut or joint in power cable of welding machine.

3.3.3) Only authorized electrical person to be allow for electrical work

3.4) Burn Injury 3.4.1) Only qualified welder must be performed welding work.

3.4.2.) Use all hot work PPEs like, apron, leather hand gloves, welding face shield etc.

3.4.3) Only welder’s helper to be allowed in work area with full welding PPEs

3.5) Physical Injury during grinding 3.5.1) Guard must be provided in grinding machine

3) HOT WORK ACTIVITY ( WELDING WORK) 3.5.2) Use hand gloves & face shield during grinding

3.5.3) Checked grinding wheel properly there is no crack on wheel.

3.6.) Fire Hazard 3.6..1) Ensure all combustible material to be removed near hot work area (min. 10 meter.)

3.6.2) If combustible material or any material could not be removed near hot work area use

fire blanket & take deviation form .

3.6.3) Fire extinguisher to be placed near hot work area.

3.6.4) Fire watcher must be available near hot work area.

3.6.5) Welding earthing tight, and also use near combustible material free area.

3.7) Fumes Inhalation 3.7.1) Use Proper Nose Mask During Welding Work.

3.8) Loose clothing 3.8.1) No loose clothing scarf shirt/open cloth shall be worn wear during Work.

3.9) Eye injury 3.9.1) Proper eye goggles/face shield/welding mask should be used during Welding Work.

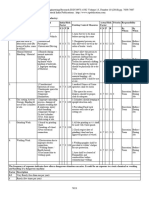

4.1.1) Before starting the work Hoses, valves, couplings and connection must be inspected

for damage & leaks.

4.1.2) During storage or when in use gas cylinders must always be secured in upright position.

4.1.3) Full or empty gas cylinders not in use shall have their valves shut and valve protection

cap screwed on.

4.1.4) Torch will be lit by friction lighters, not with matches or from hot work

4.1.5) Oxygen and Acetylene gas hoses must be different in colour ( Blue for oxygen And red

for acetylene)

4.1) Fire & Explosion during work

4) Gas cutting with Oxy-acetylene

4.1) Fire & Explosion during work 4.1.6) "Flashback" occurs when a flame burns back inside a torch, hoses or regulators and

can cause a fire or explosion if it is reach the cylinder. So use Flashback arrester both side.

4) Gas cutting with Oxy-acetylene (Torch & cylinders)

4.1.7) Cylinder must be kept in trolley when in use and secured with the chain.

4.1.8) Ensure all combustible material to be removed near hot work area (min. 10 meter.)

4.1.9) If combustible material or any material could not be removed near hot work area use

fire blanket.

4.1.10) Fire extinguisher to be placed near hot work area.

4.1.11) Fire watcher must be available near hot work area.

4.2.1) Use leather hand gloves during cutting work.

4.2) Burn Injury 4.2.2) Do not allowed any other person in work area, if required use all PPEs.

4.2.3) Use all hot work related PPEs during work.

Prepared by - Reviewed by Approved by -

Name:- Name:- Name:-

Signature:- Signature:- Signature:-

You might also like

- Fire Line Modification JSADocument124 pagesFire Line Modification JSARaj Engineering ServicesNo ratings yet

- JSA - Foam RefillingDocument13 pagesJSA - Foam RefillingMuhammad Umar GondalNo ratings yet

- 14 - Jsa-Rain Water Harvesting Pit CleaningDocument3 pages14 - Jsa-Rain Water Harvesting Pit CleaningAKBAR ALINo ratings yet

- Jsa For Sand Filling of SwampDocument5 pagesJsa For Sand Filling of SwampOgunwa Emmanuel0% (1)

- JSA For Cutting, Grinding and Welding in AtmosphereDocument21 pagesJSA For Cutting, Grinding and Welding in AtmosphereThái Đạo Phạm Lê100% (1)

- Kta Alliance Spray /touch Up Painting of Project Materials: Job Safety Analysis (JSA)Document3 pagesKta Alliance Spray /touch Up Painting of Project Materials: Job Safety Analysis (JSA)Ogunwa EmmanuelNo ratings yet

- Bag House ChimmenyDocument2 pagesBag House Chimmenyshahhussain1031No ratings yet

- JSA-RHI-ARZ-0-005 ASU - Scaffolding Works Rev00 - ArzewDocument6 pagesJSA-RHI-ARZ-0-005 ASU - Scaffolding Works Rev00 - ArzewUmit KaymakNo ratings yet

- Jsa No-01 Container UnloadingDocument4 pagesJsa No-01 Container Unloadingsumith s100% (1)

- Jsa Cable LayingDocument2 pagesJsa Cable LayingAbcd efgh100% (1)

- Jsa For Receiving and Loading of Aggregates Onto Material BargeDocument2 pagesJsa For Receiving and Loading of Aggregates Onto Material BargeOgunwa EmmanuelNo ratings yet

- JSA - Loading of Cut Plates Using Haib Truck - S06Document6 pagesJSA - Loading of Cut Plates Using Haib Truck - S06KrishVy KumærNo ratings yet

- Jsa For Scaffolding ErectionDocument7 pagesJsa For Scaffolding Erectionnoorul IslamNo ratings yet

- MAB For JHADocument8 pagesMAB For JHARohit TharseNo ratings yet

- Swing Grinding JhaDocument6 pagesSwing Grinding JhaDwitikrushna RoutNo ratings yet

- Risk Assessment Sheet - in An Indian IndustryDocument2 pagesRisk Assessment Sheet - in An Indian IndustryAswini AcharyaNo ratings yet

- WORK at HEIGHT Job Hazard AnalysisDocument3 pagesWORK at HEIGHT Job Hazard Analysistosin babayomi0% (1)

- E 503 JsaDocument3 pagesE 503 Jsarizal azizanNo ratings yet

- Jsa For Scaffolding Erection & DismentlingDocument7 pagesJsa For Scaffolding Erection & Dismentlingsanath adhikary100% (5)

- Step No Sequence of Basic Job Steps Potential Hazards Controll Measures Action byDocument6 pagesStep No Sequence of Basic Job Steps Potential Hazards Controll Measures Action byrahul tk100% (1)

- 002 Job Safety Analysis For Excavation, Backfilling and Compaction Activities at SAOO GOSPs Rev 03Document8 pages002 Job Safety Analysis For Excavation, Backfilling and Compaction Activities at SAOO GOSPs Rev 03Haleem Ur Rashid Bangash100% (2)

- 002 Job Safety Analysis For Excavation, Backfilling and Compaction Activities at SAOO GOSPs Rev 03 PDFDocument8 pages002 Job Safety Analysis For Excavation, Backfilling and Compaction Activities at SAOO GOSPs Rev 03 PDFHaleemUrRashidBangash100% (1)

- R.K Construction: Job Hazard AnalysisDocument8 pagesR.K Construction: Job Hazard AnalysisDwitikrushna Rout100% (1)

- JSA For Height WorkDocument6 pagesJSA For Height WorkMithilesh KumarNo ratings yet

- Jsa For Painting Operation: S.N o Scope of Activity Hazard Control Measures Requested byDocument3 pagesJsa For Painting Operation: S.N o Scope of Activity Hazard Control Measures Requested bywahyu nugroho100% (2)

- JSA Demolition Wall B#3Document2 pagesJSA Demolition Wall B#3tit somm100% (3)

- Risk Analysis of MachineDocument13 pagesRisk Analysis of Machineavinash bahadurNo ratings yet

- JSA - CivilDocument5 pagesJSA - CivilRajuNo ratings yet

- Jha For SMP 2Document7 pagesJha For SMP 2Rohit TharseNo ratings yet

- Risk Assessment For Concrete WorksDocument3 pagesRisk Assessment For Concrete WorksMario Marasigan86% (36)

- 15.tube Bundle Puller.Document3 pages15.tube Bundle Puller.Mohammad Fazal Khan100% (1)

- Boiler JSADocument42 pagesBoiler JSApankajbhatt376No ratings yet

- Risk Assessment & Control Measure Worksheet (RA Sheet)Document5 pagesRisk Assessment & Control Measure Worksheet (RA Sheet)alla malikNo ratings yet

- JSA For Plaster WorkDocument8 pagesJSA For Plaster WorkZakeer ShaikhNo ratings yet

- Lizof Jsa For ExcavationDocument2 pagesLizof Jsa For ExcavationOgunwa EmmanuelNo ratings yet

- BLASTING&PAINTINGDocument10 pagesBLASTING&PAINTINGLajapathi RaiNo ratings yet

- Ijaerv13n10 56-15Document1 pageIjaerv13n10 56-15nazasraf2012No ratings yet

- Sample JHADocument5 pagesSample JHAKen100% (1)

- Eta-Jsa Piping, Works Bolt Tightening Using Hydraulic ToolsDocument7 pagesEta-Jsa Piping, Works Bolt Tightening Using Hydraulic Toolslelu ojhaNo ratings yet

- Octopus Jsa For ExcavationDocument1 pageOctopus Jsa For ExcavationOgunwa EmmanuelNo ratings yet

- 01.work Instruction For Operation of Belt Conveyor-UpdatedDocument6 pages01.work Instruction For Operation of Belt Conveyor-UpdatedRahul VermaNo ratings yet

- Jha 2022Document8 pagesJha 2022Sandeep KumarNo ratings yet

- 12 Scaffolding WorkDocument5 pages12 Scaffolding WorkKoneti JanardhanaraoNo ratings yet

- Delta Corporation Risk AssessmentDocument1 pageDelta Corporation Risk AssessmentAhmed OusamaNo ratings yet

- JSEA Install Grounding & Stick Earth BuildingDocument6 pagesJSEA Install Grounding & Stick Earth BuildingGus PurNo ratings yet

- Job Safety Analysis WorksheetDocument1 pageJob Safety Analysis Worksheetsrinivasa raoNo ratings yet

- EXPERT-JSA Plastering Works (Elevated Work) - 1Document7 pagesEXPERT-JSA Plastering Works (Elevated Work) - 1mr zaibNo ratings yet

- JSA - Erection Boiler Install (SFILEDocument35 pagesJSA - Erection Boiler Install (SFILEHilman NugrahaNo ratings yet

- Shifting of Material & Equipment.: Job Safety Analysis JobDocument6 pagesShifting of Material & Equipment.: Job Safety Analysis JobPrabir PujariNo ratings yet

- Shuttering WorksDocument3 pagesShuttering WorksAbdul GhaffarNo ratings yet

- 11 - JSA (Tower Crane) 12-9-06Document11 pages11 - JSA (Tower Crane) 12-9-06sattiNo ratings yet

- Risk Assessment-Bridge ConstructionDocument1 pageRisk Assessment-Bridge ConstructionMirzojon MirzoevNo ratings yet

- Jsa For Cutting, Grinding and Welding For GulfconDocument3 pagesJsa For Cutting, Grinding and Welding For GulfconOgunwa Emmanuel100% (1)

- RADocument2 pagesRAalisheeraz0302No ratings yet

- Jsa For Installation of Pipe Railing On SkidDocument6 pagesJsa For Installation of Pipe Railing On SkidLokesh Aravindan100% (1)

- Job Security Analysis Job DataDocument2 pagesJob Security Analysis Job DataJeffrey Sanchez RojasNo ratings yet

- JSA - Manual Lifting (Using Chain Block, Sling Belt and Shackle)Document2 pagesJSA - Manual Lifting (Using Chain Block, Sling Belt and Shackle)muiqbal.workNo ratings yet

- JSA Equipment Leading With CraneDocument3 pagesJSA Equipment Leading With CraneKoneti JanardhanaraoNo ratings yet

- Work Method Statement - Soil ProtectionDocument2 pagesWork Method Statement - Soil ProtectionAugust Caezar LagatNo ratings yet

- Robotics: 3rd EditionFrom EverandRobotics: 3rd EditionRating: 1 out of 5 stars1/5 (1)

- Training Attandance SheetDocument1 pageTraining Attandance SheetRaj Engineering ServicesNo ratings yet

- Ppe Inspection Form: Personal Protective EquipmentDocument2 pagesPpe Inspection Form: Personal Protective EquipmentRaj Engineering ServicesNo ratings yet

- Area To Assess Health Check Question / Observation Y/N Comments 1Document1 pageArea To Assess Health Check Question / Observation Y/N Comments 1GuptaNo ratings yet

- Fire Line Modification JSA StepsDocument2 pagesFire Line Modification JSA StepsRaj Engineering ServicesNo ratings yet

- Helsingborg EngDocument8 pagesHelsingborg EngMassaCoNo ratings yet

- IMS DB Interview Questions: Beginner LevelDocument19 pagesIMS DB Interview Questions: Beginner LevelsudhakarcheedaraNo ratings yet

- B&G 3DX LiteratureDocument2 pagesB&G 3DX LiteratureAnonymous 7xHNgoKE6eNo ratings yet

- Paul S. Adler - Paul Du Gay - Glenn Morgan - Michael Reed (Eds.) - The Oxford Handbook of Sociology, Social Theory, and Organization Studies - Contemporary Currents-Oxford University Press, USA (2014)Document817 pagesPaul S. Adler - Paul Du Gay - Glenn Morgan - Michael Reed (Eds.) - The Oxford Handbook of Sociology, Social Theory, and Organization Studies - Contemporary Currents-Oxford University Press, USA (2014)Andreea Dobrita67% (3)

- Suggested Answers Spring 2015 Examinations 1 of 8: Strategic Management Accounting - Semester-6Document8 pagesSuggested Answers Spring 2015 Examinations 1 of 8: Strategic Management Accounting - Semester-6Abdul BasitNo ratings yet

- Vivado Power Analysis OptimizationDocument120 pagesVivado Power Analysis OptimizationBad BoyNo ratings yet

- 1100D Fuel System Installation Guide PDFDocument18 pages1100D Fuel System Installation Guide PDFjAVIER GARCIA MORIANANo ratings yet

- Kolodin Agreement For Discipline by ConsentDocument21 pagesKolodin Agreement For Discipline by ConsentJordan ConradsonNo ratings yet

- Oil Refinery OpsDocument3 pagesOil Refinery OpsPhiPhiNo ratings yet

- SHPXXX 20 IS XX 13Document240 pagesSHPXXX 20 IS XX 13Geyciane PinheiroNo ratings yet

- Germany's Three-Pillar Banking SystemDocument7 pagesGermany's Three-Pillar Banking Systemmladen_nbNo ratings yet

- Unit 8 - Week 7: Assignment 7Document3 pagesUnit 8 - Week 7: Assignment 7Nitin MoreNo ratings yet

- 671 - BP Well Control Tool Kit 2002Document19 pages671 - BP Well Control Tool Kit 2002Ibama MirillaNo ratings yet

- Latifi LAMY Catalog 2013 PDFDocument76 pagesLatifi LAMY Catalog 2013 PDFWang LinusNo ratings yet

- AMCA 210-07 PreDocument10 pagesAMCA 210-07 PretiagocieloNo ratings yet

- South West Mining LTD - Combined CFO & HWA - VerDocument8 pagesSouth West Mining LTD - Combined CFO & HWA - Verapi-3809359No ratings yet

- PraxiarDocument8 pagesPraxiara_roy003No ratings yet

- PCU CalculationDocument2 pagesPCU CalculationMidhun Joseph0% (1)

- Lab 1Document8 pagesLab 1Нурболат ТаласбайNo ratings yet

- Visa Requirements Austrian EmbassyDocument2 pagesVisa Requirements Austrian Embassyadalcayde2514No ratings yet

- Order To Cash Cycle Group 1Document4 pagesOrder To Cash Cycle Group 1AswinAniNo ratings yet

- Factors Affecting The Implementation of Green Procurement: Empirical Evidence From Indonesian Educational InstitutionDocument12 pagesFactors Affecting The Implementation of Green Procurement: Empirical Evidence From Indonesian Educational InstitutionYeni Saro ManaluNo ratings yet

- Nxivm: 2nd Superseding IndictmentDocument32 pagesNxivm: 2nd Superseding IndictmentTony Ortega100% (2)

- 14 DETEMINANTS & MATRICES PART 3 of 6 PDFDocument10 pages14 DETEMINANTS & MATRICES PART 3 of 6 PDFsabhari_ramNo ratings yet

- Steinway Case - CH 03Document5 pagesSteinway Case - CH 03Twēéty TuiñkleNo ratings yet

- How To Make Affidavit at Pune Collector OfficeDocument1 pageHow To Make Affidavit at Pune Collector Officejayram1961No ratings yet

- What Is EBSD ? Why Use EBSD ? Why Measure Microstructure ? What Does EBSD Do That Cannot Already Be Done ?Document5 pagesWhat Is EBSD ? Why Use EBSD ? Why Measure Microstructure ? What Does EBSD Do That Cannot Already Be Done ?Zahir Rayhan JhonNo ratings yet

- Riba, Its Types and ImplicationsDocument37 pagesRiba, Its Types and Implicationsmahamamir012No ratings yet

- Book Notes Covering: Andy Kirk's Book, Data Visualization - A Successful Design ProcessDocument10 pagesBook Notes Covering: Andy Kirk's Book, Data Visualization - A Successful Design ProcessDataVersed100% (1)

- Transportation Problem VAMDocument16 pagesTransportation Problem VAMLia AmmuNo ratings yet