Professional Documents

Culture Documents

Tank Vehicles For Flammable and Combustible Liquids - NFPA-385-2007.en - Ar

Uploaded by

Sultan MohammedOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tank Vehicles For Flammable and Combustible Liquids - NFPA-385-2007.en - Ar

Uploaded by

Sultan MohammedCopyright:

Available Formats

ﻣﺘﺮﺟﻢ ﻣﻦ ﺍﻹﻧﺠﻠﻴﺰﻳﺔ ﺇﻟﻰ ﺍﻟﻌﺮﺑﻴﺔ www.onlinedoctranslator.

com -

NFPA385

ﻣﻌﻴﺎﺭﻝ

ﻣﺮﻛﺒﺎﺕﺍﻟﺼﻬﺎﺭﻳﺞ ﻟﻠﺴﻮﺍﺉﻞ ﺍﻟﻘﺎﺑﻠﺔ ﻟﻼﺷﺘﻌﺎﻝ ﻭﺍﻻﺣﺘﺮﺍﻕ

ﻃﺒﻌﺔ2007

ﺣﻘﻮﻕﺍﻟﻨﺸﺮ © 2007ﺍﻟﺮﺍﺑﻄﺔ ﺍﻟﻮﻃﻨﻴﺔ ﻟﻠﺤﻤﺎﻳﺔ ﻣﻦ ﺍﻟﺤﺮﺍﺉﻖ .ﻛﻞ ﺍﻟﺤﻘﻮﻕ ﻣﺤﻔﻮﻇﺔ.

ﻫﺬﻩﺍﻟﻄﺒﻌﺔ ﻣﻦ ،NFPA 385ﺍﻟﻤﻮﺍﺻﻔﺔ ﺍﻟﻘﻴﺎﺳﻴﺔ ﻟﻤﺮﻛﺒﺎﺕ ﺍﻟﺼﻬﺎﺭﻳﺞ ﻟﻠﺴﻮﺍﺉﻞ ﺍﻟﻘﺎﺑﻠﺔ ﻟﻼﺷﺘﻌﺎﻝ

ﻭﺍﻻﺣﺘﺮﺍﻕﺗﻢ ﺇﻋﺪﺍﺩﻩ ﻣﻦ ﻗﺒﻞ ﺍﻟﻠﺠﻨﺔ ﺍﻟﻔﻨﻴﺔ ﻟﻨﻘﻞ ﺍﻟﺴﻮﺍﺉﻞ ﺍﻟﻘﺎﺑﻠﺔ ﻟﻼﺷﺘﻌﺎﻝ .ﺗﻢ ﺇﺻﺪﺍﺭﻩ ﻣﻦ ﻗﺒﻞ ﻣﺠﻠﺲ

ﺍﻟﻤﻌﺎﻳﻴﺮﻓﻲ 1ﺩﻳﺴﻤﺒﺮ ،2006ﻭﺗﺎﺭﻳﺦ ﻧﻔﺎﺫﻩ ﻫﻮ 20ﺩﻳﺴﻤﺒﺮ ،2006ﻭﻳﺤﻞ ﻣﺤﻞ ﺟﻤﻴﻊ ﺍﻹﺻﺪﺍﺭﺍﺕ

ﺍﻟﺴﺎﺑﻘﺔ.

ﺗﻤﺖﺍﻟﻤﻮﺍﻓﻘﺔ ﻋﻠﻰ ﻫﺬﻩ ﺍﻟﻄﺒﻌﺔ ﻣﻦ NFPA 385ﻛﻤﻌﻴﺎﺭ ﻭﻃﻨﻲ ﺃﻣﺮﻳﻜﻲ ﻓﻲ 20ﺩﻳﺴﻤﺒﺮ .2006

ﺃﺻﻞﻭﺗﻄﻮﺭ NFPA 385

ﺑﺪﺃﻣﺸﺮﻭﻉ ﺍﻟﻤﻌﺎﻳﻴﺮ ﻫﺬﺍ ﻓﻲ ﻋﺎﻡ ،1926ﻭﺗﻢ ﺍﻋﺘﻤﺎﺩ ﺍﻟﻄﺒﻌﺔ ﺍﻷﻭﻟﻰ ﻣﻦ NFPA 385ﺭﺳﻤﻴﺎً ﻓﻲ ﻋﺎﻡ .1929

ﻭﺗﻢﺗﻨﻘﻴﺢ NFPA 385ﻓﻲ ،1963 ،1960 ،1959 ،1958 ،1957 ،1955 ،1954 ،1953 ،1948 ،1933

،2000 ،1990 ،1985 ،1979 ،1974 ،1971 ،1966،1964ﻭ .2006ﺍﻹﺻﺪﺍﺭﺍﺕ ﺍﻟﺴﺎﺑﻘﺔ ﻟﻌﺎﻡ 1948ﻛﺎﻧﺖ

ﻟﻬﺎﻋﻨﺎﻭﻳﻦ ﻣﺨﺘﻠﻔﺔ.

ﻭﺗﻀﻤﻨﺖﻃﺒﻌﺔ ﻋﺎﻡ 2000ﺍﻟﺘﻌﺪﻳﻼﺕ ﺍﻟﺘﺎﻟﻴﺔ:

) (1ﺍﻟﻤﺘﻄﻠﺒﺎﺕ ﺍﻟﻤﻨﻘﺤﺔ ﻟﻌﻼﻣﺎﺕ ﺍﻟﺘﺤﺬﻳﺮ ،ﻓﻲ 3.4.5

) (2ﺍﻟﻤﺘﻄﻠﺒﺎﺕ ﺍﻟﻤﻨﻘﺤﺔ ﻷﺟﻬﺰﺓ ﺇﻃﻔﺎء ﺍﻟﺤﺮﻳﻖ ﻟﻤﺮﻛﺒﺎﺕ ﺍﻟﺼﻬﺎﺭﻳﺞ ،ﻓﻲ 6.3.1

ﺗﺘﻀﻤﻦﻃﺒﻌﺔ 2007ﺍﻟﺘﻌﺪﻳﻼﺕ ﺍﻟﺘﺎﻟﻴﺔ:

) (1ﺍﻟﺘﻌﺮﻳﻔﺎﺕ ﺍﻟﻤﻨﻘﺤﺔ ﻟﺘﺘﻨﺎﺳﺐ ﻣﻊ ،NFPA 30ﻗﺎﻧﻮﻥ ﺍﻟﺴﻮﺍﺉﻞ ﺍﻟﻘﺎﺑﻠﺔ ﻟﻼﺷﺘﻌﺎﻝ ﻭﺍﻻﺣﺘﺮﺍﻕ

) (2ﺗﺼﺤﻴﺢ ﺧﻄﺄ ﻓﻲ ) 6.3.1ﺍﻵﻥ (9.3.1ﻳﺘﻌﻠﻖ ﺑﺘﺼﻨﻴﻒ ﻃﻔﺎﻳﺔ ﺍﻟﺤﺮﻳﻖ

) (3ﺍﺳﺘﻜﻤﺎﻝ ﺍﻟﻤﺮﺍﺟﻌﺔ ﺍﻟﺘﺤﺮﻳﺮﻳﺔ ﻟﻼﻣﺘﺜﺎﻝ ﻟﻞﺩﻟﻴﻞ ﺍﻷﺳﻠﻮﺏ ﻟﻮﺛﺎﺉﻖ ﺍﻟﻠﺠﻨﺔ ﺍﻟﻔﻨﻴﺔ NFPA

ﺍﻟﻠﺠﻨﺔﺍﻟﻔﻨﻴﺔ ﻟﻨﻘﻞ ﺍﻟﺴﻮﺍﺉﻞ ﺍﻟﻘﺎﺑﻠﺔ ﻟﻼﺷﺘﻌﺎﻝ

ﻭﺍﻳﺪﺟﻲ ﺩﻳﻬﻴﺖ،ﻛﺮﺳﻲ

ﺣﻘﻮﻕﺍﻟﻄﺒﻊ ﻭﺍﻟﻨﺸﺮ NFPA

ﺷﺮﻛﺔﺃﺑﺎﺩﻏﻮﺳﺘﺎﺭ ﺗﺎﺳﻴﺴﺎﺕ ﺇﻳﺮﺍﻧﻴﻨﺎﻥ ﺍﻟﻤﺤﺪﻭﺩﺓ www.atapars.com

www.atapars.com/NFPA-code/

ﺍﻹﻧﻘﺎﺫﻣﻦ ﺍﻟﺤﺮﺍﺉﻖ ﻓﻲ ﻣﻘﺎﻃﻌﺔ ﻫﻴﻠﺰﺑﻮﺭﻭ ،ﻓﻠﻮﺭﻳﺪﺍ ][E

ﺟﻮﻥﺇﻝ ﻛﻮﻧﻠﻲ,ﺷﺮﻛﺔ ،.National Tank Truck Carriers Incﻓﻴﺮﺟﻴﻨﻴﺎ ][U

ﺟﻮﻥﺭ .ﻳﻮﺑﺎﻧﻜﺲ ﺍﻻﺑﻦ,ﺷﺮﻛﺔ [Loss Prevention Prevention Consultants, Inc., MS ]SE

ﺟﻴﻤﺲﺭ .ﻛﻴﺘﺮﻳﻞ,ﺷﺮﻛﺔ [KSE, MA ]SE

ﺟﻴﻒﺳﻴﻤﺰ,ﺭﺍﺑﻄﺔ ﻣﺼﻨﻌﻲ ﻣﻘﻄﻮﺭﺍﺕ ﺍﻟﺸﺎﺣﻨﺎﺕ ،ﻓﻴﺮﺟﻴﻨﻴﺎ ][M

ﺟﺎﻛﻮﺏﻓﺎﻟﺪﺷﻤﻴﺖ,ﺇﺩﺍﺭﺓ ﺍﻹﻃﻔﺎء ﺑﻤﺪﻳﻨﺔ ﻛﻴﻨﻮﺷﺎ ،ﻭﻳﺴﻜﻮﻧﺴﻦ ][E

ﻣﺎﻳﻜﻞﺑﻲ ﻭﻳﻠﺴﻮﻥ,ﻣﺠﻤﻮﻋﺔ ﺧﺪﻣﺎﺕ ﺍﻟﺘﺄﻣﻴﻦ ﺍﻷﻣﺮﻳﻜﻴﺔ ،ﻧﻴﻮﺟﻴﺮﺳﻲ ][I

ﺭﻭﺑﺮﺕﺏ .ﺑﻴﻨﻴﺪﻳﺘﻲ,ﺍﺗﺼﺎﻝ ﺍﻟﻤﻮﻇﻔﻴﻦ NFPA

ﺗﻤﺜﻞﻫﺬﻩ ﺍﻟﻘﺎﺉﻤﺔ ﺍﻷﻋﻀﺎء ﻭﻗﺖ ﺗﺼﻮﻳﺖ ﺍﻟﻠﺠﻨﺔ ﻋﻠﻰ ﺍﻟﻨﺺ ﺍﻟﻨﻬﺎﺉﻲ ﻟﻬﺬﻩ ﺍﻟﻄﺒﻌﺔ .ﻣﻨﺬ ﺫﻟﻚ ﺍﻟﻮﻗﺖ،

ﺭﺑﻤﺎﺣﺪﺛﺖ ﺗﻐﻴﻴﺮﺍﺕ ﻓﻲ ﺍﻟﻌﻀﻮﻳﺔ .ﻳﻮﺟﺪ ﻣﻔﺘﺎﺡ ﺍﻟﺘﺼﻨﻴﻔﺎﺕ ﻓﻲ ﺍﻟﺠﺰء ﺍﻟﺨﻠﻔﻲ ﻣﻦ ﺍﻟﻮﺛﻴﻘﺔ.

ﻣﻠﺤﻮﻇﺔ:ﺍﻟﻌﻀﻮﻳﺔ ﻓﻲ ﺍﻟﻠﺠﻨﺔ ﻻ ﺗﺸﻜﻞ ﻓﻲ ﺣﺪ ﺫﺍﺗﻬﺎ ﻣﻮﺍﻓﻘﺔ ﻋﻠﻰ ﺍﻟﺠﻤﻌﻴﺔ ﺃﻭ ﺃﻱ ﻭﺛﻴﻘﺔ ﺗﻀﻌﻬﺎ ﺍﻟﻠﺠﻨﺔ

ﺍﻟﺘﻲﻳﻌﻤﻞ ﻓﻴﻬﺎ ﺍﻟﻌﻀﻮ.

ﻧﻄﺎﻕﺍﻟﻠﺠﻨﺔ:ﺗﺘﻮﻟﻰ ﻫﺬﻩ ﺍﻟﻠﺠﻨﺔ ﺍﻟﻤﺴﺆﻭﻟﻴﺔ ﺍﻷﺳﺎﺳﻴﺔ ﻋﻦ ﺍﻟﻮﺛﺎﺉﻖ ﺍﻟﻤﺘﻌﻠﻘﺔ ﺑﺎﻟﺤﻤﺎﻳﺔ ﻣﻦ ﻣﺨﺎﻃﺮ

ﺍﻟﺤﺮﺍﺉﻖﻭﺍﻻﻧﻔﺠﺎﺭﺍﺕ ﺍﻟﻤﺮﺗﺒﻄﺔ ﺑﺎﻟﻨﻘﻞ ﺍﻟﺒﺮﻱ ﻟﻠﺴﻮﺍﺉﻞ ﺍﻟﻘﺎﺑﻠﺔ ﻟﻼﺷﺘﻌﺎﻝ ﻭﺍﻟﻘﺎﺑﻠﺔ ﻟﻼﺷﺘﻌﺎﻝ ﻓﻲ ﻣﺮﻛﺒﺎﺕ

ﺍﻟﺼﻬﺎﺭﻳﺞﻭﻓﻲ ﺍﻟﺼﻬﺎﺭﻳﺞ ﻭﺍﻟﺤﺎﻭﻳﺎﺕ ﺍﻟﻤﺤﻤﻮﻟﺔ.

NFPA385

ﻣﻌﻴﺎﺭﻝ

ﻣﺮﻛﺒﺎﺕﺍﻟﺼﻬﺎﺭﻳﺞ ﻟﻠﺴﻮﺍﺉﻞ ﺍﻟﻘﺎﺑﻠﺔ ﻟﻼﺷﺘﻌﺎﻝ ﻭﺍﻻﺣﺘﺮﺍﻕ

ﻃﺒﻌﺔ2007

ﻣﻼﺣﻈﺔﻫﺎﻣﺔ :ﺗﻢ ﺗﻮﻓﻴﺮ ﻭﺛﻴﻘﺔ NFPAﻫﺬﻩ ﻟﻼﺳﺘﺨﺪﺍﻡ ﻣﻊ ﻣﺮﺍﻋﺎﺓ ﺍﻹﺷﻌﺎﺭﺍﺕ ﺍﻟﻤﻬﻤﺔ ﻭﺇﺧﻼء

ﺍﻟﻤﺴﺆﻭﻟﻴﺔﺍﻟﻘﺎﻧﻮﻧﻴﺔ .ﺗﻈﻬﺮ ﻫﺬﻩ ﺍﻹﺷﻌﺎﺭﺍﺕ ﻭﺇﺧﻼءﺍﺕ ﺍﻟﻤﺴﺆﻭﻟﻴﺔ ﻓﻲ ﺟﻤﻴﻊ ﺍﻟﻤﻨﺸﻮﺭﺍﺕ ﺍﻟﺘﻲ

ﺗﺤﺘﻮﻱﻋﻠﻰ ﻫﺬﻩ ﺍﻟﻮﺛﻴﻘﺔ ﻭﻳﻤﻜﻦ ﺍﻟﻌﺜﻮﺭ ﻋﻠﻴﻬﺎ ﺗﺤﺖ ﻋﻨﻮﺍﻥ "ﺇﺷﻌﺎﺭﺍﺕ ﻭﺇﺧﻼءﺍﺕ ﻣﻬﻤﺔ

ﺑﺨﺼﻮﺹﻣﺴﺘﻨﺪﺍﺕ ."NFPAﻭﻳﻤﻜﻦ ﺃﻳﻀﺎً ﺍﻟﺤﺼﻮﻝ ﻋﻠﻴﻬﺎ ﺑﻨﺎء ًﻋﻠﻰ ﻃﻠﺐ ﻣﻦ NFPAﺃﻭ

ﺍﻻﻃﻼﻉﻋﻠﻴﻬﺎ ﻋﻠﻰ .www.nfpa.org/disclaimers

ﻣﻼﺣﻈﺔ:ﺗﺸﻴﺮ ﺍﻟﻌﻼﻣﺔ ﺍﻟﻨﺠﻤﻴﺔ )*( ﺍﻟﺘﻲ ﺗﻠﻲ ﺍﻟﺮﻗﻢ ﺃﻭ ﺍﻟﺤﺮﻑ ﺍﻟﺬﻱ ﻳﺸﻴﺮ ﺇﻟﻰ ﺍﻟﻔﻘﺮﺓ ﺇﻟﻰ ﺃﻧﻪ ﻳﻤﻜﻦ

ﺍﻟﻌﺜﻮﺭﻋﻠﻰ ﺍﻟﻤﺎﺩﺓ ﺍﻟﺘﻮﺿﻴﺤﻴﺔ ﺍﻟﺨﺎﺻﺔ ﺑﺎﻟﻔﻘﺮﺓ ﻓﻲ ﺍﻟﻤﻠﺤﻖ ﺃ.

ﺗﺘﻢﺍﻹﺷﺎﺭﺓ ﺇﻟﻰ ﺍﻟﺘﻐﻴﻴﺮﺍﺕ ﺑﺨﻼﻑ ﺍﻟﺘﻐﻴﻴﺮﺍﺕ ﺍﻟﺘﺤﺮﻳﺮﻳﺔ ﺑﻤﺴﻄﺮﺓ ﺭﺃﺳﻴﺔ ﺑﺠﺎﻧﺐ ﺍﻟﻔﻘﺮﺓ ﺃﻭ ﺍﻟﺠﺪﻭﻝ ﺃﻭ

ﺍﻟﺸﻜﻞﺍﻟﺬﻱ ﺣﺪﺙ ﻓﻴﻪ ﺍﻟﺘﻐﻴﻴﺮ .ﻳﺘﻢ ﺗﻀﻤﻴﻦ ﻫﺬﻩ ﺍﻟﻘﻮﺍﻋﺪ ﻛﻮﺳﻴﻠﺔ ﻣﺴﺎﻋﺪﺓ ﻟﻠﻤﺴﺘﺨﺪﻡ ﻓﻲ ﺗﺤﺪﻳﺪ

ﺍﻟﺘﻐﻴﻴﺮﺍﺕﻣﻦ ﺍﻹﺻﺪﺍﺭ ﺍﻟﺴﺎﺑﻖ .ﻋﻨﺪﻣﺎ ﻳﺘﻢ ﺣﺬﻑ ﻓﻘﺮﺓ ﻛﺎﻣﻠﺔ ﺃﻭ ﺃﻛﺜﺮ ،ﺗﺘﻢ ﺍﻹﺷﺎﺭﺓ ﺇﻟﻰ ﺍﻟﺤﺬﻑ ﺑﺎﻟﺮﻣﺰ

ﺍﻟﻨﻘﻄﻲ)•( ﺑﻴﻦ ﺍﻟﻔﻘﺮﺍﺕ ﺍﻟﻤﺘﺒﻘﻴﺔ.

ﻳﻤﻜﻦﺍﻟﻌﺜﻮﺭ ﻋﻠﻰ ﻣﻌﻠﻮﻣﺎﺕ ﺣﻮﻝ ﺍﻟﻤﻨﺸﻮﺭﺍﺕ ﺍﻟﻤﺮﺟﻌﻴﺔ ﻓﻲ ﺍﻟﻔﺼﻞ 2ﻭﺍﻟﻤﻠﺤﻖ ﺝ.

ﺣﻘﻮﻕﺍﻟﻄﺒﻊ ﻭﺍﻟﻨﺸﺮ NFPA

ﺷﺮﻛﺔﺃﺑﺎﺩﻏﻮﺳﺘﺎﺭ ﺗﺎﺳﻴﺴﺎﺕ ﺇﻳﺮﺍﻧﻴﻨﺎﻥ ﺍﻟﻤﺤﺪﻭﺩﺓ www.atapars.com

www.atapars.com/NFPA-code/

ﺝ ﺍﻟﻔﺼﻞ 1ﺍﻹﺩﺍﺭﺓ

1.1ﺍﻟﻨﻄﺎﻕ.

*1.1.1ﺗﻨﻄﺒﻖ ﻫﺬﻩ ﺍﻟﻤﻮﺍﺻﻔﺔ ﺍﻟﻘﻴﺎﺳﻴﺔ ﻋﻠﻰ ﺍﻟﻤﺮﻛﺒﺎﺕ ﺍﻟﺼﻬﺮﻳﺠﻴﺔ ﺍﻟﻤﺴﺘﺨﺪﻣﺔ ﻓﻲ ﻧﻘﻞ ﺍﻷﺳﻔﻠﺖ ﺃﻭ ﺍﻟﺴﻮﺍﺉﻞ ﺍﻟﻘﺎﺑﻠﺔ

ﻟﻼﺷﺘﻌﺎﻝﻭﺍﻟﻘﺎﺑﻠﺔ ﻟﻼﺷﺘﻌﺎﻝ ﻭﺍﻟﺘﻲ ﺗﻜﻮﻥ ﻧﻘﺎﻁ ﻭﻣﻴﻀﻬﺎ ﺃﻗﻞ ﻣﻦ 200ﺩﺭﺟﺔ ﻓﻬﺮﻧﻬﺎﻳﺖ ) 93ﺩﺭﺟﺔ ﻣﺉﻮﻳﺔ(.

1.1.2ﻳﺠﺐ ﺃﻥ ﺗﻮﻓﺮ ﻫﺬﻩ ﺍﻟﻤﻮﺍﺻﻔﺔ ﺍﻟﻘﻴﺎﺳﻴﺔ ﺃﻳﻀﺎً ﺍﻟﺤﺪ ﺍﻷﺩﻧﻰ ﻣﻦ ﺍﻟﻤﺘﻄﻠﺒﺎﺕ ﻟﺘﺼﻤﻴﻢ ﻭﺑﻨﺎء ﺻﻬﺎﺭﻳﺞ

ﺍﻟﺒﻀﺎﺉﻊﻭﻣﻠﺤﻘﺎﺗﻬﺎ ﻭﻳﺠﺐ ﺃﻥ ﺗﺤﺪﺩ ﺑﻌﺾ ﺍﻷﻣﻮﺭ ﺍﻟﻤﺘﻌﻠﻘﺔ ﺑﻤﺮﻛﺒﺎﺕ ﺍﻟﺼﻬﺎﺭﻳﺞ.

1.1.3ﻻ ﺗﻤﻨﻊ ﺃﺣﻜﺎﻡ ﻫﺬﻩ ﺍﻟﻤﻮﺍﺻﻔﺔ ﺍﻟﻘﻴﺎﺳﻴﺔ ﺍﺳﺘﺨﺪﺍﻡ ﻭﺳﺎﺉﻞ ﺣﻤﺎﻳﺔ ﺇﺿﺎﻓﻴﺔ ﻟﻤﺮﻛﺒﺎﺕ ﺍﻟﺼﻬﺎﺭﻳﺞ

ﺍﻟﻤﺴﺘﺨﺪﻣﺔﻓﻲ ﻧﻘﻞ ﺍﻟﺴﻮﺍﺉﻞ ﺍﻟﻘﺎﺑﻠﺔ ﻟﻼﺷﺘﻌﺎﻝ ﻭﺍﻟﻘﺎﺑﻠﺔ ﻟﻼﺣﺘﺮﺍﻕ ﻭﺍﻟﺘﻲ ﻟﻬﺎ ﺧﺼﺎﺉﺺ ﺗﺆﺩﻱ ﺇﻟﻰ

ﻋﻮﺍﻣﻞﺇﺿﺎﻓﻴﺔ ﻣﺜﻞ ﺍﻟﻤﻌﺪﻻﺕ ﺍﻟﻌﺎﻟﻴﺔ ﻟﻠﺘﻤﺪﺩ ﻭﻋﺪﻡ ﺍﻻﺳﺘﻘﺮﺍﺭ ﻭﺍﻟﺘﺂﻛﻞ ﻭﺍﻟﺴﻤﻴﺔ.

1.1.4ﺗﻨﻄﺒﻖ ﺃﺣﻜﺎﻡ ﻫﺬﻩ ﺍﻟﻤﻮﺍﺻﻔﺔ ﺍﻟﻘﻴﺎﺳﻴﺔ ﺃﻳﻀﺎً ﻋﻠﻰ ﺃﺳﻔﻠﺖ ﺍﻟﻘﻄﻊ ﺍﻟﺘﻲ ﻟﻬﺎ ﻧﻘﺎﻁ ﻭﻣﻴﺾ ﺃﻗﻞ ﻣﻦ 100

ﺩﺭﺟﺔﻓﻬﺮﻧﻬﺎﻳﺖ ) 37.8ﺩﺭﺟﺔ ﻣﺉﻮﻳﺔ( ﻭﻋﻠﻰ ﺍﻟﺴﻮﺍﺉﻞ ﺍﻟﻤﻨﻘﻮﻟﺔ ﻋﻨﺪ ﺩﺭﺟﺎﺕ ﺣﺮﺍﺭﺓ ﻣﺮﺗﻔﻌﺔ ﻓﻮﻕ ﻧﻘﺎﻁ

ﻭﻣﻴﻀﻬﺎ.

1.1.5ﻳﺠﺐ ﺃﻥ ﺗﻜﻮﻥ ﻣﺘﻄﻠﺒﺎﺕ ﻣﺮﻛﺒﺎﺕ ﺻﻬﺎﺭﻳﺞ ﺧﺪﻣﺔ ﻭﻗﻮﺩ ﺍﻟﻄﺎﺉﺮﺍﺕ ﻣﺘﻮﺍﻓﻘﺔ ﻣﻊ ،NFPA 407

ﺍﻟﻤﻌﻴﺎﺭﺍﻟﺨﺎﺹ ﺑﺨﺪﻣﺔ ﻭﻗﻮﺩ ﺍﻟﻄﺎﺉﺮﺍﺕ.

1.1.6ﺗﻌﺘﺒﺮ ﺍﻟﻤﺮﻛﺒﺔ ﺍﻟﺼﻬﺮﻳﺠﻴﺔ ﺍﻟﺘﻲ ﺗﻨﻘﻞ ﺳﺎﺉﻼً ﻗﺎﺑﻼ ًﻟﻼﺷﺘﻌﺎﻝ ﺃﻭ ﻗﺎﺑﻼ ًﻟﻼﺷﺘﻌﺎﻝ ﻓﻲ ﺍﻟﺨﺪﻣﺔ ﺑﻴﻦ

ﺍﻟﻮﻻﻳﺎﺕﻣﺘﻮﺍﻓﻘﺔ ﻣﻊ ﻫﺬﺍ ﺍﻟﻤﻌﻴﺎﺭ ﺃﺛﻨﺎء ﻭﺟﻮﺩﻫﺎ ﻓﻲ ﺍﻟﺨﺪﻣﺔ ﺑﻴﻦ ﺍﻟﻮﻻﻳﺎﺕ ﺇﺫﺍ ﻛﺎﻧﺖ ﺗﻔﻲ ﺑﻤﺘﻄﻠﺒﺎﺕ ﻭﺯﺍﺭﺓ

ﺍﻟﻨﻘﻞﺍﻷﻣﺮﻳﻜﻴﺔ " ،CFR 171–179 49ﻟﻮﺍﺉﺢ ﺍﻟﻤﻮﺍﺩ ﺍﻟﺨﻄﺮﺓ"" .

1.2ﺍﻟﻐﺮﺽ.

ﻳﺠﺐﺃﻥ ﻳﻜﻮﻥ ﺍﻟﻐﺮﺽ ﻣﻦ ﻫﺬﻩ ﺍﻟﻤﻮﺍﺻﻔﺔ ﺍﻟﻘﻴﺎﺳﻴﺔ ﻫﻮ ﺗﻮﻓﻴﺮ ﺍﻟﻨﻘﻞ ﺍﻵﻣﻦ ﻟﻠﺴﻮﺍﺉﻞ ﺍﻟﻘﺎﺑﻠﺔ ﻟﻼﺷﺘﻌﺎﻝ

ﻭﺍﻟﻘﺎﺑﻠﺔﻟﻼﺣﺘﺮﺍﻕ ﻓﻲ ﻣﺮﻛﺒﺎﺕ ﺍﻟﺼﻬﺎﺭﻳﺞ.

ﺝ ﺍﻟﻔﺼﻞ 2ﺍﻟﻤﻨﺸﻮﺭﺍﺕ ﺍﻟﻤﺮﺟﻌﻴﺔ

2.1ﻋﺎﻡ.

ﻳﺘﻢﺍﻟﺮﺟﻮﻉ ﺇﻟﻰ ﺍﻟﻤﺴﺘﻨﺪﺍﺕ ﺃﻭ ﺃﺟﺰﺍء ﻣﻨﻬﺎ ﺍﻟﻤﺪﺭﺟﺔ ﻓﻲ ﻫﺬﺍ ﺍﻟﻔﺼﻞ ﺿﻤﻦ ﻫﺬﺍ ﺍﻟﻤﻌﻴﺎﺭ ﻭﻳﺠﺐ ﺍﻋﺘﺒﺎﺭﻫﺎ

ﺟﺰءﺍًﻣﻦ ﻣﺘﻄﻠﺒﺎﺕ ﻫﺬﻩ ﺍﻟﻮﺛﻴﻘﺔ.

2.2ﻣﻨﺸﻮﺭﺍﺕ .NFPA

ﺍﻟﺮﺍﺑﻄﺔﺍﻟﻮﻃﻨﻴﺔ ﻟﻠﺤﻤﺎﻳﺔ ﻣﻦ ﺍﻟﺤﺮﺍﺉﻖ 1 ،ﺑﺎﺗﻴﺮﻳﻤﺎﺭﺵ ﺑﺎﺭﻙ ،ﻛﻮﻳﻨﺴﻲ.MA 021697471 ،

ﺇﻥﺇﻑ ﺑﻲ ﺇﻳﻪ ،10ﺍﻟﻤﻮﺍﺻﻔﺔ ﺍﻟﺨﺎﺻﺔ ﺑﺄﺟﻬﺰﺓ ﺇﻃﻔﺎء ﺍﻟﺤﺮﻳﻖ ﺍﻟﻤﺤﻤﻮﻟﺔ،ﻃﺒﻌﺔ .2007

NFPA58,ﻛﻮﺩ ﻏﺎﺯ ﺍﻟﺒﺘﺮﻭﻝ ﺍﻟﻤﺴﺎﻝ،ﻃﺒﻌﺔ .2004

NFPA70،ﺍﻟﻜﻮﺩ ﺍﻟﻜﻬﺮﺑﺎﺉﻲ ﺍﻟﻮﻃﻨﻲ®,ﻃﺒﻌﺔ .2005ﺣﻘﻮﻕ

ﺍﻟﻄﺒﻊﻭﺍﻟﻨﺸﺮ NFPA

ﺷﺮﻛﺔﺃﺑﺎﺩﻏﻮﺳﺘﺎﺭ ﺗﺎﺳﻴﺴﺎﺕ ﺇﻳﺮﺍﻧﻴﻨﺎﻥ ﺍﻟﻤﺤﺪﻭﺩﺓ www.atapars.com

www.atapars.com/NFPA-code/

NFPA407,ﻣﻌﻴﺎﺭ ﺧﺪﻣﺔ ﻭﻗﻮﺩ ﺍﻟﻄﺎﺉﺮﺍﺕ،ﻃﺒﻌﺔ .2007

2.3ﻣﻨﺸﻮﺭﺍﺕ ﺃﺧﺮﻯ.

2.3.1ﻣﻨﺸﻮﺭﺍﺕ .ANSI

ﺍﻟﻤﻌﻬﺪﺍﻷﻣﺮﻳﻜﻲ ﺍﻟﻮﻃﻨﻲ ﻟﻠﻤﻌﺎﻳﻴﺮ 25 ،ﻏﺮﺏ ﺷﺎﺭﻉ ،43ﺍﻟﻄﺎﺑﻖ ﺍﻟﺮﺍﺑﻊ ،ﻧﻴﻮﻳﻮﺭﻙ ،ﻧﻴﻮﻳﻮﺭﻙ .10036

ﺃﻧﺴﻲ،Z535.1ﺭﻣﺰ ﺍﻟﻠﻮﻥ ﺍﻵﻣﻦ.1998 ،

2.3.2ﻣﻨﺸﻮﺭﺍﺕ .ASME

ﺍﻟﺠﻤﻌﻴﺔﺍﻷﻣﺮﻳﻜﻴﺔ ﻟﻠﻤﻬﻨﺪﺳﻴﻦ ﺍﻟﻤﻴﻜﺎﻧﻴﻜﻴﻴﻦ ،ﺛﺮﻱ ﺑﺎﺭﻙ ﺃﻓﻴﻨﻴﻮ ،ﻧﻴﻮﻳﻮﺭﻙ ،ﻧﻴﻮﻳﻮﺭﻙ

.100165990

ﺭﻣﺰﺍﻟﻐﻼﻳﺎﺕ ﻭﺃﻭﻋﻴﺔ ﺍﻟﻀﻐﻂ.2004 ،

2.3.3ﻣﻨﺸﻮﺭﺍﺕ .ASTM

، 100 Barr Harbour Drive، Box C700، West Conshohocken، PA194282959.

ASTM International

ﺃﺳﺘﻢﺏ ،209ﻣﻮﺍﺻﻔﺎﺕ ﺻﻔﺎﺉﺢ ﻭﺻﻔﺎﺉﺢ ﺍﻷﻟﻮﻣﻨﻴﻮﻡ ﻭﺳﺒﺎﺉﻚ ﺍﻷﻟﻮﻣﻨﻴﻮﻡ ،ﻃﺒﻌﺔ .1996

ﺃﺳﺘﻢﺩ ،5ﺍﺧﺘﺒﺎﺭ ﺍﻻﺧﺘﺮﺍﻕ ﻟﻠﻤﻮﺍﺩ ﺍﻟﺒﻴﺘﻮﻣﻴﻨﻴﺔ ،ﻃﺒﻌﺔ .1997

ﺃﺳﺘﻢﺩ ،323ﺍﻟﻄﺮﻳﻘﺔ ﺍﻟﻘﻴﺎﺳﻴﺔ ﻻﺧﺘﺒﺎﺭ ﺿﻐﻂ ﺑﺨﺎﺭ ﺍﻟﻤﻨﺘﺠﺎﺕ ﺍﻟﺒﺘﺮﻭﻟﻴﺔ )ﻃﺮﻳﻘﺔ ﺭﻳﺪ( ،ﻃﺒﻌﺔ .1999

2.3.4ﻣﻨﺸﻮﺭﺍﺕ ﺍﻟﺤﻜﻮﻣﺔ ﺍﻷﻣﺮﻳﻜﻴﺔ.

ﻣﻜﺘﺐﺍﻟﻄﺒﺎﻋﺔ ﺍﻟﺤﻜﻮﻣﻲ ﺍﻷﻣﺮﻳﻜﻲ ،ﻭﺍﺷﻨﻄﻦ ﺍﻟﻌﺎﺻﻤﺔ .20402

ﺍﻟﻌﻨﻮﺍﻥ ،49ﻗﺎﻧﻮﻥ ﺍﻟﻠﻮﺍﺉﺢ ﺍﻟﻔﻴﺪﺭﺍﻟﻴﺔ" ،ﻟﻮﺍﺉﺢ ﺍﻟﻤﻮﺍﺩ ﺍﻟﺨﻄﺮﺓ" ،ﺍﻷﺟﺰﺍء .179-171

ﺍﻟﻌﻨﻮﺍﻥ ،49ﻗﺎﻧﻮﻥ ﺍﻟﻠﻮﺍﺉﺢ ﺍﻟﻔﻴﺪﺭﺍﻟﻴﺔ" ،ﻭﺍﻗﻴﺎﺕ ﺍﻟﺼﺪﻣﺎﺕ ﺍﻟﺨﻠﻔﻴﺔ ﻭﺣﻤﺎﻳﺔ ﺍﻷﻃﺮﺍﻑ ﺍﻟﺨﻠﻔﻴﺔ" ،ﺍﻟﺠﺰء

.393.86

2.3.5ﻣﻨﺸﻮﺭﺍﺕ ﺃﺧﺮﻯ.

ﻗﺎﻣﻮﺱ MerriamWebsterﺍﻟﺠﻤﺎﻋﻲ ،ﺍﻟﻄﺒﻌﺔ ﺍﻟﺤﺎﺩﻳﺔ ﻋﺸﺮﺓ، Inc.، Springfield، MA، 2003 ،

.MerriamWebster

2.4ﻣﺮﺍﺟﻊ ﺍﻟﻤﻘﺘﻄﻔﺎﺕ ﻓﻲ ﺍﻷﻗﺴﺎﻡ ﺍﻹﻟﺰﺍﻣﻴﺔ) .ﻣﺤﺠﻮﺯ(

ﺝ ﺍﻟﻔﺼﻞ 3ﺍﻟﺘﻌﺎﺭﻳﻒ

3.1ﻋﺎﻡ.

ﺗﻨﻄﺒﻖﺍﻟﺘﻌﺮﻳﻔﺎﺕ ﺍﻟﻮﺍﺭﺩﺓ ﻓﻲ ﻫﺬﺍ ﺍﻟﻔﺼﻞ ﻋﻠﻰ ﺍﻟﻤﺼﻄﻠﺤﺎﺕ ﺍﻟﻤﺴﺘﺨﺪﻣﺔ ﻓﻲ ﻫﺬﺍ ﺍﻟﻤﻌﻴﺎﺭ .ﺃﻳﻦ

ﺣﻘﻮﻕﺍﻟﻄﺒﻊ ﻭﺍﻟﻨﺸﺮ NFPA

ﺷﺮﻛﺔﺃﺑﺎﺩﻏﻮﺳﺘﺎﺭ ﺗﺎﺳﻴﺴﺎﺕ ﺇﻳﺮﺍﻧﻴﻨﺎﻥ ﺍﻟﻤﺤﺪﻭﺩﺓ www.atapars.com

www.atapars.com/NFPA-code/

ﺍﻟﻤﺼﻄﻠﺤﺎﺕﺍﻟﺘﻲ ﻟﻢ ﻳﺘﻢ ﺗﻌﺮﻳﻔﻬﺎ ﻓﻲ ﻫﺬﺍ ﺍﻟﻔﺼﻞ ﺃﻭ ﻓﻲ ﻓﺼﻞ ﺁﺧﺮ ،ﻳﺠﺐ ﺗﻌﺮﻳﻔﻬﺎ ﺑﺎﺳﺘﺨﺪﺍﻡ ﻣﻌﺎﻧﻴﻬﺎ

ﺍﻟﻤﻘﺒﻮﻟﺔﻋﺎﺩﺓ ﻓﻲ ﺍﻟﺴﻴﺎﻕ ﺍﻟﺬﻱ ﺗﺴﺘﺨﺪﻡ ﻓﻴﻪ .ﻗﺎﻣﻮﺱ MerriamWebsterﺍﻟﺠﻤﺎﻋﻲ ،ﺍﻟﻄﺒﻌﺔ ﺍﻟﺤﺎﺩﻳﺔ

ﻋﺸﺮﺓ،ﻳﺠﺐ ﺃﻥ ﺗﻜﻮﻥ ﻣﺼﺪﺭ ﺍﻟﻤﻌﻨﻰ ﺍﻟﻤﻘﺒﻮﻝ ﻋﺎﺩﺓ.

3.2ﺗﻌﺮﻳﻔﺎﺕ NFPAﺍﻟﺮﺳﻤﻴﺔ.

*3.2.1ﻣﻮﺍﻓﻘﺔ .ﻣﻘﺒﻮﻝ ﻟﺪﻯ ﺍﻟﺠﻬﺔ ﺫﺍﺕ ﺍﻻﺧﺘﺼﺎﺹ.

3.2.2ﺍﻟﻤﺴﻤﻰ .ﺍﻟﻤﻌﺪﺍﺕ ﺃﻭ ﺍﻟﻤﻮﺍﺩ ﺍﻟﺘﻲ ﺗﻢ ﺇﺭﻓﺎﻕ ﻋﻼﻣﺔ ﺃﻭ ﺭﻣﺰ ﺃﻭ ﻋﻼﻣﺔ ﺗﻌﺮﻳﻒ ﺃﺧﺮﻯ ﺑﻬﺎ ﻟﻤﻨﻈﻤﺔ

ﻣﻘﺒﻮﻟﺔﻟﺪﻯ ﺍﻟﺴﻠﻄﺔ ﺫﺍﺕ ﺍﻟﺴﻠﻄﺔ ﺍﻟﻘﻀﺎﺉﻴﺔ ﻭﺍﻟﻤﻌﻨﻴﺔ ﺑﺘﻘﻴﻴﻢ ﺍﻟﻤﻨﺘﺞ ،ﻭﺍﻟﺘﻲ ﺗﺤﺎﻓﻆ ﻋﻠﻰ ﺍﻟﻔﺤﺺ

ﺍﻟﺪﻭﺭﻱﻹﻧﺘﺎﺝ ﺍﻟﻤﻌﺪﺍﺕ ﺃﻭ ﺍﻟﻤﻮﺍﺩ ﺍﻟﺘﻲ ﺗﺤﻤﻞ ﻋﻼﻣﺎﺕ ،ﻭﺍﻟﺘﻲ ﻣﻦ ﺧﻼﻝ ﻭﺿﻊ ﺍﻟﻌﻼﻣﺎﺕ ﻋﻠﻴﻬﺎ ﺗﺸﻴﺮ

ﺍﻟﺸﺮﻛﺔﺍﻟﻤﺼﻨﻌﺔ ﺇﻟﻰ ﺍﻻﻣﺘﺜﺎﻝ ﻟﻠﻤﻌﺎﻳﻴﺮ ﺍﻟﻤﻨﺎﺳﺒﺔ ﺃﻭ ﺍﻷﺩﺍء ﺑﻄﺮﻳﻘﺔ ﻣﺤﺪﺩﺓ.

*3.2.3ﻣﺪﺭﺝ .ﺍﻟﻤﻌﺪﺍﺕ ﺃﻭ ﺍﻟﻤﻮﺍﺩ ﺃﻭ ﺍﻟﺨﺪﻣﺎﺕ ﺍﻟﻤﺪﺭﺟﺔ ﻓﻲ ﻗﺎﺉﻤﺔ ﻣﻨﺸﻮﺭﺓ ﻣﻦ ﻗﺒﻞ ﻣﻨﻈﻤﺔ ﻣﻘﺒﻮﻟﺔ ﻟﺪﻯ

ﺍﻟﺴﻠﻄﺔﺫﺍﺕ ﺍﻻﺧﺘﺼﺎﺹ ﻭﺍﻟﻤﻌﻨﻴﺔ ﺑﺘﻘﻴﻴﻢ ﺍﻟﻤﻨﺘﺠﺎﺕ ﺃﻭ ﺍﻟﺨﺪﻣﺎﺕ ،ﻭﺍﻟﺘﻲ ﺗﺤﺎﻓﻆ ﻋﻠﻰ ﺍﻟﺘﻔﺘﻴﺶ ﺍﻟﺪﻭﺭﻱ

ﻹﻧﺘﺎﺝﺍﻟﻤﻌﺪﺍﺕ ﺃﻭ ﺍﻟﻤﻮﺍﺩ ﺍﻟﻤﺪﺭﺟﺔ ﺃﻭ ﺍﻟﺘﻘﻴﻴﻢ ﺍﻟﺪﻭﺭﻱ ﻟﻠﺨﺪﻣﺎﺕ ،ﻭﺍﻟﺘﻲ ﺗﻨﺺ ﺍﻟﻘﺎﺉﻤﺔ ﻋﻠﻰ ﺃﻥ ﺍﻟﻤﻌﺪﺍﺕ

ﺃﻭﺍﻟﻤﻮﺍﺩ ﺃﻭ ﺍﻟﺨﺪﻣﺔ ﺗﻔﻲ ﺑﺎﻟﻤﻌﺎﻳﻴﺮ ﺍﻟﻤﺤﺪﺩﺓ ﺍﻟﻤﻨﺎﺳﺒﺔ ﺃﻭ ﺗﻢ ﺍﺧﺘﺒﺎﺭﻫﺎ ﻭﺗﺒﻴﻦ ﺃﻧﻬﺎ ﻣﻨﺎﺳﺒﺔ ﻟﻐﺮﺽ ﻣﺤﺪﺩ.

3.3ﺗﻌﺮﻳﻔﺎﺕ ﻋﺎﻣﺔ.

3.3.1ﻳﺮﺑﻚ .ﻗﺴﻢ ﻋﺮﺿﻲ ﻏﻴﺮ ﺳﺎﺉﻞ ﻓﻲ ﺧﺰﺍﻥ ﺍﻟﺒﻀﺎﺉﻊ.

3.3.2ﺣﺎﺟﺰ ﺇﻧﺸﺎﺉﻲ .ﺇﻏﻼﻕ ﻋﺮﺿﻲ ﻣﺤﻜﻢ ﻟﻠﺴﺎﺉﻞ ﺑﻴﻦ ﺣﺠﺮﺍﺕ ﺧﺰﺍﻥ ﺍﻟﺒﻀﺎﺉﻊ.

3.3.3ﺧﺰﺍﻥ ﺍﻟﺒﻀﺎﺉﻊ .ﻭﻷﻏﺮﺍﺽ ﻫﺬﻩ ﺍﻟﻤﻮﺍﺻﻔﺔ ﺍﻟﻘﻴﺎﺳﻴﺔ ،ﺃﻱ ﺧﺰﺍﻥ ﺑﻪ ﺳﻌﺔ ﺳﺎﺉﻠﺔ ﺗﺰﻳﺪ ﻋﻦ 110

ﺟﺎﻟﻮﻧﺎً) 415ﻟﺘﺮﺍً( ﻳﺴﺘﺨﺪﻡ ﻟﻨﻘﻞ ﺍﻟﺴﻮﺍﺉﻞ ﺍﻟﻘﺎﺑﻠﺔ ﻟﻼﺷﺘﻌﺎﻝ ﻭﺍﻻﺣﺘﺮﺍﻕ ﺃﻭ ﺍﻷﺳﻔﻠﺖ ﻭﻳﺘﻢ ﺗﺮﻛﻴﺒﻪ ﺑﺸﻜﻞ

ﺩﺍﺉﻢﺃﻭ ﻏﻴﺮ ﺫﻟﻚ ﻋﻠﻰ ﻣﺮﻛﺒﺔ ﺻﻬﺮﻳﺠﻴﺔ .ﻋﻠﻰ ﺍﻟﻤﺪﻯﺧﺰﺍﻥ ﺍﻟﺒﻀﺎﺉﻊﻻ ﻳﻨﻄﺒﻖ ﻋﻠﻰ ﺃﻱ ﺣﺎﻭﻳﺔ ﺗﺴﺘﺨﺪﻡ

ﻓﻘﻂﻟﻐﺮﺽ ﺗﻮﻓﻴﺮ ﺍﻟﻮﻗﻮﺩ ﻟﺪﻓﻊ ﻣﺮﻛﺒﺔ ﺍﻟﺼﻬﺮﻳﺞ ﺍﻟﺘﻲ ﺗﻢ ﺗﺮﻛﻴﺒﻬﺎ ﻋﻠﻴﻬﺎ.

*3.3.4ﺳﺎﺉﻞ ﻗﺎﺑﻞ ﻟﻼﺷﺘﻌﺎﻝ .ﺃﻱ ﺳﺎﺉﻞ ﻟﺪﻳﻪ ﻧﻘﻄﺔ ﻭﻣﻴﺾ ﻋﻨﺪ ﺃﻭ ﺃﻋﻠﻰ ﻣﻦ 100ﺩﺭﺟﺔ ﻓﻬﺮﻧﻬﺎﻳﺖ ) 37.8ﺩﺭﺟﺔ ﻣﺉﻮﻳﺔ( ﻭﺃﻗﻞ ﻣﻦ 140ﺩﺭﺟﺔ

ﻓﻬﺮﻧﻬﺎﻳﺖ) 60ﺩﺭﺟﺔ ﻣﺉﻮﻳﺔ(.

3.3.5ﺣﺠﺮﺓ .ﻭﻷﻏﺮﺍﺽ ﻫﺬﻩ ﺍﻟﻤﻮﺍﺻﻔﺔ ﺍﻟﻘﻴﺎﺳﻴﺔ ،ﻳﻘُﺼﺪ ﺑﺎﻟﺘﻘﺴﻴﻢ ﺍﻟﻤﺎﻧﻊ ﻟﻠﺴﻮﺍﺉﻞ ﻓﻲ ﺧﺰﺍﻥ ﺍﻟﺒﻀﺎﺉﻊ.

*3.3.6ﺳﺎﺉﻞ ﻗﺎﺑﻞ ﻟﻼﺷﺘﻌﺎﻝ .ﺃﻱ ﺳﺎﺉﻞ ﻳﺤﺘﻮﻱ ﻋﻠﻰ ﻧﻘﻄﺔ ﻭﻣﻴﺾ ﻛﻮﺏ ﻣﻐﻠﻖ ﺃﻗﻞ ﻣﻦ 100ﺩﺭﺟﺔ ﻓﻬﺮﻧﻬﺎﻳﺖ ) 37.8ﺩﺭﺟﺔ ﻣﺉﻮﻳﺔ(

ﻭﺿﻐﻂﺑﺨﺎﺭ ﺭﻳﺪ ﻻ ﻳﺘﺠﺎﻭﺯ 276ﻛﻴﻠﻮ ﺑﺎﺳﻜﺎﻝ ) 40ﺭﻃﻞ ﻟﻜﻞ ﺑﻮﺻﺔ ﻣﺮﺑﻌﺔ ﺃﻭ 2068ﻣﻠﻢ ﺯﺉﺒﻖ(.

*3.3.7ﻧﻘﻄﺔ ﺍﻟﻮﻣﻴﺾ .ﺍﻟﺤﺪ ﺍﻷﺩﻧﻰ ﻟﺪﺭﺟﺔ ﺍﻟﺤﺮﺍﺭﺓ ﺍﻟﺘﻲ ﻳﺒﻌﺚ ﻋﻨﺪﻫﺎ ﺍﻟﺴﺎﺉﻞ ﺃﻭ ﺍﻟﻤﺎﺩﺓ ﺍﻟﺼﻠﺒﺔ ﺑﺨﺎﺭﺍً

ﻛﺎﻓﻴﺎًﻟﺘﻜﻮﻳﻦ ﺧﻠﻴﻂ ﻗﺎﺑﻞ ﻟﻼﺷﺘﻌﺎﻝ ﻣﻊ ﺍﻟﻬﻮﺍء ﺑﺎﻟﻘﺮﺏ ﻣﻦ ﺳﻄﺢ ﺍﻟﺴﺎﺉﻞ ﺃﻭ ﺍﻟﻤﺎﺩﺓ ﺍﻟﺼﻠﺒﺔ.

3.3.8ﺭﺃﺱ .ﺇﻏﻼﻕ ﻋﺮﺿﻲ ﻣﺤﻜﻢ ﻟﻠﺴﺎﺉﻞ ﻓﻲ ﻧﻬﺎﻳﺔ ﺧﺰﺍﻥ ﺍﻟﺒﻀﺎﺉﻊ.

3.3.9ﺳﺎﺉﻞ .ﺃﻱ ﻣﺎﺩﺓ ﺫﺍﺕ ﺳﻴﻮﻟﺔ ﺃﻛﺒﺮ ﻣﻦ 300ﺃﺳﻔﻠﺖ ﻗﺎﺑﻞ ﻟﻼﺧﺘﺮﺍﻕ ﻋﻨﺪ ﺍﺧﺘﺒﺎﺭﻫﺎ ﻃﺒﻘﺎ ًﻟﻠﻤﻮﺍﺻﻔﺔ

،ASTM D5ﺍﺧﺘﺒﺎﺭ ﺍﻻﺧﺘﺮﺍﻕ ﻟﻠﻤﻮﺍﺩ ﺍﻟﺒﻴﺘﻮﻣﻴﻨﻴﺔ.

3.3.10ﺧﺰﺍﻥ.

3.3.10.1ﺧﺰﺍﻥ ﻣﻘﻄﻮﺭﺓ ﻛﺎﻣﻠﺔ .ﺃﻱ ﻣﺮﻛﺒﺔ ﻣﺰﻭﺩﺓ ﺃﻭ ﺑﺪﻭﻥ ﻗﻮﺓ ﺩﺍﻓﻌﺔ ﻣﺴﺎﻋﺪﺓ ،ﻣﺤﻤﻴﺔ ﺑﺤﻘﻮﻕ ﺍﻟﻄﺒﻊ

ﻭﺍﻟﻨﺸﺮNFPA

ﺷﺮﻛﺔﺃﺑﺎﺩﻏﻮﺳﺘﺎﺭ ﺗﺎﺳﻴﺴﺎﺕ ﺇﻳﺮﺍﻧﻴﻨﺎﻥ ﺍﻟﻤﺤﺪﻭﺩﺓ www.atapars.com

www.atapars.com/NFPA-code/

ﻣﻊﺧﺰﺍﻥ ﺑﻀﺎﺉﻊ ﻣﺜﺒﺖ ﻋﻠﻴﻪ ﺃﻭ ﻣﺒﻨﻲ ﻛﺠﺰء ﻻ ﻳﺘﺠﺰﺃ ﻣﻨﻪ ،ﻭﻳﺴﺘﺨﺪﻡ ﻟﻨﻘﻞ ﺍﻟﺴﻮﺍﺉﻞ ﺍﻟﻘﺎﺑﻠﺔ

ﻟﻼﺷﺘﻌﺎﻝﻭﺍﻻﺣﺘﺮﺍﻕ ﺃﻭ ﺍﻷﺳﻔﻠﺖ ،ﻭﻣﺒﻨﻲ ﺑﺤﻴﺚ ﻳﻘﻊ ﻛﻞ ﻭﺯﻧﻪ ﻭﺣﻤﻮﻟﺘﻪ ﺗﻘﺮﻳﺒﺎً ﻋﻠﻰ ﻋﺠﻼﺗﻪ ﺍﻟﺨﺎﺻﺔ.

3.3.10.2ﺧﺰﺍﻥ ﻧﺼﻒ ﻣﻘﻄﻮﺭﺓ .ﺃﻱ ﻣﺮﻛﺒﺔ ﺫﺍﺕ ﻗﻮﺓ ﺩﺍﻓﻌﺔ ﻣﺴﺎﻋﺪﺓ ﺃﻭ ﺑﺪﻭﻧﻬﺎ ،ﻭﻣﺠﻬﺰﺓ ﺑﺨﺰﺍﻥ ﺑﻀﺎﺉﻊ

ﻣﺜﺒﺖﻋﻠﻴﻪ ﺃﻭ ﻣﺒﻨﻲ ﻛﺠﺰء ﻻ ﻳﺘﺠﺰﺃ ﻣﻨﻪ ،ﻭﺗﺴﺘﺨﺪﻡ ﻟﻨﻘﻞ ﺍﻟﺴﻮﺍﺉﻞ ﺍﻟﻘﺎﺑﻠﺔ ﻟﻼﺷﺘﻌﺎﻝ ﺃﻭ ﺍﻟﻘﺎﺑﻠﺔ ﻟﻼﺷﺘﻌﺎﻝ

ﺃﻭﺍﻷﺳﻔﻠﺖ ،ﻭﻣﺒﻨﻴﺔ ﺑﺤﻴﺚ ﺃﻧﻪ ﻋﻨﺪﻣﺎ ﻳﺘﻢ ﺳﺤﺒﻬﺎ ﺑﻮﺍﺳﻄﺔ ﺟﺮﺍﺭ ﺑﻮﺍﺳﻄﺔ ﺍﺗﺼﺎﻝ ﺍﻟﻌﺠﻠﺔ ﺍﻟﺨﺎﻣﺴﺔ ،ﺣﻴﺚ

ﻳﻘﻊﺟﺰء ﻣﻦ ﺣﻤﻮﻟﺘﻬﺎ ﻭﻭﺯﻧﻬﺎ ﻋﻠﻰ ﻣﺮﻛﺒﺔ ﺍﻟﻘﻄﺮ.

3.3.11ﺷﺎﺣﻨﺔ ﺻﻬﺮﻳﺞ .ﺃﻱ ﻣﺮﻛﺒﺔ ﺁﻟﻴﺔ ﻭﺍﺣﺪﺓ ﺫﺍﺗﻴﺔ ﺍﻟﺪﻓﻊ ﻣﺰﻭﺩﺓ ﺑﺨﺰﺍﻥ ﺑﻀﺎﺉﻊ ﻣﺜﺒﺖ ﻋﻠﻴﻬﺎ

ﻭﺗﺴﺘﺨﺪﻡﻟﻨﻘﻞ ﺍﻟﺴﻮﺍﺉﻞ ﺍﻟﻘﺎﺑﻠﺔ ﻟﻼﺷﺘﻌﺎﻝ ﺃﻭ ﺍﻻﺷﺘﻌﺎﻝ ﺃﻭ ﺍﻷﺳﻔﻠﺖ.

3.3.12ﻣﺮﻛﺒﺔ ﺩﺑﺎﺑﺔ .ﺃﻱ ﺷﺎﺣﻨﺔ ﺻﻬﺮﻳﺠﻴﺔ ،ﺃﻭ ﻣﻘﻄﻮﺭﺓ ﺻﻬﺮﻳﺠﻴﺔ ﻛﺎﻣﻠﺔ ،ﺃﻭ ﻣﺠﻤﻮﻋﺔ ﻣﻦ ﺍﻟﺠﺮﺍﺭﺍﺕ ﻭﺷﺒﻪ

ﺍﻟﻤﻘﻄﻮﺭﺓ.

*3.3.13ﺿﻐﻂ ﺍﻟﺒﺨﺎﺭ .ﺍﻟﻀﻐﻂ ،ﺍﻟﻤﻘﺎﺱ ﺑﺎﻟﺠﻨﻴﻪ ﻟﻜﻞ ﺑﻮﺻﺔ ﻣﺮﺑﻌﺔ ،ﺍﻟﻤﻄﻠﻖ ) ،(psiaﺍﻟﺬﻱ ﻳﻤﺎﺭﺳﻪ

ﺍﻟﺴﺎﺉﻞ،ﻛﻤﺎ ﻫﻮ ﻣﺤﺪﺩ ﺑﻮﺍﺳﻄﺔ ،ASTM D 323ﺍﻟﻄﺮﻳﻘﺔ ﺍﻟﻘﻴﺎﺳﻴﺔ ﻻﺧﺘﺒﺎﺭ ﺿﻐﻂ ﺑﺨﺎﺭ ﺍﻟﻤﻨﺘﺠﺎﺕ

ﺍﻟﺒﺘﺮﻭﻟﻴﺔ)ﻃﺮﻳﻘﺔ ﺭﻳﺪ(.

ﺍﻟﻔﺼﻞﺍﻟﺮﺍﺑﻊ ﺗﺼﻨﻴﻒ ﺍﻟﻤﻮﺍﺩ ﺍﻟﻘﺎﺑﻠﺔ ﻟﻼﺷﺘﻌﺎﻝ ﻭﺍﻻﺣﺘﺮﺍﻕ

ﺍﻟﺴﻮﺍﺉﻞ

4.1ﺍﻟﻨﻄﺎﻕ.

4.1.1ﻳﺠﺐ ﺃﻥ ﻳﻀﻊ ﻫﺬﺍ ﺍﻟﻔﺼﻞ ﻧﻈﺎﻣﺎً ﻣﻮﺣﺪﺍً ﻟﺘﻌﺮﻳﻒ ﻭﺗﺼﻨﻴﻒ ﺍﻟﺴﻮﺍﺉﻞ ﺍﻟﻘﺎﺑﻠﺔ ﻟﻼﺷﺘﻌﺎﻝ ﻭﺍﻟﻘﺎﺑﻠﺔ

ﻟﻼﺣﺘﺮﺍﻕﺑﻐﺮﺽ ﺍﻟﺘﻄﺒﻴﻖ ﺍﻟﺴﻠﻴﻢ ﻟﻬﺬﻩ ﺍﻟﻤﻮﺍﺻﻔﺔ ﺍﻟﻘﻴﺎﺳﻴﺔ.

4.1.2ﺗﻨﻄﺒﻖ ﺗﺼﻨﻴﻔﺎﺕ ﻫﺬﺍ ﺍﻟﻔﺼﻞ ﻋﻠﻰ ﺃﻱ ﺳﺎﺉﻞ ﻳﻘﻊ ﺿﻤﻦ ﻧﻄﺎﻕ ﻭﻳﺨﻀﻊ ﻟﻤﺘﻄﻠﺒﺎﺕ ﻫﺬﻩ

ﺍﻟﻤﻮﺍﺻﻔﺔﺍﻟﻘﻴﺎﺳﻴﺔ.

4.2ﺗﺼﻨﻴﻒ ﺍﻟﺴﻮﺍﺉﻞ.

ﻳﺠﺐﺗﺼﻨﻴﻒ ﺃﻱ ﺳﺎﺉﻞ ﻳﻘﻊ ﺿﻤﻦ ﻧﻄﺎﻕ ﻫﺬﻩ ﺍﻟﻤﻮﺍﺻﻔﺔ ﺍﻟﻘﻴﺎﺳﻴﺔ ﻭﻳﺨﻀﻊ ﻟﻤﺘﻄﻠﺒﺎﺕ ﻫﺬﻩ ﺍﻟﻤﻮﺍﺻﻔﺔ

ﺍﻟﻘﻴﺎﺳﻴﺔﻭﻓﻘﺎً ﻟﻬﺬﺍ ﺍﻟﻘﺴﻢ.

4.2.1ﻳﺠﺐ ﺗﺼﻨﻴﻒ ﺍﻟﺴﻮﺍﺉﻞ ﺍﻟﻘﺎﺑﻠﺔ ﻟﻼﺷﺘﻌﺎﻝ ،ﻋﻠﻰ ﺍﻟﻨﺤﻮ ﺍﻟﻤﺤﺪﺩ ﻓﻲ ،3.3.6ﻋﻠﻰ ﺃﻧﻬﺎ ﺳﻮﺍﺉﻞ ﻣﻦ ﺍﻟﺪﺭﺟﺔ

ﺍﻷﻭﻟﻰﻭﻳﺠﺐ ﺗﺼﻨﻴﻔﻬﺎ ﺃﻳﻀﺎً ﻭﻓﻘﺎً ﻟﻠﺒﻨﻮﺩ ) (1ﻭ) (2ﻭ) ،(3ﻋﻠﻰ ﺍﻟﻨﺤﻮ ﺍﻟﺘﺎﻟﻲ:

) (1ﺳﺎﺉﻞ ﻣﻦ ﺍﻟﻔﺉﺔ .IAﺃﻱ ﺳﺎﺉﻞ ﻟﻪ ﻧﻘﻄﺔ ﻭﻣﻴﺾ ﺃﻗﻞ ﻣﻦ 73ﺩﺭﺟﺔ ﻓﻬﺮﻧﻬﺎﻳﺖ ) 22.8ﺩﺭﺟﺔ ﻣﺉﻮﻳﺔ( ﻭﻧﻘﻄﺔ ﻏﻠﻴﺎﻥ ﺃﻗﻞ ﻣﻦ 100ﺩﺭﺟﺔ

ﻓﻬﺮﻧﻬﺎﻳﺖ) 37.8ﺩﺭﺟﺔ ﻣﺉﻮﻳﺔ(.

) (2ﺳﺎﺉﻞ ﻓﺉﺔ .IBﺃﻱ ﺳﺎﺉﻞ ﻟﻪ ﻧﻘﻄﺔ ﻭﻣﻴﺾ ﺃﻗﻞ ﻣﻦ 73ﺩﺭﺟﺔ ﻓﻬﺮﻧﻬﺎﻳﺖ ) 22.8ﺩﺭﺟﺔ ﻣﺉﻮﻳﺔ( ﻭﻧﻘﻄﺔ ﻏﻠﻴﺎﻥ ﻋﻨﺪ ﺃﻭ ﺃﻋﻠﻰ ﻣﻦ

100ﺩﺭﺟﺔ ﻓﻬﺮﻧﻬﺎﻳﺖ ) 37.8ﺩﺭﺟﺔ ﻣﺉﻮﻳﺔ(.

) (3ﺳﺎﺉﻞ ﻓﺉﺔ .ICﺃﻱ ﺳﺎﺉﻞ ﻟﺪﻳﻪ ﻧﻘﻄﺔ ﻭﻣﻴﺾ ﻋﻨﺪ ﺃﻭ ﺃﻋﻠﻰ ﻣﻦ 73ﺩﺭﺟﺔ ﻓﻬﺮﻧﻬﺎﻳﺖ ) 22.8ﺩﺭﺟﺔ ﻣﺉﻮﻳﺔ( ﻭﻟﻜﻦ ﺃﻗﻞ ﻣﻦ 100ﺩﺭﺟﺔ

ﻓﻬﺮﻧﻬﺎﻳﺖ) 37.8ﺩﺭﺟﺔ ﻣﺉﻮﻳﺔ(.

4.2.2ﻳﺠﺐ ﺗﺼﻨﻴﻒ ﺍﻟﺴﻮﺍﺉﻞ ﺍﻟﻘﺎﺑﻠﺔ ﻟﻼﺣﺘﺮﺍﻕ ،ﻛﻤﺎ ﻫﻲ ﻣﺤﺪﺩﺓ ﻓﻲ ،3.3.4ﻃﺒﻘﺎ ًﻟـ ) (1ﻭ

ﺣﻘﻮﻕﺍﻟﻄﺒﻊ ﻭﺍﻟﻨﺸﺮ NFPA

ﺷﺮﻛﺔﺃﺑﺎﺩﻏﻮﺳﺘﺎﺭ ﺗﺎﺳﻴﺴﺎﺕ ﺇﻳﺮﺍﻧﻴﻨﺎﻥ ﺍﻟﻤﺤﺪﻭﺩﺓ www.atapars.com

www.atapars.com/NFPA-code/

) (2ﻋﻠﻰ ﺍﻟﻨﺤﻮ ﺍﻟﺘﺎﻟﻲ.

) (1ﺳﺎﺉﻞ ﻣﻦ ﺍﻟﺪﺭﺟﺔ ﺍﻟﺜﺎﻧﻴﺔ .ﺃﻱ ﺳﺎﺉﻞ ﻟﺪﻳﻪ ﻧﻘﻄﺔ ﻭﻣﻴﺾ ﻋﻨﺪ ﺃﻭ ﺃﻋﻠﻰ ﻣﻦ 100ﺩﺭﺟﺔ ﻓﻬﺮﻧﻬﺎﻳﺖ ) 37.8ﺩﺭﺟﺔ ﻣﺉﻮﻳﺔ( ﻭﺃﻗﻞ ﻣﻦ 140ﺩﺭﺟﺔ

ﻓﻬﺮﻧﻬﺎﻳﺖ) 60ﺩﺭﺟﺔ ﻣﺉﻮﻳﺔ(.

) (2ﺳﺎﺉﻞ ﻣﻦ ﺍﻟﺪﺭﺟﺔ ﺍﻟﺜﺎﻟﺜﺔ .ﺃﻱ ﺳﺎﺉﻞ ﻟﻪ ﻧﻘﻄﺔ ﻭﻣﻴﺾ ﺗﺒﻠﻎ ﺃﻭ ﺗﺰﻳﺪ ﻋﻦ 140ﺩﺭﺟﺔ ﻓﻬﺮﻧﻬﺎﻳﺖ ) 60ﺩﺭﺟﺔ

ﻣﺉﻮﻳﺔ( .ﻳﺘﻢ ﺗﺼﻨﻴﻒ ﺳﻮﺍﺉﻞ ﺍﻟﻔﺉﺔ ﺍﻟﺜﺎﻟﺜﺔ ﻭﻓﻘﺎً ﻟﻠﻔﻘﺮﺗﻴﻦ )ﺃ( ﻭ)ﺏ( ﻋﻠﻰ ﺍﻟﻨﺤﻮ ﺍﻟﺘﺎﻟﻲ:

)ﺃ( ﺳﺎﺉﻞ ﻣﻦ ﺍﻟﻔﺉﺔ .IIIAﺃﻱ ﺳﺎﺉﻞ ﻟﻪ ﻧﻘﻄﺔ ﻭﻣﻴﺾ ﺗﺒﻠﻎ ﺃﻭ ﺗﺰﻳﺪ ﻋﻦ 140ﺩﺭﺟﺔ ﻓﻬﺮﻧﻬﺎﻳﺖ ) 60ﺩﺭﺟﺔ ﻣﺉﻮﻳﺔ( ،ﻭﻟﻜﻦ ﺃﻗﻞ ﻣﻦ 200

ﺩﺭﺟﺔﻓﻬﺮﻧﻬﺎﻳﺖ ) 93ﺩﺭﺟﺔ ﻣﺉﻮﻳﺔ(.

)ﺏ( ﺳﺎﺉﻞ ﺍﻟﻔﺉﺔ .IIIBﺃﻱ ﺳﺎﺉﻞ ﻟﻪ ﻧﻘﻄﺔ ﻭﻣﻴﺾ ﺗﺒﻠﻎ ﺃﻭ ﺗﺰﻳﺪ ﻋﻦ 200ﺩﺭﺟﺔ ﻓﻬﺮﻧﻬﺎﻳﺖ ) 93ﺩﺭﺟﺔ ﻣﺉﻮﻳﺔ(.

ﺝ ﺗﺼﻤﻴﻢﻣﺮﻛﺒﺔ ﺩﺑﺎﺑﺎﺕ hapter 5

5.1ﻋﺎﻡ.

5.1.1ﻳﺠﺐ ﺃﻥ ﻳﺄﺧﺬ ﺗﺼﻤﻴﻢ ﻣﺮﻛﺒﺔ ﺍﻟﺼﻬﺮﻳﺞ ﺍﻻﻋﺘﺒﺎﺭ ﺍﻟﻬﻨﺪﺳﻲ ﻟﻠﻌﻼﻗﺔ ﺍﻟﻬﻴﻜﻠﻴﺔ ﺑﻴﻦ ﺧﺰﺍﻥ ﺍﻟﺒﻀﺎﺉﻊ

ﻭﻣﻌﺪﺍﺕﺍﻟﺪﻓﻊ ﻭﺍﻷﻋﻀﺎء ﺍﻟﺪﺍﻋﻤﺔ ،ﺇﻥ ﻭﺟﺪﺕ ،ﻣﻊ ﻣﺮﺍﻋﺎﺓ ﻭﺯﻥ ﺍﻟﺤﻤﻮﻟﺔ ﻭﺩﺭﺟﺔ ﺣﺮﺍﺭﺗﻬﺎ ﻭﺃﺩﺍء ﺍﻟﻄﺮﻳﻖ

ﻭﺍﻟﻜﺒﺢﻭﺍﻟﺼﻼﺑﺔ ﺍﻟﻤﻄﻠﻮﺑﺔ .

5.1.2ﺗﻜﻮﻥ ﺳﻤﺎﻛﺎﺕ ﺍﻟﻤﻌﺎﺩﻥ ﺍﻟﻤﺤﺪﺩﺓ ﻓﻲ ﻫﺬﺍ ﺍﻟﻔﺼﻞ ﻫﻲ ﺍﻟﺤﺪ ﺍﻷﺩﻧﻰ ﻟﻠﺴﻤﺎﻛﺎﺕ ﺍﻟﺘﻲ ﻳﺤﺪﺩﻫﺎ ﻫﻴﻜﻞ

ﺍﻟﺨﺰﺍﻥﻧﻔﺴﻪ .ﻭﻳﺴﻤﺢ ﺑﺰﻳﺎﺩﺓ ﻫﺬﻩ ﺍﻟﺴﻤﺎﻛﺔ ﻋﻨﺪﻣﺎ ﻳﺘﻌﺮﺽ ﻫﻴﻜﻞ ﺍﻟﺨﺰﺍﻥ ﻟﻀﻐﻮﻁ ﺇﺿﺎﻓﻴﺔ.

5.1.3ﻳﺠﺐ ﺃﻥ ﻳﺘﻢ ﺗﺮﺗﻴﺐ ﺍﻟﺘﺼﻤﻴﻢ ﺍﻟﻌﺎﻡ ﻟﺨﺰﺍﻥ ﺍﻟﺒﻀﺎﺉﻊ ﻭﻫﻴﻜﻞ ﺍﻟﺴﻴﺎﺭﺓ ﻟﺘﻮﻓﻴﺮ ﺃﻓﻀﻞ ﻣﺰﻳﺞ ﻣﻦ

ﺍﻟﺨﺼﺎﺉﺺﺍﻟﻬﻴﻜﻠﻴﺔ ﻭﺃﺩﺍء ﺍﻟﺴﻴﺎﺭﺓ.

5.1.4ﻳﺠﺐ ﺃﻥ ﻳﺸﺘﻤﻞ ﺗﺼﻤﻴﻢ ﻧﻈﺎﻡ ﺍﻟﺘﻌﻠﻴﻖ ﻋﻠﻰ ﻣﻴﺰﺍﺕ ﺗﺴﺎﻋﺪ ﻋﻠﻰ ﺿﻤﺎﻥ ﺍﻟﺜﺒﺎﺕ ﺍﻟﺠﺎﻧﺒﻲ ﺃﻭ ﺍﻟﺜﺒﺎﺕ

ﻋﻨﺪﺍﻧﻌﻄﺎﻑ ﺍﻟﻤﺮﻛﺒﺔ ﺍﻟﺼﻬﺮﻳﺠﻴﺔ ﻋﻨﺪ ﺍﻟﻤﻨﻌﻄﻔﺎﺕ.

5.1.5ﻳﺠﺐ ﺃﻥ ﻳﻜﻮﻥ ﻷﻱ ﺻﻬﺮﻳﺞ ﺑﻀﺎﺉﻊ ﻣﺼﻤﻢ ﻟﻨﻘﻞ ﺍﻟﻤﻮﺍﺩ ﻋﻨﺪ ﺩﺭﺟﺎﺕ ﺣﺮﺍﺭﺓ ﺳﺎﺉﻠﺔ ﺃﻋﻠﻰ ﻣﻦ

ﺩﺭﺟﺎﺕﺍﻟﺤﺮﺍﺭﺓ ﺍﻟﻤﺤﻴﻄﺔ ﻟﻮﺣﺔ ﺗﺤﺬﻳﺮ ﻣﻌﺪﻧﻴﺔ ﻣﻮﺟﻮﺩﺓ ﻓﻲ ﻣﻜﺎﻥ ﻇﺎﻫﺮ ﻋﻠﻰ ﺍﻟﺠﺎﻧﺐ ﺍﻷﻳﻤﻦ ﺑﺎﻟﻘﺮﺏ ﻣﻦ

ﺍﻟﻤﻘﺪﻣﺔ.

5.1.5.1ﻳﺠﺐ ﺃﻻ ﺗﻜﻮﻥ ﺍﻟﻠﻮﺣﺔ ﻋﺮﺿﺔ ﻟﻠﺘﺂﻛﻞ.

5.1.5.2ﻳﺠﺐ ﺃﻥ ﺗﻜﻮﻥ ﺍﻟﻠﻮﺣﺔ ﻣﺜﺒﺘﺔ ﺑﺸﻜﻞ ﺩﺍﺉﻢ ﻋﻠﻰ ﺍﻟﺨﺰﺍﻥ ﺃﻭ ﺇﻃﺎﺭ ﺍﻟﺨﺰﺍﻥ.

5.1.5.3ﻳﺠﺐ ﻭﺿﻊ ﻋﻼﻣﺔ ﻋﻠﻰ ﺍﻟﻤﻌﻠﻮﻣﺎﺕ ﺍﻟﺘﺎﻟﻴﺔ ﻋﻠﻰ ﺍﻟﻠﻮﺣﺔ ﺑﺄﺣﺮﻑ ﻻ ﻳﻘﻞ ﺍﺭﺗﻔﺎﻋﻬﺎ ﻋﻦ ½ ﺑﻮﺻﺔ )

12.5ﻣﻢ( ﻋﻦ ﻃﺮﻳﻖ ﺍﻟﺨﺘﻢ ﺃﻭ ﺍﻟﻨﻘﺶ ﺃﻭ ﺃﻱ ﻭﺳﻴﻠﺔ ﺃﺧﺮﻯ ﻟﺘﺸﻜﻴﻞ ﺍﻟﺤﺮﻭﻑ ﺩﺍﺧﻞ ﺃﻭ ﻋﻠﻰ ﻣﻌﺪﻥ

ﺍﻟﻠﻮﺣﺔﻧﻔﺴﻬﺎ:

ﺍﻟﺤﺪﺍﻷﻗﺼﻰ ﻟﺪﺭﺟﺔ ﺣﺮﺍﺭﺓ ﺍﻟﺤﻤﻮﻟﺔ ﺍﻟﻤﺴﻤﻮﺡ ﺑﻬﺎ ﻫﻮ ___ ﺩﺭﺟﺔ ﻓﻬﺮﻧﻬﺎﻳﺖ )____ ﺩﺭﺟﺔ ﻣﺉﻮﻳﺔ(.

5.1.5.4ﻳﺠﺐ ﺃﻥ ﻳﺘﻢ ﺗﺤﺪﻳﺪ ﺍﻟﺤﺪ ﺍﻷﻗﺼﻰ ﻟﺪﺭﺟﺔ ﺣﺮﺍﺭﺓ ﺍﻟﺒﻀﺎﺉﻊ ﺍﻟﻤﺴﻤﻮﺡ ﺑﻬﺎ ﻣﻦ ﻗﺒﻞ ﺍﻟﺸﺮﻛﺔ ﺍﻟﻤﺼﻨﻌﺔ

ﻟﺨﺰﺍﻥﺍﻟﺒﻀﺎﺉﻊ.

*5.1.6ﻳﺠﺐ ﺃﻥ ﻳﺘﻢ ﺇﻧﺸﺎء ﺻﻬﺎﺭﻳﺞ ﺍﻟﺒﻀﺎﺉﻊ ﺍﻟﻤﺴﺘﺨﺪﻣﺔ ﻟﻨﻘﻞ ﺍﻟﺴﻮﺍﺉﻞ ﺍﻟﻘﺎﺑﻠﺔ ﻟﻼﺷﺘﻌﺎﻝ ﺃﻭ ﺍﻟﻘﺎﺑﻠﺔ

ﻟﻼﺣﺘﺮﺍﻕﻋﻨﺪ ﺩﺭﺟﺎﺕ ﺣﺮﺍﺭﺓ ﻋﻨﺪ ﻧﻘﻄﺔ ﻏﻠﻴﺎﻧﻬﺎ ﺃﻭ ﺃﻋﻠﻰ ﻣﻨﻬﺎ ﻭﻓﻘﺎً ﻟﻠﻘﺴﻢ .5.2

ﺣﻘﻮﻕﺍﻟﻄﺒﻊ ﻭﺍﻟﻨﺸﺮ NFPA

ﺷﺮﻛﺔﺃﺑﺎﺩﻏﻮﺳﺘﺎﺭ ﺗﺎﺳﻴﺴﺎﺕ ﺇﻳﺮﺍﻧﻴﻨﺎﻥ ﺍﻟﻤﺤﺪﻭﺩﺓ www.atapars.com

www.atapars.com/NFPA-code/

5.1.7ﻳﺠﺐ ﺃﻥ ﻳﺘﻢ ﺇﻧﺸﺎء ﺻﻬﺎﺭﻳﺞ ﺍﻟﺒﻀﺎﺉﻊ ﺍﻟﻤﺴﺘﺨﺪﻣﺔ ﻟﻨﻘﻞ ﺍﻟﺴﻮﺍﺉﻞ ﺍﻟﻘﺎﺑﻠﺔ ﻟﻼﺷﺘﻌﺎﻝ ﺃﻭ ﺍﻟﻘﺎﺑﻠﺔ

ﻟﻼﺣﺘﺮﺍﻕﻋﻨﺪ ﺩﺭﺟﺎﺕ ﺣﺮﺍﺭﺓ ﺃﻗﻞ ﻣﻦ ﻧﻘﺎﻁ ﺍﻟﻐﻠﻴﺎﻥ ﻭﻓﻘﺎً ﻷﺣﻜﺎﻡ ﺍﻟﻘﺴﻢ .5.3

*5.1.8ﻳﺠﺐ ﺃﻥ ﺗﻜﻮﻥ ﺍﻟﻤﻮﺍﺩ ﺍﻟﻤﺴﺘﺨﺪﻣﺔ ﻓﻲ ﺑﻨﺎء ﺻﻬﺎﺭﻳﺞ ﺍﻟﺒﻀﺎﺉﻊ ﻣﺘﻮﺍﻓﻘﺔ ﻣﻊ ﺍﻟﺨﺼﺎﺉﺺ

ﺍﻟﻜﻴﻤﻴﺎﺉﻴﺔﻟﻠﺴﺎﺉﻞ ﺍﻟﻘﺎﺑﻞ ﻟﻼﺷﺘﻌﺎﻝ ﺃﻭ ﺍﻟﻘﺎﺑﻞ ﻟﻼﺷﺘﻌﺎﻝ ﺍﻟﻤﺮﺍﺩ ﻧﻘﻠﻪ.

5.1.9ﻋﻨﺪﻣﺎ ﻳﺘﻢ ﺗﻘﺴﻴﻢ ﺧﺰﺍﻥ ﺑﻀﺎﺉﻊ ﻭﺍﺣﺪ ﺇﻟﻰ ﺣﺠﻴﺮﺍﺕ ﺫﺍﺕ ﻣﻮﺍﺻﻔﺎﺕ ﺑﻨﺎء ﻣﺨﺘﻠﻔﺔ ،ﻳﺠﺐ ﺃﻥ

ﺗﺘﻮﺍﻓﻖﻛﻞ ﺣﺠﻴﺮﺓ ﻣﻦ ﻫﺬﻩ ﺍﻟﺤﺠﺮﺓ ﻣﻊ ﻣﺘﻄﻠﺒﺎﺕ ﺍﻟﻤﻮﺍﺻﻔﺎﺕ ﺍﻟﻤﻌﻨﻴﺔ ﻭﺃﻥ ﻳﺘﻢ ﺗﺤﺪﻳﺪﻫﺎ ﻋﻠﻰ ﻫﺬﺍ

ﺍﻟﻨﺤﻮﺑﻠﻮﺣﺔ ﻣﻌﺪﻧﻴﺔ ﺩﺍﺉﻤﺔ.

5.2ﺻﻬﺎﺭﻳﺞ ﺍﻟﺒﻀﺎﺉﻊ ﻭﺍﻷﻧﺎﺑﻴﺐ ﻭﺍﻟﻮﺻﻼﺕ ﺍﻟﻤﺼﻤﻤﺔ ﻟﻨﻘﻞ ﺍﻟﺴﻮﺍﺉﻞ ﺍﻟﻘﺎﺑﻠﺔ ﻟﻼﺷﺘﻌﺎﻝ ﺃﻭ

ﺍﻟﻘﺎﺑﻠﺔﻟﻼﺣﺘﺮﺍﻕ ﻋﻨﺪ ﺩﺭﺟﺎﺕ ﺣﺮﺍﺭﺓ ﻋﻨﺪ ﻧﻘﻄﺔ ﻏﻠﻴﺎﻧﻬﺎ ﺃﻭ ﺃﻋﻠﻰ ﻣﻨﻬﺎ.

ﻳﺠﺐﺇﻧﺸﺎء ﺻﻬﺎﺭﻳﺞ ﺍﻟﺸﺤﻦ ﻭﺍﻷﻧﺎﺑﻴﺐ ﻭﺍﻟﻮﺻﻼﺕ ﺍﻟﻤﺼﻤﻤﺔ ﻟﻨﻘﻞ ﺍﻟﺴﻮﺍﺉﻞ ﺍﻟﻘﺎﺑﻠﺔ ﻟﻼﺷﺘﻌﺎﻝ ﺃﻭ

ﺍﻟﻘﺎﺑﻠﺔﻟﻼﺣﺘﺮﺍﻕ ﻋﻨﺪ ﺃﻭ ﺃﻋﻠﻰ ﻣﻦ ﻧﻘﺎﻁ ﺍﻟﻐﻠﻴﺎﻥ ﻭﻓﻘﺎً ﻟﻠﻮﺍﺉﺢ ﻭﺯﺍﺭﺓ ﺍﻟﻨﻘﻞ ﺍﻷﻣﺮﻳﻜﻴﺔ ﻓﻲ ،CFR 178 49

"ﻟﻮﺍﺉﺢ ﺍﻟﻤﻮﺍﺩ ﺍﻟﺨﻄﺮﺓ" ،ﻭﻓﻘﺎً ﻟﻠﻔﺼﻞ 6ﻣﻦ ،NFPA 58ﻛﻮﺩ ﻏﺎﺯ ﺍﻟﺒﺘﺮﻭﻝ ﺍﻟﻤﺴﺎﻝ.

5.3ﺻﻬﺎﺭﻳﺞ ﺍﻟﺒﻀﺎﺉﻊ ﻭﺍﻷﻧﺎﺑﻴﺐ ﻭﺍﻟﻮﺻﻼﺕ ﺍﻟﻤﺼﻤﻤﺔ ﻟﻨﻘﻞ ﺍﻟﺴﻮﺍﺉﻞ ﺍﻟﻘﺎﺑﻠﺔ ﻟﻼﺷﺘﻌﺎﻝ ﺃﻭ

ﺍﻟﻘﺎﺑﻠﺔﻟﻼﺷﺘﻌﺎﻝ ﻋﻨﺪ ﺩﺭﺟﺎﺕ ﺣﺮﺍﺭﺓ ﺃﻗﻞ ﻣﻦ ﻧﻘﻄﺔ ﻏﻠﻴﺎﻧﻬﺎ.

5.3.1ﻋﺎﻡ.

5.3.1.1ﻳﺠﺐ ﺇﻧﺸﺎء ﺻﻬﺎﺭﻳﺞ ﺍﻟﺒﻀﺎﺉﻊ ﺍﻟﺘﻲ ﺗﻢ ﺑﻨﺎﺅﻫﺎ ﺑﻌﺪ ﺗﺎﺭﻳﺦ ﻧﻔﺎﺫ ﻫﺬﻩ ﺍﻟﻤﻮﺍﺻﻔﺔ ﺍﻟﻘﻴﺎﺳﻴﺔ ﻭﻓﻘﺎً

ﻟﻠﻘﺴﻢ.5.3

5.3.1.2ﻳﺴُﻤﺢ ﺑﻤﻮﺍﺻﻠﺔ ﺍﺳﺘﺨﺪﺍﻡ ﺻﻬﺎﺭﻳﺞ ﺍﻟﺒﻀﺎﺉﻊ ﺍﻟﺤﺎﻟﻴﺔ ﺍﻟﺘﻲ ﺗﻢ ﺇﻧﺸﺎﺅﻫﺎ ﻭﻓﻘﺎً ﻟﻺﺻﺪﺍﺭﺍﺕ ﺍﻟﺴﺎﺑﻘﺔ

ﻣﻦﻫﺬﻩ ﺍﻟﻤﻮﺍﺻﻔﺔ ﺍﻟﻘﻴﺎﺳﻴﺔ ،ﻭﻟﻜﻦ ﻻ ﻳﺴُﻤﺢ ﺑﺎﻟﺒﻨﺎء ﺍﻟﺠﺪﻳﺪ ﻭﻓﻘﺎً ﻟﻠﻤﻌﺎﻳﻴﺮ ﺍﻟﻘﺪﻳﻤﺔ.

*5.3.2ﻣﺎﺩﺓ.ﺟﻤﻴﻊ ﻣﻮﺍﺩ ﺍﻷﻟﻮﺍﺡ ﻭﺍﻷﻟﻮﺍﺡ ﻟﻠﻬﻴﻜﻞ ﻭﺍﻟﺮﺅﻭﺱ ﻭﺍﻟﺤﻮﺍﺟﺰ ﻭﺍﻟﺤﻮﺍﺟﺰ ﻟﺼﻬﺎﺭﻳﺞ ﺍﻟﺒﻀﺎﺉﻊ ﺍﻟﺘﻲ ﻻ

ﻳﻠﺰﻡﺗﺼﻨﻴﻌﻬﺎ ﻭﻓﻘﺎً ﻟﻤﻌﺎﻳﻴﺮ ASMEﺭﻣﺰ ﺍﻟﻐﻼﻳﺎﺕ ﻭﺃﻭﻋﻴﺔ ﺍﻟﻀﻐﻂﻳﺠﺐ ﺃﻥ ﺗﺴﺘﻮﻓﻲ ﺍﻟﺤﺪ ﺍﻷﺩﻧﻰ ﻣﻦ

ﺍﻟﻤﺘﻄﻠﺒﺎﺕﺍﻟﻤﻄﺒﻘﺔ ﺍﻟﺘﺎﻟﻴﺔ:

) (1ﺳﺒﺎﺉﻚ ﺍﻷﻟﻮﻣﻨﻴﻮﻡ ) - (ALﻓﻘﻂ ﻣﺎﺩﺓ ﺳﺒﺎﺉﻚ ﺍﻷﻟﻮﻣﻨﻴﻮﻡ ﺍﻟﻤﻨﺎﺳﺒﺔ ﻟﻠﺤﺎﻡ ﺍﻻﻧﺼﻬﺎﺭ ﻭﺍﻟﻤﺘﻮﺍﻓﻘﺔ ﻣﻊ

،ASTM B209ﻣﻮﺍﺻﻔﺎﺕ ﺻﻔﺎﺉﺢ ﻭﺻﻔﺎﺉﺢ ﺍﻷﻟﻮﻣﻨﻴﻮﻡ ﻭﺳﺒﺎﺉﻚ ﺍﻷﻟﻮﻣﻨﻴﻮﻡ ،ﻳﺠﺐ ﺍﻥ

ﺗﺴﺘﺨﺪﻡ.ﻳﺴُﻤﺢ ﻟﻠﺮﺅﻭﺱ ﻭﺍﻟﺤﻮﺍﺟﺰ ﻭﺍﻟﺤﻮﺍﺟﺰ ﻭﺃﺩﻭﺍﺕ ﺗﻘﻮﻳﺔ ﺍﻟﺤﻠﻘﺎﺕ ﺑﺎﺳﺘﺨﺪﺍﻡ ﺩﺭﺟﺎﺕ ﺣﺮﺍﺭﺓ 0

)ﻣﻠﺪﻧﺔ( ﺃﻭ ﺩﺭﺟﺎﺕ ﺣﺮﺍﺭﺓ ﺃﻗﻮﻯ .ﻳﺠﺐ ﺃﻥ ﺗﺼﻨﻊ ﺍﻷﺻﺪﺍﻑ ﻣﻦ ﻣﻮﺍﺩ ﺫﺍﺕ ﺧﻮﺍﺹ ﻣﻜﺎﻓﺉﺔ

ﻟﺪﺭﺟﺎﺕﺣﺮﺍﺭﺓ H32ﺃﻭ ،H34ﺑﺎﺳﺘﺜﻨﺎء ﺃﻧﻪ ﻳﺠﺐ ﺍﻟﺴﻤﺎﺡ ﺑﺎﺳﺘﺨﺪﺍﻡ ﺩﺭﺟﺎﺕ ﺣﺮﺍﺭﺓ ﻧﻬﺎﺉﻴﺔ ﺃﻗﻞ

ﺇﺫﺍﺗﻤﺖ ﺯﻳﺎﺩﺓ ﺍﻟﺤﺪ ﺍﻷﺩﻧﻰ ﻟﺴﻤﻚ ﺍﻟﻘﺸﺮﺓ ﻓﻲ ﺍﻟﺠﺪﻭﻝ ) 5.3.3.1ﺏ( ﺑﻨﺴﺒﺔ ﻋﻜﺴﻴﺔ ﺇﻟﻰ ﺍﻟﻘﻮﺓ

ﺍﻟﻨﻬﺎﺉﻴﺔﺍﻷﻗﻞ. .

) (2ﺍﻟﺼﻠﺐ -ﻳﺠﺐ ﺃﻥ ﻳﻔﻲ ﺍﻟﻔﻮﻻﺫ ﺑﻤﺘﻄﻠﺒﺎﺕ ﺍﻟﺠﺪﻭﻝ .5.3.2

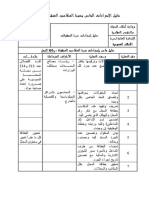

ﺍﻟﺠﺪﻭﻝ 5.3.2ﺧﺼﺎﺉﺺ ﺍﻟﻔﻮﻻﺫ

ﺍﻟﻔﻮﻻﺫﺍﻟﻤﻘﺎﻭﻡ ﻟﻠﺼﺪﺃ ﻗﻮﺓﻋﺎﻟﻴﺔ ﻣﻨﺨﻔﻀﺔ

)ﺱ.ﺱ( ﺳﺒﺎﺉﻚﺍﻟﺼﻠﺐ )(HSLA ﺍﻟﻔﻮﻻﺫﺍﻟﻄﺮﻱ )(MS ﻣﻠﻜﻴﺔ

25000ﺭﻃﻞ ﻟﻜﻞ ﺑﻮﺻﺔ ﻣﺮﺑﻌﺔ 170ﻣﻴﺠﺎ ﺑﺎﺳﻜﺎﻝ 45000ﺭﻃﻞ ﻟﻜﻞ ﺑﻮﺻﺔ ﻣﺮﺑﻌﺔ ) 310ﻣﻴﺠﺎ ﺑﺎﺳﻜﺎﻝ(. 25000ﺭﻃﻞ ﻟﻜﻞ ﺑﻮﺻﺔ ﻣﺮﺑﻌﺔ 170ﻣﻴﺠﺎ ﺑﺎﺳﻜﺎﻝ ﻗﻮﺓﺍﻟﻌﺎﺉﺪ

ﺣﻘﻮﻕﺍﻟﻄﺒﻊ ﻭﺍﻟﻨﺸﺮ NFPA

ﺷﺮﻛﺔﺃﺑﺎﺩﻏﻮﺳﺘﺎﺭ ﺗﺎﺳﻴﺴﺎﺕ ﺇﻳﺮﺍﻧﻴﻨﺎﻥ ﺍﻟﻤﺤﺪﻭﺩﺓ www.atapars.com

www.atapars.com/NFPA-code/

ﺍﻟﺠﺪﻭﻝ 5.3.2ﺧﺼﺎﺉﺺ ﺍﻟﻔﻮﻻﺫ

ﺍﻟﻔﻮﻻﺫﺍﻟﻤﻘﺎﻭﻡ ﻟﻠﺼﺪﺃ ﻗﻮﺓﻋﺎﻟﻴﺔ ﻣﻨﺨﻔﻀﺔ

)ﺱ.ﺱ( ﺳﺒﺎﺉﻚﺍﻟﺼﻠﺐ )(HSLA ﺍﻟﻔﻮﻻﺫﺍﻟﻄﺮﻱ )(MS ﻣﻠﻜﻴﺔ

70,000ﺭﻃﻞ ﻟﻜﻞ ﺑﻮﺻﺔ ﻣﺮﺑﻌﺔ 480ﻣﻴﺠﺎ ﺑﺎﺳﻜﺎﻝ 60,000ﺭﻃﻞ ﻟﻜﻞ ﺑﻮﺻﺔ ﻣﺮﺑﻌﺔ 410ﻣﻴﺠﺎ ﺑﺎﺳﻜﺎﻝ 45000ﺭﻃﻞ ﻟﻜﻞ ﺑﻮﺻﺔ ﻣﺮﺑﻌﺔ 310 ﻗﻮﺓﻏﻴﺮ ﻣﺤﺪﻭﺩﺓ

%30 %25 ﻣﻴﺠﺎﺑﺎﺳﻜﺎﻝ%20 ﺍﺳﺘﻄﺎﻟﺔ

]ﻋﻴﻨﺔ ﻣﻘﺎﺱ 2ﺑﻮﺻﺔ ) 50.8ﻣﻢ([

5.3.3ﺳﻤﻚ ﺍﻷﻟﻮﺍﺡ ﻭﺍﻟﺮﺅﻭﺱ ﻭﺍﻟﺤﻮﺍﺟﺰ ﻭﺍﻟﺤﻮﺍﺟﺰ.

5.3.3.1ﻳﺠﺐ ﺃﻥ ﻳﻌﺘﻤﺪ ﺍﻟﺤﺪ ﺍﻷﺩﻧﻰ ﻟﺴﻤﺎﻛﺔ ﻣﺎﺩﺓ ﺍﻟﺨﺰﺍﻥ ﻋﻠﻰ ﻋﺪﻡ ﺗﺠﺎﻭﺯ ﺍﻟﺤﺪ ﺍﻷﻗﺼﻰ ﻟﻤﺴﺘﻮﻯ

ﺍﻟﻀﻐﻂﺍﻟﻤﺴﻤﻮﺡ ﺑﻪ ،ﻭﻟﻜﻦ ﻳﺠﺐ ﺃﻻ ﻳﻘﻞ ﺑﺄﻱ ﺣﺎﻝ ﻣﻦ ﺍﻷﺣﻮﺍﻝ ﻋﻦ ﺗﻠﻚ ﺍﻟﻤﻮﺿﺤﺔ ﻓﻲ ﺍﻟﺠﺪﻭﻝ ) 5.3.3.1

ﺃ( ﻭﺍﻟﺠﺪﻭﻝ ) 5.3.3.1ﺏ(.

ﺍﻟﺠﺪﻭﻝ) 5.3.3.1ﺃ( ﺍﻟﺤﺪ ﺍﻷﺩﻧﻰ ﻟﺴﻤﺎﻛﺔ ﺍﻟﺮﺅﻭﺱ ﻭﺍﻟﺤﻮﺍﺟﺰ ﻭﺍﻟﺤﻮﺍﺟﺰ ﻓﻲ ﺍﻟﻮﻻﻳﺎﺕ ﺍﻟﻤﺘﺤﺪﺓ

ﻣﻘﻴﺎﺱﻗﻴﺎﺳﻲ )ﺍﻟﻔﻮﻻﺫ( ﺃﻭ ﺍﻟﺒﻮﺻﺔ ﺍﻟﻌﺸﺮﻳﺔ )ﺍﻷﻟﻮﻣﻨﻴﻮﻡ(

ﺳﻌﺔﺍﻟﺤﺠﻢ ﺑﺎﻟﺠﺎﻟﻮﻥ ﻟﻜﻞ ﺑﻮﺻﺔ

18ﻭﺃﻛﺜﺮ 14ﺇﻟﻰ 18 ﺃﻛﺜﺮﻣﻦ 10ﺇﻟﻰ 14 10ﺃﻭ ﺃﻗﻞ

HSLA HSL ﺍﻟﻨﻈﺎﻡﺍﻟﻤﻨﺴﻖ ﺍﻟﻨﻈﺎﻡﺍﻟﻤﻨﺴﻖ

, ﺃ، ﻡﻟﻮﺱﺃﻧﺠﻠﻮﺱ، ﻟﻮﺱﺃﻧﺠﻠﻮﺱ،

ﺁﻧﺴﺔ ﺳﺲ ﺍﻝ ﺁﻧﺴﺔ ﺳﺲ ﺍﻝ ﺱ ﺳﺲ ﺍﻝ ﺁﻧﺴﺔ ﺳﺲ ﺍﻝ

0.151 12 11 0.130 13 12 0.10 14 13 0.096 15 14 ﺳﻤﺎﻛﺔ

9

.ﺍﻟﻔﻮﻻﺫﺍﻟﻤﻘﺎﻭﻡ ﻟﻠﺼﺪﺃ ﺍﻷﻭﺳﺘﻨﻴﺘﻲ .ﺁﻝ :ﺍﻷﻟﻮﻣﻨﻴﻮﻡ . SS:ﻓﻮﻻﺫ ﻋﺎﻟﻲ ﺍﻟﻘﻮﺓ ﻭﻣﻨﺨﻔﺾ ﺍﻟﺴﺒﺎﺉﻚ . HSLA:ﺍﻟﻔﻮﻻﺫ ﺍﻟﻄﺮﻱ MS:

ﺍﻟﺠﺪﻭﻝ) 5.3.3.1ﺏ( ﺍﻟﺤﺪ ﺍﻷﺩﻧﻰ ﻟﺴﻤﺎﻛﺔ ﺻﻔﺎﺉﺢ ﺍﻟﻘﺸﺮﺓ ﻭﻓﻘﺎً ﻟﻠﻤﻘﻴﺎﺱ ﺍﻟﻘﻴﺎﺳﻲ ﺍﻷﻣﺮﻳﻜﻲ )ﺍﻟﻔﻮﻻﺫ(

ﺃﻭﺍﻟﺒﻮﺻﺔ ﺍﻟﻌﺸﺮﻳﺔ )ﺍﻷﻟﻮﻣﻨﻴﻮﻡ(

ﺳﻌﺔﺍﻟﺤﺠﻢ ﺑﺎﻟﺠﺎﻟﻮﻥ ﻟﻜﻞ ﺑﻮﺻﺔ

18ﻭ

ﺯﻳﺎﺩﺓ 14ﺇﻟﻰ 18 ﺃﻛﺜﺮﻣﻦ 10ﺇﻟﻰ 14 10ﺃﻭ ﺃﻗﻞ

ﺡ

ﺱ

ﻝ ﺍﻟﻨﻈﺎﻡﺍﻟﻤﻨﺴﻖ ﺍﻟﻨﻈﺎﻡﺍﻟﻤﻨﺴﻖ ﺍﻟﻤﺴﺎﻓﺔﺑﻴﻦ

ﺃ، ﻟﻮﺱﺃﻧﺠﻠﻮﺱ ﺍﻟﻨﻈﺎﻡﺍﻟﻤﻨﺴﻖ ﻟﻮﺱﺃﻧﺠﻠﻮﺱ ﺣﻮﺍﺟﺰ,

ﻡ ﺱﺃ ،ﺃ ﻟﻮﺱﺃﻧﺠﻠﻮﺱ، , ﻳﺤﻴﺮ،ﺃﻭ ﺍﻟﺪﺍﺉﺮﻱ ﺃﻗﺼﻰﺷﻞ

ﺱ ﺱﻝ ﺁﻧﺴﺔ ﺳﺲﻝ ﺁﻧﺴﺔ ﺳﺲ ﺍﻝ ﺁﻧﺴﺔ ﺳﺲﺍﻝ ﺍﻟﺘﻘﻮﻳﺔ ﻧﺼﻒﺍﻟﻘﻄﺮ

.0 14 13 .0 15 14 0.087 16 14 0.0 16 14 36ﺑﻮﺻﺔ ﺃﻭ ﺃﻗﻞ ﺃﻗﻞﻣﻦ 70ﺑﻮﺻﺔ

10 09 87

9 6

.0 13 12 .0 14 13 0.096 15 14 0.0 16 14 ﺃﻛﺜﺮﻣﻦ 36ﺑﻮﺻﺔ ﺇﻟﻰ 54

13 10 87 ﺑﻮﺻﺔ.

0 9

.0 12 11 .0 13 12 0.109 14 13 0.0 15 14 ﺃﻛﺜﺮﻣﻦ 54ﺑﻮﺻﺔ.

15 13 96 ﻣﻦﺧﻼﻝ 60ﺑﻮﺻﺔ.

1 0

ﺣﻘﻮﻕﺍﻟﻄﺒﻊ ﻭﺍﻟﻨﺸﺮ NFPA

ﺷﺮﻛﺔﺃﺑﺎﺩﻏﻮﺳﺘﺎﺭ ﺗﺎﺳﻴﺴﺎﺕ ﺇﻳﺮﺍﻧﻴﻨﺎﻥ ﺍﻟﻤﺤﺪﻭﺩﺓ www.atapars.com

www.atapars.com/NFPA-code/

ﺍﻟﺠﺪﻭﻝ) 5.3.3.1ﺏ( ﺍﻟﺤﺪ ﺍﻷﺩﻧﻰ ﻟﺴﻤﺎﻛﺔ ﺻﻔﺎﺉﺢ ﺍﻟﻘﺸﺮﺓ ﻭﻓﻘﺎً ﻟﻠﻤﻘﻴﺎﺱ ﺍﻟﻘﻴﺎﺳﻲ ﺍﻷﻣﺮﻳﻜﻲ )ﺍﻟﻔﻮﻻﺫ(

ﺃﻭﺍﻟﺒﻮﺻﺔ ﺍﻟﻌﺸﺮﻳﺔ )ﺍﻷﻟﻮﻣﻨﻴﻮﻡ(

ﺳﻌﺔﺍﻟﺤﺠﻢ ﺑﺎﻟﺠﺎﻟﻮﻥ ﻟﻜﻞ ﺑﻮﺻﺔ

18ﻭ

ﺯﻳﺎﺩﺓ 14ﺇﻟﻰ 18 ﺃﻛﺜﺮﻣﻦ 10ﺇﻟﻰ 14 10ﺃﻭ ﺃﻗﻞ

ﺡ

ﺱ

ﻝ ﺍﻟﻨﻈﺎﻡﺍﻟﻤﻨﺴﻖ ﺍﻟﻨﻈﺎﻡﺍﻟﻤﻨﺴﻖ ﺍﻟﻤﺴﺎﻓﺔﺑﻴﻦ

ﺃ، ﻟﻮﺱﺃﻧﺠﻠﻮﺱ ﺍﻟﻨﻈﺎﻡﺍﻟﻤﻨﺴﻖ ﻟﻮﺱﺃﻧﺠﻠﻮﺱ ﺣﻮﺍﺟﺰ,

ﻡ ﺱﺃ ،ﺃ ﻟﻮﺱﺃﻧﺠﻠﻮﺱ، , ﻳﺤﻴﺮ،ﺃﻭ ﺍﻟﺪﺍﺉﺮﻱ ﺃﻗﺼﻰﺷﻞ

ﺱ ﺱﻝ ﺁﻧﺴﺔ ﺳﺲﻝ ﺁﻧﺴﺔ ﺳﺲ ﺍﻝ ﺁﻧﺴﺔ ﺳﺲﺍﻝ ﺍﻟﺘﻘﻮﻳﺔ ﻧﺼﻒﺍﻟﻘﻄﺮ

.0 13 12 .0 14 13 0.096 15 14 0.0 16 14 36ﺑﻮﺻﺔ ﺃﻭ ﺃﻗﻞ 70ﺑﻮﺻﺔ ﺃﻭ ﺃﻛﺜﺮ،

13 10 87 ﺃﻗﻞﻣﻦ 90ﺑﻮﺻﺔ

0 9

.0 12 11 .0 13 12 0.109 14 13 0.0 15 14 ﺃﻛﺜﺮﻣﻦ 36ﺑﻮﺻﺔ ﺇﻟﻰ 54

15 13 96 ﺑﻮﺻﺔ.

1 0

.0 11 10 .0 12 11 0.130 13 12 0.1 14 13 ﺃﻛﺜﺮﻣﻦ 54ﺑﻮﺻﺔ.

17 15 09 ﻣﻦﺧﻼﻝ 60ﺑﻮﺻﺔ.

3 1

.0 12 11 .0 13 12 0.109 14 13 0.0 15 14 36ﺑﻮﺻﺔ ﺃﻭ ﺃﻗﻞ 90ﺑﻮﺻﺔ ﺃﻭ ﺃﻛﺜﺮ،

15 13 96 ﺃﻗﻞﻣﻦ 125ﺑﻮﺻﺔ

1 0

.0 11 10 .0 12 11 0.130 13 12 0.1 14 13 ﺃﻛﺜﺮﻣﻦ 36ﺑﻮﺻﺔ ﺇﻟﻰ 54

17 15 09 ﺑﻮﺻﺔ.

3 1

.0 10 9 .0 11 10 0.151 12 11 0.1 13 12 ﺃﻛﺜﺮﻣﻦ 54ﺑﻮﺻﺔ.

19 17 30 ﻣﻦﺧﻼﻝ 60ﺑﻮﺻﺔ.

4 3

.0 11 10 .0 12 11 0.130 13 12 0.1 14 13 36ﺑﻮﺻﺔ ﺃﻭ ﺃﻗﻞ 125ﺑﻮﺻﺔ ﺃﻭ ﺃﻛﺜﺮ

17 15 09

3 1

.0 10 9 .0 11 10 0.151 12 11 0.1 13 12 ﺃﻛﺜﺮﻣﻦ 36ﺑﻮﺻﺔ ﺇﻟﻰ 54

19 17 30 ﺑﻮﺻﺔ.

4 3

.0 9 8 .010 9 0.17311 10 0.112 11 ﺃﻛﺜﺮﻣﻦ 54ﺑﻮﺻﺔ.

21 19 51 ﻣﻦﺧﻼﻝ 60ﺑﻮﺻﺔ.

6 4

.ﺍﻟﻔﻮﻻﺫﺍﻟﻤﻘﺎﻭﻡ ﻟﻠﺼﺪﺃ ﺍﻷﻭﺳﺘﻨﻴﺘﻲ .ﺁﻝ :ﺍﻷﻟﻮﻣﻨﻴﻮﻡ . SS:ﻓﻮﻻﺫ ﻋﺎﻟﻲ ﺍﻟﻘﻮﺓ ﻭﻣﻨﺨﻔﺾ ﺍﻟﺴﺒﺎﺉﻚ . HSLA:ﺍﻟﻔﻮﻻﺫ ﺍﻟﻄﺮﻱ MS:

5.3.3.2ﺍﻟﺤﺪ ﺍﻷﺩﻧﻰ ﻟﺴﻤﻚ ﺍﻟﻤﺎﺩﺓ ﺍﻟﻮﺍﺭﺩ ﻓﻲ ﺍﻟﺠﺪﻭﻝ ) 5.3.3.1ﺃ( ﻭﺍﻟﺠﺪﻭﻝ

ﻳﺠﺐﺃﻥ ﻳﻌﺘﻤﺪ )5.3.3.1ﺏ( ﻋﻠﻰ ﺣﺪ ﺃﻗﺼﻰ ﻳﺒﻠﻎ 7.2ﺭﻃﻞ ﻟﻜﻞ ﺟﺎﻟﻮﻥ ) 0.86ﻛﺠﻢ/ﻟﺘﺮ( ﻣﻦ ﻭﺯﻥ ﺍﻟﻤﻨﺘﺞ .ﺇﺫﺍ

ﻛﺎﻥﺍﻟﺨﺰﺍﻥ ﻣﺼﻤﻤﺎً ﻟﻨﻘﻞ ﻣﻨﺘﺠﺎﺕ ﻳﺰﻳﺪ ﻭﺯﻧﻬﺎ ﻋﻦ 7.2ﺭﻃﻞ ﻟﻜﻞ ﺟﺎﻟﻮﻥ ) 0.86ﻛﺠﻢ/ﻟﺘﺮ( ،ﻓﺈﻥ ﻗﻴﻤﺔ ﺍﻟﺠﺎﻟﻮﻥ

ﻟﻜﻞﺑﻮﺻﺔ ﺍﻟﻤﺴﺘﺨﺪﻣﺔ ﻟﺘﺤﺪﻳﺪ ﺍﻟﺤﺪ ﺍﻷﺩﻧﻰ ﻟﺴﻤﻚ ﺍﻟﺮﺅﻭﺱ ﺃﻭ ﺍﻟﺤﻮﺍﺟﺰ ﺃﻭ ﺍﻟﺤﻮﺍﺟﺰ ﺃﻭ ﺻﻔﺎﺉﺢ ﺍﻟﻘﺸﺮﺓ ﻳﺠﺐ

ﺃﻥﺗﻜﻮﻥ ﺳﻌﺔ ﺍﻟﻘﺴﻢ ﺍﻟﻔﻌﻠﻴﺔ ﺍﻟﻤﻄﻠﻮﺑﺔ ﺑﺎﻟﺠﺎﻟﻮﻥ ﻓﻲ ﺍﻟﺒﻮﺻﺔ ﻣﻀﺮﻭﺑﺎً ﻓﻲ ﻛﺜﺎﻓﺔ ﺍﻟﻤﻨﺘﺞ ﺍﻟﻔﻌﻠﻴﺔ ﺑﺎﻟﺠﻨﻴﻪ ﻟﻜﻞ

ﺟﺎﻟﻮﻥﻣﻘﺴﻮﻣﺎً ﻋﻠﻰ .7.2

5.3.3.3ﻋﻨﺪﻣﺎ ﻳﺘﻢ ﺍﺳﺘﺨﺪﺍﻡ ﺍﻷﻟﻮﻣﻨﻴﻮﻡ ﻓﻲ ﺻﻬﺎﺭﻳﺞ ﺍﻟﺒﻀﺎﺉﻊ ﺍﻟﻤﺨﺼﺼﺔ ﻟﻨﻘﻞ ﺍﻟﺒﻀﺎﺉﻊ ﻋﻨﺪ ﺩﺭﺟﺎﺕ ﺣﺮﺍﺭﺓ ﺳﺎﺉﻠﺔ

ﺗﺰﻳﺪﻋﻦ 250ﺩﺭﺟﺔ ﻓﻬﺮﻧﻬﺎﻳﺖ ) 121ﺩﺭﺟﺔ ﻣﺉﻮﻳﺔ( ،ﻳﺠﺐ ﺯﻳﺎﺩﺓ ﺍﻟﺤﺪ ﺍﻷﺩﻧﻰ ﻟﻠﺴﻤﻚ ﺑﻨﺴﺒﺔ 1ﺑﺎﻟﻤﺎﺉﺔ ﺣﻘﻮﻕ ﺍﻟﻄﺒﻊ

ﻭﺍﻟﻨﺸﺮNFPA

ﺷﺮﻛﺔﺃﺑﺎﺩﻏﻮﺳﺘﺎﺭ ﺗﺎﺳﻴﺴﺎﺕ ﺇﻳﺮﺍﻧﻴﻨﺎﻥ ﺍﻟﻤﺤﺪﻭﺩﺓ www.atapars.com

www.atapars.com/NFPA-code/

ﻟﻜﻞ 10ﺩﺭﺟﺎﺕ ﻓﻬﺮﻧﻬﺎﻳﺖ ) 5.6ﺩﺭﺟﺔ ﻣﺉﻮﻳﺔ( ﺃﻭ ﺟﺰء ﻣﻨﻬﺎ ﺃﻋﻠﻰ ﻣﻦ 250ﺩﺭﺟﺔ ﻓﻬﺮﻧﻬﺎﻳﺖ ) 121ﺩﺭﺟﺔ ﻣﺉﻮﻳﺔ( .ﻋﻨﺪﻣﺎ ﺗﻜﻮﻥ ﺩﺭﺟﺎﺕ ﺣﺮﺍﺭﺓ ﺍﻟﺴﺎﺉﻞ

ﺃﻋﻠﻰﻣﻦ 500ﺩﺭﺟﺔ ﻓﻬﺮﻧﻬﺎﻳﺖ ) 260ﺩﺭﺟﺔ ﻣﺉﻮﻳﺔ( ،ﻳﺠﺐ ﺃﻥ ﻳﻜﻮﻥ ﻫﻨﺎﻙ 1ﺑﺎﻟﻤﺎﺉﺔ ﺇﺿﺎﻓﻴﺔ ﻟﻜﻞ 10ﺩﺭﺟﺎﺕ ﻓﻬﺮﻧﻬﺎﻳﺖ ) 5.6ﺩﺭﺟﺔ ﻣﺉﻮﻳﺔ( ﺃﻭ ﺟﺰء

ﻣﻨﻬﺎﻓﻮﻕ 500ﺩﺭﺟﺔ ﻓﻬﺮﻧﻬﺎﻳﺖ ) 260ﺩﺭﺟﺔ ﻣﺉﻮﻳﺔ( .ﻻ ﻳﺠﻮﺯ ﺍﺳﺘﺨﺪﺍﻡ ﺍﻷﻟﻮﻣﻨﻴﻮﻡ ﻓﻲ ﺻﻬﺎﺭﻳﺞ ﺍﻟﺒﻀﺎﺉﻊ ﺍﻟﺘﻲ ﺗﻨﻘﻞ ﺍﻟﺒﻀﺎﺉﻊ ﻋﻨﺪ ﺩﺭﺟﺎﺕ ﺣﺮﺍﺭﺓ ﺃﻋﻠﻰ

ﻣﻦ 550ﺩﺭﺟﺔ ﻓﻬﺮﻧﻬﺎﻳﺖ ) 288ﺩﺭﺟﺔ ﻣﺉﻮﻳﺔ(.

5.3.4ﺍﻟﺴﻼﻣﺔ ﺍﻟﻬﻴﻜﻠﻴﺔ.

5.3.4.1ﻳﺠﺐ ﺃﻻ ﺗﺘﺠﺎﻭﺯ ﻗﻴﻤﺔ ﺍﻟﻀﻐﻂ ﺍﻟﻘﺼﻮﻯ ﺍﻟﻤﺤﺴﻮﺑﺔ 20ﺑﺎﻟﻤﺎﺉﺔ ﻣﻦ ﺍﻟﺤﺪ ﺍﻷﺩﻧﻰ ﻟﻠﻘﻮﺓ

ﺍﻟﻨﻬﺎﺉﻴﺔﻟﻠﻤﺎﺩﺓ ﻋﻠﻰ ﺍﻟﻨﺤﻮ ﺍﻟﻤﺴﻤﻮﺡ ﺑﻪ ﺇﻻ ﻓﻲ ﺣﺎﻟﺔ ﺗﻄﺒﻴﻖ ﻣﺘﻄﻠﺒﺎﺕ ﺗﺼﻤﻴﻢ ﺃﻭﻋﻴﺔ ﺍﻟﻀﻐﻂ )ASME

ﺍﻧﻈﺮﻛﻮﺩ ASMEﻟﻠﻐﻼﻳﺎﺕ ﻭﺃﻭﻋﻴﺔ ﺍﻟﻀﻐﻂ ،ﺍﻟﻘﺴﻢ ﺍﻟﺜﺎﻣﻦ(.

5.3.4.2ﻳﺠﺐ ﺗﺰﻭﻳﺪ ﺻﻬﺎﺭﻳﺞ ﺍﻟﺒﻀﺎﺉﻊ ﺑﻌﻨﺎﺻﺮ ﻫﻴﻜﻠﻴﺔ ﺇﺿﺎﻓﻴﺔ ﺣﺴﺐ ﺍﻟﻀﺮﻭﺭﺓ ﻟﻤﻨﻊ ﺍﻟﻀﻐﻮﻁ ﺍﻟﻨﺎﺗﺠﺔ

ﺍﻟﺘﻲﺗﺰﻳﺪ ﻋﻦ ﺗﻠﻚ ﺍﻟﻤﺴﻤﻮﺡ ﺑﻬﺎ ﻓﻲ .5.3.4.1ﻳﺠﺐ ﻣﺮﺍﻋﺎﺓ ﺍﻟﻘﻮﻯ ﺍﻟﺘﻲ ﺗﻔﺮﺿﻬﺎ ﻛﻞ ﻣﻦ ﺍﻷﺣﻤﺎﻝ ﺍﻟﺘﺎﻟﻴﺔ

ﺑﺸﻜﻞﻓﺮﺩﻱ ،ﻭﺣﻴﺜﻤﺎ ﺃﻣﻜﻦ ،ﺍﻟﺠﻤﻊ ﺍﻟﻤﺘﺠﻪ ﻷﻱ ﻣﺠﻤﻮﻋﺔ ﻣﻨﻬﺎ:

) (1ﺍﻟﺘﺤﻤﻴﻞ ﺍﻟﺪﻳﻨﺎﻣﻴﻜﻲ ﺿﻤﻦ ﻛﺎﻓﺔ ﺗﻜﻮﻳﻨﺎﺕ ﺗﺤﻤﻴﻞ ﺍﻟﻤﻨﺘﺞ

) (2ﺍﻟﻀﻐﻂ ﺍﻟﺪﺍﺧﻠﻲ

) (3ﺍﻷﺣﻤﺎﻝ ﺍﻟﻤﺘﺮﺍﻛﺒﺔ ﻣﺜﻞ ﻣﻌﺪﺍﺕ ﺍﻟﺘﺸﻐﻴﻞ ﻭﺍﻟﻌﺰﻝ ﻭﺍﻟﺒﻄﺎﻧﺎﺕ ﻭﺃﻧﺎﺑﻴﺐ ﺍﻟﺨﺮﺍﻃﻴﻢ ﻭﺍﻟﺨﺰﺍﺉﻦ

ﻭﺍﻷﻧﺎﺑﻴﺐ

) (4ﺭﺩﻭﺩ ﻓﻌﻞ ﺍﻟﻌﺮﻭﺍﺕ ﻭﺍﻟﺴﺮﻭﺝ ﺍﻟﺪﺍﻋﻤﺔ ﺃﻭ ﻏﻴﺮﻫﺎ ﻣﻦ ﺍﻟﺪﻋﺎﻣﺎﺕ

) (5ﺗﺄﺛﻴﺮ ﺍﻟﺘﺪﺭﺟﺎﺕ ﺍﻟﺤﺮﺍﺭﻳﺔ ﺍﻟﻨﺎﺗﺠﺔ ﻋﻦ ﺍﻟﻤﻨﺘﺞ ﻭﺩﺭﺟﺔ ﺍﻟﺤﺮﺍﺭﺓ ﺍﻟﻤﺤﻴﻄﺔ )ﻳﺠﺐ ﺍﺳﺘﻴﻌﺎﺏ

ﺍﻟﻤﻌﺎﻣﻼﺕﺍﻟﺤﺮﺍﺭﻳﺔ ﻟﻠﻤﻮﺍﺩ ﺍﻟﻤﺨﺘﻠﻔﺔ ﺣﻴﺚ ﻳﺘﻢ ﺍﺳﺘﺨﺪﺍﻣﻬﺎ(.

5.3.5ﺍﻟﻤﻔﺎﺻﻞ.

5.3.5.1ﻳﺠﺐ ﺃﻥ ﻳﺘﻢ ﻟﺤﺎﻡ ﺟﻤﻴﻊ ﺍﻟﻮﺻﻼﺕ ﺑﻴﻦ ﻫﻴﺎﻛﻞ ﺍﻟﺨﺰﺍﻧﺎﺕ ﻭﺍﻟﺮﺅﻭﺱ ﻭﺍﻟﺤﻮﺍﺟﺰ )ﺃﻭ ﺣﻠﻘﺎﺕ

ﺭﺑﻂﺍﻟﺤﻮﺍﺟﺰ( ﻭﺍﻟﺤﻮﺍﺟﺰ ﻭﻓﻘﺎً ﻟﻠﻤﺘﻄﻠﺒﺎﺕ ﺍﻟﻮﺍﺭﺩﺓ ﻓﻲ ﻫﺬﺍ ﺍﻟﻘﺴﻢ.

5.3.5.2ﻳﺠﺐ ﺃﻥ ﺗﻜﻮﻥ ﺟﻤﻴﻊ ﻭﺻﻼﺕ ﺳﺒﺎﺉﻚ ﺍﻷﻟﻮﻣﻨﻴﻮﻡ ﺍﻟﻤﻠﺤﻮﻣﺔ ﻣﺼﻨﻮﻋﺔ ﻭﻓﻘﺎ ًﻟﻤﻤﺎﺭﺳﺎﺕ ﺍﻟﻠﺤﺎﻡ

ﺍﻟﻤﻘﺒﻮﻟﺔ،ﻭﻳﺠﺐ ﺃﻻ ﺗﻘﻞ ﻛﻔﺎءﺓ ﺍﻟﻮﺻﻼﺕ ﻋﻦ 85ﺑﺎﻟﻤﺎﺉﺔ ﻣﻦ ﺧﻮﺍﺹ ﺍﻟﻤﺎﺩﺓ ﺍﻟﻤﺠﺎﻭﺭﺓ .ﻳﺘﻢ ﺭﺑﻂ ﺳﺒﺎﺉﻚ

ﺍﻷﻟﻮﻣﻨﻴﻮﻡﻋﻦ ﻃﺮﻳﻖ ﻋﻤﻠﻴﺔ ﻟﺤﺎﻡ ﻗﻮﺱ ﺍﻟﻐﺎﺯ ﺍﻟﺨﺎﻣﻞ ﺑﺎﺳﺘﺨﺪﺍﻡ ﻣﻌﺎﺩﻥ ﺣﺸﻮ ﺍﻷﻟﻮﻣﻨﻴﻮﻡ ﻭﺍﻟﻤﻐﻨﻴﺴﻴﻮﻡ

ﺍﻟﺘﻲﺗﺘﻮﺍﻓﻖ ﻣﻊ ﺗﻮﺻﻴﺎﺕ ﻣﻮﺭﺩ ﺍﻟﻤﻮﺍﺩ.

5.3.5.3ﻳﺠﺐ ﺃﻥ ﺗﻜﻮﻥ ﺟﻤﻴﻊ ﺍﻟﻮﺻﻼﺕ ﺍﻟﻤﻠﺤﻮﻣﺔ ﻣﻦ ﺍﻟﻔﻮﻻﺫ ﺍﻟﻄﺮﻱ ) ،(MSﻭﺍﻟﻔﻮﻻﺫ ﻋﺎﻟﻲ ﺍﻟﻘﻮﺓ

ﻣﻨﺨﻔﺾﺍﻟﺴﺒﺎﺉﻚ ) ،(HSLAﻭﺍﻟﻔﻮﻻﺫ ﺍﻟﻤﻘﺎﻭﻡ ﻟﻠﺼﺪﺃ ﺍﻷﻭﺳﺘﻨﻴﺘﻲ ) (SSﻣﺼﻨﻮﻋﺔ ﻭﻓﻘﺎً ﻟﻤﻤﺎﺭﺳﺎﺕ

ﺍﻟﻠﺤﺎﻡﺍﻟﻤﻘﺒﻮﻟﺔ ،ﻭﻳﺠﺐ ﺃﻻ ﺗﻘﻞ ﻛﻔﺎءﺓ ﺍﻟﻮﺻﻼﺕ ﻋﻦ 85ﺑﺎﻟﻤﺎﺉﺔ ﻣﻦ ﺍﻟﺨﻮﺍﺹ ﺍﻟﻤﻴﻜﺎﻧﻴﻜﻴﺔ ﻟﻠﻤﻌﺪﻥ

ﺍﻟﻤﺠﺎﻭﺭﻓﻲ ﺍﻟﺨﺰﺍﻥ.

5.3.5.4ﻳﺴُﻤﺢ ﺑﺎﺳﺘﺨﺪﺍﻡ ﻣﺠﻤﻮﻋﺎﺕ ﻣﻦ ﺍﻟﻔﻮﻻﺫ ﺍﻟﻄﺮﻱ ) ،(MSﻭﺍﻟﻔﻮﻻﺫ ﻋﺎﻟﻲ ﺍﻟﻘﻮﺓ ﻣﻨﺨﻔﺾ

ﺍﻟﺴﺒﺎﺉﻚ) ،(HSLAﻭﺍﻟﻔﻮﻻﺫ ﺍﻟﻤﻘﺎﻭﻡ ﻟﻠﺼﺪﺃ ﺍﻷﻭﺳﺘﻨﻴﺘﻲ ) (SSﻓﻲ ﺑﻨﺎء ﺧﺰﺍﻥ ﻭﺍﺣﺪ ،ﺑﺸﺮﻁ ﺃﻥ ﺗﺘﻮﺍﻓﻖ

ﻛﻞﻣﺎﺩﺓ ،ﻋﻨﺪ ﺍﺳﺘﺨﺪﺍﻣﻬﺎ ،ﻣﻊ ﺍﻟﺤﺪ ﺍﻷﺩﻧﻰ ﻣﻦ ﺍﻟﻤﺘﻄﻠﺒﺎﺕ ﺍﻟﻤﺤﺪﺩﺓ ﻟﻠﻤﻮﺍﺩ ﺍﻟﻤﺴﺘﺨﺪﻣﺔ ﻓﻲ ﺑﻨﺎء ﺫﻟﻚ

ﺍﻟﻘﺴﻢﻣﻦ ﺍﻟﺨﺰﺍﻥ.

5.3.5.4.1ﻋﻨﺪﻣﺎ ﻳﺘﻢ ﺍﺳﺘﺨﺪﺍﻡ ﺻﻔﺎﺉﺢ ﺍﻟﻔﻮﻻﺫ ﺍﻟﻤﻘﺎﻭﻡ ﻟﻠﺼﺪﺃ ﻣﻊ ﺻﻔﺎﺉﺢ ﻣﻦ ﺃﻧﻮﺍﻉ ﺃﺧﺮﻯ ﻣﻦ ﺍﻟﻔﻮﻻﺫ،

ﻳﺠﺐﺃﻥ ﻳﺘﻢ ﺗﺸﻜﻴﻞ ﺍﻟﻮﺻﻼﺕ ﺍﻟﻤﺼﻨﻮﻋﺔ ﻋﻦ ﻃﺮﻳﻖ ﺍﻟﻠﺤﺎﻡ ﺑﺎﺳﺘﺨﺪﺍﻡ ﺃﻗﻄﺎﺏ ﺍﻟﻔﻮﻻﺫ ﺍﻟﻤﻘﺎﻭﻡ ﻟﻠﺼﺪﺃ ﺃﻭ

ﻗﻀﺒﺎﻥﺍﻟﺤﺸﻮ ﻭﻳﺠﺐ ﺃﻥ ﺗﻜﻮﻥ ﺃﻗﻄﺎﺏ ﺍﻟﻔﻮﻻﺫ ﺍﻟﻤﻘﺎﻭﻡ ﻟﻠﺼﺪﺃ ﺃﻭ ﻗﻀﺒﺎﻥ ﺍﻟﺤﺸﻮ ﺍﻟﻤﺴﺘﺨﺪﻣﺔ ﻓﻲ ﺍﻟﻠﺤﺎﻡ

ﻣﻨﺎﺳﺒﺔ.

ﺷﺮﻛﺔﺃﺑﺎﺩﻏﻮﺳﺘﺎﺭ ﺗﺎﺳﻴﺴﺎﺕ ﺇﻳﺮﺍﻧﻴﻨﺎﻥ ﺍﻟﻤﺤﺪﻭﺩﺓ www.atapars.com

www.atapars.com/NFPA-code/

ﻟﻼﺳﺘﺨﺪﺍﻡﻣﻊ ﺩﺭﺟﺔ ﺍﻟﻔﻮﻻﺫ ﺍﻟﻤﻘﺎﻭﻡ ﻟﻠﺼﺪﺃ ﺍﻟﻤﻌﻨﻴﺔ ﻭﻓﻘﺎً ﻟﺘﻮﺻﻴﺎﺕ ﺍﻟﺸﺮﻛﺔ ﺍﻟﻤﺼﻨﻌﺔ ﻷﻗﻄﺎﺏ ﺍﻟﻔﻮﻻﺫ

ﺍﻟﻤﻘﺎﻭﻡﻟﻠﺼﺪﺃ ﺃﻭ ﻗﻀﺒﺎﻥ ﺍﻟﺤﺸﻮ.

5.3.5.5ﻳﺠﺐ ﺗﺤﺪﻳﺪ ﺍﻻﻣﺘﺜﺎﻝ ﻟﻠﻤﺘﻄﻠﺒﺎﺕ ﺍﻟﻮﺍﺭﺩﺓ ﻓﻲ 5.3.5.2ﺃﻭ 5.3.5.3ﻟﻠﻮﺻﻼﺕ ﺍﻟﻤﻠﺤﻮﻣﺔ

ﺍﻟﻤﻮﺿﺤﺔﻓﻲ 5.3.5.1ﻣﻦ ﺧﻼﻝ ﺍﻟﺘﺤﻀﻴﺮ ،ﻣﻦ ﻣﻮﺍﺩ ﻣﻤﺜﻠﺔ ﻟﺘﻠﻚ ﺍﻟﺘﻲ ﺳﻴﺘﻢ ﺍﺳﺘﺨﺪﺍﻣﻬﺎ ﻓﻲ ﺍﻟﺨﺰﺍﻧﺎﺕ

ﺍﻟﺨﺎﺿﻌﺔﻟﻬﺬﻩ ﺍﻟﻤﻮﺍﺻﻔﺎﺕ ﻭﺑﻨﻔﺲ ﺗﻘﻨﻴﺔ ﺍﻟﺘﺼﻨﻴﻊ ،ﻋﻴﻨﺘﻴﻦ ﺍﺧﺘﺒﺎﺭﻳﺘﻴﻦ ﻣﺘﻄﺎﺑﻘﺘﻴﻦ ﻣﻊ ﺍﻟﺸﻜﻞ 5.3.5.5

ﻭﺍﺧﺘﺒﺎﺭﻫﻤﺎﺣﺘﻰ ﻓﺸﻞ ﺍﻟﺘﻮﺗﺮ.

ﺍﻟﺸﻜﻞ 5.3.5.5ﻋﻴﻨﺔ ﺍﺧﺘﺒﺎﺭ ﺍﻟﺸﺪ.

5.3.5.5.1ﻳﺠﺐ ﺃﻥ ﻳﻤﺜﻞ ﺯﻭﺝ ﻭﺍﺣﺪ ﻣﻦ ﻋﻴﻨﺎﺕ ﺍﻻﺧﺘﺒﺎﺭ ﺟﻤﻴﻊ ﺍﻟﺨﺰﺍﻧﺎﺕ ﺍﻟﺘﻲ ﺳﻴﺘﻢ ﺗﺼﻨﻴﻌﻬﺎ ﻣﻦ ﻧﻔﺲ

ﻣﺠﻤﻮﻋﺔﺍﻟﻤﻮﺍﺩ ﻭﺑﻨﻔﺲ ﺗﻘﻨﻴﺔ ﺍﻟﺘﺼﻨﻴﻊ ﻭﻓﻲ ﻧﻔﺲ ﺍﻟﻮﺭﺷﺔ ،ﺧﻼﻝ 6ﺃﺷﻬﺮ ﺑﻌﺪ ﺍﻻﻧﺘﻬﺎء ﻣﻦ ﺍﻻﺧﺘﺒﺎﺭﺍﺕ

ﻋﻠﻰﻫﺬﻩ ﺍﻟﻌﻴﻨﺎﺕ.

5.3.5.5.2ﻳﺠﺐ ﺍﻋﺘﺒﺎﺭ ﺍﻟﻌﻴﻨﺎﺕ ﺍﻟﻤﻠﺤﻮﻣﺔ ﺑﻌﻘﺐ ﺍﻟﺘﻲ ﺗﻢ ﺍﺧﺘﺒﺎﺭﻫﺎ ﻣﺆﻫﻠﺔ ﻷﻧﻮﺍﻉ ﺃﻭ ﻣﺠﻤﻮﻋﺎﺕ ﺃﺧﺮﻯ

ﻣﻦﺃﻧﻮﺍﻉ ﺍﻟﻠﺤﺎﻡ ﺑﺎﺳﺘﺨﺪﺍﻡ ﻧﻔﺲ ﻣﺎﺩﺓ ﺍﻟﺤﺸﻮ ﻭﻋﻤﻠﻴﺔ ﺍﻟﻠﺤﺎﻡ ﻃﺎﻟﻤﺎ ﺃﻥ ﺍﻟﻤﻌﺎﺩﻥ ﺍﻷﺻﻠﻴﺔ ﻣﻦ ﻧﻔﺲ ﺃﻧﻮﺍﻉ

ﺍﻟﻤﻮﺍﺩ.

5.3.6ﺍﻟﺪﻋﺎﻣﺎﺕ ﻭﺍﻹﺭﺳﺎء.

5.3.6.1ﻳﺠﺐ ﺃﻥ ﺗﺰﻭﺩ ﺻﻬﺎﺭﻳﺞ ﺍﻟﺒﻀﺎﺉﻊ ﺫﺍﺕ ﺍﻹﻃﺎﺭﺍﺕ ﻏﻴﺮ ﺍﻟﻤﺘﻜﺎﻣﻠﺔ ﻣﻊ ﺍﻟﺼﻬﺮﻳﺞ )ﻛﻤﺎ ﻫﻮ ﺍﻟﺤﺎﻝ ﻋﻦ

ﻃﺮﻳﻖﺍﻟﻠﺤﺎﻡ( ﺑﺄﺟﻬﺰﺓ ﺗﻘﻴﻴﺪ ﻟﻤﻨﻊ ﺃﻱ ﺣﺮﻛﺔ ﻧﺴﺒﻴﺔ ﺑﻴﻦ ﺍﻟﺼﻬﺮﻳﺞ ﻭﺍﻹﻃﺎﺭ ﻳﻤﻜﻦ ﺃﻥ ﺗﻨﺘﺞ ﻋﻦ ﺇﻳﻘﺎﻑ ﺍﻟﺴﻴﺎﺭﺓ

ﺃﻭﺗﺸﻐﻴﻠﻬﺎ ﺃﻭ ﺩﻭﺭﺍﻧﻬﺎ .ﻳﺠﺐ ﺃﻥ ﻳﻜﻮﻥ ﺍﻟﻮﺻﻮﻝ ﺇﻟﻰ ﺃﺟﻬﺰﺓ ﺍﻟﺘﻘﻴﻴﺪ ﻫﺬﻩ ﺳﻬﻼ ًﻟﻠﻔﺤﺺ ﻭﺍﻟﺼﻴﺎﻧﺔ ،ﺑﺎﺳﺘﺜﻨﺎء

ﺃﻧﻪﻳﺠﺐ ﺍﻟﺴﻤﺎﺡ ﺑﺎﻟﻌﺰﻝ ﻭﺍﻟﺘﻐﻄﻴﺔ ﺑﺘﻐﻄﻴﺔ ﺃﺟﻬﺰﺓ ﺍﻟﺘﻘﻴﻴﺪ.

5.3.6.2ﻳﺠﺐ ﺩﻋﻢ ﺃﻱ ﺧﺰﺍﻥ ﺑﻀﺎﺉﻊ ﻣﺼﻤﻢ ﻭﻣﺒﻨﻲ ﺑﺤﻴﺚ ﻳﺸﻜﻞ ﻛﻠﻴﺎً ﺃﻭ ﺟﺰﺉﻴﺎً ﺍﻟﻌﻀﻮ ﺍﻟﻬﻴﻜﻠﻲ

ﺍﻟﻤﺴﺘﺨﺪﻡﺑﺪﻻ ًﻣﻦ ﺍﻹﻃﺎﺭ ﺑﻄﺮﻳﻘﺔ ﻻ ﺗﺘﺠﺎﻭﺯ ﻓﻴﻬﺎ ﻣﺴﺘﻮﻳﺎﺕ ﺍﻟﻀﻐﻂ ﺍﻟﻨﺎﺗﺠﺔ ﻓﻲ ﺧﺰﺍﻥ ﺍﻟﺒﻀﺎﺉﻊ ﺗﻠﻚ

ﺍﻟﻤﺤﺪﺩﺓﻓﻲ .5.3.4.1ﻳﺠﺐ ﺃﻥ ﺗﺸﻤﻞ ﺍﻟﺤﺴﺎﺑﺎﺕ ﺍﻟﺘﺼﻤﻴﻤﻴﺔ ﻟﻌﻨﺎﺻﺮ ﺍﻟﺪﻋﻢ ﺍﻷﺣﻤﺎﻝ ﺍﻟﻤﻔﺮﻭﺿﺔ ﻋﻦ

ﻃﺮﻳﻖﺍﻟﺘﻮﻗﻒ ﻭﺍﻟﺒﺪء ﻭﺍﻟﺪﻭﺭﺍﻥ ﺑﺎﻹﺿﺎﻓﺔ ﺇﻟﻰ ﺗﻠﻚ ﺍﻟﻤﻔﺮﻭﺿﺔ ﻛﻤﺎ ﻫﻮ ﻣﻮﺿﺢ ﻓﻲ 5.3.4.2ﺑﺎﺳﺘﺨﺪﺍﻡ 20

ﺑﺎﻟﻤﺎﺉﺔﻣﻦ ﺍﻟﺤﺪ ﺍﻷﺩﻧﻰ ﻣﻦ ﺍﻟﻘﻮﺓ ﺍﻟﻨﻬﺎﺉﻴﺔ ﻟﻤﻮﺍﺩ ﺍﻟﺪﻋﻢ.

5.3.7ﺍﻟﺘﻌﺰﻳﺰ ﺍﻟﻤﺤﻴﻄﻲ.

5.3.7.1ﻳﺠﺐ ﺃﻥ ﻳﺘﻢ ﺗﻘﻮﻳﺔ ﺍﻟﺨﺰﺍﻧﺎﺕ ﺍﻟﺘﻲ ﻳﻘﻞ ﺳﻤﻚ ﻗﺸﺮﺗﻬﺎ ﻋﻦ ﺑﻮﺻﺔ ) 9ﻣﻢ( ،ﺑﺎﻹﺿﺎﻓﺔ ﺇﻟﻰ

ﺍﻟﺘﻌﺰﻳﺰﺍﻟﺬﻱ ﺗﻮﻓﺮﻩ ﺭﺅﻭﺱ ﺍﻟﺨﺰﺍﻧﺎﺕ ،ﻣﺤﻴﻄﻴﺎً ﺑﺤﻮﺍﺟﺰ ﺃﻭ ﺣﻮﺍﺟﺰ ﺃﻭ ﺃﺩﻭﺍﺕ ﺗﻘﻮﻳﺔ ﺣﻠﻘﻴﺔ .ﻳﺴُﻤﺢ

ﺑﺎﺳﺘﺨﺪﺍﻡﺃﻱ ﻣﺠﻤﻮﻋﺔ ﻣﻦ ﺍﻟﺘﻌﺰﻳﺰﺍﺕ ﺍﻟﻤﺬﻛﻮﺭﺓ ﺃﻋﻼﻩ ﻓﻲ ﺻﻬﺮﻳﺞ ﺑﻀﺎﺉﻊ ﻭﺍﺣﺪ.

ﺣﻘﻮﻕﺍﻟﻄﺒﻊ ﻭﺍﻟﻨﺸﺮ NFPA

ﺷﺮﻛﺔﺃﺑﺎﺩﻏﻮﺳﺘﺎﺭ ﺗﺎﺳﻴﺴﺎﺕ ﺇﻳﺮﺍﻧﻴﻨﺎﻥ ﺍﻟﻤﺤﺪﻭﺩﺓ www.atapars.com

www.atapars.com/NFPA-code/

5.3.7.2ﻳﺠﺐ ﺃﻥ ﻳﺘﻢ ﻭﺿﻊ ﺍﻟﺘﻌﺰﻳﺰ ﺍﻟﻤﺤﻴﻄﻲ ﺑﺤﻴﺚ ﻳﻜﻮﻥ ﺍﻟﺤﺪ ﺍﻷﻗﺼﻰ ﻟﻠﺠﺰء ﻏﻴﺮ ﺍﻟﻤﻘﻮﻯ ﻣﻦ

ﺍﻟﻐﻼﻑﻛﻤﺎ ﻫﻮ ﻣﺤﺪﺩ ﻓﻲ ﺍﻟﺠﺪﻭﻝ ) 5.3.3.1ﺏ( ﻭﻳﺠﺐ ﺃﻻ ﻳﺰﻳﺪ ﺑﺄﻱ ﺣﺎﻝ ﻣﻦ ﺍﻷﺣﻮﺍﻝ ﻋﻦ 60ﺑﻮﺻﺔ )

1500ﻣﻠﻢ( .ﺑﺎﻹﺿﺎﻓﺔ ﺇﻟﻰ ﺫﻟﻚ ،ﻳﺠﺐ ﺃﻥ ﻳﻘﻊ ﻫﺬﺍ ﺍﻟﺘﻌﺰﻳﺰ ﺍﻟﻤﺤﻴﻄﻲ ﺿﻤﻦ 1ﺑﻮﺻﺔ ) 25ﻣﻢ( ﻣﻦ

ﺍﻟﻨﻘﺎﻁﺍﻟﺘﻲ ﻳﺘﺠﺎﻭﺯ ﻓﻴﻬﺎ ﺍﻻﻧﻘﻄﺎﻉ ﻓﻲ ﻣﺤﺎﺫﺍﺓ ﺻﻔﺎﺉﺢ ﺍﻟﻐﻼﻑ ﺍﻟﻄﻮﻟﻴﺔ 10ﺩﺭﺟﺎﺕ ﻣﺎ ﻟﻢ ﻳﺘﻢ ﺗﻌﺰﻳﺰﻫﺎ

ﺑﺄﻋﻀﺎءﻫﻴﻜﻠﻴﺔ ﻗﺎﺩﺭﺓ ﻋﻠﻰ ﺍﻟﺤﻔﺎﻅ ﻋﻠﻰ ﻣﺴﺘﻮﻳﺎﺕ ﺇﺟﻬﺎﺩ ﺻﻔﺎﺉﺢ ﺍﻟﻐﻼﻑ ﺍﻟﻤﺴﻤﻮﺡ ﺑﻬﺎ ﻓﻲ .5.3.6.2

5.3.7.3ﻳﺠﺐ ﺃﻥ ﺗﻜﻮﻥ ﺍﻟﺤﻮﺍﺟﺰ ﺃﻭ ﺣﻠﻘﺎﺕ ﺭﺑﻂ ﺍﻟﺤﻮﺍﺟﺰ ،ﻋﻨﺪ ﺍﺳﺘﺨﺪﺍﻣﻬﺎ ﻛﺄﻋﻀﺎء ﺗﻘﻮﻳﺔ ،ﻣﻠﺤﻮﻣﺔ ﺑﺸﻜﻞ

ﻣﺤﻴﻄﻲﺑﻬﻴﻜﻞ ﺍﻟﺨﺰﺍﻥ .ﻭﻳﺠﺐ ﺃﻻ ﻳﻘﻞ ﺍﻟﻠﺤﺎﻡ ﻋﻦ 50ﺑﺎﻟﻤﺎﺉﺔ ﻣﻦ ﺇﺟﻤﺎﻟﻲ ﻣﺤﻴﻂ ﺍﻟﻮﻋﺎء ،ﻭﻳﺠﺐ ﺃﻻ

ﻳﺘﺠﺎﻭﺯﺍﻟﺤﺪ ﺍﻷﻗﺼﻰ ﻟﻠﻤﺴﺎﺣﺔ ﻏﻴﺮ ﺍﻟﻤﻠﺤﻮﻣﺔ ﻋﻠﻰ ﻫﺬﻩ ﺍﻟﻮﺻﻠﺔ 40ﻣﺮﺓ ﺳﻤﻚ ﺍﻟﻘﺸﺮﺓ.

5.3.7.4ﺃﻳﻨﻤﺎ ﻳﺘﻢ ﺗﻮﻓﻴﺮ ﺣﻮﺍﺟﺰ ﻣﺰﺩﻭﺟﺔ ،ﻳﺠﺐ ﺃﻥ ﻳﺘﻢ ﻓﺼﻠﻬﺎ ﺑﻤﺴﺎﺣﺔ ﻫﻮﺍﺉﻴﺔ .ﻭﻳﺠﺐ ﺃﻥ ﻳﺘﻢ ﺗﻬﻮﻳﺔ

ﻫﺬﺍﺍﻟﻤﺠﺎﻝ ﺍﻟﺠﻮﻱ ﻭﺗﺠﻬﻴﺰﻩ ﺑﻮﺳﺎﺉﻞ ﻣﺮﺍﻓﻖ ﺍﻟﺼﺮﻑ ﺍﻟﺘﻲ ﻳﺠﺐ ﺃﻥ ﺗﻈﻞ ﻋﺎﻣﻠﺔ ﻓﻲ ﺟﻤﻴﻊ ﺍﻷﻭﻗﺎﺕ)

ﺍﻧﻈﺮ.(9.1.8

5.3.7.5ﻓﻲ ﺣﺎﻟﺔ ﺍﺳﺘﺨﺪﺍﻡ ﺃﺩﻭﺍﺕ ﺍﻟﺘﻘﻮﻳﺔ ﺍﻟﺤﻠﻘﻴﺔ ﻟﻼﻣﺘﺜﺎﻝ ﻟﻬﺬﺍ ﺍﻟﻘﺴﻢ ،ﻳﺠﺐ ﺃﻥ ﺗﻜﻮﻥ ﻣﺴﺘﻤﺮﺓ ﺣﻮﻝ

ﻣﺤﻴﻂﻫﻴﻜﻞ ﺍﻟﺨﺰﺍﻥ ﻭﻳﺠﺐ ﺃﻥ ﻳﻜﻮﻥ ﻟﻬﺎ ﻣﻌﺎﻣﻞ ﻗﺴﻢ ﺣﻮﻝ ﺍﻟﻤﺤﻮﺭ ﺍﻟﻤﺤﺎﻳﺪ ﻟﻠﻘﺴﻢ ﺍﻟﺪﺍﺉﺮﻱ ﺍﻟﻤﻮﺍﺯﻱ

ﻟﻠﻐﻼﻑﻋﻠﻰ ﺍﻷﻗﻞ ﻳﺴﺎﻭﻱ ﻣﺎ ﺗﺤﺪﺩﻩ ﺍﻟﺼﻴﻎ ﺍﻟﺘﺎﻟﻴﺔ :

ﺃﻳﻦ:

= ﻣﻌﺎﻣﻞ ﺍﻟﻘﺴﻢ )ﻓﻲ (3.ﺩﺑﻠﻴﻮ=

ﻋﺮﺽﺍﻟﺨﺰﺍﻥ ﺃﻭ ﺍﻟﻘﻄﺮ )ﺑﻮﺻﺔ(

ﻝ=ﺗﺒﺎﻋﺪ ﺍﻟﺤﻠﻘﺔ )ﺑﻮﺻﺔ( ،ﺃﻱ ﺃﻗﺼﻰ ﻣﺴﺎﻓﺔ ﻣﻦ ﻧﻘﻄﺔ ﺍﻟﻤﻨﺘﺼﻒ ﻟﻠﻐﻼﻑ ﻏﻴﺮ ﺍﻟﻤﺪﻋﻮﻡ ﻋﻠﻰ ﺃﺣﺪ

ﺟﺎﻧﺒﻲﺃﺩﺍﺓ ﺗﻘﻮﻳﺔ ﺍﻟﺤﻠﻘﺔ ﺇﻟﻰ ﻧﻘﻄﺔ ﻣﻨﺘﺼﻒ ﺍﻟﻐﻼﻑ ﻏﻴﺮ ﺍﻟﻤﺪﻋﻢ ﻋﻠﻰ ﺍﻟﺠﺎﻧﺐ ﺍﻵﺧﺮ ﻣﻦ ﻣﺎﺩﺓ ﺗﻘﻮﻳﺔ

ﺍﻟﺤﻠﻘﺔ

5.3.7.5.1ﻋﻨﺪﻣﺎ ﻳﺘﻢ ﻟﺤﺎﻡ ﻣﺎﺩﺓ ﺗﻘﻮﻳﺔ ﺣﻠﻘﻴﺔ ﺑﻬﻴﻜﻞ ﺍﻟﺨﺰﺍﻥ )ﺣﻴﺚ ﻻ ﻳﻘﻞ ﻛﻞ ﻟﺤﺎﻡ ﻣﺤﻴﻄﻲ ﻋﻦ 50

ﺑﺎﻟﻤﺎﺉﺔﻣﻦ ﺇﺟﻤﺎﻟﻲ ﻣﺤﻴﻂ ﺍﻟﻮﻋﺎء ﻭﻻ ﻳﺘﺠﺎﻭﺯ ﺍﻟﺤﺪ ﺍﻷﻗﺼﻰ ﻟﻠﻤﺴﺎﺣﺔ ﻏﻴﺮ ﺍﻟﻤﻠﺤﻮﻣﺔ ﻋﻠﻰ ﻫﺬﻩ ﺍﻟﻮﺻﻠﺔ

40ﺿﻌﻒ ﺳﻤﻚ ﺍﻟﺼﺪﻓﺔ( ،ﻳﺠﺐ ﺃﻥ ﻳﻜﻮﻥ ﻫﻨﺎﻙ ﺟﺰء ﻣﻦ ﺍﻟﻐﻼﻑ ﻳﺴُﻤﺢ ﺑﺎﻋﺘﺒﺎﺭﻫﺎ ﺟﺰءﺍً ﻣﻦ ﻗﺴﻢ

ﺍﻟﺤﻠﻘﺔﻷﻏﺮﺍﺽ ﺣﺴﺎﺏ ﻣﻌﺎﻣﻞ ﻗﺴﻢ ﺍﻟﺤﻠﻘﺔ .ﻳﺠﺐ ﺃﻥ ﻳﻜﻮﻥ ﺍﻟﺤﺪ ﺍﻷﻗﺼﻰ ﻟﺠﺰء ﺍﻟﻐﻼﻑ ﺍﻟﻤﺴﺘﺨﺪﻡ ﻓﻲ

ﻫﺬﻩﺍﻟﺤﺴﺎﺑﺎﺕ ﻛﻤﺎ ﻫﻮ ﻣﻮﺿﺢ ﻓﻲ ﺍﻟﺠﺪﻭﻝ .5.3.7.5.1

ﺍﻟﺠﺪﻭﻝ 5.3.7.5.1ﺟﺰء ﻏﻼﻑ ﺍﻟﺨﺰﺍﻥ ﺍﻟﺬﻱ ﻳﺴﺎﻫﻢ ﻓﻲ ﻣﻌﺎﻣﻞ ﺍﻟﻘﺴﻢ ﺍﻟﺪﺍﺉﺮﻱ

ﺍﻟﻤﺴﺎﻓﺔﺑﻴﻦ ﺍﻟﻤﻮﺍﺯﻱ

ﺣﻠﻘﺔﻣﺤﻴﻄﻴﺔ ﺣﻠﻘﺔﻣﺤﻴﻄﻴﺔ

ﻗﺴﻢﺷﻞ ﺍﻻﺉﺘﻤﺎﻥ ﺍﻟﻠﺤﺎﻣﺎﺕﺍﻟﻤﻘﻮﻳﺔ ﺇﻟﻰ ﻏﻼﻑ ﺍﻟﺨﺰﺍﻥ ﺍﻟﻠﺤﺎﻣﺎﺕﺍﻟﻤﻘﻮﻳﺔ ﺇﻟﻰ ﻏﻼﻑ ﺍﻟﺨﺰﺍﻥ

20ﺭ — 1

20ﺭ+ﺩﺑﻠﻴﻮ ﺃﻗﻞﻣﻦ 20ﺭ 2

40ﺭ 20ﺭﺍﻭ ﺍﻛﺜﺮ 2

ﺣﻘﻮﻕﺍﻟﻄﺒﻊ ﻭﺍﻟﻨﺸﺮ NFPA

ﺷﺮﻛﺔﺃﺑﺎﺩﻏﻮﺳﺘﺎﺭ ﺗﺎﺳﻴﺴﺎﺕ ﺇﻳﺮﺍﻧﻴﻨﺎﻥ ﺍﻟﻤﺤﺪﻭﺩﺓ www.atapars.com

www.atapars.com/NFPA-code/

ﺍﻟﺠﺪﻭﻝ 5.3.7.5.1ﺟﺰء ﻏﻼﻑ ﺍﻟﺨﺰﺍﻥ ﺍﻟﺬﻱ ﻳﺴﺎﻫﻢ ﻓﻲ ﻣﻌﺎﻣﻞ ﺍﻟﻘﺴﻢ ﺍﻟﺪﺍﺉﺮﻱ

ﺍﻟﻤﺴﺎﻓﺔﺑﻴﻦ ﺍﻟﻤﻮﺍﺯﻱ

ﺣﻠﻘﺔﻣﺤﻴﻄﻴﺔ ﺣﻠﻘﺔﻣﺤﻴﻄﻴﺔ

ﻗﺴﻢﺷﻞ ﺍﻻﺉﺘﻤﺎﻥ ﺍﻟﻠﺤﺎﻣﺎﺕﺍﻟﻤﻘﻮﻳﺔ ﺇﻟﻰ ﻏﻼﻑ ﺍﻟﺨﺰﺍﻥ ﺍﻟﻠﺤﺎﻣﺎﺕﺍﻟﻤﻘﻮﻳﺔ ﺇﻟﻰ ﻏﻼﻑ ﺍﻟﺨﺰﺍﻥ

ﺭ :ﺳﻤﻚ ﺍﻟﻘﺸﺮﺓ.ﺩﺑﻠﻴﻮ :ﺍﻟﻤﺴﺎﻓﺔ ﺑﻴﻦ ﺗﻘﻮﻳﺔ ﺍﻟﺤﻠﻘﺔ ﺍﻟﻤﺤﻴﻄﻴﺔ ﺍﻟﻤﺘﻮﺍﺯﻳﺔ ﻭﺍﻟﻠﺤﺎﻣﺎﺕ ﺍﻟﺼﺪﻓﻴﺔ.

5.3.7.5.2ﺇﺫﺍ ﻛﺎﻥ ﺗﻜﻮﻳﻦ ﺗﻘﻮﻳﺔ ﺍﻟﺤﻠﻘﺔ ﺍﻟﺪﺍﺧﻠﻴﺔ ﺃﻭ ﺍﻟﺨﺎﺭﺟﻴﺔ ﻳﺤﻴﻂ ﺑﻤﺴﺎﺣﺔ ﻫﻮﺍﺉﻴﺔ ،ﻳﺠﺐ ﺃﻥ ﻳﺘﻢ

ﺗﺮﺗﻴﺐﻫﺬﺍ ﺍﻟﻤﺴﺎﺣﺔ ﺍﻟﻬﻮﺍﺉﻴﺔ ﻟﻠﺘﻬﻮﻳﺔ ﻭﻳﺠﺐ ﺃﻥ ﺗﻜﻮﻥ ﻣﺠﻬﺰﺓ ﺑﻮﺳﺎﺉﻞ ﺍﻟﺼﺮﻑ ﺍﻟﺘﻲ ﻳﺠﺐ ﺃﻥ ﺗﻈﻞ

ﻋﺎﻣﻠﺔﻓﻲ ﺟﻤﻴﻊ ﺍﻷﻭﻗﺎﺕ.

5.3.8ﺍﻟﺤﻤﺎﻳﺔ ﻣﻦ ﺃﺿﺮﺍﺭ ﺍﻟﺤﻮﺍﺩﺙ.

5.3.8.1ﻳﺠﺐ ﺃﻥ ﻳﻜﻮﻥ ﺗﺼﻤﻴﻢ ﻭﺑﻨﺎء ﻭﺗﺮﻛﻴﺐ ﺃﻱ ﻣﻠﺤﻘﺎﺕ ﻟﻬﻴﻜﻞ ﺃﻭ ﺭﺃﺱ ﺧﺰﺍﻥ ﺍﻟﺒﻀﺎﺉﻊ ﻋﻠﻰ ﻧﺤﻮ

ﻳﻘﻠﻞﻣﻦ ﺍﺣﺘﻤﺎﻟﻴﺔ ﺗﻠﻒ ﺍﻟﻤﻠﺤﻘﺎﺕ ﺃﻭ ﻓﺸﻠﻬﺎ ﻣﻤﺎ ﻳﺆﺛﺮ ﺳﻠﺒﺎً ﻋﻠﻰ ﺳﻼﻣﺔ ﺍﻻﺣﺘﻔﺎﻅ ﺑﺎﻟﻤﻨﺘﺞ ﻓﻲ ﺍﻟﺨﺰﺍﻥ.

5.3.8.2ﻳﺠﺐ ﺍﺳﺘﺨﺪﺍﻡ ﺍﻷﻋﻀﺎء ﺍﻟﻬﻴﻜﻠﻴﺔ ،ﻣﺜﻞ ﺍﻹﻃﺎﺭ ﺍﻟﻔﺮﻋﻲ ﻟﻠﺘﻌﻠﻴﻖ ،ﻭﺍﻟﺤﻤﺎﻳﺔ ﻣﻦ ﺍﻻﻧﻘﻼﺏ،

ﻭﺍﻟﺤﻠﻘﺎﺕﺍﻟﺨﺎﺭﺟﻴﺔ ،ﻋﻨﺪﻣﺎ ﻳﻜﻮﻥ ﺫﻟﻚ ﻋﻤﻠﻴﺎً ،ﻛﻤﻮﺍﻗﻊ ﻟﺮﺑﻂ ﺍﻟﻤﻠﺤﻘﺎﺕ ﻭﺃﻱ ﻣﻠﺤﻘﺎﺕ ﺃﺧﺮﻯ ﺑﺨﺰﺍﻥ

ﺍﻟﺒﻀﺎﺉﻊ.

5.3.8.3ﺑﺎﺳﺘﺜﻨﺎء ﻣﺎ ﻫﻮ ﻣﻨﺼﻮﺹ ﻋﻠﻴﻪ ﻓﻲ ،5.3.8.5ﻳﺠﺐ ﺃﻥ ﻳﺘﻢ ﻟﺤﺎﻡ ﺃﻱ ﻣﻠﺤﻘﺎﺕ ﻟﻠﺼﺪﻓﺔ ﺃﻭ

ﺍﻟﺮﺃﺱﻋﻦ ﻃﺮﻳﻖ ﺭﺑﻄﻬﺎ ﺑﻠﻮﺣﺔ ﺍﻟﺘﺜﺒﻴﺖ.

5.3.8.3.1ﻳﺠﺐ ﺃﻻ ﻳﻘﻞ ﺳﻤﻚ ﻟﻮﺣﺔ ﺍﻟﺘﺜﺒﻴﺖ ﻋﻦ ﺳﻤﻚ ﺍﻟﻘﺸﺮﺓ ﺃﻭ ﺍﻟﺮﺃﺱ ﺍﻟﻤﺮﻓﻘﺔ ﺑﻪ.

5.3.8.3.2ﻳﺠﺐ ﺃﻥ ﺗﻤﺘﺪ ﻭﺳﺎﺩﺓ ﺍﻟﺘﺜﺒﻴﺖ ﻋﻠﻰ ﺍﻷﻗﻞ 2ﺑﻮﺻﺔ ) 50ﻣﻢ( ﻓﻲ ﻛﻞ ﺍﺗﺠﺎﻩ ﻣﻦ ﺃﻱ ﻧﻘﻄﺔ

ﺭﺑﻂﻷﺣﺪ ﺍﻟﻤﻠﺤﻘﺎﺕ.

5.3.8.3.3ﻳﺠﺐ ﺃﻥ ﺗﻜﻮﻥ ﻭﺳﺎﺩﺓ ﺍﻟﺘﺜﺒﻴﺖ ﺫﺍﺕ ﺯﻭﺍﻳﺎ ﻣﺴﺘﺪﻳﺮﺓ ﺃﻭ ﻳﺘﻢ ﺗﺸﻜﻴﻠﻬﺎ ﺑﻄﺮﻳﻘﺔ ﺗﻤﻨﻊ ﺗﺮﻛﻴﺰﺍﺕ

ﺍﻟﻀﻐﻂﻋﻠﻰ ﺍﻟﻐﻼﻑ ﺃﻭ ﺍﻟﺮﺃﺱ.

5.3.8.3.4ﻳﺠﺐ ﺃﻥ ﻳﺘﻢ ﺭﺑﻂ ﻭﺳﺎﺩﺓ ﺍﻟﺘﺜﺒﻴﺖ ﺑﻠﺤﺎﻡ ﻣﺴﺘﻤﺮ ﺣﻮﻝ ﺍﻟﻮﺳﺎﺩﺓ.

5.3.8.4ﻳﺠﺐ ﺃﻥ ﻳﺘﻢ ﺭﺑﻂ ﺍﻟﻤﻠﺤﻘﺎﺕ ﺑﻤﻨﺼﺎﺕ ﺍﻟﺘﺜﺒﻴﺖ ﺣﺘﻰ ﻻ ﻳﻜﻮﻥ ﻫﻨﺎﻙ ﺃﻱ ﺗﺄﺛﻴﺮ ﺳﻠﺒﻲ ﻋﻠﻰ ﺳﻼﻣﺔ

ﺍﻻﺣﺘﻔﺎﻅﺑﺎﻟﻤﻨﺘﺞ ﻓﻲ ﺍﻟﺨﺰﺍﻥ ﺇﺫﺍ ﺗﻢ ﺗﻄﺒﻴﻖ ﺃﻱ ﻗﻮﺓ ﻋﻠﻰ ﺍﻟﻤﻠﺤﻘﺎﺕ ،ﻓﻲ ﺃﻱ ﺍﺗﺠﺎﻩ ،ﺑﺎﺳﺘﺜﻨﺎء ﺍﻻﺗﺠﺎﻩ

ﺍﻟﻄﺒﻴﻌﻲﻟﻠﺨﺰﺍﻥ ،ﺃﻭ ﻓﻲ ﺣﺪﻭﺩ 45ﺩﺭﺟﺔ ﻣﻦ ﺍﻟﻮﺿﻊ ﺍﻟﻄﺒﻴﻌﻲ.

5.3.8.5ﻫﻴﺎﻛﻞ ﺍﻟﺤﻮﺍﻑ ،ﻭﻣﺸﺎﺑﻚ ﺍﻟﻘﻨﻮﺍﺕ ،ﻭﻣﺸﺎﺑﻚ ﺧﻂ ﺍﻟﻔﺮﺍﻣﻞ ،ﻭﺍﻟﻤﻠﺤﻘﺎﺕ ﺍﻟﻤﻤﺎﺛﻠﺔ ﺧﻔﻴﻔﺔ ﺍﻟﻮﺯﻥ،

ﻭﺍﻟﺘﻲﺗﻜﻮﻥ ﺫﺍﺕ ﺳﻤﺎﻛﺔ ﻣﻌﺪﻧﻴﺔ ﺃﻭ ﺑﻨﺎء ﺃﻭ ﻣﺎﺩﺓ ﺃﻗﻞ ﻗﻮﺓ ﺑﺸﻜﻞ ﻣﻠﺤﻮﻅ ﻭﻟﻜﻦ ﻻ ﺗﺰﻳﺪ ﻋﻦ 72ﺑﺎﻟﻤﺎﺉﺔ

ﻣﻦﺳﻤﻚ ﻫﻴﻜﻞ ﺍﻟﺨﺰﺍﻥ ﺃﻭ ﺍﻟﺮﺃﺱ ﺍﻟﺬﻱ ﻳﺘﻢ ﺗﻮﺻﻴﻞ ﻣﺜﻞ ﻫﺬﺍ ﺍﻟﺠﻬﺎﺯ ﺑﻪ ،ﻳﺠﺐ ﺍﻟﺴﻤﺎﺡ ﺑﺘﺄﻣﻴﻨﻪ ﻣﺒﺎﺷﺮﺓ

ﻋﻠﻰﻫﻴﻜﻞ ﺍﻟﺨﺰﺍﻥ ﺃﻭ ﺭﺃﺳﻪ ،ﺇﺫﺍ ﺗﻢ ﺗﺼﻤﻴﻢ ﻛﻞ ﺟﻬﺎﺯ ﻭﺗﺮﻛﻴﺒﻪ ﺑﺤﻴﺚ ﻻ ﻳﺆﺛﺮ ﺍﻟﻀﺮﺭ ﺍﻟﺬﻱ ﻳﻠﺤﻖ ﺑﻪ ﻋﻠﻰ

ﺳﻼﻣﺔﺍﻻﺣﺘﻔﺎﻅ ﺑﺎﻟﻤﻨﺘﺞ ﻓﻲ ﺍﻟﺨﺰﺍﻥ.

5.3.8.5.1ﻳﺠﺐ ﺗﺜﺒﻴﺖ ﻫﺬﻩ ﺍﻟﻤﻠﺤﻘﺎﺕ ﺧﻔﻴﻔﺔ ﺍﻟﻮﺯﻥ ﻋﻠﻰ ﻫﻴﻜﻞ ﺍﻟﺨﺰﺍﻥ ﻋﻦ ﻃﺮﻳﻖ ﺍﻟﻠﺤﺎﻡ ﺍﻟﻤﺴﺘﻤﺮ

ﺃﻭﺑﻄﺮﻳﻘﺔ ﺗﻤﻨﻊ ﺗﻜﻮﻳﻦ ﺍﻟﺠﻴﻮﺏ ،ﻭﺍﻟﺘﻲ ﻳﻤﻜﻦ ﺃﻥ ﺗﺼﺒﺢ ﻣﻮﺍﻗﻊ ﻟﻠﺘﺂﻛﻞ ﺍﻷﻭﻟﻲ.

ﺣﻘﻮﻕﺍﻟﻄﺒﻊ ﻭﺍﻟﻨﺸﺮ NFPA

ﺷﺮﻛﺔﺃﺑﺎﺩﻏﻮﺳﺘﺎﺭ ﺗﺎﺳﻴﺴﺎﺕ ﺇﻳﺮﺍﻧﻴﻨﺎﻥ ﺍﻟﻤﺤﺪﻭﺩﺓ www.atapars.com

www.atapars.com/NFPA-code/

5.3.8.6ﻳﺠﺐ ﺃﻥ ﻳﺘﻢ ﺗﺰﻭﻳﺪ ﻛﻞ ﺧﺰﺍﻥ ﺑﻀﺎﺉﻊ ﺑﻤﺼﺪ ﺧﻠﻔﻲ ﻟﺤﻤﺎﻳﺔ ﺍﻟﺨﺰﺍﻥ ﻭﺍﻷﻧﺎﺑﻴﺐ ﻓﻲ ﺣﺎﻟﺔ ﺣﺪﻭﺙ

ﺗﺼﺎﺩﻡﻣﻦ ﺍﻟﺨﻠﻒ ﻭﻟﺘﻘﻠﻴﻞ ﺍﺣﺘﻤﺎﻟﻴﺔ ﺍﺻﻄﺪﺍﻡ ﺃﻱ ﺟﺰء ﻣﻦ ﺍﻟﻤﺮﻛﺒﺔ ﺍﻟﻤﺘﺼﺎﺩﻣﺔ ﺑﺎﻟﺨﺰﺍﻥ.

5.3.8.6.1ﻳﺠﺐ ﺃﻥ ﻳﻘﻊ ﺍﻟﻤﺼﺪ ﻋﻠﻰ ﺑﻌﺪ 6ﺑﻮﺻﺎﺕ ) 150ﻣﻢ( ﻋﻠﻰ ﺍﻷﻗﻞ ﻓﻲ ﺍﻟﺠﺰء ﺍﻟﺨﻠﻔﻲ ﻣﻦ ﺃﻱ ﻣﻜﻮﻥ ﻣﻦ

ﻣﻜﻮﻧﺎﺕﺍﻟﺴﻴﺎﺭﺓ ﻳﺴُﺘﺨﺪﻡ ﻷﻏﺮﺍﺽ ﺍﻟﺘﺤﻤﻴﻞ ﺃﻭ ﺍﻟﺘﻔﺮﻳﻎ ﺃﻭ ﻗﺪ ﻳﺤﺘﻮﻱ ﻓﻲ ﺃﻱ ﻭﻗﺖ ﻋﻠﻰ ﺷﺤﻦ ﺃﺛﻨﺎء ﺍﻟﻨﻘﻞ.

5.3.8.6.2ﻣﻦ ﺍﻟﻨﺎﺣﻴﺔ ﺍﻷﺑﻌﺎﺩ ،ﻳﺠﺐ ﺃﻥ ﻳﺘﻮﺍﻓﻖ ﺍﻟﻤﺼﺪ ﻣﻊ ﻟﻮﺍﺉﺢ ﻭﺯﺍﺭﺓ ﺍﻟﻨﻘﻞ ﺍﻷﻣﺮﻳﻜﻴﺔ ﻓﻲ CFR 49

ﺍﻟﺠﺰء" ،393.86ﻭﺍﻗﻴﺎﺕ ﺍﻟﺼﺪﻣﺎﺕ ﺍﻟﺨﻠﻔﻴﺔ ﻭﺣﻤﺎﻳﺔ ﺍﻟﻨﻬﺎﻳﺔ ﺍﻟﺨﻠﻔﻴﺔ" .ﻣﻦ ﺍﻟﻨﺎﺣﻴﺔ ﺍﻟﻬﻴﻜﻠﻴﺔ ،ﻳﺠﺐ

ﺗﺼﻤﻴﻢﺍﻟﻤﺼﺪ ﺑﺤﻴﺚ ﻳﻤﺘﺺ ﺑﻨﺠﺎﺡ ﺗﺄﺛﻴﺮ ﺍﻟﺴﻴﺎﺭﺓ ﺫﺍﺕ ﺍﻟﺤﻤﻮﻟﺔ ﺍﻟﻤﻘﺪﺭﺓ )ﺃﻱ ﻣﻨﻊ ﺍﻟﻀﺮﺭ ﺍﻟﺬﻱ ﻗﺪ

ﻳﺘﺴﺒﺐﻓﻲ ﺗﺴﺮﺏ ﺍﻟﻤﻨﺘﺞ( ،ﻣﻊ ﺗﺒﺎﻃﺆ ﻗﺪﺭﻩ 2ﺟﺮﺍﻡ ،ﺑﺎﺳﺘﺨﺪﺍﻡ ﻋﺎﻣﻞ ﺃﻣﺎﻥ ﻗﺪﺭﻩ 2ﺑﻨﺎء ًﻋﻠﻰ ﺍﻟﻘﻮﺓ

ﺍﻟﻨﻬﺎﺉﻴﺔﻣﻦ ﻣﺎﺩﺓ ﺍﻟﻮﻓﻴﺮ.

5.3.8.6.3ﻭﻷﻏﺮﺍﺽ ﻫﺬﻩ ﺍﻟﻠﻮﺍﺉﺢ ،ﻳﺠﺐ ﺍﻋﺘﺒﺎﺭ ﻫﺬﺍ ﺍﻟﺘﺄﺛﻴﺮ ﻣﻮﺯﻋﺎً ﺑﺸﻜﻞ ﻣﻮﺣﺪ ﻭﻣﻄﺒﻖ ﺃﻓﻘﻴﺎً )ﻣﻮﺍﺯﻳﺎً

ﻟﻸﺭﺽ( ﻣﻦ ﺃﻱ ﺍﺗﺠﺎﻩ ﻭﺑﺰﺍﻭﻳﺔ ﻻ ﺗﺰﻳﺪ ﻋﻦ 30ﺩﺭﺟﺔ ﻋﻠﻰ ﺍﻟﻤﺤﻮﺭ ﺍﻟﻄﻮﻟﻲ ﻟﻠﻤﺮﻛﺒﺔ.

5.3.9ﺍﻟﺤﻤﺎﻳﺔ ﻣﻦ ﺍﻻﻧﻘﻼﺏ.

5.3.9.1ﻳﺠﺐ ﺣﻤﺎﻳﺔ ﺟﻤﻴﻊ ﻣﻐﻼﻗﺎﺕ ﺍﻟﺘﻌﺒﺉﺔ ﺃﻭ ﻏﺮﻑ ﺍﻟﺘﻔﺘﻴﺶ ﺃﻭ ﻓﺘﺤﺎﺕ ﺍﻟﺘﻔﺘﻴﺶ ﻣﻦ ﺍﻟﺘﻠﻒ

ﺍﻟﺬﻱﻗﺪ ﻳﺆﺩﻱ ﺇﻟﻰ ﺗﺴﺮﺏ ﺍﻟﺸﺤﻦ ﻓﻲ ﺣﺎﻟﺔ ﺍﻧﻘﻼﺏ ﺍﻟﻤﺮﻛﺒﺔ ﻭﺫﻟﻚ ﺑﺘﻄﻮﻳﻘﻬﺎ ﺩﺍﺧﻞ ﺟﺴﻢ ﺍﻟﺨﺰﺍﻥ ﺃﻭ

ﺍﻟﻘﺒﺔﺍﻟﻤﻠﺤﻘﺔ ﺑﺎﻟﺨﺰﺍﻥ ﺃﻭ ﺑﻮﺍﺳﻄﺔ ﺣﺮﺍﺱ.

5.3.9.2ﻋﻨﺪﻣﺎ ﺗﻜﻮﻥ ﻫﻨﺎﻙ ﺣﺎﺟﺔ ﺇﻟﻰ ﻭﺍﻗﻴﺎﺕ ،ﻳﺠﺐ ﺗﺼﻤﻴﻤﻬﺎ ﻭﺗﺮﻛﻴﺒﻬﺎ ﺑﺤﻴﺚ ﺗﺘﺤﻤﻞ ﺣﻤﻼ ًﺭﺃﺳﻴﺎ ًﻳﺒﻠﻎ

ﺿﻌﻒﻭﺯﻥ ﺍﻟﺼﻬﺮﻳﺞ ﺍﻟﻤﺤﻤﻞ ﻭﺣﻤﻼ ًﺃﻓﻘﻴﺎ ًﻓﻲ ﺃﻱ ﺍﺗﺠﺎﻩ ﻳﻌﺎﺩﻝ ﻧﺼﻒ ﻭﺯﻥ ﺍﻟﺼﻬﺮﻳﺞ ﺍﻟﻤﺤﻤﻞ .ﻭﻳﺠﺐ

ﺍﻟﺴﻤﺎﺡﺑﺪﺭﺍﺳﺔ ﺃﺣﻤﺎﻝ ﺍﻟﺘﺼﻤﻴﻢ ﻫﺬﻩ ﺑﺸﻜﻞ ﻣﺴﺘﻘﻞ.

5.3.9.2.1ﻳﺠﺐ ﺍﺳﺘﺨﺪﺍﻡ ﺍﻟﻘﻮﺓ ﺍﻟﻨﻬﺎﺉﻴﺔ ﻟﻠﻤﺎﺩﺓ ﻛﻘﺎﻋﺪﺓ ﺣﺴﺎﺑﻴﺔ.

5.3.9.2.2ﻭﻓﻲ ﺣﺎﻟﺔ ﺍﺳﺘﺨﺪﺍﻡ ﺃﻛﺜﺮ ﻣﻦ ﺣﺎﺭﺱ ﻭﺍﺣﺪ ،ﻳﺠﺐ ﺃﻥ ﻳﺤﻤﻞ ﻛﻞ ﻣﻨﻬﻢ ﻧﺼﻴﺒﻪ ﺍﻟﻤﺘﻨﺎﺳﺐ ﻣﻦ ﺍﻟﺤﻤﻮﻟﺔ.

5.3.9.2.3ﺇﺫﺍ ﺗﻢ ﺃﺧﺬ ﺍﻟﺤﻤﺎﻳﺔ ﺑﺨﻼﻑ ﺍﻟﺤﺮﺍﺱ ﻓﻲ ﺍﻻﻋﺘﺒﺎﺭ ،ﻓﻴﺠﺐ ﺗﻄﺒﻴﻖ ﻧﻔﺲ ﻣﻌﺎﻳﻴﺮ ﺍﻟﺤﻤﻞ

ﺍﻟﺘﺼﻤﻴﻤﻲ.

5.3.9.3ﺑﺎﺳﺘﺜﻨﺎء ﻓﺘﺤﺎﺕ ﺍﻟﺘﻬﻮﻳﺔ ﺍﻟﺘﻲ ﻳﺘﻢ ﺗﺸﻐﻴﻠﻬﺎ ﺑﺎﻟﻀﻐﻂ ،ﻻ ﻳﻠﺰﻡ ﺗﻮﻓﻴﺮ ﺣﻤﺎﻳﺔ ﻣﻦ ﺍﻻﻧﻘﻼﺏ

ﻟﻠﻔﻮﻫﺎﺕﺃﻭ ﺍﻟﺘﺮﻛﻴﺒﺎﺕ ﻏﻴﺮ ﺍﻟﻌﺎﻣﻠﺔ ﺍﻟﺘﻲ ﻳﻘﻞ ﻗﻄﺮﻫﺎ ﻋﻦ 5ﺑﻮﺻﺎﺕ ) 125ﻣﻠﻢ( )ﻭﺍﻟﺘﻲ ﻻ ﺗﺤﺘﻮﻱ ﻋﻠﻰ

ﻣﻨﺘﺞﺃﺛﻨﺎء ﺍﻟﻨﻘﻞ( ﻭﺍﻟﺘﻲ ﺗﺒﺮﺯ ﻣﺴﺎﻓﺔ ﺃﻗﻞ ﻣﻦ ﺍﻟﻘﻄﺮ ﺍﻟﺪﺍﺧﻠﻲ ﻟﻠﺘﺮﻛﻴﺐ .ﻳﺴُﻤﺢ ﺑﻘﻴﺎﺱ ﻫﺬﻩ ﺍﻟﻤﺴﺎﻓﺔ

ﺍﻟﻤﺘﻮﻗﻌﺔﺇﻣﺎ ﻣﻦ ﺍﻟﻐﻼﻑ ﺃﻭ ﻣﻦ ﺃﻋﻠﻰ ﺃﺩﺍﺓ ﺗﻘﻮﻳﺔ ﺍﻟﺤﻠﻘﺔ ﺍﻟﻤﺠﺎﻭﺭﺓ ﺑﺸﺮﻁ ﺃﻥ ﻳﻜﻮﻥ ﻫﺬﺍ ﺍﻟﻤﻘﻮﻱ ﻓﻲ

ﺣﺪﻭﺩ 30ﺑﻮﺻﺔ ) 750ﻣﻢ( ﻣﻦ ﻣﺮﻛﺰ ﺍﻟﻔﻮﻫﺔ ﺃﻭ ﺍﻟﺘﺮﻛﻴﺐ.

5.3.9.4ﺇﺫﺍ ﺗﻢ ﺇﻧﺸﺎء ﻧﻈﺎﻡ ﺍﻟﺤﻤﺎﻳﺔ ﻣﻦ ﺍﻻﻧﻘﻼﺏ ﺑﺤﻴﺚ ﻳﺴﻤﺢ ﺑﺘﺮﺍﻛﻢ ﺍﻟﺴﺎﺉﻞ ﻋﻠﻰ ﺍﻟﺠﺰء ﺍﻟﻌﻠﻮﻱ ﻣﻦ

ﺍﻟﺨﺰﺍﻥ،ﻓﻴﺠﺐ ﺗﺰﻭﻳﺪﻩ ﺑﻮﺳﺎﺉﻞ ﺗﺼﺮﻳﻒ ﻣﻮﺟﻬﺔ ﺇﻟﻰ ﻧﻘﻄﺔ ﺗﺼﺮﻳﻒ ﺁﻣﻨﺔ.

5.3.10ﺍﻷﻧﺎﺑﻴﺐ.

5.3.10.1ﻳﺠﺐ ﺃﻥ ﺗﺰﻭﺩ ﺃﻧﺎﺑﻴﺐ ﺗﻔﺮﻳﻎ ﺍﻟﻤﻨﺘﺞ ﺑﺎﻟﺤﻤﺎﻳﺔ ﺑﻄﺮﻳﻘﺔ ﺗﻀﻤﻦ ﺑﺸﻜﻞ ﻣﻌﻘﻮﻝ ﺿﺪ ﺍﻟﻬﺮﻭﺏ

ﺍﻟﻌﺮﺿﻲﻟﻠﻤﺤﺘﻮﻳﺎﺕ .ﻳﺠﺐ ﺃﻥ ﺗﻜﻮﻥ ﻫﺬﻩ ﺍﻟﺤﻤﺎﻳﺔ

ﺣﻘﻮﻕﺍﻟﻄﺒﻊ ﻭﺍﻟﻨﺸﺮ NFPA

ﺷﺮﻛﺔﺃﺑﺎﺩﻏﻮﺳﺘﺎﺭ ﺗﺎﺳﻴﺴﺎﺕ ﺇﻳﺮﺍﻧﻴﻨﺎﻥ ﺍﻟﻤﺤﺪﻭﺩﺓ www.atapars.com

www.atapars.com/NFPA-code/

ﻳﺴُﻤﺢﺑﺘﻘﺪﻳﻤﻬﺎ ﺑﻮﺍﺳﻄﺔ ﺃﺣﺪ ﺍﻹﺟﺮﺍءﺍﺕ ﺍﻟﺘﺎﻟﻴﺔ:

) (1ﻳﺠﺐ ﻭﺿﻊ ﻗﺴﻢ ﺍﻟﻘﺺ ﺧﺎﺭﺝ ﻛﻞ ﻣﻘﻌﺪ ﻣﻦ ﻣﻘﺎﻋﺪ ﺻﻤﺎﻡ ﺍﻟﻄﻮﺍﺭﺉ ﻭﻋﻠﻰ ﻣﺴﺎﻓﺔ 4ﺑﻮﺻﺎﺕ )100

ﻣﻢ( ﻣﻦ ﺍﻟﺴﻔﻴﻨﺔ .ﻳﺠﺐ ﺃﻥ ﻳﻨﻜﺴﺮ ﻗﺴﻢ ﺍﻟﻘﺺ ﺗﺤﺖ ﺍﻟﻀﻐﻂ ﻭﻳﺘﺮﻙ ﻣﻘﻌﺪ ﺻﻤﺎﻡ ﺍﻟﻄﻮﺍﺭﺉ

ﻭﻣﻠﺤﻘﻪﺑﺎﻟﻮﻋﺎء ﻭﺭﺃﺱ ﺍﻟﺼﻤﺎﻡ ﺳﻠﻴﻤﻴﻦ ﻭﻗﺎﺩﺭﻳﻦ ﻋﻠﻰ ﺍﻻﺣﺘﻔﺎﻅ ﺑﺎﻟﻤﻨﺘﺞ .ﻳﺠﺐ ﺃﻥ ﻳﺘﻢ ﺗﺸﻜﻴﻞ

ﻗﺴﻢﺍﻟﻘﺺ ﺑﻄﺮﻳﻘﺔ ﺗﻘﻠﻞ ﺑﺸﻜﻞ ﻣﻔﺎﺟﺊ ﺳﻤﺎﻛﺔ ﺟﺪﺍﺭ ﻣﺎﺩﺓ ﺍﻷﻧﺎﺑﻴﺐ )ﺃﻭ ﺍﻟﺼﻤﺎﻡ( ﺍﻟﻤﺠﺎﻭﺭﺓ

ﺑﻨﺴﺒﺔ 20ﺑﺎﻟﻤﺎﺉﺔ ﻋﻠﻰ ﺍﻷﻗﻞ.

) (2ﻳﺠﺐ ﺃﻥ ﺗﻜﻮﻥ ﺍﻟﻮﺍﻗﻴﺎﺕ ﺍﻟﻤﻨﺎﺳﺒﺔ ﻗﺎﺩﺭﺓ ﻋﻠﻰ ﺍﻣﺘﺼﺎﺹ ﻗﻮﺓ ﺃﻓﻘﻴﺔ ﻣﺮﻛﺰﺓ ﻻ ﺗﻘﻞ ﻋﻦ 8000ﺭﻃﻞ )

3630ﻛﺠﻢ( ﺑﻨﺠﺎﺡ ﻣﻦ ﺃﻱ ﺍﺗﺠﺎﻩ ﺃﻓﻘﻲ ،ﺩﻭﻥ ﺇﺗﻼﻑ ﺃﻧﺎﺑﻴﺐ ﺍﻟﺘﻔﺮﻳﻎ ﺍﻟﺘﻲ ﻗﺪ ﺗﺆﺛﺮ ﺳﻠﺒﺎً ﻋﻠﻰ

ﺳﻼﻣﺔﺍﻻﺣﺘﻔﺎﻅ ﺑﺎﻟﻤﻨﺘﺞ ﻓﻲ ﺻﻤﺎﻡ ﺍﻟﺘﻔﺮﻳﻎ.

5.3.10.2ﻳﺠﺐ ﺃﻥ ﻳﻜﻮﻥ ﺍﻟﺤﺪ ﺍﻷﺩﻧﻰ ﺍﻟﻤﺴﻤﻮﺡ ﺑﻪ ﻟﺨﻠﻮﺹ ﺍﻟﻄﺮﻳﻖ ﻷﻱ ﻣﻜﻮﻥ ﻣﻦ ﻣﻜﻮﻧﺎﺕ ﺧﺰﺍﻥ ﺍﻟﺒﻀﺎﺉﻊ

ﺃﻭﺟﻬﺎﺯ ﺍﻟﺤﻤﺎﻳﺔ ﺍﻟﻤﻮﺟﻮﺩ ﺑﻴﻦ ﺃﻱ ﻣﺤﻮﺭﻳﻦ ﻣﺘﺠﺎﻭﺭﻳﻦ ﻋﻠﻰ ﺍﻟﻤﺮﻛﺒﺔ ﺃﻭ ﻣﺠﻤﻮﻋﺔ ﺍﻟﻤﺮﻛﺒﺎﺕ ½ ﺑﻮﺻﺔ ) 12.5ﻣﻢ(

ﻋﻠﻰﺍﻷﻗﻞ ﻟﻜﻞ ﻗﺪﻡ ﺗﻔﺼﻞ ﺑﻴﻦ ﻫﺬﻩ ﺍﻟﻤﺤﺎﻭﺭ ﻭﻻ ﻳﻘﻞ ﺑﺄﻱ ﺣﺎﻝ ﻣﻦ ﺍﻷﺣﻮﺍﻝ ﻋﻦ 12ﺑﻮﺻﺔ ) 300ﻣﻠﻢ(.

5.3.10.3ﻳﺠﺐ ﺃﻥ ﺗﻜﻮﻥ ﺍﻟﺨﺮﺍﻃﻴﻢ ﻭﺍﻷﻧﺎﺑﻴﺐ ﻭﺍﻟﺘﺠﻬﻴﺰﺍﺕ ﺍﻟﺨﺎﺻﺔ ﺑﺎﻟﺨﺰﺍﻧﺎﺕ ﺍﻟﺘﻲ ﺳﻴﺘﻢ ﺗﻔﺮﻳﻐﻬﺎ

ﺑﺎﻟﻀﻐﻂﻣﺼﻤﻤﺔ ﻟﻀﻐﻂ ﺍﻧﻔﺠﺎﺭ ﻻ ﻳﻘﻞ ﻋﻦ 100ﺭﻃﻞ ﻟﻜﻞ ﺑﻮﺻﺔ ﻣﺮﺑﻌﺔ ) 689.5ﻛﻴﻠﻮ ﺑﺎﺳﻜﺎﻝ( ،ﻭﻟﻜﻦ ﻻ

ﻳﻘﻞﺑﺄﻱ ﺣﺎﻝ ﻣﻦ ﺍﻷﺣﻮﺍﻝ ﻋﻦ ﺃﺭﺑﻌﺔ ﺃﺿﻌﺎﻑ ﺍﻟﻀﻐﻂ ﺍﻟﺬﻱ ﻗﺪ ﻳﺘﻌﺮﺽ ﻟﻪ ﺃﺛﻨﺎء ﺍﻟﺨﺪﻣﺔ .ﺑﻮﺍﺳﻄﺔ ﺃﻱ

ﻣﻀﺨﺔﻣﺜﺒﺘﺔ ﻋﻠﻰ ﺍﻟﺴﻴﺎﺭﺓ ﺃﻭ ﺃﻱ ﺟﻬﺎﺯ ﺁﺧﺮ )ﻻ ﻳﺸﻤﻞ ﺻﻤﺎﻣﺎﺕ ﺗﺨﻔﻴﻒ ﺍﻷﻣﺎﻥ( .ﻳﺠﺐ ﺃﻥ ﺗﻜﻮﻥ ﺃﻱ

ﻭﺻﻠﺔﺗﻮﺻﻴﻞ ﺗﺴﺘﺨﺪﻡ ﻋﻠﻰ ﺍﻟﺨﺮﻃﻮﻡ ﻹﺟﺮﺍء ﺍﻟﺘﻮﺻﻴﻼﺕ ﻣﺼﻤﻤﺔ ﻟﻀﻐﻂ ﺗﺸﻐﻴﻞ ﻻ ﻳﻘﻞ ﻋﻦ 20ﺑﺎﻟﻤﺎﺉﺔ

ﺯﻳﺎﺩﺓﻋﻦ ﺍﻟﻀﻐﻂ ﺍﻟﺘﺼﻤﻴﻤﻲ ﻟﻠﺨﺮﻃﻮﻡ ،ﻭﻳﺠﺐ ﺃﻥ ﺗﻜﻮﻥ ﻣﺼﻤﻤﺔ ﺑﺤﻴﺚ ﻻ ﻳﺤﺪﺙ ﺃﻱ ﺗﺴﺮﺏ ﻋﻨﺪ

ﺍﻟﺘﻮﺻﻴﻞ.

5.3.10.4ﻳﺠﺐ ﺍﺗﺨﺎﺫ ﺍﻟﺘﺪﺍﺑﻴﺮ ﺍﻟﻤﻨﺎﺳﺒﺔ ﻓﻲ ﻛﻞ ﺣﺎﻟﺔ ﻟﻠﺴﻤﺎﺡ ﻭﻣﻨﻊ ﺍﻟﻀﺮﺭ ﺍﻟﻨﺎﺗﺞ ﻋﻦ ﺍﻟﺘﻤﺪﺩ

ﻭﺍﻻﻧﻜﻤﺎﺵﻭﺍﻟﺘﻨﺎﻓﺮ ﻭﺍﻻﻫﺘﺰﺍﺯ ﻟﺠﻤﻴﻊ ﺍﻷﻧﺎﺑﻴﺐ .ﻻ ﻳﺠﻮﺯ ﺍﺳﺘﺨﺪﺍﻡ ﺍﻟﻤﻔﺎﺻﻞ ﺍﻻﻧﺰﻻﻗﻴﺔ ﻟﻬﺬﺍ ﺍﻟﻐﺮﺽ.

5.3.10.5ﻳﺠﺐ ﺃﻥ ﺗﻜﻮﻥ ﻣﻠﻔﺎﺕ ﺍﻟﺴﺨﺎﻥ ،ﻋﻨﺪ ﺗﺮﻛﻴﺒﻬﺎ ،ﺑﺤﻴﺚ ﻻ ﻳﺆﺩﻱ ﺍﻧﻘﻄﺎﻉ ﺗﻮﺻﻴﻼﺗﻬﺎ ﺍﻟﺨﺎﺭﺟﻴﺔ

ﺇﻟﻰﺗﺴﺮﺏ ﻣﺤﺘﻮﻳﺎﺕ ﺍﻟﺨﺰﺍﻥ.

5.3.10.6ﻳﺠﺐ ﺃﻥ ﺗﺰﻭﺩ ﺃﺟﻬﺰﺓ ﺍﻟﻘﻴﺎﺱ ﻭﺍﻟﺘﺤﻤﻴﻞ ﻭﻣﺪﺧﻞ ﺍﻟﻬﻮﺍء ،ﺑﻤﺎ ﻓﻲ ﺫﻟﻚ ﺻﻤﺎﻣﺎﺗﻬﺎ ،ﺑﻮﺳﺎﺉﻞ

ﻛﺎﻓﻴﺔﻹﻏﻼﻗﻬﺎ ﺑﺸﻜﻞ ﺁﻣﻦ ،ﻛﻤﺎ ﻳﺠﺐ ﺗﻮﻓﻴﺮ ﻭﺳﺎﺉﻞ ﻹﻏﻼﻕ ﻭﺻﻼﺕ ﺃﻧﺎﺑﻴﺐ ﺍﻟﺼﻤﺎﻣﺎﺕ.

5.3.11ﺇﻏﻼﻕ ﻓﺘﺤﺎﺕ ﺍﻟﺘﻌﺒﺉﺔ ﻭﻏﺮﻑ ﺍﻟﺘﻔﺘﻴﺶ.

5.3.11.1ﻳﺠﺐ ﺍﻟﻮﺻﻮﻝ ﺇﻟﻰ ﻛﻞ ﺣﺠﺮﺓ ﺗﺰﻳﺪ ﺳﻌﺘﻬﺎ ﻋﻦ 2500ﺟﺎﻟﻮﻥ ) 9500ﻟﺘﺮ( ﻣﻦ ﺧﻼﻝ ﻓﺘﺤﺔ

ﻻﺗﻘﻞ ﻋﻦ 11ﺑﻮﺻﺔ × 15ﺑﻮﺻﺔ ) 280ﻣﻢ × 380ﻣﻢ(.

5.3.11.2ﻳﺠﺐ ﺗﺼﻤﻴﻢ ﺃﻏﻄﻴﺔ ﻓﺘﺤﺎﺕ ﺍﻟﺘﻔﺘﻴﺶ ﻭﺍﻟﻤﻞء ﺑﺤﻴﺚ ﺗﻮﻓﺮ ﺇﻏﻼﻗﺎ ًﺁﻣﻨﺎ ًﻟﻠﻔﺘﺤﺎﺕ.

5.3.11.3ﻳﺠﺐ ﺃﻥ ﺗﺘﻤﺘﻊ ﻋﻤﻠﻴﺎﺕ ﺍﻹﻏﻼﻕ ﺑﺎﻟﻘﺪﺭﺓ ﺍﻟﻬﻴﻜﻠﻴﺔ ﻋﻠﻰ ﺗﺤﻤﻞ ﺿﻐﻂ ﺍﻟﺴﺎﺉﻞ ﺍﻟﺪﺍﺧﻠﻲ

ﺑﻤﻘﺪﺍﺭ 9ﺭﻃﻞ ﻟﻜﻞ ﺑﻮﺻﺔ ﻣﺮﺑﻌﺔ )ﺿﻐﻂ ﻣﻘﻴﺎﺱ 62ﻛﻴﻠﻮ ﺑﺎﺳﻜﺎﻝ( ﺩﻭﻥ ﺗﺸﻮﻩ ﺩﺍﺉﻢ.

5.3.11.4ﻳﺠﺐ ﺗﻮﻓﻴﺮ ﺃﺟﻬﺰﺓ ﺍﻟﺴﻼﻣﺔ ﻟﻤﻨﻊ ﻓﺘﺤﺎﺕ ﺍﻟﺘﻔﺘﻴﺶ ﻭﺃﻏﻄﻴﺔ ﺍﻟﺮﺩﻡ ﻣﻦ ﺍﻟﻔﺘﺢ ﺑﺸﻜﻞ ﻛﺎﻣﻞ

ﻋﻨﺪﻭﺟﻮﺩ ﺿﻐﻂ ﺩﺍﺧﻠﻲ.

ﺣﻘﻮﻕﺍﻟﻄﺒﻊ ﻭﺍﻟﻨﺸﺮ NFPA

ﺷﺮﻛﺔﺃﺑﺎﺩﻏﻮﺳﺘﺎﺭ ﺗﺎﺳﻴﺴﺎﺕ ﺇﻳﺮﺍﻧﻴﻨﺎﻥ ﺍﻟﻤﺤﺪﻭﺩﺓ www.atapars.com

www.atapars.com/NFPA-code/

5.3.12ﺍﻟﻔﺘﺤﺎﺕ ﺍﻟﻌﺎﺩﻳﺔ ﻟﺼﻬﺎﺭﻳﺞ ﺍﻟﺒﻀﺎﺉﻊ ﻓﻲ ﻏﻴﺮ ﺧﺪﻣﺔ ﺍﻷﺳﻔﻠﺖ.

5.3.12.1ﻳﺠﺐ ﺃﻥ ﺗﺰﻭﺩ ﻛﻞ ﺣﺠﺮﺓ ﻣﻦ ﻣﻘﺼﻮﺭﺓ ﺧﺰﺍﻥ ﺍﻟﺒﻀﺎﺉﻊ ﺑﺄﺟﻬﺰﺓ ﺗﻨﻔﻴﺲ ﻟﻠﺴﻼﻣﺔ ﺗﺘﻮﺍﺻﻞ ﻣﻊ

ﻣﺴﺎﺣﺔﺍﻟﺒﺨﺎﺭ ﺍﻟﻤﻮﺟﻮﺩﺓ ﻓﻲ ﺧﺰﺍﻥ ﺍﻟﺒﻀﺎﺉﻊ ﻭﻓﻘﺎ ًﻟﻠﻤﺘﻄﻠﺒﺎﺕ ﺍﻟﻮﺍﺭﺩﺓ ﻓﻲ ﻫﺬﺍ ﺍﻟﻘﺴﻢ.

5.3.12.1.1ﻻ ﻳﺠﻮﺯ ﺗﺮﻛﻴﺐ ﺻﻤﺎﻣﺎﺕ ﺍﻹﻏﻼﻕ ﺑﻴﻦ ﻓﺘﺤﺔ ﺍﻟﺨﺰﺍﻥ ﻭﺃﻱ ﺟﻬﺎﺯ ﺃﻣﺎﻥ.

5.3.12.1.2ﻳﺠﺐ ﺗﺮﻛﻴﺐ ﺃﺟﻬﺰﺓ ﺗﻨﻔﻴﺲ ﺍﻟﺴﻼﻣﺔ ﺃﻭ ﺗﻐﻄﻴﺘﻬﺎ ﺃﻭ ﺗﺼﺮﻳﻔﻬﺎ ﻟﻤﻨﻊ ﺗﺮﺍﻛﻢ ﺍﻟﻤﻴﺎﻩ ،ﻭﺍﻟﺘﻲ ﻗﺪ

ﻳﺆﺩﻱﺗﺠﻤﻴﺪﻫﺎ ﺇﻟﻰ ﺇﺿﻌﺎﻑ ﺗﺸﻐﻴﻞ ﺍﻟﺠﻬﺎﺯ ﺃﻭ ﻗﺪﺭﺗﻪ ﻋﻠﻰ ﺍﻟﺘﻔﺮﻳﻎ.

5.3.12.2ﻳﺠﺐ ﺃﻥ ﺗﺰﻭﺩ ﻛﻞ ﺣﺠﺮﺓ ﻣﻦ ﺣﺠﺮﺍﺕ ﺻﻬﺎﺭﻳﺞ ﺍﻟﺒﻀﺎﺉﻊ ﺑﻔﺘﺤﺎﺕ ﺿﻐﻂ ﻋﺎﺩﻳﺔ ﻭﻓﺘﺤﺎﺕ ﺗﻔﺮﻳﻎ ،ﺑﺤﻴﺚ

ﻳﻜﻮﻥﻟﻜﻞ ﻣﻨﻬﺎ ﺻﺎﻓﻲ ﻣﺴﺎﺣﺔ ﻣﻘﻄﻊ ﻋﺮﺿﻲ ﺣﺮ ﻻ ﻳﻘﻞ ﻋﻦ 0.44ﺑﻮﺻﺔ 284)2.ﻣﻠﻢ .(2ﻳﺠﺐ ﺿﺒﻂ ﻓﺘﺤﺎﺕ

ﺍﻟﻀﻐﻂﻟﺘﻔﺘﺢ ﻋﻨﺪ ﺿﻐﻂ ﻗﻴﺎﺱ ﻻ ﻳﺰﻳﺪ ﻋﻦ 1ﺭﻃﻞ ﻟﻜﻞ ﺑﻮﺻﺔ ﻣﺮﺑﻌﺔ ) 6.9ﻛﻴﻠﻮ ﺑﺎﺳﻜﺎﻝ( .ﻳﺠﺐ ﺿﺒﻂ ﻓﺘﺤﺎﺕ

ﺍﻟﺘﻔﺮﻳﻎﻟﺘﻔﺘﺢ ﻋﻨﺪ 6ﺃﻭﻧﺼﺔ ) 170ﺟﻢ(.

5.3.12.3ﻳﺠﺐ ﺗﺼﻤﻴﻢ ﻓﺘﺤﺎﺕ ﺍﻟﻀﻐﻂ ﻭﺍﻟﻔﺮﺍﻍ ﻟﻤﻨﻊ ﻓﻘﺪﺍﻥ ﺍﻟﺴﺎﺉﻞ ﻓﻲ ﺣﺎﻟﺔ ﺍﻧﻘﻼﺏ ﺍﻟﺴﻴﺎﺭﺓ.

5.3.12.4ﻋﻨﺪﻣﺎ ﺗﻜﻮﻥ ﺣﺠﺮﺓ ﺧﺰﺍﻥ ﺍﻟﺒﻀﺎﺉﻊ ﻣﺼﻤﻤﺔ ﻟﻴﺘﻢ ﺗﺤﻤﻴﻠﻬﺎ ﺃﻭ ﺗﻔﺮﻳﻐﻬﺎ ﻣﻊ ﺇﻏﻼﻕ ﻏﻄﺎء ﺍﻟﻘﺒﺔ ،ﻳﺠﺐ ﺃﻥ ﺗﺤﺪﺩ

ﻓﺘﺤﺔﺍﻟﺘﻬﻮﻳﺔ ﺃﻭ ﺍﻟﻔﺘﺤﺎﺕ ﺍﻟﻤﻮﺻﻮﻓﺔ ﻓﻲ 5.3.12.2ﺃﻭ ﻓﺘﺤﺎﺕ ﺇﺿﺎﻓﻴﺔ ﺍﻟﻔﺮﺍﻍ ﺇﻟﻰ 1ﺭﻃﻞ ﻟﻜﻞ ﺑﻮﺻﺔ ﻣﺮﺑﻌﺔ ) 6.9ﻛﻴﻠﻮ

ﺑﺎﺳﻜﺎﻝ( ﻭﺿﻐﻂ ﺍﻟﺨﺰﺍﻥ ﺇﻟﻰ ﺿﻐﻂ ﻗﻴﺎﺱ ﻗﺪﺭﻩ 3ﺭﻃﻞ ﻟﻜﻞ ﺑﻮﺻﺔ ﻣﺮﺑﻌﺔ ) 20.7ﻛﻴﻠﻮ ﺑﺎﺳﻜﺎﻝ( ﺑﻨﺎء ًﻋﻠﻰ ﺍﻟﺤﺪ ﺍﻷﻗﺼﻰ

ﻟﻤﻌﺪﻝﻧﻘﻞ ﺍﻟﻤﻨﺘﺞ.

5.3.12.4.1ﻣﺎ ﻟﻢ ﻳﺘﻢ ﺗﻮﻓﻴﺮ ﺣﻤﺎﻳﺔ ﻓﻌﺎﻟﺔ ﺿﺪ ﺍﻟﻤﻞء ﺍﻟﺰﺍﺉﺪ ،ﻳﺠﺐ ﺃﻥ ﺗﺘﻤﺘﻊ ﻓﺘﺤﺔ ﺍﻟﻀﻐﻂ ﺃﻳﻀﺎً ﺑﺴﻌﺔ

ﺳﺎﺉﻠﺔﻛﺎﻓﻴﺔ ﻟﻤﻨﻊ ﺍﻟﻀﻐﻂ ﻣﻦ ﺗﺠﺎﻭﺯ ﺿﻐﻂ ﻗﻴﺎﺱ ﻗﺪﺭﻩ 3ﺭﻃﻞ ﻟﻜﻞ ﺑﻮﺻﺔ ﻣﺮﺑﻌﺔ ) 20.7ﻛﻴﻠﻮ ﺑﺎﺳﻜﺎﻝ(

ﻓﻲﺣﺎﻟﺔ ﺍﻟﻤﻞء ﺍﻟﺰﺍﺉﺪ ﻋﻦ ﻏﻴﺮ ﻗﺼﺪ.

5.3.12.4.2ﻳﺴُﻤﺢ ﺑﺘﺸﻐﻴﻞ ﻓﺘﺤﺔ ﺍﻟﻀﻐﻂ ﻫﺬﻩ ﺑﺎﻟﻀﻐﻂ ﺃﻭ ﺗﺸﺎﺑﻜﻬﺎ ﻣﻊ ﺟﻬﺎﺯ ﺗﺤﻤﻴﻞ ﺍﻟﺨﺰﺍﻥ ﻭﻳﺠﺐ ﺃﻥ

ﺗﻜﻮﻥﻣﺼﻤﻤﺔ ﻟﻤﻨﻊ ﻓﻘﺪﺍﻥ ﺍﻟﺴﺎﺉﻞ ﻣﻦ ﺧﻼﻝ ﻓﺘﺤﺔ ﺍﻟﺘﻬﻮﻳﺔ ﺗﺤﺖ ﺃﻱ ﺣﺎﻟﺔ ﻣﻦ ﺣﺎﻻﺕ ﺍﻧﻘﻼﺏ ﺍﻟﺴﻴﺎﺭﺓ.

5.3.13ﺍﻟﺘﻨﻔﻴﺲ ﻓﻲ ﺣﺎﻻﺕ ﺍﻟﻄﻮﺍﺭﺉ ﻋﻨﺪ ﺍﻟﺘﻌﺮﺽ ﻟﻠﺤﺮﻳﻖ.

5.3.13.1ﻳﺠﺐ ﺃﻻ ﺗﻘﻞ ﺳﻌﺔ ﺗﻨﻔﻴﺲ ﺍﻟﻄﻮﺍﺭﺉ ﺍﻹﺟﻤﺎﻟﻴﺔ ﺑﺎﻟﻘﺪﻡ ﺍﻟﻤﻜﻌﺒﺔ/ﺍﻟﺴﺎﻋﺔ )ﻣﺘﺮ ﻣﻜﻌﺐ/ﺍﻟﺜﺎﻧﻴﺔ(

ﻟﻜﻞﻣﻘﺼﻮﺭﺓ ﺧﺰﺍﻥ ﺑﻀﺎﺉﻊ ﻋﻦ ﺗﻠﻚ ﺍﻟﻤﺤﺪﺩﺓ ﻓﻲ ﺍﻟﺠﺪﻭﻝ .5.3.13.1

ﺍﻟﺠﺪﻭﻝ 5.3.13.1ﺍﻟﺤﺪ ﺍﻷﺩﻧﻰ ﻟﻘﺪﺭﺓ ﺗﻨﻔﻴﺲ ﺍﻟﻄﻮﺍﺭﺉ

ﻣﻌُﺮﺽﻝ

ﻗﺪﺭﺓﺗﻨﻔﻴﺲ ﺍﻟﻬﻮﺍء ﺍﻟﺤﺮ ﻣﻨﻄﻘﺔ ﻗﺪﺭﺓﺗﻨﻔﻴﺲ ﺍﻟﻬﻮﺍء ﺍﻟﺤﺮ ﺍﻟﻤﻨﻄﻘﺔﺍﻟﻤﻜﺸﻮﻓﺔ

)ﻗﺪﻡ/3ﺳﺎﻋﺔ(* )ﻗﺪﻡ(2 )ﻗﺪﻡ/3ﺳﺎﻋﺔ(* )ﻗﺪﻡ(2

214,300 275 15800 20

225,100 300 23,700 30

245,700 350 31,600 40

265,000 400 39,500 50

283,200 450 47,400 60

300,600 500 55,300 70

317,300 550 63,300 80

ﺣﻘﻮﻕﺍﻟﻄﺒﻊ ﻭﺍﻟﻨﺸﺮ NFPA

ﺷﺮﻛﺔﺃﺑﺎﺩﻏﻮﺳﺘﺎﺭ ﺗﺎﺳﻴﺴﺎﺕ ﺇﻳﺮﺍﻧﻴﻨﺎﻥ ﺍﻟﻤﺤﺪﻭﺩﺓ www.atapars.com

www.atapars.com/NFPA-code/

ﺍﻟﺠﺪﻭﻝ 5.3.13.1ﺍﻟﺤﺪ ﺍﻷﺩﻧﻰ ﻟﻘﺪﺭﺓ ﺗﻨﻔﻴﺲ ﺍﻟﻄﻮﺍﺭﺉ

ﻣﻌُﺮﺽﻝ

ﻗﺪﺭﺓﺗﻨﻔﻴﺲ ﺍﻟﻬﻮﺍء ﺍﻟﺤﺮ ﻣﻨﻄﻘﺔ ﻗﺪﺭﺓﺗﻨﻔﻴﺲ ﺍﻟﻬﻮﺍء ﺍﻟﺤﺮ ﺍﻟﻤﻨﻄﻘﺔﺍﻟﻤﻜﺸﻮﻓﺔ

)ﻗﺪﻡ/3ﺳﺎﻋﺔ(* )ﻗﺪﻡ(2 )ﻗﺪﻡ/3ﺳﺎﻋﺔ(* )ﻗﺪﻡ(2

333,300 600 71,200 90

348,800 650 79,100 100

363,700 700 94,900 120

378,200 750 110,700 140

392,200 800 126,500 160

405,900 850 142,300 180

419,300 900 158,100 200

432,300 950 191,300 225

445,000 1000 203,100 250

ﻟﻮﺣﺪﺍﺕ SI، 1ﻗﺪﻡ 0.093 =2ﻡ2؛ 1ﻗﺪﻡ 0.028 =3ﻡ.3

ﻣﻼﺣﻈﺔ:ﺍﺳﺘﻴﻔﺎء ﻟﻸﺣﺠﺎﻡ ﺍﻟﻤﺘﻮﺳﻄﺔ.

ﻋﻨﺪ 14.7ﺭﻃﻞ ﻟﻜﻞ ﺑﻮﺻﺔ ﻣﺮﺑﻌﺔ ) 101.3ﻛﻴﻠﻮ ﺑﺎﺳﻜﺎﻝ( ﻭ 60ﺩﺭﺟﺔ ﻓﻬﺮﻧﻬﺎﻳﺖ ) 15.6ﺩﺭﺟﺔ ﻣﺉﻮﻳﺔ(

*

5.3.13.2ﻳﺠﺐ ﺃﻥ ﺗﻜﻮﻥ ﻛﻞ ﻣﻘﺼﻮﺭﺓ ﻟﺼﻬﺎﺭﻳﺞ ﺍﻟﺒﻀﺎﺉﻊ ﻣﺠﻬﺰﺓ ﺑﻔﺘﺤﺔ ﺃﻭ ﺃﻛﺜﺮ ﻣﻦ ﻓﺘﺤﺎﺕ ﺍﻟﺘﻬﻮﻳﺔ ﺍﻟﺘﻲ ﻳﺘﻢ ﺗﺸﻐﻴﻠﻬﺎ ﺑﺎﻟﻀﻐﻂ ،ﻭﺍﻟﺘﻲ ﻳﺘﻢ

ﻓﺘﺤﻬﺎﻋﻨﺪ ﺿﻐﻂ ﻗﻴﺎﺱ ﻻ ﻳﻘﻞ ﻋﻦ 3ﺭﻃﻞ ﻟﻜﻞ ﺑﻮﺻﺔ ﻣﺮﺑﻌﺔ ) 20.7ﻛﻴﻠﻮ ﺑﺎﺳﻜﺎﻝ( ﻭﺗﻐﻠﻖ ﻋﻨﺪﻣﺎ ﻳﻨﺨﻔﺾ ﺍﻟﻀﻐﻂ ﺇﻟﻰ ﻣﺎ ﺩﻭﻥ ﻧﻘﻄﺔ

ﺍﻟﺘﺤﺪﻳﺪﺍﻟﺒﺎﻟﻐﺔ 3ﺭﻃﻞ ﻟﻜﻞ ﺑﻮﺻﺔ ﻣﺮﺑﻌﺔ ) 20.7ﻛﻴﻠﻮ ﺑﺎﺳﻜﺎﻝ(.

ﻗﺪﻡ3 5.3.13.2.1ﻳﺠﺐ ﺃﻥ ﻳﻜﻮﻥ ﺍﻟﺤﺪ ﺍﻷﺩﻧﻰ ﻟﻘﺪﺭﺓ ﺍﻟﺘﻨﻔﻴﺲ ﻟﻠﻔﺘﺤﺎﺕ ﺍﻟﺘﻲ ﺗﻌﻤﻞ ﺑﺎﻟﻀﻐﻂ 6000

) 170ﻡ (3ﻣﻦ ﺍﻟﻬﻮﺍء ﺍﻟﺤﺮ ﻓﻲ ﺍﻟﺴﺎﻋﺔ ]ﻳﺘﻢ ﻗﻴﺎﺳﻪ ﻓﻲ ﻇﺮﻭﻑ ﻗﻴﺎﺳﻴﺔ ﺗﺒﻠﻎ 14.7ﺭﻃﻞ ﻟﻜﻞ ﺑﻮﺻﺔ ﻣﺮﺑﻌﺔ ) 101.3ﻛﻴﻠﻮ ﺑﺎﺳﻜﺎﻝ( ﻭ 60ﺩﺭﺟﺔ ﻓﻬﺮﻧﻬﺎﻳﺖ )15.6

ﺩﺭﺟﺔﻣﺉﻮﻳﺔ([ ﻋﻨﺪ ﺿﻐﻂ ﻗﻴﺎﺱ ﻳﺒﻠﻎ 5ﺭﻃﻞ ﻟﻜﻞ ﺑﻮﺻﺔ ﻣﺮﺑﻌﺔ ) 35ﻛﻴﻠﻮ ﺑﺎﺳﻜﺎﻝ(.

5.3.13.2.2ﻳﺠﺐ ﺗﺼﻤﻴﻢ ﺍﻷﺟﻬﺰﺓ ﺍﻟﺘﻲ ﺗﻌﻤﻞ ﺑﺎﻟﻀﻐﻂ ﺑﺤﻴﺚ ﺗﻤﻨﻊ ﺗﺴﺮﺏ ﺍﻟﺴﺎﺉﻞ ﻋﺒﺮ ﺍﻟﺠﻬﺎﺯ ﻓﻲ

ﺣﺎﻟﺔﺣﺪﻭﺙ ﺍﺭﺗﻔﺎﻉ ﻣﻔﺎﺟﺊ ﺃﻭ ﺍﺿﻄﺮﺍﺏ ﻓﻲ ﺍﻟﺴﻴﺎﺭﺓ ،ﺇﻻ ﺃﻧﻬﺎ ﻳﺠﺐ ﺃﻥ ﺗﻌﻤﻞ ﻓﻲ ﺣﺎﻟﺔ ﺍﺭﺗﻔﺎﻉ ﺍﻟﻀﻐﻂ

ﻓﻲﺃﻱ ﺣﺎﻟﺔ ﻣﻦ ﺣﺎﻻﺕ ﺍﻧﻘﻼﺏ ﺍﻟﺴﻴﺎﺭﺓ.

5.3.13.3ﻋﻨﺪﻣﺎ ﻻ ﺗﻮﻓﺮ ﺍﻟﺘﻬﻮﻳﺔ ﺍﻟﻤﺸﻐﻠﺔ ﺑﺎﻟﻀﻐﻂ ﺍﻟﻤﻄﻠﻮﺑﺔ ﺑﻤﻮﺟﺐ 5.3.13.2ﺳﻌﺔ ﺍﻟﺘﻨﻔﻴﺲ

ﺍﻹﺟﻤﺎﻟﻴﺔﺍﻟﻤﻄﻠﻮﺑﺔ ﺑﻤﻮﺟﺐ ،5.3.13.1ﻳﺠﺐ ﺗﻮﻓﻴﺮ ﺳﻌﺔ ﺇﺿﺎﻓﻴﺔ ﻋﻦ ﻃﺮﻳﻖ ﺇﺿﺎﻓﺔ ﺃﺟﻬﺰﺓ ﺗﻬﻮﻳﺔ

ﻗﺎﺑﻠﺔﻟﻼﻧﺼﻬﺎﺭ ،ﺗﺒﻠﻎ ﻣﺴﺎﺣﺔ ﻛﻞ ﻣﻨﻬﺎ 1.25ﺑﻮﺻﺔ ﻋﻠﻰ ﺍﻷﻗﻞ 800)2.ﻣﻠﻢ.(2

5.3.13.3.1ﻭﻳﺠﺐ ﺃﻥ ﻳﺘﻢ ﻭﺿﻊ ﻫﺬﻩ ﺍﻟﻌﻨﺎﺻﺮ ﺍﻟﻘﺎﺑﻠﺔ ﻟﻼﻧﺼﻬﺎﺭ ﺑﺤﻴﺚ ﻻ ﺗﺘﻼﻣﺲ ﻣﻊ ﺗﻌﺒﺉﺔ ﺍﻟﺨﺰﺍﻥ

ﻓﻲﻇﻞ ﻇﺮﻭﻑ ﺍﻟﺘﺸﻐﻴﻞ ﺍﻟﻌﺎﺩﻳﺔ.

5.3.13.3.2ﻳﺠﺐ ﺗﺸﻐﻴﻞ ﻓﺘﺤﺔ ﺍﻟﺘﻬﻮﻳﺔ ﺃﻭ ﺍﻟﻔﺘﺤﺎﺕ ﺍﻟﻘﺎﺑﻠﺔ ﻟﻼﻧﺼﻬﺎﺭ ﺑﻮﺍﺳﻄﺔ ﻋﻨﺎﺻﺮ ﺗﻌﻤﻞ ﻋﻨﺪ ﺩﺭﺟﺔ ﺣﺮﺍﺭﺓ ﻻ

ﺗﺘﺠﺎﻭﺯ 250ﺩﺭﺟﺔ ﻓﻬﺮﻧﻬﺎﻳﺖ ) 120ﺩﺭﺟﺔ ﻣﺉﻮﻳﺔ(.

5.3.13.3.3ﻳﺠﺐ ﺃﻥ ﻳﺘﻢ ﺗﻘﻴﻴﻢ ﻗﺪﺭﺓ ﺍﻟﺘﻨﻔﻴﺲ ﻟﻬﺬﻩ ﺍﻷﺟﻬﺰﺓ ﻋﻨﺪ ﺿﻐﻂ ﻗﻴﺎﺱ ﻻ ﻳﺰﻳﺪ ﻋﻦ 5ﺭﻃﻞ ﻟﻜﻞ ﺑﻮﺻﺔ

ﻣﺮﺑﻌﺔ) 35ﻛﻴﻠﻮ ﺑﺎﺳﻜﺎﻝ(.

5.3.13.3.4ﻳﺠﺐ ﺍﺳﺘﺨﺪﺍﻡ ﺟﻬﺎﺯﻳﻦ ﻋﻠﻰ ﺍﻷﻗﻞ ﻣﻦ ﻫﺬﺍ ﺍﻟﻨﻮﻉ ﻓﻲ ﺃﻱ ﺧﺰﺍﻥ ﺑﻀﺎﺉﻊ ﺃﻭ ﺣﺠﺮﺓ ﺧﺰﺍﻥ ﺗﺰﻳﺪ

ﺳﻌﺘﻬﺎﻋﻦ 2500ﺟﺎﻟﻮﻥ ) 9500ﻟﺘﺮ(.

5.3.13.3.5ﻭﻳﺠﺐ ﻭﺿﻊ ﺟﻬﺎﺯ ﻭﺍﺣﺪ ﻋﻠﻰ ﺍﻷﻗﻞ ﺑﺎﻟﻘﺮﺏ ﻣﻦ ﻃﺮﻓﻲ ﺧﺰﺍﻥ ﺍﻟﺒﻀﺎﺉﻊ ﺃﻭ ﺣﺠﺮﺓ ﺍﻟﺨﺰﺍﻥ.

*5.3.13.4ﻳﺠﺐ ﺍﺧﺘﺒﺎﺭ ﺍﻟﺘﺪﻓﻖ ﻟﻜﻞ ﻧﻮﻉ ﻭﺣﺠﻢ ﻟﺠﻬﺎﺯ ﺍﻟﺘﻨﻔﻴﺲ ﻓﻲ ﺍﻟﻨﻄﺎﻕ ﺍﻟﻤﺤﺪﺩ ﻓﻲ ﺣﻘﻮﻕ ﺍﻟﻄﺒﻊ

ﻭﺍﻟﻨﺸﺮNFPA

ﺷﺮﻛﺔﺃﺑﺎﺩﻏﻮﺳﺘﺎﺭ ﺗﺎﺳﻴﺴﺎﺕ ﺇﻳﺮﺍﻧﻴﻨﺎﻥ ﺍﻟﻤﺤﺪﻭﺩﺓ www.atapars.com

www.atapars.com/NFPA-code/

5.3.13.1ﺣﺘﻰ .5.3.13.3

5.3.13.4.1ﻗﺪﺭﺓ ﺍﻟﺘﺪﻓﻖ ﺍﻟﻔﻌﻠﻴﺔ ﺍﻟﻤﻘﺪﺭﺓ ﻟﻠﻔﺘﺤﺔ ،ﺑﺎﻟﻘﺪﻡ ﺍﻟﻤﻜﻌﺐ )ﻗﺪﻡ] (3ﻣﺘﺮ ﻣﻜﻌﺐ )ﻡ [(3ﻣﻦ ﺍﻟﻬﻮﺍء

ﺍﻟﺤﺮﻓﻲ ﺍﻟﺴﺎﻋﺔ ﻋﻨﺪ ﻗﻴﺎﺱ ﺍﻟﻀﻐﻂ ﺑﺎﻟﺠﻨﻴﻪ ﻟﻜﻞ ﺑﻮﺻﺔ ﻣﺮﺑﻌﺔ )] (psiﻛﻴﻠﻮﺑﺎﺳﻜﺎﻝ ) [(kPaﺍﻟﺬﻱ ﻳﺘﻢ

ﻋﻨﺪﻩﺗﺤﺪﻳﺪ ﺳﻌﺔ ﺍﻟﺘﺪﻓﻖ ،ﻳﺠﺐ ﺃﻥ ﻳﺘﻢ ﺧﺘﻤﻪ ﻋﻠﻰ ﺍﻟﺠﻬﺎﺯ.

5.3.13.4.2ﻳﺠﺐ ﺃﻥ ﻳﺘﻢ ﺗﺤﺪﻳﺪ ﻣﻌﺪﻝ ﺗﺪﻓﻖ ﻓﺘﺤﺔ ﺍﻟﺘﻬﻮﻳﺔ ﺃﻭ ﺍﻟﻔﺘﺤﺎﺕ ﺍﻟﻘﺎﺑﻠﺔ ﻟﻼﻧﺼﻬﺎﺭ ﻋﻨﺪ ﻓﺮﻕ ﻗﺪﺭﻩ 5ﺭﻃﻞ ﻟﻜﻞ ﺑﻮﺻﺔ ﻣﺮﺑﻌﺔ ) 35ﻛﻴﻠﻮ

ﺑﺎﺳﻜﺎﻝ(.

5.3.13.4.3ﻳﺴُﻤﺢ ﺑﺈﺟﺮﺍء ﺍﺧﺘﺒﺎﺭﺍﺕ ﺍﻟﺘﺪﻓﻖ ﻣﻦ ﻗﺒﻞ ﺍﻟﺸﺮﻛﺔ ﺍﻟﻤﺼﻨﻌﺔ ،ﺇﺫﺍ ﺗﻢ ﺍﻋﺘﻤﺎﺩﻫﺎ ﻣﻦ ﻗﺒﻞ

ﻣﺮﺍﻗﺐﻣﺤﺎﻳﺪ ﻣﺆﻫﻞ ،ﺃﻭ ﺗﻢ ﺗﻔﻮﻳﻀﻬﺎ ﺇﻟﻰ ﻭﻛﺎﻟﺔ ﺧﺎﺭﺟﻴﺔ.

5.4ﺍﻟﺘﺤﻜﻢ ﻓﻲ ﺍﻟﺘﻔﺮﻳﻎ ﻓﻲ ﺣﺎﻻﺕ ﺍﻟﻄﻮﺍﺭﺉ.

5.4.1ﺍﻟﺴﻮﺍﺉﻞ ﺫﺍﺕ ﺍﻟﻠﺰﻭﺟﺔ ﺃﻗﻞ ﻣﻦ 45ﻭﺣﺪﺓ ﻗﻴﺎﺳﻴﺔ ﺳﺎﻳﺒﻮﻟﺖ ).(SUS

*5.4.1.1ﻳﺠﺐ ﺃﻥ ﻳﻜﻮﻥ ﻛﻞ ﻣﻨﻔﺬ ﻟﺨﺰﺍﻥ ﺍﻟﺒﻀﺎﺉﻊ ﺃﻭ ﺍﻟﺤﺠﺮﺓ ﺍﻟﻤﺴﺘﺨﺪﻣﺔ ﻟﻨﻘﻞ ﺳﻮﺍﺉﻞ ﺍﻟﻔﺉﺔ ﺍﻷﻭﻟﻰ

ﻭﺍﻟﺸﺎﺣﻨﺎﺕﺍﻟﺘﻲ ﻳﺘﻢ ﺑﻨﺎﺅﻫﺎ ﻓﻴﻤﺎ ﺑﻌﺪ ﻟﻨﻘﻞ ﺳﻮﺍﺉﻞ ﺍﻟﻔﺉﺘﻴﻦ IIﻭ ،IIIAﻭﺍﻟﺘﻲ ﺗﺘﻤﺘﻊ ﺑﻠﺰﻭﺟﺔ ﺃﻗﻞ ﻣﻦ

SUS45ﻋﻨﺪ 100ﺩﺭﺟﺔ ﻓﻬﺮﻧﻬﺎﻳﺖ ) 37.8ﺩﺭﺟﺔ ﻣﺉﻮﻳﺔ( ،ﻣﺰﻭﺩﺍً ﺑـ ﺻﻤﺎﻡ ﺇﻏﻼﻕ ﺫﺍﺗﻲ ﺗﻢ ﺗﺼﻤﻴﻤﻪ

ﻭﺗﺮﻛﻴﺒﻪﻭﺗﺸﻐﻴﻠﻪ ﻟﻀﻤﺎﻥ ﻋﺪﻡ ﺍﻟﻬﺮﻭﺏ ﺍﻟﻌﺮﺿﻲ ﻟﻠﻤﺤﺘﻮﻳﺎﺕ.

5.4.1.2ﻳﺠﺐ ﺃﻥ ﻳﻜﻮﻥ ﺻﻤﺎﻡ ﺍﻹﻏﻼﻕ ﺩﺍﺧﻞ ﺍﻟﺨﺰﺍﻥ ﺃﻭ ﻋﻨﺪ ﻧﻘﻄﺔ ﺧﺎﺭﺝ ﺍﻟﺨﺰﺍﻥ ﺣﻴﺚ ﻳﺪﺧﻞ ﺍﻟﺨﻂ ﺃﻭ

ﻳﺨﺮﺝﻣﻦ ﺍﻟﺨﺰﺍﻥ.

5.4.1.3ﻳﺠﺐ ﺃﻥ ﻳﻜﻮﻥ ﻣﻘﻌﺪ ﺍﻟﺼﻤﺎﻡ ﻣﻮﺟﻮﺩﺍً ﺩﺍﺧﻞ ﺍﻟﺨﺰﺍﻥ ﺃﻭ ﺩﺍﺧﻞ ﺍﻟﺤﺎﻓﺔ ﺍﻟﻤﻠﺤﻮﻣﺔ ﺃﻭ ﺍﻟﺤﺎﻓﺔ

ﺍﻟﻤﺼﺎﺣﺒﺔﻟﻪ ﺃﻭ ﺍﻟﻔﻮﻫﺔ ﺃﻭ ﺃﺩﺍﺓ ﺍﻟﺘﻮﺻﻴﻞ ،ﻭﻳﺠﺐ ﺃﻥ ﻳﻜﻮﻥ ﻣﺼﻤﻤﺎً ﺑﺤﻴﺚ ﻳﺠﺐ ﺃﻥ ﻳﺒﻘﻰ ﺍﻟﺼﻤﺎﻡ

ﻣﻐﻠﻘﺎًﺇﻻ ﺃﺛﻨﺎء ﻋﻤﻠﻴﺎﺕ ﺍﻟﺘﺤﻤﻴﻞ ﻭﺍﻟﺘﻔﺮﻳﻎ.

5.4.1.4ﻳﺠﺐ ﺃﻥ ﺗﺰﻭﺩ ﺁﻟﻴﺔ ﺗﺸﻐﻴﻞ ﺍﻟﺼﻤﺎﻡ ﺑﺠﻬﺎﺯ ﺗﺤﻜﻢ ﺛﺎﻧﻮﻱ ،ﺑﻌﻴﺪ ﻋﻦ ﻓﺘﺤﺎﺕ ﺍﻟﺘﻌﺒﺉﺔ ﻭﻭﺻﻼﺕ

ﺍﻟﺘﻔﺮﻳﻎ،ﻻﺳﺘﺨﺪﺍﻣﻪ ﻓﻲ ﺣﺎﻟﺔ ﻭﻗﻮﻉ ﺣﻮﺍﺩﺙ ﺃﻭ ﺣﺮﻳﻖ ﺃﺛﻨﺎء ﻋﻤﻠﻴﺎﺕ ﺍﻟﺘﺴﻠﻴﻢ.

5.4.1.5ﻳﺠﺐ ﺃﻥ ﺗﺰﻭﺩ ﺁﻟﻴﺔ ﺍﻟﺘﺤﻜﻢ ﺑﻌﻨﺼﺮ ﻗﺎﺑﻞ ﻟﻼﻧﺼﻬﺎﺭ ﻭﺍﺣﺪ ﻋﻠﻰ ﺍﻷﻗﻞ ﻳﺼﺒﺢ ﻓﻌﺎﻻ ًﻋﻨﺪ ﺩﺭﺟﺔ

ﺣﺮﺍﺭﺓﻻ ﺗﺰﻳﺪ ﻋﻦ 250ﺩﺭﺟﺔ ﻓﻬﺮﻧﻬﺎﻳﺖ ) 120ﺩﺭﺟﺔ ﻣﺉﻮﻳﺔ( ،ﻣﻤﺎ ﻳﺴﻤﺢ ﻟﻠﺼﻤﺎﻡ ﺑﺎﻹﻏﻼﻕ ﺗﻠﻘﺎﺉﻴﺎً

ﻓﻲﺣﺎﻟﺔ ﻧﺸﻮﺏ ﺣﺮﻳﻖ.

5.4.1.5.1ﻳﺠﺐ ﺃﻥ ﻳﻜﻮﻥ ﻫﻨﺎﻙ ﻋﻨﺼﺮ ﻭﺍﺣﺪ ﻗﺎﺑﻞ ﻟﻼﻧﺼﻬﺎﺭ ﻋﻠﻰ ﺍﻷﻗﻞ ﻓﻲ ﺍﻟﻌﺮﺍء ﺣﻴﺚ ﻗﺪ ﻳﺘﻌﺮﺽ

ﻟﺤﺮﺍﺭﺓﺍﻟﻨﺎﺭ ﺃﺳﻔﻞ ﺍﻟﺴﻴﺎﺭﺓ.

5.4.1.6ﻳﺠﺐ ﺃﻥ ﻳﺘﻢ ﺗﺰﻭﻳﺪ ﻛﻞ ﺻﻤﺎﻡ ﺇﻏﻼﻕ ﺑﻘﺴﻢ ﻗﺺ ،ﻳﻘﻊ ﺧﺎﺭﺝ ﻛﻞ ﻣﻘﻌﺪ ﺻﻤﺎﻡ ﻃﻮﺍﺭﺉ ﻭﻋﻠﻰ

ﻣﺴﺎﻓﺔ 4ﺑﻮﺻﺎﺕ ) 100ﻣﻢ( ﻣﻦ ﺍﻟﻮﻋﺎء ،ﻭﺍﻟﺬﻱ ﺳﻴﻨﻜﺴﺮ ﺗﺤﺖ ﺍﻟﻀﻐﻂ ﻭﻳﺘﺮﻙ ﻣﻘﻌﺪ ﺻﻤﺎﻡ ﺍﻟﻄﻮﺍﺭﺉ

ﻭﻣﻠﺤﻘﻪﺑﺎﻟﺴﻔﻴﻨﺔ ﻭ ﺭﺃﺱ ﺍﻟﺼﻤﺎﻡ ﺳﻠﻴﻢ ﻭﻗﺎﺩﺭ ﻋﻠﻰ ﺍﻻﺣﺘﻔﺎﻅ ﺑﺎﻟﻤﻨﺘﺞ.

5.4.1.6.1ﻳﺠﺐ ﺃﻥ ﻳﺘﻢ ﺗﺸﻜﻴﻞ ﻗﺴﻢ ﺍﻟﻘﺺ ﺑﻄﺮﻳﻘﺔ ﺗﻘﻠﻞ ﺑﺸﻜﻞ ﻣﻔﺎﺟﺊ ﺳﻤﺎﻛﺔ ﺟﺪﺍﺭ ﻣﺎﺩﺓ

ﺍﻷﻧﺎﺑﻴﺐ)ﺃﻭ ﺍﻟﺼﻤﺎﻡ( ﺍﻟﻤﺠﺎﻭﺭﺓ ﺑﻨﺴﺒﺔ 20ﺑﺎﻟﻤﺎﺉﺔ ﻋﻠﻰ ﺍﻷﻗﻞ.

5.4.2ﺳﻮﺍﺉﻞ ﺫﺍﺕ ﻟﺰﻭﺟﺔ SUS 45ﺃﻭ ﺃﻛﺜﺮ.ﻳﺠﺐ ﺃﻥ ﻳﻜﻮﻥ ﻛﻞ ﻣﻨﻔﺬ ﻟﺨﺰﺍﻥ ﺍﻟﺒﻀﺎﺉﻊ ﺃﻭ ﺍﻟﺤﺠﺮﺓ

ﺍﻟﻤﺴﺘﺨﺪﻣﺔﻟﻨﻘﻞ ﺍﻟﺴﻮﺍﺉﻞ ﺍﻟﺘﻲ ﺗﺒﻠﻎ ﻟﺰﻭﺟﺘﻬﺎ SUS 45ﺃﻭ ﺃﻛﺜﺮ ﻋﻨﺪ 100ﺩﺭﺟﺔ ﻓﻬﺮﻧﻬﺎﻳﺖ ) 37.8ﺩﺭﺟﺔ

ﻣﺉﻮﻳﺔ( ﻣﺠﻬﺰﺍً ﺑﺄﺣﺪ ﻣﺎ ﻳﻠﻲ:

) (1ﺻﻤﺎﻡ ﺇﻏﻼﻕ ﻣﻨﺎﺳﺐ ،ﻣﻮﺟﻮﺩ ﺩﺍﺧﻠﻴﺎً ،ﻭﻣﺼﻤﻢ ﺑﺤﻴﺚ ﻳﻈﻞ ﺍﻟﺼﻤﺎﻡ ﺧﺎﺿﻌﺎً ﻟﺤﻘﻮﻕ ﺍﻟﻄﺒﻊ

ﻭﺍﻟﻨﺸﺮNFPA

ﺷﺮﻛﺔﺃﺑﺎﺩﻏﻮﺳﺘﺎﺭ ﺗﺎﺳﻴﺴﺎﺕ ﺇﻳﺮﺍﻧﻴﻨﺎﻥ ﺍﻟﻤﺤﺪﻭﺩﺓ www.atapars.com

www.atapars.com/NFPA-code/

ﻳﻤﻜﻦﺗﺸﻐﻴﻠﻪ ﺇﺫﺍ ﺗﻢ ﻗﻄﻊ ﺍﻻﺗﺼﺎﻝ ﺍﻟﺨﺎﺭﺟﻲ

) (2ﺻﻤﺎﻡ ﻣﺜﺒﺖ ﻋﻠﻰ ﺍﻟﺮﺃﺱ ﺍﻷﻣﺎﻣﻲ ﺃﻭ ﺍﻟﺨﻠﻔﻲ ﻣﻌﺰﺯ ﺑﺸﻜﻞ ﺁﻣﻦ ﻭﻣﺤﻤﻲ ﺿﺪ ﺍﻟﺼﺪﻣﺎﺕ ﺃﻭ ﻣﺨﺎﻃﺮ

ﺍﻟﻄﺮﻳﻖ

5.5ﺍﻻﺧﺘﺒﺎﺭﺍﺕ.

5.5.1ﻓﻲ ﻭﻗﺖ ﺍﻟﺘﺼﻨﻴﻊ ،ﻳﺠﺐ ﺍﺧﺘﺒﺎﺭ ﻛﻞ ﺧﺰﺍﻥ ﺑﻀﺎﺉﻊ ﻋﻦ ﻃﺮﻳﻖ ﺍﻟﻬﻮﺍء ﺃﻭ ﺍﻟﻬﻴﺪﺭﻭﺳﺘﺎﺗﻴﻜﻲ ﺇﻟﻰ ﺣﺪ ﺃﺩﻧﻰ

ﻣﻦﺍﻟﻀﻐﻂ ﻗﺪﺭﻩ 3ﺭﻃﻞ ﻟﻜﻞ ﺑﻮﺻﺔ ﻣﺮﺑﻌﺔ ) 20.7ﻛﻴﻠﻮ ﺑﺎﺳﻜﺎﻝ( ﺃﻭ ﻋﻠﻰ ﺍﻷﻗﻞ ﻣﺴﺎﻭ ٍﻟﻠﻀﻐﻂ ﺍﻟﺘﺼﻤﻴﻤﻲ

ﻟﻠﺨﺰﺍﻥ،ﺃﻳﻬﻤﺎ ﺃﻛﺒﺮ.

5.5.1.1ﻭﻓﻲ ﺣﺎﻟﺔ ﺗﻘﺴﻴﻤﻬﺎ ﺇﻟﻰ ﺃﻗﺴﺎﻡ ،ﻳﺠﺐ ﺍﺧﺘﺒﺎﺭ ﻛﻞ ﺣﺠﺮﺓ ﻋﻠﻰ ﺣﺪﺓ ﺑﺎﻟﻤﺜﻞ ﻣﻊ ﺟﻌﻞ

ﺍﻟﺤﺠﻴﺮﺍﺕﺍﻟﻤﺠﺎﻭﺭﺓ ﻓﺎﺭﻏﺔ ﻭﺗﺤﺖ ﺿﻐﻂ ﺟﻮﻱ.

5.5.1.2ﻳﺠﺐ ﺃﻥ ﻳﺘﻢ ﺍﻻﺣﺘﻔﺎﻅ ﺑﻀﻐﻂ ﺍﻟﻬﻮﺍء ،ﻓﻲ ﺣﺎﻟﺔ ﺍﺳﺘﺨﺪﺍﻣﻪ ،ﻟﻤﺪﺓ ﻻ ﺗﻘﻞ ﻋﻦ 5ﺩﻗﺎﺉﻖ ﻳﺘﻢ

ﺧﻼﻟﻬﺎﻃﻼء ﻛﺎﻣﻞ ﺳﻄﺢ ﺟﻤﻴﻊ ﺍﻟﻮﺻﻼﺕ ﺗﺤﺖ ﺍﻟﻀﻐﻂ ﺑﻤﺤﻠﻮﻝ ﻣﻦ ﺍﻟﺼﺎﺑﻮﻥ ﻭﺍﻟﻤﺎء ﺃﻭ ﺍﻟﺰﻳﺖ ﺍﻟﺜﻘﻴﻞ ﺃﻭ

ﺃﻱﻣﺎﺩﺓ ﺃﺧﺮﻯ ﻣﻨﺎﺳﺒﺔ ﻟﻐﺮﺽ ﺍﻟﺮﻏﻮﺓ .ﺃﻭ ﻓﻘﺎﻋﺘﻬﺎ ﻣﻤﺎ ﻳﺪﻝ ﻋﻠﻰ ﻭﺟﻮﺩ ﺗﺴﺮﺑﺎﺕ.

5.5.1.3ﻳﺠﺐ ﺃﻥ ﻳﺘﻢ ﺍﻟﻀﻐﻂ ﺍﻟﻬﻴﺪﺭﻭﺳﺘﺎﺗﻴﻜﻲ ،ﻓﻲ ﺣﺎﻟﺔ ﺍﺳﺘﺨﺪﺍﻣﻪ ،ﺑﺎﺳﺘﺨﺪﺍﻡ ﺍﻟﻤﺎء ﺃﻭ ﺳﺎﺉﻞ ﺁﺧﺮ ﻟﻪ

ﻟﺰﻭﺟﺔﻣﻤﺎﺛﻠﺔ ،ﻭﻳﺠﺐ ﺃﻻ ﺗﺘﺠﺎﻭﺯ ﺩﺭﺟﺔ ﺣﺮﺍﺭﺗﻪ 100ﺩﺭﺟﺔ ﻓﻬﺮﻧﻬﺎﻳﺖ ) 37.8ﺩﺭﺟﺔ ﻣﺉﻮﻳﺔ( ﺃﺛﻨﺎء ﺍﻻﺧﺘﺒﺎﺭ،

ﻭﺗﻄﺒﻴﻖﺍﻟﻀﻐﻂ ﻋﻠﻰ ﺍﻟﻨﺤﻮ ﺍﻟﻤﻨﺼﻮﺹ ﻋﻠﻴﻪ ﻓﻲ 5.5.1ﺇﻟﻰ ،1.2. 5.5ﻳﺘﻢ ﻗﻴﺎﺳﻬﺎ ﻓﻲ ﺃﻋﻠﻰ ﺍﻟﺨﺰﺍﻥ،

ﻭﺣﻴﻨﻬﺎﻳﺠﺐ ﻓﺤﺺ ﺟﻤﻴﻊ ﺍﻟﻮﺻﻼﺕ ﺗﺤﺖ ﺍﻟﻀﻐﻂ ﻟﺨﺮﻭﺝ ﺍﻟﺴﺎﺉﻞ ﻟﻠﺪﻻﻟﺔ ﻋﻠﻰ ﺍﻟﺘﺴﺮﺑﺎﺕ.

5.5.1.4ﻳﺠﺐ ﺃﻥ ﺗﻜﻮﻥ ﺟﻤﻴﻊ ﻋﻤﻠﻴﺎﺕ ﺍﻹﻏﻼﻕ ﻓﻲ ﻣﻜﺎﻧﻬﺎ ﺃﺛﻨﺎء ﺇﺟﺮﺍء ﺍﻻﺧﺘﺒﺎﺭ ﺑﺄﻱ ﻣﻦ ﺍﻟﻄﺮﻳﻘﺘﻴﻦ.

5.5.1.5ﺃﺛﻨﺎء ﻫﺬﻩ ﺍﻻﺧﺘﺒﺎﺭﺍﺕ ،ﻳﺠﺐ ﺗﺜﺒﻴﺖ ﺃﺟﻬﺰﺓ ﺍﻟﺘﻨﻔﻴﺲ ﺍﻟﺠﺮﺍﺣﻴﺔ ﺃﻭ ﺗﻮﺻﻴﻠﻬﺎ ﺃﻭ ﺟﻌﻠﻬﺎ ﻏﻴﺮ

ﺻﺎﻟﺤﺔﻟﻠﻌﻤﻞ؛ ﻭﻳﺠﺐ ﺇﺯﺍﻟﺔ ﻫﺬﻩ ﺍﻟﻤﺸﺎﺑﻚ ﻭﺍﻟﻤﻘﺎﺑﺲ ﻭﺍﻷﺟﻬﺰﺓ ﺍﻟﻤﻤﺎﺛﻠﺔ ﻓﻮﺭ ﺍﻧﺘﻬﺎء ﺍﻻﺧﺘﺒﺎﺭ.

5.5.2ﻳﺠﺐ ﺗﻜﺮﺍﺭ ﺍﻻﺧﺘﺒﺎﺭ ﺍﻟﻮﺍﺭﺩ ﻓﻲ 5.5.1ﺑﻌﺪ ﺇﺟﺮﺍء ﺍﻟﺘﻌﺪﻳﻼﺕ ﺃﻭ ﺍﻹﺻﻼﺣﺎﺕ ﺍﻟﺘﻲ ﺗﺘﻌﻠﻖ ﺑﺴﻼﻣﺔ

ﺍﻟﺨﺰﺍﻥ.

5.5.2.1ﻓﻲ ﺣﺎﻟﺔ ﻭﺟﻮﺩ ﺃﻱ ﺗﺴﺮﺏ ﺃﻭ ﺗﺸﻮﻳﻪ ﻻ ﻣﺒﺮﺭ ﻟﻪ ،ﺃﻭ ﻓﻲ ﺣﺎﻟﺔ ﺣﺪﻭﺙ ﻋﻄﻞ ﻭﺷﻴﻚ ،ﻻ ﻳﺠﻮﺯ ﻭﺿﻊ

ﺧﺰﺍﻥﺍﻟﺒﻀﺎﺉﻊ ﻓﻲ ﺍﻟﺨﺪﻣﺔ ﻣﺎ ﻟﻢ ﻳﺘﻢ ﺇﺟﺮﺍء ﺍﻹﺻﻼﺡ ﺍﻟﻤﻨﺎﺳﺐ.

5.5.2.2ﻳﺘﻢ ﺗﺤﺪﻳﺪ ﻣﺪﻯ ﻛﻔﺎﻳﺔ ﺍﻹﺻﻼﺡ ﺑﻨﻔﺲ ﻃﺮﻳﻘﺔ ﺍﻻﺧﺘﺒﺎﺭ.

5.6ﺍﻟﻔﺼﻞ ﻟﻤﻨﻊ ﺍﻻﺧﺘﻼﻁ.

ﻳﺠﺐﺃﻥ ﺗﺰﻭﺩ ﻣﺮﻛﺒﺎﺕ ﺍﻟﺼﻬﺎﺭﻳﺞ ﺍﻟﻤﺼﻤﻤﺔ ﻟﻨﻘﻞ ﺳﺎﺉﻞ ﺍﻟﻔﺉﺔ ﺍﻷﻭﻟﻰ ﻓﻲ ﺣﺠﺮﺓ ﻭﺍﺣﺪﺓ ﺃﻭ ﺃﻛﺜﺮ

ﻭﺳﻮﺍﺉﻞﺍﻟﻔﺉﺔ ﺍﻟﺜﺎﻧﻴﺔ ﺃﻭ ﺍﻟﺜﺎﻟﺜﺔ ﻓﻲ ﺣﺠﻴﺮﺓ ﺃﻭ ﺣﺠﻴﺮﺍﺕ ﺃﺧﺮﻯ ﺃﻭ ﻟﻨﻘﻞ ﺍﻟﺴﻮﺍﺉﻞ ﻏﻴﺮ ﺍﻟﻤﺘﻮﺍﻓﻘﺔ

ﻛﻴﻤﻴﺎﺉﻴﺎًﺑﺤﻮﺍﺟﺰ ﻣﺰﺩﻭﺟﺔ ،ﻭﻳﺠﺐ ﺃﻥ ﺗﻜﻮﻥ ﻣﺠﻬﺰﺓ ﺑﺄﻧﺎﺑﻴﺐ ﻭﻣﻀﺨﺎﺕ ﻭﻋﺪﺍﺩﺍﺕ ﻭﺃﻧﺎﺑﻴﺐ ﻣﻨﻔﺼﻠﺔ

ﺧﺮﺍﻃﻴﻢﻟﻤﺜﻞ ﻫﺬﻩ ﺍﻟﻔﺉﺎﺕ ﻣﻦ ﺍﻟﻤﻨﺘﺠﺎﺕ.

5.7ﺍﻹﺿﺎءﺓ.

5.7.1ﻳﺠﺐ ﺃﻥ ﺗﺘﻤﺘﻊ ﺩﻭﺍﺉﺮ ﺍﻹﺿﺎءﺓ ﺑﺤﻤﺎﻳﺔ ﻣﻨﺎﺳﺒﺔ ﻣﻦ ﺍﻟﺘﻴﺎﺭ ﺍﻟﺰﺍﺉﺪ )ﺍﻟﺼﻤﺎﻣﺎﺕ ﺃﻭ ﻗﻮﺍﻃﻊ ﺍﻟﺪﺍﺉﺮﺓ

ﺍﻷﻭﺗﻮﻣﺎﺗﻴﻜﻴﺔ(.

5.7.2ﻳﺠﺐ ﺃﻥ ﺗﺘﻤﺘﻊ ﺍﻷﺳﻼﻙ ﺑﻘﺪﺭﺓ ﺣﻤﻞ ﻛﺎﻓﻴﺔ ﻭﻗﻮﺓ ﻣﻴﻜﺎﻧﻴﻜﻴﺔ

ﺣﻘﻮﻕﺍﻟﻄﺒﻊ ﻭﺍﻟﻨﺸﺮ NFPA

ﺷﺮﻛﺔﺃﺑﺎﺩﻏﻮﺳﺘﺎﺭ ﺗﺎﺳﻴﺴﺎﺕ ﺇﻳﺮﺍﻧﻴﻨﺎﻥ ﺍﻟﻤﺤﺪﻭﺩﺓ www.atapars.com

www.atapars.com/NFPA-code/

ﻣﺆﻣﻨﺔﻭﻣﻌﺰﻭﻟﺔ ﻭﻣﺤﻤﻴﺔ ﻣﻦ ﺍﻷﺿﺮﺍﺭ ﺍﻟﻤﺎﺩﻳﺔ ،ﺑﻤﺎ ﻳﺘﻤﺎﺷﻰ ﻣﻊ ﺍﻟﻤﻤﺎﺭﺳﺎﺕ ﺍﻟﺠﻴﺪﺓ ﺍﻟﻤﻌﺘﺮﻑ ﺑﻬﺎ.

ﺝ ﻣﺮﻛﺒﺎﺕﺧﺰﺍﻥ ﺍﻷﺳﻔﻠﺖ hapter 6

6.1ﻋﺎﻡ.

ﻳﺠﺐﺃﻥ ﺗﻜﻮﻥ ﺻﻬﺎﺭﻳﺞ ﺍﻟﺒﻀﺎﺉﻊ ﺧﺎﻟﻴﺔ ﻣﻦ ﺍﻟﻤﺎء ﺃﻭ ﺍﻟﺴﻮﺍﺉﻞ ﺍﻟﻤﺘﻄﺎﻳﺮﺓ ﻗﺒﻞ ﺗﺤﻤﻴﻠﻬﺎ ﺑﺎﻹﺳﻔﻠﺖ ﺍﻟﺴﺎﺧﻦ.

6.2ﻓﺘﺤﺎﺕ ﺻﻬﺎﺭﻳﺞ ﺍﻟﺒﻀﺎﺉﻊ ﻓﻲ ﺧﺪﻣﺔ ﺍﻷﺳﻔﻠﺖ.

6.2.1ﻳﺠﺐ ﺃﻥ ﻳﺘﻢ ﺗﺰﻭﻳﺪ ﻛﻞ ﺧﺰﺍﻥ ﺑﻀﺎﺉﻊ ﻳﺴﺘﺨﺪﻡ ﻓﻲ ﺧﺪﻣﺔ ﺍﻷﺳﻔﻠﺖ ﺑﻔﺘﺤﺔ ﺗﻬﻮﻳﺔ ﺫﺍﺕ

ﻓﺘﺤﺔﻓﻌﺎﻟﺔ ﺗﻌﺎﺩﻝ ﻋﻠﻰ ﺍﻷﻗﻞ ﺃﻧﺒﻮﺑﺎً ﺍﺳﻤﻴﺎً ﻳﺒﻠﻎ ﻗﻄﺮﻩ 2ﺑﻮﺻﺔ ) 50ﻣﻢ(.

6.2.2ﻳﺠﺐ ﺗﺰﻭﻳﺪ ﻛﻞ ﺧﺰﺍﻥ ﺑﻀﺎﺉﻊ ﻟﺨﺪﻣﺔ ﺍﻷﺳﻔﻠﺖ ﺑﻔﺘﺤﺔ ﺫﺍﺕ ﻓﺘﺤﺔ ﺣﺮﺓ ﻻ ﻳﻘﻞ ﻗﻄﺮﻫﺎ ﻋﻦ 15

ﺑﻮﺻﺔ) 375ﻣﻠﻢ( ﻣﺼﻤﻤﺔ ﻟﺘﺨﻔﻴﻒ ﺍﻟﻀﻐﻂ ﺍﻟﺪﺍﺧﻠﻲ ﻋﻨﺪ ﺿﻐﻂ ﻗﻴﺎﺱ ﻳﺘﺮﺍﻭﺡ ﺑﻴﻦ 2ﻭ 3ﺭﻃﻞ ﻟﻜﻞ

ﺑﻮﺻﺔﻣﺮﺑﻌﺔ )ﺑﻴﻦ 13.8ﻭ 20.7ﻛﻴﻠﻮ ﺑﺎﺳﻜﺎﻝ( ﺃﻭ ﺟﻬﺎﺯ ﺍﻹﻏﺎﺛﺔ ﺍﻟﻤﻜﺎﻓﺊ.

6.3ﺍﻟﻔﻴﻀﺎﻧﺎﺕ ﻭﺍﻟﻤﺼﺎﺭﻑ ﻟﻤﺮﻛﺒﺎﺕ ﺻﻬﺎﺭﻳﺞ ﺍﻷﺳﻔﻠﺖ.

6.3.1ﻳﺠﺐ ﺗﻮﻓﻴﺮ ﺍﻟﺤﻤﺎﻳﺔ ﻣﻦ ﺍﻟﻔﺎﺉﺾ ﻟﻤﺮﻛﺒﺎﺕ ﺍﻟﺼﻬﺎﺭﻳﺞ ﺍﻹﺳﻔﻠﺘﻴﺔ ﻋﻠﻰ ﺷﻜﻞ ﺧﺰﺍﻧﺎﺕ ﺃﻭ

ﻭﻣﻴﺾﺣﻮﻝ ﺃﻧﺎﺑﻴﺐ ﺍﻟﺘﻌﺒﺉﺔ ﻭﺍﻟﺘﻬﻮﻳﺔ.

6.3.2ﻳﺠﺐ ﺃﻥ ﻳﻜﻮﻥ ﺳﻤﻚ ﺃﻧﺎﺑﻴﺐ ﺍﻟﻔﺎﺉﺾ ﻭﺍﻟﺼﺮﻑ ﺃﺛﻘﻞ ﻣﻦ ﻫﻴﻜﻞ ﺍﻟﺨﺰﺍﻥ ﻭﻳﺠﺐ ﺃﻥ ﺗﻜﻮﻥ ﻣﺼﻤﻤﺔ

ﺑﺤﻴﺚﻻ ﻳﻨﺴﻜﺐ ﺍﻷﺳﻔﻠﺖ ﺍﻟﺴﺎﺧﻦ ﻋﻠﻰ ﺍﻹﻃﺎﺭﺍﺕ ﺃﻭ ﺍﻟﻔﺮﺍﻣﻞ ﺃﻭ ﻣﻌﺪﺍﺕ ﺍﻟﺸﻌﻼﺕ ﺃﻭ ﻧﻈﺎﻡ ﻋﺎﺩﻡ

ﺍﻟﺴﻴﺎﺭﺓ.

6.4ﺃﻧﺎﺑﻴﺐ ﺍﻟﺸﻌﻼﺕ ﻭﺍﻟﺸﻌﻼﺕ ﻟﻤﺮﻛﺒﺎﺕ ﺻﻬﺎﺭﻳﺞ ﺍﻷﺳﻔﻠﺖ.

6.4.1ﻳﺠﺐ ﺃﻥ ﺗﻜﻮﻥ ﺍﻟﺸﻌﻼﺕ ﺑﻌﻴﺪﺓ ﻋﻦ ﺧﺰﺍﻧﺎﺕ ﺍﻟﻮﻗﻮﺩ ﻟﻤﺤﺮﻙ ﺍﻟﺴﻴﺎﺭﺓ ﻭﺧﺰﺍﻧﺎﺕ ﺍﻟﻮﻗﻮﺩ ﻟﻠﺸﻌﻼﺕ ،ﺃﻭ

ﻳﺠﺐﺗﻮﻓﻴﺮ ﺩﺭﻉ ﻏﻴﺮ ﻗﺎﺑﻞ ﻟﻼﺣﺘﺮﺍﻕ ﺑﻴﻦ ﺍﻟﻤﻮﻗﺪ ﻭﺧﺰﺍﻧﺎﺕ ﺍﻟﻮﻗﻮﺩ ﻟﻤﻨﻊ ﺍﻻﺭﺗﺪﺍﺩ.

6.4.2ﻳﺠﺐ ﺗﺮﻛﻴﺐ ﻭﺻﻴﺎﻧﺔ ﺃﻧﺎﺑﻴﺐ ﺍﻟﻤﻮﻗﺪ ﺑﺸﻜﻞ ﺻﺤﻴﺢ.

6.4.3ﻳﺠﺐ ﺃﻥ ﻳﻜﻮﻥ ﺍﻟﺠﺰء ﺍﻟﺴﻔﻠﻲ ﻣﻦ ﺃﻧﺎﺑﻴﺐ ﺍﻟﺸﻌﻠﺔ ﺍﻟﺪﺍﺧﻠﻴﺔ ﻣﻨﺨﻔﻀﺎً ﻓﻲ ﺍﻟﺨﺰﺍﻥ ﺣﺴﺐ ﻣﺎ ﻳﺴﻤﺢ ﺑﻪ

ﺍﻟﺘﺼﻤﻴﻢﺍﻟﻤﻨﺎﺳﺐ ﻭﺗﺸﻐﻴﻠﻪ.

6.4.4ﻳﺠﺐ ﺗﻮﻓﻴﺮ ﺗﻌﻠﻴﻤﺎﺕ ﺣﻮﻝ ﺍﻟﻄﺮﻳﻘﺔ ﺍﻟﺼﺤﻴﺤﺔ ﻟﺘﺸﻐﻴﻞ ﻣﻌﺪﺍﺕ ﺍﻟﻤﻮﻗﺪ ﻭﻣﻌﺪﺍﺕ ﺍﻟﻀﺦ ،ﺇﺫﺍ ﻛﺎﻧﺖ

ﻣﺠﻬﺰﺓﺑﺬﻟﻚ .ﻭﻳﺠﺐ ﺃﻥ ﺗﻜﻮﻥ ﻫﺬﻩ ﺍﻟﺘﻌﻠﻴﻤﺎﺕ ﻣﺼﺎﺣﺒﺔ ﻟﻠﺴﻴﺎﺭﺓ ﻓﻲ ﺟﻤﻴﻊ ﺍﻷﻭﻗﺎﺕ.

6.4.5ﻋﻼﻣﺔ ﺗﺤﺬﻳﺮ ﺃﻭ ﻣﻠﺼﻖ ﻳﻠﺒﻲ ﻣﺘﻄﻠﺒﺎﺕ ،ANSI Z535.1ﺭﻣﺰ ﺍﻟﻠﻮﻥ ﺍﻵﻣﻦﻳﺠﺐ ﺃﻥ ﻳﺘﻢ ﺗﺜﺒﻴﺘﻪ

ﺑﺸﻜﻞﺩﺍﺉﻢ ﺑﺎﻟﻘﺮﺏ ﻣﻦ ﺍﻟﺸﻌﻼﺕ ﻓﻲ ﺃﻱ ﻣﺮﻛﺒﺔ ﺻﻬﺮﻳﺠﻴﺔ ﻣﺠﻬﺰﺓ ﺑﺎﻟﺸﻌﻼﺕ ،ﻭﻳﺠﺐ ﺃﻥ ﻳﺸﺘﻤﻞ

ﻋﻠﻰﺍﻟﻤﻌﻠﻮﻣﺎﺕ ﺍﻟﺘﺎﻟﻴﺔ ﻋﻠﻰ ﺍﻷﻗﻞ:

ﺗﺤﺬﻳﺮ:ﻳﺠﺐ ﻋﺪﻡ ﺗﺸﻐﻴﻞ ﺟﻬﺎﺯ ﺍﻟﻤﻮﻗﺪ ﻫﺬﺍ ﺃﺛﻨﺎء ﺗﺤﻤﻴﻞ ﺍﻟﺴﻴﺎﺭﺓ ﺃﻭ ﺃﺛﻨﺎء ﻋﺒﻮﺭﻫﺎ ﺃﻭ ﻋﻨﺪﻣﺎ ﻻ ﺗﻜﻮﻥ ﺃﻧﺎﺑﻴﺐ ﺍﻟﻤﻮﻗﺪ ﻣﻐﻤﻮﺭﺓ

ﺑﺎﻟﻜﺎﻣﻞ.

ﺣﻘﻮﻕﺍﻟﻄﺒﻊ ﻭﺍﻟﻨﺸﺮ NFPA

ﺷﺮﻛﺔﺃﺑﺎﺩﻏﻮﺳﺘﺎﺭ ﺗﺎﺳﻴﺴﺎﺕ ﺇﻳﺮﺍﻧﻴﻨﺎﻥ ﺍﻟﻤﺤﺪﻭﺩﺓ www.atapars.com

www.atapars.com/NFPA-code/

ﺝ ﺍﻟﻔﺼﻞ 7ﻭﺿﻊ ﺍﻟﻌﻼﻣﺎﺕ ﻋﻠﻰ ﻣﺮﻛﺒﺎﺕ ﺍﻟﺪﺑﺎﺑﺎﺕ

7.1ﻭﺿﻊ ﺍﻟﻌﻼﻣﺎﺕ.

7.1.1ﻳﺠﺐ ﻭﺿﻊ ﻋﻼﻣﺔ ﻭﺍﺿﺤﺔ ﻭﻣﻘﺮﻭءﺓ ﻋﻠﻰ ﻛﻞ ﻣﺮﻛﺒﺔ ﺻﻬﺮﻳﺠﻴﺔ ﺗﺴﺘﺨﺪﻡ ﻟﻨﻘﻞ ﺃﻱ ﺳﻮﺍﺉﻞ ﻗﺎﺑﻠﺔ

ﻟﻼﺷﺘﻌﺎﻝﺃﻭ ﻗﺎﺑﻠﺔ ﻟﻼﺣﺘﺮﺍﻕ ،ﺑﻐﺾ ﺍﻟﻨﻈﺮ ﻋﻦ ﺍﻟﻜﻤﻴﺔ ﺍﻟﻤﻨﻘﻮﻟﺔ ﺃﻭ ﺳﻮﺍء ﻛﺎﻧﺖ ﻣﺤﻤﻠﺔ ﺃﻭ ﻓﺎﺭﻏﺔ ،ﻭﻓﻘﺎً

ﻟﻤﺘﻄﻠﺒﺎﺕﻟﻮﺍﺉﺢ ﻭﺯﺍﺭﺓ ﺍﻟﻨﻘﻞ ﺍﻷﻣﺮﻳﻜﻴﺔ ﻓﻲ " ، .CFR 171–179 49ﻟﻮﺍﺉﺢ ﺍﻟﻤﻮﺍﺩ ﺍﻟﺨﻄﺮﺓ".

7.1.2ﺷﻬﺎﺩﺓ ﺍﻟﺸﺮﻛﺔ ﺍﻟﻤﺼﻨﻌﺔ.ﻭﻳﺠﺐ ﺍﻟﺤﺼﻮﻝ ﻋﻠﻰ ﺷﻬﺎﺩﺓ ﺗﺜﺒﺖ ﺃﻥ ﻛﻞ ﺧﺰﺍﻥ ﺑﻀﺎﺉﻊ ﻗﺪ ﺗﻢ

ﺗﺼﻤﻴﻤﻪﻭﺑﻨﺎﺉﻪ ﻭﺍﺧﺘﺒﺎﺭﻩ ﺑﻤﺎ ﻳﺘﻮﺍﻓﻖ ﻣﻊ ﻫﺬﺍ ﺍﻟﻤﻌﻴﺎﺭ .ﻳﺠﺐ ﺃﻥ ﻳﺘﻢ ﺗﻮﻗﻴﻊ ﺍﻟﺸﻬﺎﺩﺓ ﻣﻦ ﻗﺒﻞ ﻣﺴﺆﻭﻝ

ﻣﺴﺆﻭﻝﻣﻦ ﺍﻟﺸﺮﻛﺔ ﺍﻟﻤﺼﻨﻌﺔ ﻟﺨﺰﺍﻥ ﺍﻟﺒﻀﺎﺉﻊ ﺃﻭ ﻣﻦ ﻭﻛﺎﻟﺔ ﺍﺧﺘﺒﺎﺭ ﻣﺨﺘﺼﺔ ﻭﻳﺠﺐ ﺍﻻﺣﺘﻔﺎﻅ ﺑﻬﺎ ﻓﻲ

ﻣﻠﻔﺎﺕﺍﻟﻨﺎﻗﻞ ﺧﻼﻝ ﻓﺘﺮﺓ ﺍﺳﺘﺨﺪﺍﻡ ﺍﻟﻨﺎﻗﻞ ﻟﺨﺰﺍﻥ ﺍﻟﺒﻀﺎﺉﻊ ﻫﺬﺍ ،ﺑﺎﻹﺿﺎﻓﺔ ﺇﻟﻰ ﺳﻨﺔ ﻭﺍﺣﺪﺓ.

7.1.3ﺑﺎﻹﺿﺎﻓﺔ ﺇﻟﻰ ﺍﻟﺸﻬﺎﺩﺓ ﺍﻟﻤﺤﺪﺩﺓ ﻓﻲ ،7.1.2ﻳﺠﺐ ﺃﻥ ﺗﻜﻮﻥ ﻫﻨﺎﻙ ﻟﻮﺣﺔ ﻣﻌﺪﻧﻴﺔ ﻋﻠﻰ ﻛﻞ ﺧﺰﺍﻥ

ﺑﻀﺎﺉﻊ)ﺃﻭ ﺣﺠﺮﺓ ﺍﻟﺨﺰﺍﻥ ﺇﺫﺍ ﺗﻢ ﺑﻨﺎﺅﻫﺎ ﺑﻤﻮﺍﺻﻔﺎﺕ ﻣﺨﺘﻠﻔﺔ(.

7.1.3.1ﻳﺠﺐ ﺃﻻ ﺗﻜﻮﻥ ﺍﻟﻠﻮﺣﺔ ﻋﺮﺿﺔ ﻟﻠﺘﺂﻛﻞ.

7.1.3.2ﻳﺠﺐ ﺃﻥ ﺗﻜﻮﻥ ﺍﻟﻠﻮﺣﺔ ﻣﻮﺟﻮﺩﺓ ﻋﻠﻰ ﺍﻟﺠﺎﻧﺐ ﺍﻷﻳﻤﻦ ﺑﺎﻟﻘﺮﺏ ﻣﻦ ﺍﻟﻤﻘﺪﻣﺔ ،ﻓﻲ ﻣﻜﺎﻥ

ﻳﺴﻬﻞﺍﻟﻮﺻﻮﻝ ﺇﻟﻴﻪ ﻟﻠﻔﺤﺺ.

7.1.3.3ﻳﺠﺐ ﺃﻥ ﻳﺘﻢ ﺗﺜﺒﻴﺖ ﺍﻟﻠﻮﺣﺔ ﺑﺸﻜﻞ ﺩﺍﺉﻢ ﻋﻠﻰ ﺍﻟﺨﺰﺍﻥ ﻋﻦ ﻃﺮﻳﻖ ﺍﻟﻠﺤﺎﻡ ﺃﻭ ﺍﻟﻠﺤﺎﻡ ﺃﻭ ﺃﻱ ﻭﺳﻴﻠﺔ

ﺃﺧﺮﻯﻣﻨﺎﺳﺒﺔ.

7.1.3.4ﻳﺠﺐ ﺃﻥ ﻳﺘﻢ ﻭﺿﻊ ﻋﻼﻣﺔ ﻋﻠﻰ ﺍﻟﻠﻮﺣﺔ ﺑﺄﺣﺮﻑ ﻻ ﻳﻘﻞ ﺍﺭﺗﻔﺎﻋﻬﺎ ﻋﻦ 5ﻣﻢ ﻋﻦ ﻃﺮﻳﻖ ﺍﻟﺨﺘﻢ ﺃﻭ

ﺍﻟﻨﻘﺶﺃﻭ ﺃﻱ ﻭﺳﻴﻠﺔ ﺃﺧﺮﻯ ﻟﺘﺸﻜﻴﻞ ﺍﻟﺤﺮﻭﻑ ﺩﺍﺧﻞ ﺃﻭ ﻋﻠﻰ ﻣﻌﺪﻥ ﺍﻟﻠﻮﺣﺔ ﻧﻔﺴﻬﺎ ،ﻋﻠﻰ ﺍﻷﻗﻞ

ﺍﻟﻤﻌﻠﻮﻣﺎﺕﺍﻟﺘﺎﻟﻴﺔ:

) (1ﺍﻟﺸﺮﻛﺔ ﺍﻟﻤﺼﻨﻌﺔ ﻟﻠﻤﺮﻛﺒﺔ

) (2ﺍﻟﺮﻗﻢ ﺍﻟﺘﺴﻠﺴﻠﻲ ﻟﻠﺸﺮﻛﺔ ﺍﻟﻤﺼﻨﻌﺔ

) (3ﺗﺤﺪﻳﺪ ﺍﻟﻤﻮﺍﺻﻔﺎﺕ

) (4ﺗﺎﺭﻳﺦ ﺍﻟﺼﻨﻊ

) (5ﺗﺎﺭﻳﺦ ﺍﻻﺧﺘﺒﺎﺭ ﺍﻷﺻﻠﻲ

) (6ﺗﺎﺭﻳﺦ ﺍﻟﺸﻬﺎﺩﺓ

) (7ﺿﻐﻂ ﺍﻟﺘﺼﻤﻴﻢ )ﺭﻃﻞ ﻟﻜﻞ ﺑﻮﺻﺔ ﻣﺮﺑﻌﺔ(

) (8ﺿﻐﻂ ﺍﻻﺧﺘﺒﺎﺭ )ﺭﻃﻞ ﻟﻜﻞ ﺑﻮﺻﺔ ﻣﺮﺑﻌﺔ(

) (9ﻣﺎﺩﺓ ﺍﻟﺮﺃﺱ

) (10ﻣﺎﺩﺓ ﺍﻟﺼﺪﻓﺔ

) (11ﻣﺎﺩﺓ ﺍﻟﻠﺤﺎﻡ

ﺣﻘﻮﻕﺍﻟﻄﺒﻊ ﻭﺍﻟﻨﺸﺮ NFPA

ﺷﺮﻛﺔﺃﺑﺎﺩﻏﻮﺳﺘﺎﺭ ﺗﺎﺳﻴﺴﺎﺕ ﺇﻳﺮﺍﻧﻴﻨﺎﻥ ﺍﻟﻤﺤﺪﻭﺩﺓ www.atapars.com

www.atapars.com/NFPA-code/

) (12ﻣﺎﺩﺓ ﺍﻟﺒﻄﺎﻧﺔ

) (13ﺳﻌﺔ ﺍﻟﺨﺰﺍﻥ ﺍﻻﺳﻤﻴﺔ ﺣﺴﺐ ﺍﻟﻤﻘﺼﻮﺭﺓ )ﻣﻦ ﺍﻷﻣﺎﻡ ﺇﻟﻰ ﺍﻟﺨﻠﻒ( )ﺟﺎﻟﻮﻥ ﺃﻣﺮﻳﻜﻲ(

) (14ﺍﻟﺤﺪ ﺍﻷﻗﺼﻰ ﻟﺤﻤﻞ ﺍﻟﻤﻨﺘﺞ )ﺭﻃﻞ(

) (15ﺣﺪﻭﺩ ﺍﻟﺘﺤﻤﻴﻞ )ﺟﺎﻟﻮﻥ ﻓﻲ ﺍﻟﺪﻗﻴﻘﺔ ﻭ/ﺃﻭ ﺭﻃﻞ ﻟﻜﻞ ﺑﻮﺻﺔ ﻣﺮﺑﻌﺔ(

) (16ﺣﺪﻭﺩ ﺍﻟﺘﻔﺮﻳﻎ ) gpmﻭ/ﺃﻭ (psi

7.1.3.5ﻻ ﻳﺠﻮﺯ ﻃﻼء ﺍﻟﻠﻮﺣﺔ ﺑﺤﻴﺚ ﺗﺤﺠﺐ ﺍﻟﻌﻼﻣﺎﺕ ﺍﻟﻤﻮﺟﻮﺩﺓ ﻋﻠﻴﻬﺎ.

7.1.4ﺇﺫﺍ ﻛﺎﻥ ﺳﻴﺘﻢ ﺗﻌﺪﻳﻞ ﺧﺰﺍﻥ ﺍﻟﺒﻀﺎﺉﻊ ﻣﺎﺩﻳﺎً ﻟﺘﻠﺒﻴﺔ ﻣﻮﺍﺻﻔﺎﺕ ﺃﺧﺮﻯ )ﺃﻭ ﻻﺳﺘﻴﻌﺎﺏ ﺳﻠﻌﺔ ﻻ

ﺗﺘﻄﻠﺐﺧﺰﺍﻧﺎً ﻟﻠﻤﻮﺍﺻﻔﺎﺕ( ،ﻓﻴﺠﺐ ﺍﻹﺷﺎﺭﺓ ﺇﻟﻰ ﻫﺬﻩ ﺍﻟﻤﺠﻤﻮﻋﺎﺕ ﺑﺠﺎﻧﺐ ﺗﻌﺮﻳﻒ ﺍﻟﻤﻮﺍﺻﻔﺎﺕ.

7.1.5ﻋﻨﺪﻣﺎ ﻳﺤﺘﻮﻱ ﺧﺰﺍﻥ ﺍﻟﺒﻀﺎﺉﻊ ﻋﻠﻰ ﻟﻮﺣﺔ ﺍﻋﺘﻤﺎﺩ ﻣﻌﺪﻧﻴﺔ ﻟﻤﻮﺍﺻﻔﺎﺕ ،MC 306ﻳﺴُﻤﺢ ﺑﺈﺿﺎﻓﺔ

ﺍﻹﺷﺎﺭﺓ" "NFPA 385ﺇﻟﻰ ﺳﻄﺮ ﺗﻌﺮﻳﻒ ﺍﻟﻤﻮﺍﺻﻔﺎﺕ ﻋﻠﻰ ﺍﻟﻠﻮﺣﺔ ﺍﻟﻤﻌﺪﻧﻴﺔ.

ﺝ ﺍﻟﻤﻌﺪﺍﺕﺍﻟﻤﺴﺎﻋﺪﺓ hapter 8

8.1ﻣﺤﺮﻛﺎﺕ ﺍﻻﺣﺘﺮﺍﻕ ﺍﻟﺪﺍﺧﻠﻲ ﺍﻟﻤﺴﺎﻋﺪﺓ.

8.1.1ﻳﺠﺐ ﺃﻥ ﺗﺴﺘﻮﻓﻲ ﻣﺤﺮﻛﺎﺕ ﺍﻻﺣﺘﺮﺍﻕ ﺍﻟﺪﺍﺧﻠﻲ ،ﺑﺨﻼﻑ ﺗﻠﻚ ﺍﻟﺘﻲ ﺗﻮﻓﺮ ﺍﻟﻄﺎﻗﺔ ﺍﻟﺪﺍﻓﻌﺔ ،ﺍﻟﻤﺜﺒﺘﺔ ﺃﻭ

ﺍﻟﻤﺤﻤﻮﻟﺔﻋﻠﻰ ﻣﺮﻛﺒﺔ ﺻﻬﺮﻳﺠﻴﺔ ﺗﻨﻘﻞ ﺳﻮﺍﺉﻞ ﻣﻦ ﺍﻟﻔﺉﺔ ﺍﻷﻭﻟﻰ ﻟﻐﺮﺽ ﺗﻮﻓﻴﺮ ﺍﻟﻄﺎﻗﺔ ﻟﺘﺸﻐﻴﻞ

ﺍﻟﻤﻀﺨﺎﺕﺃﻭ ﺍﻷﺟﻬﺰﺓ ﺍﻷﺧﺮﻯ ،ﺍﻟﻤﺘﻄﻠﺒﺎﺕ ﺍﻟﻮﺍﺭﺩﺓ ﻓﻲ 8.1.2ﺇﻟﻰ .8.1.8

8.1.2ﻳﺠﺐ ﺃﻥ ﻳﻜﻮﻥ ﻣﺪﺧﻞ ﻫﻮﺍء ﺍﻟﻤﺤﺮﻙ ﻣﺰﻭﺩﺍً ﺑﻤﺎﻧﻊ ﺍﻟﻠﻬﺐ ﺍﻟﻔﻌﺎﻝ ﺃﻭ ﻣﻨﻈﻒ ﺍﻟﻬﻮﺍء ﺍﻟﺬﻱ ﻳﺘﻤﺘﻊ

ﺑﺨﺼﺎﺉﺺﻣﺎﻧﻌﺔ ﺍﻟﻠﻬﺐ ﺍﻟﻔﻌﺎﻟﺔ ،ﻭﺃﻥ ﻳﻜﻮﻥ ﻣﺜﺒﺘﺎً ﻭﻗﺎﺩﺭﺍً ﻋﻠﻰ ﻣﻨﻊ ﺍﻧﺒﻌﺎﺙ ﺍﻟﻠﻬﺐ ﻣﻦ ﺟﺎﻧﺐ

ﺍﻟﺴﺤﺐﺑﺎﻟﻤﺤﺮﻙ ﻓﻲ ﺣﺎﻟﺔ ﺣﺪﻭﺙ ﻧﺘﺎﺉﺞ ﻋﻜﺴﻴﺔ.

8.1.3ﻳﺠﺐ ﺃﻥ ﻳﺘﻢ ﺗﺤﺪﻳﺪ ﻣﻮﻗﻊ ﻧﻈﺎﻡ ﺍﻟﻮﻗﻮﺩ ﺃﻭ ﺇﻧﺸﺎﺉﻪ ﺑﻄﺮﻳﻘﺔ ﺗﻘﻠﻞ ﻣﻦ ﺧﻄﺮ ﺍﻟﺤﺮﻳﻖ.

8.1.3.1ﻋﻨﺪﻣﺎ ﻳﻘﻊ ﺧﺰﺍﻥ ﺍﻟﻮﻗﻮﺩ ﺃﻋﻠﻰ ﺍﻟﻤﺤﺮﻙ ﺃﻭ ﺑﺠﻮﺍﺭﻩ ﻣﺒﺎﺷﺮﺓ ،ﻳﺠﺐ ﺗﻮﻓﻴﺮ ﺩﺭﻉ ﻣﻨﺎﺳﺐ ﻟﻤﻨﻊ

ﺍﻻﻧﺴﻜﺎﺏﺃﺛﻨﺎء ﻋﻤﻠﻴﺔ ﺍﻟﺘﻌﺒﺉﺔ ﺃﻭ ﺍﻟﺘﺴﺮﺏ ﻣﻦ ﺍﻟﺨﺰﺍﻥ ﺃﻭ ﻧﻈﺎﻡ ﺍﻟﻮﻗﻮﺩ ﻣﻦ ﻣﻼﻣﺴﺔ ﺍﻟﻤﺤﺮﻙ ﺃﻭ ﺃﻱ ﺃﺟﺰﺍء

ﻣﻦﺃﻧﻈﻤﺔ ﺍﻹﺷﻌﺎﻝ ﻭﺍﻟﻌﺎﺩﻡ .

8.1.3.2ﻳﺠﺐ ﺃﻥ ﻳﺘﻢ ﺗﺼﻨﻴﻊ ﺟﻤﻴﻊ ﺃﺟﺰﺍء ﻧﻈﺎﻡ ﺍﻟﻮﻗﻮﺩ ﻭﺗﺮﻛﻴﺒﻬﺎ ﺑﻄﺮﻳﻘﺔ ﻓﻌﺎﻟﺔ.

8.1.4ﻳﺠﺐ ﺃﻥ ﺗﻜﻮﻥ ﺍﻟﻤﻀﺨﺎﺕ ﻭﺍﻟﻤﻠﺤﻘﺎﺕ ﺍﻷﺧﺮﻯ ﻓﻲ ﻣﻜﺎﻥ ﻣﻨﺎﺳﺐ ﺑﺎﻟﻨﺴﺒﺔ ﻟﻠﻤﺤﺮﻙ ﺑﺤﻴﺚ ﻳﻤﻨﻊ

ﺍﻻﻧﺴﻜﺎﺏﺃﻭ ﺍﻟﺘﺴﺮﺏ ﻣﻦ ﻫﺬﻩ ﺍﻷﺟﺰﺍء ﻣﻦ ﺍﻻﺗﺼﺎﻝ ﺑﺎﻟﻤﺤﺮﻙ ﺃﻭ ﺃﻱ ﺃﺟﺰﺍء ﻣﻦ ﻧﻈﺎﻡ ﺍﻹﺷﻌﺎﻝ ﻭﺍﻟﻌﺎﺩﻡ ،ﺃﻭ

ﻳﺠﺐﺗﻮﻓﻴﺮ ﺩﺭﻉ ﻣﻨﺎﺳﺐ ﻟﺘﺤﻘﻴﻖ ﻧﻔﺲ ﺍﻟﻐﺮﺽ .

8.1.5ﻳﺠﺐ ﺃﻥ ﻳﺘﻢ ﻭﺿﻊ ﻣﺮﻭﺣﺔ ﺗﺒﺮﻳﺪ ﺍﻟﻤﺤﺮﻙ ﺃﻭ ﺗﺪﻭﻳﺮﻫﺎ ﺃﻭ ﺗﻐﻄﻴﺘﻬﺎ ﺑﺤﻴﺚ ﺗﻘﻠﻞ ﺍﺣﺘﻤﺎﻟﻴﺔ ﺳﺤﺐ

ﺍﻷﺑﺨﺮﺓﺍﻟﻘﺎﺑﻠﺔ ﻟﻼﺷﺘﻌﺎﻝ ﻧﺤﻮ ﺍﻟﻤﺤﺮﻙ.

8.1.6ﻋﻨﺪﻣﺎ ﻳﻜﻮﻥ ﺍﻟﻤﺤﺮﻙ ﻓﻲ ﻭﺿﻊ ﻳﻤﻜﻦ ﺃﻥ ﻳﺸﻜﻞ ﻓﻴﻪ ﺍﻻﻧﺴﻜﺎﺏ ﻣﻦ ﺧﺰﺍﻥ ﺍﻟﺤﻤﻮﻟﺔ ﺃﻭ ﻣﻠﺤﻘﺎﺗﻪ ﺃﻭ

ﻣﻦﺍﻟﺮﻓﻮﻑ ﺍﻟﺠﺎﻧﺒﻴﺔ ﺧﻄﺮﺍً ،ﻳﺠﺐ ﺗﻮﻓﻴﺮ ﺩﺭﻉ ﻟﻤﻨﻊ ﻫﺬﺍ ﺍﻻﻧﺴﻜﺎﺏ ﻣﻦ ﻣﻼﻣﺴﺔ ﺍﻟﻤﺤﺮﻙ ﺃﻭ ﻧﻈﺎﻡ ﻋﺎﺩﻡ

ﺍﻟﻤﺤﺮﻙﻭﻟﺘﺼﺮﻳﻒ ﺍﻟﻤﻴﺎﻩ

ﺣﻘﻮﻕﺍﻟﻄﺒﻊ ﻭﺍﻟﻨﺸﺮ NFPA

ﺷﺮﻛﺔﺃﺑﺎﺩﻏﻮﺳﺘﺎﺭ ﺗﺎﺳﻴﺴﺎﺕ ﺇﻳﺮﺍﻧﻴﻨﺎﻥ ﺍﻟﻤﺤﺪﻭﺩﺓ www.atapars.com

www.atapars.com/NFPA-code/

ﻣﺜﻞﻫﺬﺍ ﺍﻻﻧﺴﻜﺎﺏ ﺑﻌﻴﺪﺍ ﻋﻦ ﺍﻟﻤﻨﻄﻘﺔ ﺍﻟﻤﺠﺎﻭﺭﺓ ﻟﻠﻤﺤﺮﻙ.

8.1.7ﻋﻨﺪﻣﺎ ﻳﺘﻢ ﻧﻘﻞ ﺍﻟﻤﺤﺮﻙ ﺩﺍﺧﻞ ﻣﻜﺎﻥ ﻣﻐﻠﻖ ،ﻳﺠﺐ ﺗﻮﻓﻴﺮ ﺩﻭﺭﺍﻥ ﻛﺎﻑ ٍﻟﻠﻬﻮﺍء ﻓﻲ ﺟﻤﻴﻊ ﺍﻷﻭﻗﺎﺕ

ﻟﻤﻨﻊﺗﺮﺍﻛﻢ ﺍﻷﺑﺨﺮﺓ ﺍﻟﻤﺘﻔﺠﺮﺓ ﻭﺗﺠﻨﺐ ﺍﻟﺴﺨﻮﻧﺔ ﺍﻟﺰﺍﺉﺪﺓ.

8.1.8ﻳﺠﺐ ﺇﻧﺸﺎء ﻭﺗﺮﻛﻴﺐ ﻧﻈﺎﻡ ﺍﻟﻌﺎﺩﻡ ﺑﺤﻴﺚ ﻳﻜﻮﻥ ﺧﺎﻟﻴﺎ ًﻣﻦ ﺍﻟﺘﺴﺮﺑﺎﺕ.

8.1.8.1ﻳﺠﺐ ﺃﻥ ﻳﻜﻮﻥ ﻟﺨﻂ ﺍﻟﻌﺎﺩﻡ ﻭﻛﺎﺗﻢ ﺍﻟﺼﻮﺕ ﻣﺴﺎﻓﺔ ﻛﺎﻓﻴﺔ ﻣﻦ ﺍﻟﻤﻮﺍﺩ ﺍﻟﻘﺎﺑﻠﺔ ﻟﻼﺣﺘﺮﺍﻕ.

8.1.8.2ﻳﺠﺐ ﺗﻔﺮﻳﻎ ﻏﺎﺯﺍﺕ ﺍﻟﻌﺎﺩﻡ ﻓﻲ ﻣﻜﺎﻥ ﻻ ﻳﺸﻜﻞ ﺧﻄﺮﺍ.

8.1.8.3ﻋﻨﺪﻣﺎ ﻳﺘﻢ ﻧﻘﻞ ﺍﻟﻤﺤﺮﻛﺎﺕ ﻛﻤﺎ ﻫﻮ ﻣﻮﺿﺢ ﻓﻲ ،8.1.7ﻳﺠﺐ ﺗﻔﺮﻳﻎ ﻏﺎﺯﺍﺕ ﺍﻟﻌﺎﺩﻡ ﺧﺎﺭﺝ ﻛﻞ

ﻣﻜﺎﻥﻣﻐﻠﻖ.

8.1.9ﻳﺠﺐ ﺗﺮﻛﻴﺐ ﺃﺳﻼﻙ ﺍﻹﺷﻌﺎﻝ ﺑﻮﺻﻼﺕ ﺛﺎﺑﺘﺔ .ﻳﺠﺐ ﻋﺰﻝ ﺃﻃﺮﺍﻑ ﺷﻤﻌﺎﺕ ﺍﻹﺷﻌﺎﻝ ﻭﺟﻤﻴﻊ

ﺍﻷﻃﺮﺍﻑﺍﻷﺧﺮﻯ ﻟﻤﻨﻊ ﺣﺪﻭﺙ ﺷﺮﺍﺭﺓ ﻓﻲ ﺣﺎﻟﺔ ﻣﻼﻣﺴﺘﻬﺎ ﻟﻠﻤﻮﺍﺩ ﺍﻟﻤﻮﺻﻠﺔ .ﻳﺠﺐ ﺃﻥ ﻳﻜﻮﻥ ﻣﻔﺘﺎﺡ

ﺍﻹﺷﻌﺎﻝﻣﻦ ﺍﻟﻨﻮﻉ ﺍﻟﻤﻐﻠﻖ.

8.2ﺍﻟﻤﻮﻟﺪﺍﺕ ﻭﺍﻟﻤﺤﺮﻛﺎﺕ ﺍﻟﻜﻬﺮﺑﺎﺉﻴﺔ ﺍﻟﻤﺴﺎﻋﺪﺓ.

8.2.1ﻳﺠﺐ ﺃﻥ ﺗﺴﺘﻮﻓﻲ ﺍﻟﻤﻌﺪﺍﺕ ﺍﻟﻜﻬﺮﺑﺎﺉﻴﺔ ﺍﻟﻤﺜﺒﺘﺔ ﺃﻭ ﺍﻟﻤﺤﻤﻮﻟﺔ ﻋﻠﻰ ﻣﺮﻛﺒﺔ ﺻﻬﺮﻳﺠﻴﺔ ﺗﻨﻘﻞ

ﺳﻮﺍﺉﻞﺍﻟﻔﺉﺔ ﺍﻷﻭﻟﻰ ﻟﺘﺸﻐﻴﻞ ﺍﻟﻤﻀﺨﺎﺕ ﺃﻭ ﺍﻷﺟﻬﺰﺓ ﺍﻷﺧﺮﻯ ﺍﻟﻤﺴﺘﺨﺪﻣﺔ ﻓﻲ ﺍﻟﺘﻌﺎﻣﻞ ﻣﻊ ﺍﻟﻤﻨﺘﺞ

ﻭﺗﺸﻐﻴﻞﻣﻠﺤﻘﺎﺕ ﻣﻨﺎﻭﻟﺔ ﺍﻟﻤﻨﺘﺞ ﻣﺘﻄﻠﺒﺎﺕ 8.2.2ﺇﻟﻰ .8.2.6

8.2.2ﺍﻟﻤﻮﻟﺪﺍﺕ ﺍﻟﻤﺮﻛﺒﺔ ﻋﻠﻰ ﺍﻟﻤﺤﺮﻙ ﻭﺍﻟﺘﻲ ﺗﻮﻓﺮ ﺍﻟﻄﺎﻗﺔ ﺍﻟﺪﺍﻓﻌﺔ ﻟﻠﻤﺮﻛﺒﺔ ﺃﻭ ﺍﻟﻤﺤﺮﻙ ﺍﻟﻤﺴﺎﻋﺪ ﺃﻭ

ﺍﻟﻤﻮﺟﻮﺩﺓﻓﻲ ﺍﻟﻤﻨﻄﻘﺔ ﺍﻟﻤﺠﺎﻭﺭﺓ ﻣﺒﺎﺷﺮﺓ ﻟﻬﺬﺍ ﺍﻟﻤﺤﺮﻙ ﺃﻭ ﻧﻈﺎﻡ ﺍﻟﻌﺎﺩﻡ ﺍﻟﺨﺎﺹ ﺑﻪ ،ﻳﺠﺐ ﺃﻥ ﺗﻜﻮﻥ ﻟﻬﺎ

ﺣﺎﻭﻳﺎﺕﻟﻸﻏﺮﺍﺽ ﺍﻟﻌﺎﻣﺔ .ﻳﺠﺐ ﺃﻥ ﺗﺰﻭﺩ ﺍﻟﻤﻮﻟﺪﺍﺕ ﺍﻟﻤﻮﺟﻮﺩﺓ ﻓﻲ ﺃﻣﺎﻛﻦ ﺃﺧﺮﻯ ﺑﻐﻼﻑ ﻣﻘﺎﻭﻡ ﻟﻼﻧﻔﺠﺎﺭ.

8.2.3ﻳﺠﺐ ﺃﻥ ﺗﺰﻭﺩ ﺍﻟﻤﺤﺮﻛﺎﺕ ﺍﻟﺘﻲ ﻟﻬﺎ ﻭﺻﻼﺕ ﺷﺮﺍﺭﺓ ﺑﻤﻐﻠﻔﺎﺕ ﻣﻘﺎﻭﻣﺔ ﻟﻼﻧﻔﺠﺎﺭ.

8.2.4ﻳﺠﺐ ﺃﻥ ﺗﻜﻮﻥ ﺍﻷﺳﻼﻙ ﻛﺎﻓﻴﺔ ﻟﺘﺤﻤﻞ ﺍﻟﺤﺪ ﺍﻷﻗﺼﻰ ﻣﻦ ﺍﻷﺣﻤﺎﻝ ﻭﻳﺠﺐ ﺗﺮﻛﻴﺒﻬﺎ ﺑﺤﻴﺚ ﺗﻜﻮﻥ

ﻣﺤﻤﻴﺔﻣﻦ ﺍﻷﺿﺮﺍﺭ ﺍﻟﻤﺎﺩﻳﺔ ﻭﺍﻟﺘﻼﻣﺲ ﻣﻊ ﺍﺣﺘﻤﺎﻝ ﺍﻧﺴﻜﺎﺏ ﺍﻟﻤﻨﺘﺞ ﺇﻣﺎ ﻋﻦ ﻃﺮﻳﻖ ﺍﻟﻤﻮﻗﻊ ﺃﻭ ﻋﻦ ﻃﺮﻳﻖ

ﻭﺿﻌﻬﺎﻓﻲ ﻗﻨﺎﺓ ﻣﻌﺪﻧﻴﺔ ﺃﻭ ﺃﻱ ﺃﻏﻄﻴﺔ ﻭﺍﻗﻴﺔ ﺃﺧﺮﻯ ﻣﻘﺎﻭﻣﺔ ﻟﻠﺰﻳﺖ .ﻳﺠﺐ ﺃﻥ ﺗﻜﻮﻥ ﺻﻨﺎﺩﻳﻖ ﺍﻟﺘﻮﺻﻴﻞ

ﻣﺨﺘﻮﻣﺔ.

8.2.5ﻳﺠﺐ ﺃﻥ ﺗﻜﻮﻥ ﺍﻟﻤﻔﺎﺗﻴﺢ ﻭﺃﺟﻬﺰﺓ ﺍﻟﺤﻤﺎﻳﺔ ﻣﻦ ﺍﻟﺤﻤﻞ ﺍﻟﺰﺍﺉﺪ ﻭﻣﻌﺪﺍﺕ ﺍﻹﺷﻌﺎﻝ ﺍﻷﺧﺮﻯ ﻣﻮﺟﻮﺩﺓ

ﻭﻣﺤﺎﻃﺔﻛﻤﺎ ﻫﻮ ﻣﻨﺼﻮﺹ ﻋﻠﻴﻪ ﻟﻠﻤﻮﻟﺪﺍﺕ ﻓﻲ .8.2.2

8.2.6ﻋﻨﺪﻣﺎ ﻳﻘﻊ ﺍﻟﻤﻮﻟﺪ ﺃﻭ ﺍﻟﻤﺤﺮﻙ ﺩﺍﺧﻞ ﻣﻜﺎﻥ ﻣﻐﻠﻖ ،ﻳﺠﺐ ﺗﻮﻓﻴﺮ ﺩﻭﺭﺍﻥ ﻛﺎﻑ ٍﻟﻠﻬﻮﺍء ﻟﻤﻨﻊ ﺍﺭﺗﻔﺎﻉ

ﺩﺭﺟﺔﺍﻟﺤﺮﺍﺭﺓ ﻭﺍﺣﺘﻤﺎﻝ ﺗﺮﺍﻛﻢ ﺍﻟﺒﺨﺎﺭ ﺍﻟﻤﺘﻔﺠﺮ.

8.3ﺍﻟﻤﻀﺨﺎﺕ ﻭﺍﻟﺨﺮﺍﻃﻴﻢ.

8.3.1ﻋﻨﺪ ﺍﺳﺘﺨﺪﺍﻡ ﻣﻀﺨﺔ ﻟﺘﻮﺻﻴﻞ ﺍﻟﻤﻨﺘﺠﺎﺕ ،ﻳﺠﺐ ﺗﻮﻓﻴﺮ ﻭﺳﺎﺉﻞ ﺃﻭﺗﻮﻣﺎﺗﻴﻜﻴﺔ ﻟﻤﻨﻊ ﺍﻟﻀﻐﻂ

ﺍﻟﺰﺍﺉﺪﻋﻦ ﺿﻐﻮﻁ ﺍﻟﻌﻤﻞ ﺍﻟﺘﺼﻤﻴﻤﻴﺔ ﻟﻠﻤﻠﺤﻘﺎﺕ ﻭﺍﻷﻧﺎﺑﻴﺐ ﻭﺍﻟﺨﺮﻃﻮﻡ.

8.3.2ﻳﺠﺐ ﻭﺿﻊ ﻋﻼﻣﺔ ﻋﻠﻰ ﻛﻞ ﻃﻮﻝ ﺧﺮﻃﻮﻡ ﻳﺴﺘﺨﺪﻡ ﻟﺘﻮﺻﻴﻞ ﺍﻟﻤﻨﺘﺞ ﺑﻮﺍﺳﻄﺔ ﺍﻟﻤﻀﺨﺔ ﻟﻺﺷﺎﺭﺓ ﺇﻟﻴﻪ

ﺣﻘﻮﻕﺍﻟﻄﺒﻊ ﻭﺍﻟﻨﺸﺮ NFPA

ﺷﺮﻛﺔﺃﺑﺎﺩﻏﻮﺳﺘﺎﺭ ﺗﺎﺳﻴﺴﺎﺕ ﺇﻳﺮﺍﻧﻴﻨﺎﻥ ﺍﻟﻤﺤﺪﻭﺩﺓ www.atapars.com

www.atapars.com/NFPA-code/

ﺿﻐﻂﺍﻟﻌﻤﻞ ﺍﻟﻤﻮﺻﻰ ﺑﻪ ﻣﻦ ﻗﺒﻞ ﺍﻟﺸﺮﻛﺔ ﺍﻟﻤﺼﻨﻌﺔ.

8.3.3ﻳﺠﺐ ﻓﺤﺺ ﺟﻤﻴﻊ ﺧﺮﺍﻃﻴﻢ ﺍﻟﻀﻐﻂ ﻭﺍﻟﻮﺻﻼﺕ ﻋﻠﻰ ﻓﺘﺮﺍﺕ ﻣﻨﺎﺳﺒﺔ ﻟﻠﺨﺪﻣﺔ.

8.3.3.1ﻣﻊ ﺗﻤﺪﻳﺪ ﺍﻟﺨﺮﻃﻮﻡ ،ﻳﺠﺐ ﺗﻄﺒﻴﻖ ﺍﻟﻀﻐﻂ ﻋﻠﻰ ﺍﻟﺨﺮﻃﻮﻡ ﻭﺍﻟﻮﺻﻼﺕ ﺣﺘﻰ ﺃﻗﺼﻰ ﺿﻐﻂ

ﺗﺸﻐﻴﻞ.

8.3.3.2ﺃﻱ ﺧﺮﻃﻮﻡ ﻳﻈﻬﺮ ﻋﻠﻴﻪ ﺗﻠﻒ ﻣﺎﺩﻱ ﺃﻭ ﻋﻼﻣﺎﺕ ﺗﺴﺮﺏ ﺃﻭ ﺿﻌﻒ ﻓﻲ ﻫﻴﻜﻠﻪ ﺃﻭ ﻓﻲ

ﺍﻟﻮﺻﻼﺕﻳﺠﺐ ﺳﺤﺒﻪ ﻣﻦ ﺍﻟﺨﺪﻣﺔ ﻭﺇﺻﻼﺣﻪ ﺃﻭ ﺍﻟﺘﺨﻠﺺ ﻣﻨﻪ.

ﺝ ﺍﻟﻔﺼﻞ 9ﺗﺸﻐﻴﻞ ﻣﺮﻛﺒﺎﺕ ﺍﻟﺪﺑﺎﺑﺎﺕ

9.1ﻇﺮﻭﻑ ﺍﻟﺘﺸﻐﻴﻞ ﺍﻟﻌﺎﻣﺔ.

9.1.1ﻳﺠﺐ ﺃﻥ ﻳﺘﻢ ﺗﺪﺭﻳﺐ ﺍﻟﺴﺎﺉﻘﻴﻦ ﺑﺸﻜﻞ ﻛﺎﻣﻞ ﻋﻠﻰ ﺍﻟﻄﺮﻳﻘﺔ ﺍﻟﺼﺤﻴﺤﺔ ﻟﺘﺸﻐﻴﻞ ﻣﺮﻛﺒﺎﺕ

ﺍﻟﺼﻬﺎﺭﻳﺞﻭﻋﻠﻰ ﺍﻹﺟﺮﺍءﺍﺕ ﺍﻟﺼﺤﻴﺤﺔ ﻟﺘﺤﻤﻴﻞ ﻭﺗﻔﺮﻳﻎ ﻣﺮﻛﺒﺎﺕ ﺍﻟﺼﻬﺎﺭﻳﺞ.

9.1.2ﻻ ﻳﺠﻮﺯ ﺗﺸﻐﻴﻞ ﺍﻟﻤﺮﻛﺒﺎﺕ ﺍﻟﺼﻬﺮﻳﺠﻴﺔ ﺇﻻ ﺇﺫﺍ ﻛﺎﻧﺖ ﻓﻲ ﺣﺎﻟﺔ ﺇﺻﻼﺡ ﺳﻠﻴﻢ ،ﻭﺧﺎﻟﻴﺔ ﻣﻦ ﺗﺮﺍﻛﻤﺎﺕ

ﺍﻟﺸﺤﻮﻡﻭﺍﻟﺰﻳﻮﺕ ﻭﻏﻴﺮﻫﺎ ﻣﻦ ﺍﻟﻤﻮﺍﺩ ﺍﻟﻘﺎﺑﻠﺔ ﻟﻼﺷﺘﻌﺎﻝ ،ﻭﺧﺎﻟﻴﺔ ﻣﻦ ﺍﻟﺘﺴﺮﻳﺒﺎﺕ.

9.1.3ﻳﺠﺐ ﺃﻥ ﺗﻜﻮﻥ ﺃﻏﻄﻴﺔ ﺍﻟﻘﺒﺔ ﻣﻐﻠﻘﺔ ﻭﻣﺜﺒﺘﺔ ﺑﻤﺰﻻﺝ ﺃﺛﻨﺎء ﻣﺮﻭﺭ ﻣﺮﻛﺒﺔ ﺍﻟﺼﻬﺮﻳﺞ.

9.1.4ﻻ ﻳﺠﻮﺯ ﺗﺸﻐﻴﻞ ﺃﻱ ﻣﺮﻛﺒﺔ ﺻﻬﺮﻳﺠﻴﺔ ﺑﺪﺭﺟﺔ ﺣﺮﺍﺭﺓ ﺣﻤﻮﻟﺔ ﺃﻋﻠﻰ ﻣﻦ ﺍﻟﺤﺪ ﺍﻷﻗﺼﻰ ﺍﻟﻤﺴﻤﻮﺡ

ﺑﻪﻟﺪﺭﺟﺔ ﺣﺮﺍﺭﺓ ﺍﻟﺤﻤﻮﻟﺔ ﺍﻟﻤﺤﺪﺩﺓ ﻓﻲ ﻋﻼﻣﺔ ﺍﻟﺘﺤﺬﻳﺮ ﺍﻟﻤﻄﻠﻮﺑﺔ ﺑﻤﻮﺟﺐ .5.1.5

9.1.5ﻻ ﻳﺠﻮﺯ ﺗﺤﻤﻴﻞ ﺃﻱ ﻣﺎﺩﺓ ﺃﻭ ﻧﻘﻠﻬﺎ ﻓﻲ ﺻﻬﺮﻳﺞ ﺍﻟﺒﻀﺎﺉﻊ ﻋﻨﺪ ﺩﺭﺟﺔ ﺣﺮﺍﺭﺓ ﺃﻋﻠﻰ ﻣﻦ ﺩﺭﺟﺔ ﺣﺮﺍﺭﺓ

ﺍﻻﺷﺘﻌﺎﻝﻣﺎ ﻟﻢ ﻳﺘﻢ ﺣﻤﺎﻳﺘﻬﺎ ﺑﺸﻜﻞ ﺻﺤﻴﺢ ﻭﺑﻄﺮﻳﻘﺔ ﺗﻮﺍﻓﻖ ﻋﻠﻴﻬﺎ ﺍﻟﺴﻠﻄﺔ ﺫﺍﺕ ﺍﻻﺧﺘﺼﺎﺹ.

9.1.6ﻳﺠﺐ ﺗﺤﻤﻴﻞ ﺍﻟﺴﻮﺍﺉﻞ ﺍﻟﻘﺎﺑﻠﺔ ﻟﻼﺷﺘﻌﺎﻝ ﻭﺍﻟﻘﺎﺑﻠﺔ ﻟﻼﺣﺘﺮﺍﻕ ﺍﻟﺘﻲ ﻳﺘﻢ ﺗﺤﻤﻴﻠﻬﺎ ﻋﻨﺪ ﻧﻘﺎﻁ ﻏﻠﻴﺎﻧﻬﺎ

ﺃﻭﺃﻋﻠﻰ ﻣﻨﻬﺎ ﺃﻭ ﺍﻟﺘﻲ ﻗﺪ ﺗﺼﻞ ﺇﻟﻰ ﺩﺭﺟﺎﺕ ﺣﺮﺍﺭﺓ ﻧﻘﻄﺔ ﻏﻠﻴﺎﻧﻬﺎ ﺃﺛﻨﺎء ﺍﻟﻨﻘﻞ ﻓﻘﻂ ﻓﻲ ﺻﻬﺎﺭﻳﺞ ﺍﻟﺒﻀﺎﺉﻊ

ﺍﻟﻤﻨﺸﺄﺓﻭﻓﻘﺎً ﻟﻠﻘﺴﻢ .5.2

*9.1.7ﻻ ﻳﺠﻮﺯ ﺗﺤﻤﻴﻞ ﺍﻟﺴﻮﺍﺉﻞ ﺍﻟﻘﺎﺑﻠﺔ ﻟﻼﺷﺘﻌﺎﻝ ﻭﺍﻻﺣﺘﺮﺍﻕ ﺇﻻ ﻓﻲ ﺻﻬﺎﺭﻳﺞ ﺍﻟﺒﻀﺎﺉﻊ ﺍﻟﺘﻲ ﺗﺘﻮﺍﻓﻖ

ﻣﻮﺍﺩﺑﻨﺎﺉﻬﺎ ﻣﻊ ﺍﻟﺨﺼﺎﺉﺺ ﺍﻟﻜﻴﻤﻴﺎﺉﻴﺔ ﻟﻠﺴﺎﺉﻞ ﺍﻟﻤﺮﺍﺩ ﻧﻘﻠﻪ .ﻳﺠﺐ ﺃﻳﻀﺎً ﺃﻥ ﻳﻜﻮﻥ ﺍﻟﺴﺎﺉﻞ ﺍﻟﻘﺎﺑﻞ

ﻟﻼﺷﺘﻌﺎﻝﺃﻭ ﺍﻟﻘﺎﺑﻞ ﻟﻼﺣﺘﺮﺍﻕ ﺍﻟﺬﻱ ﻳﺘﻢ ﺗﺤﻤﻴﻠﻪ ﻣﺘﻮﺍﻓﻘﺎً ﻛﻴﻤﻴﺎﺉﻴﺎً ﻣﻊ ﺍﻟﺴﺎﺉﻞ ﺍﻟﻤﻨﻘﻮﻟﺔ ﻋﻠﻰ ﺍﻟﺤﻤﻮﻟﺔ

ﺍﻟﺴﺎﺑﻘﺔﻣﺎ ﻟﻢ ﻳﺘﻢ ﺗﻨﻈﻴﻒ ﺧﺰﺍﻥ ﺍﻟﺒﻀﺎﺉﻊ.

9.1.8ﻻ ﻳﺠﻮﺯ ﺗﺤﻤﻴﻞ ﺳﻮﺍﺉﻞ ﺍﻟﻔﺉﺔ IIﺃﻭ ﺍﻟﻔﺉﺔ IIIﻓﻲ ﺣﺠﺮﺓ ﻣﺠﺎﻭﺭﺓ ﻟﺴﻮﺍﺉﻞ ﺍﻟﻔﺉﺔ ﺍﻷﻭﻟﻰ ﻣﺎ ﻟﻢ

ﻳﺘﻢﺗﻮﻓﻴﺮ ﺣﻮﺍﺟﺰ ﻣﺰﺩﻭﺟﺔ.

9.1.9ﻻ ﻳﺠﻮﺯ ﺗﺤﻤﻴﻞ ﺍﻟﻤﻮﺍﺩ ﻏﻴﺮ ﺍﻟﻤﺘﻮﺍﻓﻘﺔ ﻛﻴﻤﻴﺎﺉﻴﺎ ًﻓﻲ ﺣﺠﺮﺍﺕ ﻣﺠﺎﻭﺭﺓ ﻣﺎ ﻟﻢ ﻳﺘﻢ ﻓﺼﻠﻬﺎ ﺑﺤﻮﺍﺟﺰ

ﻣﺰﺩﻭﺟﺔ.

*9.1.10ﻟﻤﻨﻊ ﺣﺪﻭﺙ ﺧﻄﺮ ﻣﻦ ﺗﻐﻴﻴﺮ ﻧﻘﺎﻁ ﻭﻣﻴﺾ ﺍﻟﺴﻮﺍﺉﻞ ،ﻳﺠﺐ ﺃﻻ ﻳﺘﻢ ﺗﺤﻤﻴﻞ ﺃﻱ ﺧﺰﺍﻥ ﺑﻀﺎﺉﻊ ﺃﻭ

ﺃﻱﺣﺠﺮﺓ ﻣﻨﻪ ﺗﻢ ﺍﺳﺘﺨﺪﺍﻣﻪ ﻟﺴﺎﺉﻞ ﺍﻟﻔﺉﺔ ﺍﻷﻭﻟﻰ ﺑﺴﺎﺉﻞ ﻣﻦ ﺍﻟﺪﺭﺟﺔ ﺍﻟﺜﺎﻧﻴﺔ ﺃﻭ ﺍﻟﻔﺉﺔ ﺍﻟﺜﺎﻟﺜﺔ ﺣﺘﻰ ﻫﺬﺍ

ﺍﻟﺨﺰﺍﻥﺃﻭ ﺍﻟﺤﺠﺮﺓ ﻭﺟﻤﻴﻊ ﺍﻷﻧﺎﺑﻴﺐ ،ﺗﻢ ﺗﺼﺮﻳﻒ ﺍﻟﻤﻀﺨﺎﺕ ﻭﺍﻟﻌﺪﺍﺩﺍﺕ ﻭﺍﻟﺨﺮﺍﻃﻴﻢ ﺍﻟﻤﺘﺼﻠﺔ ﺑﻬﺎ ﺑﺎﻟﻜﺎﻣﻞ.

ﺣﻘﻮﻕﺍﻟﻄﺒﻊ ﻭﺍﻟﻨﺸﺮ NFPA

ﺷﺮﻛﺔﺃﺑﺎﺩﻏﻮﺳﺘﺎﺭ ﺗﺎﺳﻴﺴﺎﺕ ﺇﻳﺮﺍﻧﻴﻨﺎﻥ ﺍﻟﻤﺤﺪﻭﺩﺓ www.atapars.com

www.atapars.com/NFPA-code/

9.1.10.1ﻳﺠﺐ ﺃﻥ ﻳﺘﻢ ﺷﻄﻒ ﺍﻟﺨﺰﺍﻥ ﺃﻭ ﺍﻟﺤﺠﺮﺓ ﺃﻭ ﺍﻷﻧﺎﺑﻴﺐ ﺃﻭ ﺍﻟﻤﻀﺨﺔ ﺃﻭ ﺍﻟﻌﺪﺍﺩ ﺃﻭ ﺍﻟﺨﺮﻃﻮﻡ ﺍﻟﺬﻱ ﻻ

ﻳﺘﻢﺗﺼﺮﻳﻔﻪ ﺑﺎﻟﻜﺎﻣﻞ ﻋﻨﺪ ﻧﻘﻄﺔ ﺍﻟﺘﺤﻤﻴﻞ ﺑﻜﻤﻴﺔ ﻣﻦ ﺳﺎﺉﻞ ﺍﻟﺼﻨﻒ IIﺃﻭ ﺍﻟﺼﻨﻒ IIIﺗﺴﺎﻭﻱ ﺿﻌﻒ

ﺳﻌﺔﺍﻷﻧﺎﺑﻴﺐ ﻭﺍﻟﻤﻀﺨﺔ ﻭﺍﻟﻌﺪﺍﺩ ﻭﺍﻟﺨﺮﻃﻮﻡ ،ﻹﺯﺍﻟﺔ ﺃﻱ ﺑﻘﺎﻳﺎ ﻣﻦ ﺳﺎﺉﻞ ﺍﻟﻔﺉﺔ ﺍﻷﻭﻟﻰ ﻣﻦ ﺍﻟﻨﻈﺎﻡ.

9.1.11ﻻ ﻳﺠﻮﺯ ﺇﺟﺮﺍء ﺃﻱ ﺇﺻﻼﺣﺎﺕ ﻋﻠﻰ ﺃﻱ ﻣﺮﻛﺒﺔ ﺻﻬﺮﻳﺠﻴﺔ ﻣﺎ ﻟﻢ ﻳﻜﻦ ﻣﻦ ﺍﻟﻤﻤﻜﻦ ﺇﺟﺮﺍء ﺍﻹﺻﻼﺣﺎﺕ

ﺩﻭﻥﻣﺨﺎﻃﺮ ،ﻛﻤﺎ ﻻ ﻳﺠﻮﺯ ﺇﺻﻼﺡ ﺃﻱ ﻣﺮﻛﺒﺔ ﺁﻟﻴﺔ ﻣﺤﻤﻠﺔ ﻓﻲ ﻣﺮﺁﺏ ﻣﻐﻠﻖ.

9.1.12ﻻ ﻳﺠﻮﺯ ﺇﺻﻼﺡ ﺃﻱ ﺧﺰﺍﻥ ﺑﻀﺎﺉﻊ ﺑﺄﻱ ﻃﺮﻳﻘﺔ ﺗﺴﺘﺨﺪﻡ ﻟﻬﺒﺎً ﺃﻭ ﻗﻮﺳﺎً ﺃﻭ ﺃﻱ ﻣﺼﺪﺭ ﺍﺷﺘﻌﺎﻝ

ﺁﺧﺮﻣﺎ ﻟﻢ ﻳﺘﻢ ﺍﻟﺤﻔﺎﻅ ﻋﻠﻰ ﺍﻟﺨﺰﺍﻥ ﺧﺎﻟﻴﺎً ﻣﻦ ﺍﻟﻐﺎﺯ ﺃﻭ ﺟﻌﻠﻪ ﺁﻣﻨﺎً ﺑﻄﺮﻳﻘﺔ ﻣﻌﺘﻤﺪﺓ.

9.2ﺗﺤﻤﻴﻞ ﻭﺗﻔﺮﻳﻎ ﻣﺮﻛﺒﺎﺕ ﺍﻟﺼﻬﺎﺭﻳﺞ.

9.2.1ﻳﺠﺐ ﺃﻥ ﻳﺘﻢ ﺗﺤﻤﻴﻞ ﻭﺗﻔﺮﻳﻎ ﺍﻟﻤﺮﻛﺒﺎﺕ ﺍﻟﺼﻬﺮﻳﺠﻴﺔ ﻓﻘﻂ ﻓﻲ ﺍﻟﻤﻮﺍﻗﻊ ﺍﻟﻤﻌﺘﻤﺪﺓ.

9.2.2ﻻ ﻳﺠﻮﺯ ﻟﻠﺴﺎﺉﻖ ﺃﻭ ﺍﻟﻤﺸﻐﻞ ﺃﻭ ﺍﻟﻤﺮﺍﻓﻖ ﻷﻱ ﻣﺮﻛﺒﺔ ﺻﻬﺮﻳﺠﻴﺔ ﺍﻟﺒﻘﺎء ﻓﻲ ﺍﻟﻤﺮﻛﺒﺔ ﻭﻟﻜﻦ ﻻ ﻳﺠﻮﺯ ﻟﻪ

ﺗﺮﻙﺍﻟﻤﺮﻛﺒﺔ ﺩﻭﻥ ﻣﺮﺍﻗﺒﺔ ﺃﺛﻨﺎء ﻋﻤﻠﻴﺔ ﺍﻟﺘﺤﻤﻴﻞ ﺃﻭ ﺍﻟﺘﻔﺮﻳﻎ .ﻳﻌﺘﺒﺮ ﺧﺮﻃﻮﻡ ﺍﻟﺘﻮﺻﻴﻞ ،ﻋﻨﺪ ﺗﻮﺻﻴﻠﻪ ﺑﻌﺮﺑﺔ

ﺍﻟﺼﻬﺮﻳﺞ،ﺟﺰءﺍً ﻣﻦ ﻋﺮﺑﺔ ﺍﻟﺼﻬﺮﻳﺞ.

9.2.3ﺃﺛﻨﺎء ﻧﻘﻞ ﺳﻮﺍﺉﻞ ﺍﻟﻔﺉﺔ ﺍﻷﻭﻟﻰ ،ﻳﺠﺐ ﺇﻳﻘﺎﻑ ﺗﺸﻐﻴﻞ ﻣﺤﺮﻛﺎﺕ ﺍﻟﻤﺮﻛﺒﺎﺕ ﺍﻟﺼﻬﺮﻳﺠﻴﺔ ﺃﻭ

ﻣﺤﺮﻛﺎﺕﺍﻟﻤﻀﺨﺎﺕ ﺍﻟﻤﺴﺎﻋﺪﺓ ﺃﻭ ﺍﻟﻤﺤﻤﻮﻟﺔ ﺃﺛﻨﺎء ﻋﻤﻞ ﻭﻛﺴﺮ ﻭﺻﻼﺕ ﺍﻟﺨﺮﺍﻃﻴﻢ.

9.2.3.1ﻋﻨﺪﻣﺎ ﻳﺘﻢ ﺍﻟﺘﺤﻤﻴﻞ ﺃﻭ ﺍﻟﺘﻔﺮﻳﻎ ﺩﻭﻥ ﺍﻟﺤﺎﺟﺔ ﺇﻟﻰ ﺍﺳﺘﺨﺪﺍﻡ ﻣﺤﺮﻙ ﻣﺮﻛﺒﺔ ﺍﻟﺼﻬﺮﻳﺞ ،ﻳﺠﺐ

ﺇﻳﻘﺎﻑﺍﻟﻤﺤﺮﻙ ﻃﻮﺍﻝ ﻋﻤﻠﻴﺎﺕ ﻧﻘﻞ ﺳﻮﺍﺉﻞ ﺍﻟﻔﺉﺔ ﺍﻷﻭﻟﻰ.

9.2.4ﻋﻨﺪﻣﺎ ﻳﺘﻢ ﺍﺳﺘﺨﺪﺍﻡ ﺍﻟﻤﻀﺨﺎﺕ ﺍﻟﻤﺤﻤﻮﻟﺔ ﻟﻨﻘﻞ ﺳﻮﺍﺉﻞ ﺍﻟﻔﺉﺔ ﺍﻷﻭﻟﻰ ،ﻳﺠﺐ ﺃﻥ ﺗﻤﺘﺜﻞ

ﺍﻟﻤﻀﺨﺎﺕﺍﻟﻤﺤﻤﻮﻟﺔ ﻟﻸﺣﻜﺎﻡ ﺍﻟﻤﻌﻤﻮﻝ ﺑﻬﺎ ﻓﻲ ﺍﻟﻘﺴﻢ 8.1ﺃﻭ ﺍﻟﻘﺴﻢ .8.2

9.2.5ﻻ ﻳﺠﻮﺯ ﺗﺤﻤﻴﻞ ﺃﻱ ﺧﺰﺍﻥ ﺑﻀﺎﺉﻊ ﺃﻭ ﺣﺠﺮﺓ ﻣﻨﻪ ﺗﺴﺘﺨﺪﻡ ﻟﻨﻘﻞ ﺃﻱ ﺳﺎﺉﻞ ﺃﻭ ﺃﺳﻔﻠﺖ ﻗﺎﺑﻞ

ﻟﻼﺷﺘﻌﺎﻝﺃﻭ ﺍﻻﺷﺘﻌﺎﻝ ﺑﺎﻟﺴﻮﺍﺉﻞ ﺑﺎﻟﻜﺎﻣﻞ .ﻭﻳﺠﺐ ﺗﻮﻓﻴﺮ ﻣﺴﺎﺣﺔ ﻛﺎﻓﻴﺔ )ﺍﻧﻘﻄﺎﻉ( ﻓﻲ ﻛﻞ ﺣﺎﻟﺔ ﻟﻤﻨﻊ

ﺍﻟﺘﺴﺮﺏﻣﻦ ﻫﺬﺍ ﺍﻟﺨﺰﺍﻥ ﺃﻭ ﺍﻟﺤﺠﺮﺓ ﻋﻦ ﻃﺮﻳﻖ ﺗﻤﺪﺩ ﺍﻟﻤﺤﺘﻮﻳﺎﺕ ﺑﺴﺒﺐ ﺍﺭﺗﻔﺎﻉ ﺩﺭﺟﺔ ﺍﻟﺤﺮﺍﺭﺓ ﺃﺛﻨﺎء ﺍﻟﻨﻘﻞ،

ﻭﻋﻠﻰﺃﻻ ﻳﻘﻞ ﺑﺄﻱ ﺣﺎﻝ ﻣﻦ ﺍﻷﺣﻮﺍﻝ ﻋﻦ 1ﺑﺎﻟﻤﺎﺉﺔ.

9.2.6ﻳﺠﺐ ﺃﻥ ﻳﺘﻢ ﺗﻮﺻﻴﻞ ﺳﻮﺍﺉﻞ ﺍﻟﻔﺉﺔ ﺍﻷﻭﻟﻰ ﺇﻟﻰ ﺍﻟﺨﺰﺍﻧﺎﺕ ﺗﺤﺖ ﺍﻷﺭﺽ ﺍﻟﺘﻲ ﺗﺰﻳﺪ ﺳﻌﺘﻬﺎ

ﻋﻦ 1000ﺟﺎﻟﻮﻥ ) 3800ﻟﺘﺮ( ﻋﻦ ﻃﺮﻳﻖ ﺍﻟﺘﻮﺻﻴﻼﺕ ﺍﻟﻤﺤﻜﻤﺔ ﺑﻴﻦ ﺍﻟﺨﺮﻃﻮﻡ ﻭﺃﻧﺒﻮﺏ ﺍﻟﺘﻌﺒﺉﺔ.

9.2.6.1ﻓﻲ ﺟﻤﻴﻊ ﺍﻟﺤﺎﻻﺕ ﺍﻟﺘﻲ ﺗﻜﻮﻥ ﻓﻴﻬﺎ ﺍﻟﺨﺰﺍﻧﺎﺕ ﺍﻟﻤﻮﺟﻮﺩﺓ ﺗﺤﺖ ﺍﻷﺭﺽ ﻣﺠﻬﺰﺓ ﺑﺄﻱ ﻧﻮﻉ ﻣﻦ

ﺃﻧﻈﻤﺔﺍﺳﺘﻌﺎﺩﺓ ﺍﻟﺒﺨﺎﺭ ،ﻳﺠﺐ ﺇﺟﺮﺍء ﺟﻤﻴﻊ ﺍﻟﺘﻮﺻﻴﻼﺕ ﺍﻟﻤﻄﻠﻮﺑﺔ ﻣﻦ ﺃﺟﻞ ﺍﻟﺘﺸﻐﻴﻞ ﺍﻵﻣﻦ ﻭﺍﻟﺴﻠﻴﻢ

ﻟﻌﻤﻠﻴﺔﺍﺳﺘﻌﺎﺩﺓ ﺍﻟﺒﺨﺎﺭ ﺍﻟﻤﺤﺪﺩﺓ.

9.2.6.2ﻳﺠﺐ ﺃﻥ ﺗﻜﻮﻥ ﻫﺬﻩ ﺍﻟﻮﺻﻼﺕ ﻣﺼﻤﻤﺔ ﻟﻤﻨﻊ ﺇﻃﻼﻕ ﺍﻷﺑﺨﺮﺓ ﻋﻠﻰ ﻣﺴﺘﻮﻯ ﺍﻟﺼﻒ ،ﻭﻳﺠﺐ ﺃﻥ

ﺗﻈﻞﻣﺘﺼﻠﺔ ﻃﻮﺍﻝ ﻋﻤﻠﻴﺔ ﺍﻟﺘﺤﻤﻴﻞ ﺃﻭ ﺍﻟﺘﻔﺮﻳﻎ.

9.2.7ﻋﻨﺪﻣﺎ ﻳﺘﻢ ﻣﻞء ﺧﺰﺍﻥ ﺍﻟﺒﻀﺎﺉﻊ ﻣﻦ ﺧﻼﻝ ﺍﻟﺘﺤﻤﻴﻞ ﺍﻟﺴﻔﻠﻲ ،ﻳﺠﺐ ﺗﻮﻓﻴﺮ ﻭﺳﻴﻠﺔ ﺇﻳﺠﺎﺑﻴﺔ ﻟﺘﺤﻤﻴﻞ

ﻛﻤﻴﺔﻣﺤﺪﺩﺓ ﻣﺴﺒﻘﺎً ﻣﻦ ﺍﻟﺴﺎﺉﻞ ،ﻭﻳﺠﺐ ﺗﺮﻛﻴﺐ ﺟﻬﺎﺯ ﺗﺤﻜﻢ ﺃﻭﺗﻮﻣﺎﺗﻴﻜﻲ ﻟﻺﻏﻼﻕ ﺍﻟﺜﺎﻧﻮﻱ ﻓﻲ ﻛﻞ ﺣﺠﺮﺓ

ﻟﻤﻨﻊﺍﻟﻤﻞء ﺍﻟﺰﺍﺉﺪ.

9.2.8ﻳﺠﺐ ﺃﻥ ﻳﺘﻢ ﻭﺿﻊ ﻣﻠﺼﻖ ﻋﻠﻰ ﻧﻈﺎﻡ ﺍﻟﺘﺤﻜﻢ ﻓﻲ ﺍﻹﻏﻼﻕ ﺍﻟﺜﺎﻧﻮﻱ ﺣﺴﺐ ﺍﻟﺸﺮﻛﺔ ﺍﻟﻤﺼﻨﻌﺔ ﻭﺍﻟﻨﻮﻉ.

9.2.8.1ﻳﺠﺐ ﺃﻥ ﻳﻜﻮﻥ ﺃﻱ ﻧﻈﺎﻡ ﻛﻬﺮﺑﺎﺉﻲ ﻳﺴﺘﺨﺪﻡ ﻟﻺﻏﻼﻕ ﺍﻟﺜﺎﻧﻮﻱ ﻣﺘﻮﺍﻓﻘﺎً ﻣﻊ NFPA

ﺣﻘﻮﻕﺍﻟﻄﺒﻊ ﻭﺍﻟﻨﺸﺮ NFPA

ﺷﺮﻛﺔﺃﺑﺎﺩﻏﻮﺳﺘﺎﺭ ﺗﺎﺳﻴﺴﺎﺕ ﺇﻳﺮﺍﻧﻴﻨﺎﻥ ﺍﻟﻤﺤﺪﻭﺩﺓ www.atapars.com

www.atapars.com/NFPA-code/

،70ﺍﻟﻜﻮﺩ ﺍﻟﻜﻬﺮﺑﺎﺉﻲ ﺍﻟﻮﻃﻨﻲ.

9.2.9ﻋﻨﺪﻣﺎ ﺗﻜﻮﻥ ﻣﺮﻛﺒﺎﺕ ﺍﻟﺘﺤﻤﻴﻞ ﺍﻟﺴﻔﻠﻲ ﻣﺠﻬﺰﺓ ﻻﺳﺘﻌﺎﺩﺓ ﺍﻟﺒﺨﺎﺭ ﻭﻻ ﺗﻜﻮﻥ ﻫﻨﺎﻙ ﺣﺎﺟﺔ ﻻﺳﺘﺮﺩﺍﺩ

ﺍﻟﺒﺨﺎﺭ،ﻳﺠﺐ ﺃﻥ ﻳﻜﻮﻥ ﻧﻈﺎﻡ ﺑﺨﺎﺭ ﺍﻟﺨﺰﺍﻥ ﻣﻔﺘﻮﺣﺎً ﻟﻠﻬﻮﺍء ﺍﻟﺠﻮﻱ ﻟﻤﻨﻊ ﺿﻐﻂ ﺍﻟﺨﺰﺍﻥ ﻭﻧﻈﺎﻡ ﺍﻟﺒﺨﺎﺭ.

9.2.10ﻋﻨﺪ ﺍﺳﺘﺨﺪﺍﻡ ﻣﺤﻮﻝ ﺍﺳﺘﻌﺎﺩﺓ ﺍﻟﺒﺨﺎﺭ ﺍﻟﻤﻨﻔﺼﻞ ﺍﻟﺠﺎﻑ ،ﻳﺠﺐ ﺍﺗﺨﺎﺫ ﺍﻟﺘﺪﺍﺑﻴﺮ ﺍﻟﻼﺯﻣﺔ ﻟﻀﻤﺎﻥ

ﺗﻬﻮﻳﺔﻧﻈﺎﻡ ﺍﺳﺘﻌﺎﺩﺓ ﺍﻟﺒﺨﺎﺭ ﺑﺎﻟﻜﺎﻣﻞ ﻗﺒﻞ ﺍﻟﺘﻔﺮﻳﻎ ﻟﻤﻨﻊ ﺍﻧﻬﻴﺎﺭ ﺍﻟﺨﺰﺍﻥ .ﻳﻨﻄﺒﻖ ﻫﺬﺍ ﺍﻟﺸﺮﻁ ﻋﻠﻰ ﻛﻞ ﻣﻦ

ﺍﻟﺘﺤﻤﻴﻞﺍﻟﺴﻔﻠﻲ ﻭﺍﻟﻌﻠﻮﻱ.

9.2.11ﺃﺛﻨﺎء ﺍﻟﺘﺤﻤﻴﻞ ﺍﻟﺴﻔﻠﻲ ﻟﻠﺨﺰﺍﻥ ﺍﻟﻤﺠﻬﺰ ﺑﻨﻈﺎﻡ ﺍﺳﺘﺮﺩﺍﺩ ﺍﻟﺒﺨﺎﺭ ،ﻳﺠﺐ ﺍﺳﺘﺨﺪﺍﻡ ﻭﺻﻠﺔ ﺍﺳﺘﺮﺩﺍﺩ

ﺍﻟﺒﺨﺎﺭﻟﻨﻘﻞ ﺍﻟﺒﺨﺎﺭ ﺑﻌﻴﺪﺍً ﻋﻦ ﻣﻨﻄﻘﺔ ﺍﻟﺘﺤﻤﻴﻞ ﺑﺎﺳﺘﺨﺪﺍﻡ ﻧﻈﺎﻡ ﺍﺳﺘﻌﺎﺩﺓ ﺍﻟﺒﺨﺎﺭ ﺍﻟﻄﺮﻓﻲ ﺃﻭ ﺃﻧﺒﻮﺏ ﺍﻟﺘﻔﺮﻳﻎ

ﺍﻟﻘﺎﺉﻢﺃﻭ ﻋﻦ ﻃﺮﻳﻖ ﻓﺘﺢ ﻓﺘﺤﺎﺕ ﺗﻌﺒﺉﺔ ﺍﻟﺨﺰﺍﻥ )ﻓﺘﺤﺎﺕ ﺍﻟﺘﻔﺘﻴﺶ(.

9.2.12ﻋﻨﺪﻣﺎ ﻳﺘﻢ ﻣﻞء ﺧﺰﺍﻥ ﺍﻟﺒﻀﺎﺉﻊ ﻣﻦ ﺧﻼﻝ ﻓﺘﺤﺔ ﻋﻠﻮﻳﺔ ،ﻳﺠﺐ ﺭﺑﻂ ﺧﺰﺍﻥ ﺍﻟﺒﻀﺎﺉﻊ ﺑﺴﺎﻕ ﺍﻟﺘﻌﺒﺉﺔ

ﺃﻭﺑﺠﺰء ﻣﻦ ﻫﻴﻜﻞ ﺍﻟﺤﺎﻣﻞ ﺍﻟﻤﺘﺼﻞ ﻛﻬﺮﺑﺎﺉﻴﺎً ﺑﺄﻧﺎﺑﻴﺐ ﺳﺎﻕ ﺍﻟﺘﻌﺒﺉﺔ.

9.2.12.1ﻻ ﻳﻠﺰﻡ ﺍﻟﺮﺑﻂ ﻋﻨﺪ ﺗﺤﻤﻴﻞ ﺍﻷﺳﻔﻠﺖ ﺃﻭ ﺍﻟﺰﻳﺖ ﺍﻟﺨﺎﻡ ﺃﻭ ﺃﻱ ﻣﻨﺘﺞ ﻳﺤﺘﻮﻱ ﻋﻠﻰ ﻧﺴﺐ ﻛﺒﻴﺮﺓ

ﻣﻦﺍﻟﺒﻘﺎﻳﺎ ﺍﻟﺨﺎﻡ.

9.2.12.2ﻻ ﻳﻠﺰﻡ ﺍﻟﺮﺑﻂ ﻟﻤﺮﻛﺒﺎﺕ ﺍﻟﺼﻬﺎﺭﻳﺞ ﺍﻟﻤﺴﺘﺨﺪﻣﺔ ﺣﺼﺮﻳﺎً ﻟﻨﻘﻞ ﺳﻮﺍﺉﻞ ﺍﻟﺪﺭﺟﺔ ﺍﻟﺜﺎﻧﻴﺔ ﺃﻭ

ﺍﻟﺪﺭﺟﺔﺍﻟﺜﺎﻟﺜﺔ ﻋﻨﺪ ﺗﺤﻤﻴﻠﻬﺎ ﻓﻲ ﻣﻮﺍﻗﻊ ﻻ ﻳﺘﻢ ﻓﻴﻬﺎ ﺍﻟﺘﻌﺎﻣﻞ ﻣﻊ ﺳﻮﺍﺉﻞ ﺍﻟﻔﺉﺔ ﺍﻷﻭﻟﻰ.

*9.2.12.3ﻳﺠﺐ ﺃﻥ ﻳﺘﻢ ﺗﻮﺻﻴﻞ ﺳﻠﻚ ﺍﻟﺮﺑﻂ ﻗﺒﻞ ﻓﺘﺢ ﺃﻏﻄﻴﺔ ﺍﻟﻘﺒﺔ ﻭﻳﺠﺐ ﺍﻟﺤﻔﺎﻅ ﻋﻠﻴﻪ ﻓﻲ ﻣﻜﺎﻧﻪ ﺃﺛﻨﺎء

ﻋﻤﻠﻴﺔﺍﻟﺘﻌﺒﺉﺔ ﺑﺄﻛﻤﻠﻬﺎ.

9.2.12.4ﻳﺠﺐ ﺃﻥ ﺗﻜﻮﻥ ﺃﻏﻄﻴﺔ ﺍﻟﻘﺒﺔ ﻣﻐﻠﻘﺔ ﺑﺈﺣﻜﺎﻡ ﻗﺒﻞ ﻓﺼﻞ ﺳﻠﻚ ﺍﻟﺮﺑﻂ ﻋﻦ ﺧﺰﺍﻥ ﺍﻟﺒﻀﺎﺉﻊ.

9.2.13ﻻ ﻳﻠﺰﻡ ﻭﺟﻮﺩ ﻭﺻﻠﺔ ﺳﻠﻚ ﺭﺑﻂ ﺧﺎﺭﺟﻲ ﺃﻭ ﺳﻠﻚ ﺭﺑﻂ ﻣﺘﻜﺎﻣﻞ ﻣﻊ ﺧﺮﻃﻮﻡ ﻟﺘﻔﺮﻳﻎ ﺍﻟﺴﻮﺍﺉﻞ ﺍﻟﻘﺎﺑﻠﺔ

ﻟﻼﺷﺘﻌﺎﻝﻭﺍﻟﻘﺎﺑﻠﺔ ﻟﻼﺣﺘﺮﺍﻕ ﻓﻲ ﺍﻟﺨﺰﺍﻧﺎﺕ ﺗﺤﺖ ﺍﻷﺭﺽ ﻭﻻ ﻋﻨﺪ ﺗﺤﻤﻴﻞ ﺃﻭ ﺗﻔﺮﻳﻎ ﻣﺮﻛﺒﺔ ﺍﻟﺼﻬﺮﻳﺞ ﻣﻦ

ﺧﻼﻝﻭﺻﻼﺕ ﻣﺤﻜﻤﺔ ﻣﺜﻞ ﺍﻟﺨﺰﺍﻥ ﺍﻟﻤﻮﺟﻮﺩ ﻓﻮﻕ ﺍﻷﺭﺽ ﺃﻭ ﻣﻦ ﺧﻼﻝ ﺍﻟﻮﺻﻼﺕ ﺍﻟﺴﻔﻠﻴﺔ.

9.2.14ﻳﻤﻨﻊ ﺍﻟﺘﺪﺧﻴﻦ ﻋﻠﻰ ﺃﻭ ﺣﻮﻝ ﺃﻱ ﻣﺮﻛﺒﺔ ﺻﻬﺮﻳﺠﻴﺔ ﺃﺛﻨﺎء ﺗﺤﻤﻴﻞ ﺃﻭ ﺗﻔﺮﻳﻎ ﺃﻱ ﺳﺎﺉﻞ ﻗﺎﺑﻞ

ﻟﻼﺷﺘﻌﺎﻝﺃﻭ ﺍﻻﺷﺘﻌﺎﻝ.

9.2.15ﻳﺠﺐ ﺗﻮﺧﻲ ﺍﻟﺤﺬﺭ ﺍﻟﺸﺪﻳﺪ ﻋﻨﺪ ﺗﺤﻤﻴﻞ ﺃﻭ ﺗﻔﺮﻳﻎ ﺃﻱ ﺳﺎﺉﻞ ﻗﺎﺑﻞ ﻟﻼﺷﺘﻌﺎﻝ ﺩﺍﺧﻞ ﺃﻭ ﻣﻦ ﺃﻱ

ﺧﺰﺍﻥﺑﻀﺎﺉﻊ ﻹﺑﻌﺎﺩ ﺍﻟﻨﺎﺭ ﻭﻣﻨﻊ ﺍﻷﺷﺨﺎﺹ ﺍﻟﻤﻮﺟﻮﺩﻳﻦ ﻓﻲ ﺍﻟﻤﻨﻄﻘﺔ ﺍﻟﻤﺠﺎﻭﺭﺓ ﻣﻦ ﺍﻟﺘﺪﺧﻴﻦ ﺃﻭ ﺇﺷﻌﺎﻝ

ﺃﻋﻮﺍﺩﺍﻟﺜﻘﺎﺏ ﺃﻭ ﺣﻤﻞ ﺃﻱ ﻟﻬﺐ ﺃﻭ ﺳﻴﺠﺎﺭ ﺃﻭ ﻏﻠﻴﻮﻥ ﺃﻭ ﺳﻴﺠﺎﺭﺓ ﻣﺸﺘﻌﻠﺔ.

9.2.16ﻻ ﻳﺠﻮﺯ ﻧﻘﻞ ﺃﻱ ﺳﺎﺉﻞ ﻗﺎﺑﻞ ﻟﻼﺷﺘﻌﺎﻝ ﺃﻭ ﺍﻻﺷﺘﻌﺎﻝ ﻣﻦ ﻭﺇﻟﻰ ﺃﻱ ﻣﺮﻛﺒﺔ ﺻﻬﺮﻳﺠﻴﺔ ﻣﺎ ﻟﻢ ﻳﺘﻢ

ﺿﺒﻂﻓﺮﺍﻣﻞ ﺍﻻﻧﺘﻈﺎﺭ ﺑﺸﻜﻞ ﺁﻣﻦ ﻭﺗﻢ ﺍﺗﺨﺎﺫ ﺟﻤﻴﻊ ﺍﻻﺣﺘﻴﺎﻃﺎﺕ ﺍﻟﻤﻌﻘﻮﻟﺔ ﺍﻷﺧﺮﻯ ﻟﻤﻨﻊ ﺣﺮﻛﺔ ﺍﻟﻤﺮﻛﺒﺔ.

9.3ﻃﻔﺎﻳﺎﺕ ﺍﻟﺤﺮﻳﻖ.

9.3.1ﻳﺠﺐ ﺃﻥ ﺗﺰﻭﺩ ﻛﻞ ﻣﺮﻛﺒﺔ ﺻﻬﺮﻳﺞ ﺑﻄﻔﺎﻳﺔ ﺣﺮﻳﻖ ﻣﺤﻤﻮﻟﺔ ﺫﺍﺕ ﺗﺼﻨﻴﻒ ﻻ ﻳﻘﻞ ﻋﻦ A: 40B,C

4ﺃﻭ ﺑﺄﻛﺜﺮ ﻣﻦ ﻃﻔﺎﻳﺔ ﺣﺮﻳﻖ ﻣﺤﻤﻮﻟﺔ ،ﻛﻞ ﻣﻨﻬﺎ ﻟﻬﺎ ﺗﺼﻨﻴﻒ .2A: 20B,C

ﺣﻘﻮﻕﺍﻟﻄﺒﻊ ﻭﺍﻟﻨﺸﺮ NFPA

ﺷﺮﻛﺔﺃﺑﺎﺩﻏﻮﺳﺘﺎﺭ ﺗﺎﺳﻴﺴﺎﺕ ﺇﻳﺮﺍﻧﻴﻨﺎﻥ ﺍﻟﻤﺤﺪﻭﺩﺓ www.atapars.com

www.atapars.com/NFPA-code/

9.3.2ﻳﺠﺐ ﺃﻥ ﺗﻜﻮﻥ ﺍﻟﺘﻘﻴﻴﻤﺎﺕ ﻣﺘﻮﺍﻓﻘﺔ ﻣﻊ ،NFPA 10ﺍﻟﻤﻮﺍﺻﻔﺔ ﺍﻟﻘﻴﺎﺳﻴﺔ ﻷﺟﻬﺰﺓ ﺇﻃﻔﺎء ﺍﻟﺤﺮﻳﻖ

ﺍﻟﻤﺤﻤﻮﻟﺔ.

9.3.3ﻳﺠﺐ ﺃﻥ ﺗﻈﻞ ﻃﻔﺎﻳﺎﺕ ﺍﻟﺤﺮﻳﻖ ﻓﻲ ﺣﺎﻟﺔ ﺗﺸﻐﻴﻞ ﺟﻴﺪﺓ ﻓﻲ ﺟﻤﻴﻊ ﺍﻷﻭﻗﺎﺕ ،ﻭﻳﺠﺐ ﺃﻥ ﺗﻜﻮﻥ ﻣﻮﺟﻮﺩﺓ ﻓﻲ

ﻣﻜﺎﻥﻳﺴﻬﻞ ﺍﻟﻮﺻﻮﻝ ﺇﻟﻴﻪ ﻓﻲ ﻛﻞ ﻣﺮﻛﺒﺔ ﺻﻬﺮﻳﺠﻴﺔ.

9.3.4ﻳﺠﺐ ﺻﻴﺎﻧﺔ ﻃﻔﺎﻳﺎﺕ ﺍﻟﺤﺮﻳﻖ ﻃﺒﻘﺎ ًﻟﻠﻤﻮﺍﺻﻔﺔ ،NFPA 10ﺍﻟﻤﻮﺍﺻﻔﺔ ﺍﻟﻘﻴﺎﺳﻴﺔ ﻷﺟﻬﺰﺓ ﺇﻃﻔﺎء

ﺍﻟﺤﺮﻳﻖﺍﻟﻤﺤﻤﻮﻟﺔ.

ﺃ ﻣﻠﺤﻖﺃ ﻣﺎﺩﺓ ﺗﻮﺿﻴﺤﻴﺔ

ﻻﻳﻌﺪ ﺍﻟﻤﻠﺤﻖ ﺃ ﺟﺰءﺍً ﻣﻦ ﻣﺘﻄﻠﺒﺎﺕ ﻭﺛﻴﻘﺔ NFPAﻭﻟﻜﻨﻪ ﺗﻢ ﺗﻀﻤﻴﻨﻪ ﻷﻏﺮﺍﺽ ﺇﻋﻼﻣﻴﺔ ﻓﻘﻂ.

ﻳﺤﺘﻮﻱﻫﺬﺍ ﺍﻟﻤﻠﺤﻖ ﻋﻠﻰ ﻣﺎﺩﺓ ﺗﻮﺿﻴﺤﻴﺔ ﻣﺮﻗﻤﺔ ﻟﺘﺘﻮﺍﻓﻖ ﻣﻊ ﻓﻘﺮﺍﺕ ﺍﻟﻨﺺ ﺍﻟﻤﻌﻤﻮﻝ ﺑﻬﺎ.

ﺃ1.1.1.ﺍﻟﻤﻮﺍﺩ ﺍﻟﻤﺴﺘﻘﺮﺓ ﻋﺎﺩﺓ ﻫﻲ ﺗﻠﻚ ﺍﻟﺘﻲ ﺗﺘﻤﺘﻊ ﺑﺎﻟﻘﺪﺭﺓ ﺍﻟﻨﺴﺒﻴﺔ ﻋﻠﻰ ﻣﻘﺎﻭﻣﺔ ﺍﻟﺘﻐﻴﺮﺍﺕ ﻓﻲ ﺗﺮﻛﻴﺒﻬﺎ

ﺍﻟﻜﻴﻤﻴﺎﺉﻲﺍﻟﺘﻲ ﻣﻦ ﺷﺄﻧﻬﺎ ﺃﻥ ﺗﻨﺘﺞ ﺗﻔﺎﻋﻼﺕ ﺃﻭ ﺍﻧﻔﺠﺎﺭﺍﺕ ﻋﻨﻴﻔﺔ ﻋﻠﻰ ﺍﻟﺮﻏﻢ ﻣﻦ ﺗﻌﺮﺿﻬﺎ ﻟﻠﻬﻮﺍء ﺃﻭ ﺍﻟﻤﺎء

ﺃﻭﺍﻟﺤﺮﺍﺭﺓ ،ﺑﻤﺎ ﻓﻲ ﺫﻟﻚ ﺍﻟﻨﻄﺎﻕ ﺍﻟﻄﺒﻴﻌﻲ ﻟﻠﻈﺮﻭﻑ ﺍﻟﺘﻲ ﺗﻮﺍﺟﻬﻬﺎ ﺃﺛﻨﺎء ﺍﻟﻤﻨﺎﻭﻟﺔ ﺃﻭ ﺍﻟﺘﺨﺰﻳﻦ ﺃﻭ ﺍﻟﻨﻘﻞ.

ﺍﻟﺴﻮﺍﺉﻞﻏﻴﺮ ﺍﻟﻤﺴﺘﻘﺮﺓ )ﺍﻟﻤﺘﻔﺎﻋﻠﺔ( ﺍﻟﻘﺎﺑﻠﺔ ﻟﻼﺷﺘﻌﺎﻝ ﻭﺍﻟﻘﺎﺑﻠﺔ ﻟﻼﺣﺘﺮﺍﻕ ﻫﻲ ﺍﻟﺴﻮﺍﺉﻞ ﺍﻟﺘﻲ ﻓﻲ ﺣﺎﻟﺘﻬﺎ

ﺍﻟﻨﻘﻴﺔﺃﻭ ﻛﻤﺎ ﻳﺘﻢ ﺇﻧﺘﺎﺟﻬﺎ ﺃﻭ ﻧﻘﻠﻬﺎ ﺗﺠﺎﺭﻳﺎً ﺳﻮﻑ ﺗﺘﺒﻠﻤﺮ ﺑﻘﻮﺓ ﺃﻭ ﺗﺘﺤﻠﻞ ﺃﻭ ﺗﺘﻜﺜﻒ ﺃﻭ ﺗﺼﺒﺢ ﺫﺍﺗﻴﺔ ﺍﻟﺘﻔﺎﻋﻞ

ﺗﺤﺖﻇﺮﻭﻑ ﺍﻟﺼﺪﻣﺔ ﺃﻭ ﺍﻟﻀﻐﻂ ﺃﻭ ﺩﺭﺟﺔ ﺍﻟﺤﺮﺍﺭﺓ.

ﺃ3.2.1.ﺗﻤﺖ ﺍﻟﻤﻮﺍﻓﻘﺔ ﻋﻠﻴﻪ.ﻻ ﺗﻮﺍﻓﻖ ﺍﻟﺮﺍﺑﻄﺔ ﺍﻟﻮﻃﻨﻴﺔ ﻟﻠﺤﻤﺎﻳﺔ ﻣﻦ ﺍﻟﺤﺮﺍﺉﻖ ﻋﻠﻰ ﺃﻱ ﻣﻨﺸﺂﺕ ﺃﻭ

ﺇﺟﺮﺍءﺍﺕﺃﻭ ﻣﻌﺪﺍﺕ ﺃﻭ ﻣﻮﺍﺩ ﺃﻭ ﺗﻘﻮﻡ ﺑﺘﻔﺘﻴﺸﻬﺎ ﺃﻭ ﺍﻟﺘﺼﺪﻳﻖ ﻋﻠﻴﻬﺎ؛ ﻛﻤﺎ ﺃﻧﻬﺎ ﻻ ﺗﻮﺍﻓﻖ ﻋﻠﻰ ﻣﺨﺘﺒﺮﺍﺕ

ﺍﻻﺧﺘﺒﺎﺭﺃﻭ ﺗﻘﻴﻤﻬﺎ .ﻋﻨﺪ ﺗﺤﺪﻳﺪ ﻣﺪﻯ ﻗﺒﻮﻝ ﺍﻟﺘﺮﻛﻴﺒﺎﺕ ﺃﻭ ﺍﻹﺟﺮﺍءﺍﺕ ﺃﻭ ﺍﻟﻤﻌﺪﺍﺕ ﺃﻭ ﺍﻟﻤﻮﺍﺩ ،ﻳﺠﻮﺯ ﻟﻠﺴﻠﻄﺔ

ﺫﺍﺕﺍﻻﺧﺘﺼﺎﺹ ﺍﻟﻘﻀﺎﺉﻲ ﺃﻥ ﺗﺒﻨﻲ ﺍﻟﻘﺒﻮﻝ ﻋﻠﻰ ﺍﻻﻣﺘﺜﺎﻝ ﻟﻤﻌﺎﻳﻴﺮ NFPAﺃﻭ ﻣﻌﺎﻳﻴﺮ ﺃﺧﺮﻯ ﻣﻨﺎﺳﺒﺔ .ﻭﻓﻲ

ﺣﺎﻟﺔﻋﺪﻡ ﻭﺟﻮﺩ ﻣﺜﻞ ﻫﺬﻩ ﺍﻟﻤﻌﺎﻳﻴﺮ ،ﻗﺪ ﺗﻄﻠﺐ ﺍﻟﺴﻠﻄﺔ ﺍﻟﻤﺬﻛﻮﺭﺓ ﺩﻟﻴﻼ ًﻋﻠﻰ ﺍﻟﺘﺜﺒﻴﺖ ﺃﻭ ﺍﻹﺟﺮﺍء ﺃﻭ

ﺍﻻﺳﺘﺨﺪﺍﻡﺍﻟﺼﺤﻴﺢ .ﻳﺠﻮﺯ ﻟﻠﺴﻠﻄﺔ ﺫﺍﺕ ﺍﻟﻮﻻﻳﺔ ﺍﻟﻘﻀﺎﺉﻴﺔ ﺃﻳﻀﺎً ﺍﻟﺮﺟﻮﻉ ﺇﻟﻰ ﺍﻟﻘﻮﺍﺉﻢ ﺃﻭ ﻣﻤﺎﺭﺳﺎﺕ ﻭﺿﻊ

ﺍﻟﻌﻼﻣﺎﺕﺍﻟﺨﺎﺻﺔ ﺑﻤﻨﻈﻤﺔ ﻣﻌﻨﻴﺔ ﺑﺘﻘﻴﻴﻤﺎﺕ ﺍﻟﻤﻨﺘﺠﺎﺕ ﻭﺑﺎﻟﺘﺎﻟﻲ ﺗﻜﻮﻥ ﻓﻲ ﻭﺿﻊ ﻳﻤﻜﻨﻬﺎ ﻣﻦ ﺗﺤﺪﻳﺪ

ﺍﻻﻣﺘﺜﺎﻝﻟﻠﻤﻌﺎﻳﻴﺮ ﺍﻟﻤﻨﺎﺳﺒﺔ ﻟﻺﻧﺘﺎﺝ ﺍﻟﺤﺎﻟﻲ ﻟﻠﻌﻨﺎﺻﺮ ﺍﻟﻤﺪﺭﺟﺔ.

ﺃ3.2.3.ﻣﺪﺭﺝ ﻓﻲ ﺍﻟﻘﺎﺉﻤﺔ.ﻗﺪ ﺗﺨﺘﻠﻒ ﻭﺳﺎﺉﻞ ﺗﺤﺪﻳﺪ ﺍﻟﻤﻌﺪﺍﺕ ﺍﻟﻤﺪﺭﺟﺔ ﻟﻜﻞ ﻣﻨﻈﻤﺔ ﻣﻌﻨﻴﺔ ﺑﺘﻘﻴﻴﻢ

ﺍﻟﻤﻨﺘﺞ؛ﺑﻌﺾ ﺍﻟﻤﻨﻈﻤﺎﺕ ﻻ ﺗﻌﺘﺮﻑ ﺑﺎﻟﻤﻌﺪﺍﺕ ﺍﻟﻤﺪﺭﺟﺔ ﻣﺎ ﻟﻢ ﻳﺘﻢ ﺗﺼﻨﻴﻔﻬﺎ ﺃﻳﻀﺎً .ﻳﺠﺐ ﻋﻠﻰ ﺍﻟﺴﻠﻄﺔ

ﺫﺍﺕﺍﻻﺧﺘﺼﺎﺹ ﺃﻥ ﺗﺴﺘﺨﺪﻡ ﺍﻟﻨﻈﺎﻡ ﺍﻟﺬﻱ ﺗﺴﺘﺨﺪﻣﻪ ﺍﻟﻤﻨﻈﻤﺔ ﺍﻟﻘﺎﺉﻤﺔ ﻓﻲ ﺍﻟﻘﺎﺉﻤﺔ ﻟﺘﺤﺪﻳﺪ ﺍﻟﻤﻨﺘﺞ

ﺍﻟﻤﺪﺭﺝ.

ﺃ3.3.4.ﺳﺎﺉﻞ ﻗﺎﺑﻞ ﻟﻼﺣﺘﺮﺍﻕ.ﻟﺘﺼﻨﻴﻒ ﺍﻟﺴﻮﺍﺉﻞ ﺍﻟﻘﺎﺑﻠﺔ ﻟﻼﺣﺘﺮﺍﻕ ،ﺭﺍﺟﻊ 4.2.2ﻣﻦ ﻫﺬﻩ

ﺍﻟﻤﻮﺍﺻﻔﺔﻭ 1.7.3.1ﻣﻦ ،NFPA 30ﻗﺎﻧﻮﻥ ﺍﻟﺴﻮﺍﺉﻞ ﺍﻟﻘﺎﺑﻠﺔ ﻟﻼﺷﺘﻌﺎﻝ ﻭﺍﻻﺣﺘﺮﺍﻕ.

ﺃ3.3.6.ﺍﻟﺴﻮﺍﺉﻞ ﺍﻟﻘﺎﺑﻠﺔ ﻟﻼﺷﺘﻌﺎﻝ.ﻟﺘﺼﻨﻴﻒ ﺍﻟﺴﻮﺍﺉﻞ ﺍﻟﻘﺎﺑﻠﺔ ﻟﻼﺷﺘﻌﺎﻝ ،ﺭﺍﺟﻊ 4.2.1ﻣﻦ ﻫﺬﻩ

ﺍﻟﻤﻮﺍﺻﻔﺔﻭ 1.7.3.2ﻣﻦ ،NFPA 30ﻗﺎﻧﻮﻥ ﺍﻟﺴﻮﺍﺉﻞ ﺍﻟﻘﺎﺑﻠﺔ ﻟﻼﺷﺘﻌﺎﻝ ﻭﺍﻻﺣﺘﺮﺍﻕ .ﻟﻠﺤﺼﻮﻝ ﻋﻠﻰ

ﻣﻌﻠﻮﻣﺎﺕﺣﻮﻝ ﺇﺟﺮﺍءﺍﺕ ﺍﻻﺧﺘﺒﺎﺭ ﻭﺃﺟﻬﺰﺓ ﺗﺤﺪﻳﺪ ﻧﻘﻄﺔ ﺍﻟﻮﻣﻴﺾ ،ﺭﺍﺟﻊ 1.7.4ﻣﻦ ،NFPA 30ﻗﺎﻧﻮﻥ

ﺍﻟﺴﻮﺍﺉﻞﺍﻟﻘﺎﺑﻠﺔ ﻟﻼﺷﺘﻌﺎﻝ ﻭﺍﻻﺣﺘﺮﺍﻕ.

ﺃ3.3.7.ﻧﻘﻄﺔ ﺍﻟﻮﻣﻴﺾ.ﻧﻘﻄﺔ ﺍﻟﻮﻣﻴﺾ ﻫﻲ ﻣﻘﻴﺎﺱ ﻣﺒﺎﺷﺮ ﻟﺘﻄﺎﻳﺮ ﺍﻟﺴﺎﺉﻞ ،ﻭﻣﻴﻠﻪ ﺇﻟﻰ ﺍﻟﺘﺒﺨﺮ .ﻛﻠﻤﺎ

ﺍﻧﺨﻔﻀﺖﻧﻘﻄﺔ ﺍﻟﻮﻣﻴﺾ ،ﺯﺍﺩﺕ ﺍﻟﺘﻘﻠﺒﺎﺕ ﻭﺯﺍﺩ ﺧﻄﺮ ﻧﺸﻮﺏ ﺣﺮﻳﻖ .ﻳﺘﻢ ﺗﺤﺪﻳﺪ ﻧﻘﻄﺔ ﺍﻟﻮﻣﻴﺾ

ﺑﺎﺳﺘﺨﺪﺍﻡﺃﺣﺪ ﺇﺟﺮﺍءﺍﺕ ﺍﻻﺧﺘﺒﺎﺭ ﺍﻟﻤﺨﺘﻠﻔﺔ ﻭﺍﻷﺟﻬﺰﺓ ﺍﻟﺘﻲ ﺗﺘﻤﺘﻊ ﺑﺤﻘﻮﻕ ﺍﻟﻄﺒﻊ ﻭﺍﻟﻨﺸﺮ NFPA

ﺷﺮﻛﺔﺃﺑﺎﺩﻏﻮﺳﺘﺎﺭ ﺗﺎﺳﻴﺴﺎﺕ ﺇﻳﺮﺍﻧﻴﻨﺎﻥ ﺍﻟﻤﺤﺪﻭﺩﺓ www.atapars.com

www.atapars.com/NFPA-code/

ﺗﻢﺗﺤﺪﻳﺪﻫﺎ ﻓﻲ ،NFPA 30ﻗﺎﻧﻮﻥ ﺍﻟﺴﻮﺍﺉﻞ ﺍﻟﻘﺎﺑﻠﺔ ﻟﻼﺷﺘﻌﺎﻝ ﻭﺍﻻﺣﺘﺮﺍﻕ.1.7.4 ،

ﻣﻦﺍﻟﺴﻬﻞ ﺍﺷﺘﻌﺎﻝ ﺍﻟﺴﺎﺉﻞ ﺍﻟﺬﻱ ﻟﻪ ﻧﻘﻄﺔ ﻭﻣﻴﺾ ﻋﻨﺪ ﺩﺭﺟﺔ ﺍﻟﺤﺮﺍﺭﺓ ﺍﻟﻤﺤﻴﻄﺔ ﺃﻭ ﺃﻗﻞ ﻣﻨﻬﺎ ﻭﺳﻴﺤﺘﺮﻕ

ﺑﺴﺮﻋﺔ.ﻋﻨﺪ ﺍﻻﺷﺘﻌﺎﻝ ،ﺳﻴﻜﻮﻥ ﺍﻧﺘﺸﺎﺭ ﺍﻟﻠﻬﺐ ﻋﻠﻰ ﺳﻄﺢ ﻫﺬﺍ ﺍﻟﺴﺎﺉﻞ ﺳﺮﻳﻌﺎً ،ﻷﻧﻪ ﻟﻴﺲ ﻣﻦ ﺍﻟﻀﺮﻭﺭﻱ

ﺃﻥﺗﺴﺘﻬﻠﻚ ﺍﻟﻨﺎﺭ ﻃﺎﻗﺔ ﻓﻲ ﺗﺴﺨﻴﻦ ﺍﻟﺴﺎﺉﻞ ﻟﺘﻮﻟﻴﺪ ﺍﻟﻤﺰﻳﺪ ﻣﻦ ﺍﻟﺒﺨﺎﺭ .ﺍﻟﺒﻨﺰﻳﻦ ﻣﺜﺎﻝ ﻣﺄﻟﻮﻑ .ﻳﺸﻜﻞ

ﺍﻟﺴﺎﺉﻞﺍﻟﺬﻱ ﺗﻜﻮﻥ ﻧﻘﻄﺔ ﻭﻣﻴﻀﻪ ﺃﻋﻠﻰ ﻣﻦ ﺩﺭﺟﺔ ﺍﻟﺤﺮﺍﺭﺓ ﺍﻟﻤﺤﻴﻄﺔ ﺧﻄﺮﺍً ﺃﻗﻞ ﻷﻧﻪ ﻳﺠﺐ ﺗﺴﺨﻴﻨﻪ ﻟﺘﻮﻟﻴﺪ

ﻣﺎﻳﻜﻔﻲ ﻣﻦ ﺍﻟﺒﺨﺎﺭ ﻟﻴﺼﺒﺢ ﻗﺎﺑﻼ ًﻟﻼﺷﺘﻌﺎﻝ؛ ﻭﻣﻦ ﺍﻟﺼﻌﺐ ﺍﺷﺘﻌﺎﻟﻪ ﻭﻳﻤﺜﻞ ﺍﺣﺘﻤﺎﻟﻴﺔ ﺃﻗﻞ ﻟﺘﻮﻟﻴﺪ ﻭﺍﻧﺘﺸﺎﺭ

ﺍﻟﺒﺨﺎﺭ.ﻭﻣﻦ ﺍﻷﻣﺜﻠﺔ ﺍﻟﺸﺎﺉﻌﺔ ﺯﻳﺖ ﺍﻟﺘﺪﻓﺉﺔ ﺍﻟﻤﻨﺰﻟﻴﺔ )ﺯﻳﺖ ﺍﻟﻮﻗﻮﺩ ﺭﻗﻢ ،(2ﺍﻟﺬﻱ ﻳﺠﺐ ﺫﺭﺗﻪ ﺇﻟﻰ ﺭﺫﺍﺫ

ﺧﻔﻴﻒﺣﺘﻰ ﻳﻤﻜﻦ ﺇﺷﻌﺎﻟﻪ ﺑﺴﻬﻮﻟﺔ.

ﺗﻈﻬﺮﻣﺤﺎﻟﻴﻞ ﻣﻌﻴﻨﺔ ﻟﻠﺴﻮﺍﺉﻞ ﻓﻲ ﺍﻟﻤﺎء ﻧﻘﻄﺔ ﻭﻣﻴﺾ ﺑﺎﺳﺘﺨﺪﺍﻡ ﺇﺟﺮﺍءﺍﺕ ﺍﺧﺘﺒﺎﺭ ﺍﻟﻜﻮﺏ ﺍﻟﻤﻐﻠﻖ

ﺍﻟﻘﻴﺎﺳﻴﺔﻭﻟﻜﻨﻬﺎ ﻟﻦ ﺗﺤﺘﺮﻕ ﻭﻗﺪ ﺗﻄﻔﺊ ﺍﻟﺤﺮﻳﻖ .ﻟﻠﻤﺴﺎﻋﺪﺓ ﻓﻲ ﺗﺤﺪﻳﺪ ﻣﺜﻞ ﻫﺬﻩ ﺍﻟﺤﻠﻮﻝ ،ﺗﻌﺘﺒﺮ ﺍﻟﻤﻌﺎﻳﻴﺮ

ﺍﻟﺘﺎﻟﻴﺔﻣﻔﻴﺪﺓ،ASTM D 4207 :ﻃﺮﻳﻘﺔ ﺍﻻﺧﺘﺒﺎﺭ ﺍﻟﻘﻴﺎﺳﻴﺔ ﻟﻠﺤﺮﻕ ﺍﻟﻤﺴﺘﻤﺮ ﻟﻠﻤﺨﺎﻟﻴﻂ ﺍﻟﺴﺎﺉﻠﺔ ﻣﻨﺨﻔﻀﺔ

ﺍﻟﻠﺰﻭﺟﺔﺑﻮﺍﺳﻄﺔ ﺍﺧﺘﺒﺎﺭ ﺍﻟﻔﺘﻴﻞﻭ ،ASTM D 4206ﻃﺮﻳﻘﺔ ﺍﻻﺧﺘﺒﺎﺭ ﺍﻟﻘﻴﺎﺳﻴﺔ ﻟﻠﺤﺮﻕ ﺍﻟﻤﺴﺘﻤﺮ ﻟﻠﻤﺨﺎﻟﻴﻂ

ﺍﻟﺴﺎﺉﻠﺔﺑﻮﺍﺳﻄﺔ ﺟﻬﺎﺯ ﺍﺧﺘﺒﺎﺭ ) Setaflashﺍﻟﻜﻮﺏ ﺍﻟﻤﻔﺘﻮﺡ( .ﺗﻌﺘﺒﺮ ﺍﻟﻤﺨﺎﻟﻴﻂ ﺍﻟﺴﺎﺉﻠﺔ ﺍﻟﺘﻲ ﻻ ﺗﺴﺘﻤﺮ ﻓﻲ

ﺍﻻﺣﺘﺮﺍﻕﻟﻔﺘﺮﺓ ﻣﺤﺪﺩﺓ ﻋﻨﺪ ﺩﺭﺟﺔ ﺣﺮﺍﺭﺓ ﻣﺤﺪﺩﺓ ﻏﻴﺮ ﻗﺎﺑﻠﺔ ﻟﻼﺣﺘﺮﺍﻕ .ﺗﻮﻓﺮ ﻫﺬﻩ ﺍﻻﺧﺘﺒﺎﺭﺍﺕ ﺑﻴﺎﻧﺎﺕ ﺇﺿﺎﻓﻴﺔ

ﻟﺘﺤﺪﻳﺪﺍﻟﺘﺨﺰﻳﻦ ﻭﺍﻟﺘﻌﺎﻣﻞ ﺍﻟﻤﻨﺎﺳﺒﻴﻦ ﻣﻊ ﻫﺬﻩ ﺍﻟﻤﺨﺎﻟﻴﻂ .ﻓﻲ ﻣﻜﺎﻥ ﺿﻴﻖ ،ﻗﺪ ﺗﺴﺘﻤﺮ ﻫﺬﻩ ﺍﻟﺨﻼﺉﻂ ﻓﻲ

ﺗﻜﻮﻳﻦﺧﻠﻴﻂ ﺑﺨﺎﺭ ﻭﻫﻮﺍء ﻗﺎﺑﻞ ﻟﻼﺷﺘﻌﺎﻝ ،ﺍﻋﺘﻤﺎﺩﺍً ﻋﻠﻰ ﻛﻤﻴﺔ ﺍﻟﺴﺎﺉﻞ ﺍﻟﻘﺎﺑﻞ ﻟﻼﺷﺘﻌﺎﻝ ﻓﻲ ﺍﻟﺨﻠﻴﻂ ﻭﻛﻤﻴﺔ

ﺍﻻﻧﺴﻜﺎﺏ.

ﺍﻟﻤﺘﻌﻠﻘﺔﺑﻨﻘﻄﺔ ﺍﻟﻮﻣﻴﺾ ﻫﻲ ﻧﻘﻄﺔ ﺍﻟﻨﺎﺭ .ﻧﻘﻄﺔ ﺍﺷﺘﻌﺎﻝ ﺍﻟﺴﺎﺉﻞ ﻫﻲ ﺩﺭﺟﺔ ﺍﻟﺤﺮﺍﺭﺓ ﺍﻟﺘﻲ ﻳﺆﺩﻱ ﻋﻨﺪﻫﺎ

ﺍﺷﺘﻌﺎﻝﺍﻷﺑﺨﺮﺓ ﺇﻟﻰ ﺍﺳﺘﻤﺮﺍﺭ ﺍﻻﺣﺘﺮﺍﻕ .ﻛﻤﺎ ﺍﻟﻤﺼﻄﻠﺢﻧﻘﻄﺔ ﺍﻟﻮﻣﻴﺾﻭﻳﺸﻴﺮ ﺫﻟﻚ ﺇﻟﻰ ﺃﻥ ﺍﻷﺑﺨﺮﺓ ﺍﻟﻤﺘﻮﻟﺪﺓ

ﻋﻨﺪﺩﺭﺟﺔ ﺍﻟﺤﺮﺍﺭﺓ ﻫﺬﻩ ﺳﻮﻑ ﺗﻮﻣﺾ ،ﻟﻜﻨﻬﺎ ﻟﻦ ﺗﺴﺘﻤﺮ ﺑﺎﻟﻀﺮﻭﺭﺓ ﻓﻲ ﺍﻻﺣﺘﺮﺍﻕ .ﺍﻟﻔﺮﻕ ﺑﻴﻦ ﻧﻘﻄﺔ

ﺍﻟﻮﻣﻴﺾﻭﻧﻘﻄﺔ ﺍﻟﺤﺮﻳﻖ ﻟﻪ ﺑﻌﺾ ﺍﻷﻫﻤﻴﺔ ﻋﻨﺪ ﺇﺟﺮﺍء ﺍﺧﺘﺒﺎﺭﺍﺕ ﻧﻘﻄﺔ ﺍﻟﻮﻣﻴﺾ)ﺭﺍﺟﻊ ،ASTM D 92

ﻃﺮﻳﻘﺔﺍﻻﺧﺘﺒﺎﺭ ﺍﻟﻘﻴﺎﺳﻴﺔ ﻟﻨﻘﺎﻁ ﺍﻟﻮﻣﻴﺾ ﻭﺍﻟﻨﺎﺭ ﺑﻮﺍﺳﻄﺔ ،Cleveland Open Cupﻭﻟﻮﺍﺉﺢ ﻭﺯﺍﺭﺓ ﺍﻟﻨﻘﻞ

ﺍﻷﻣﺮﻳﻜﻴﺔﻓﻲ ،CFR 173 49ﺍﻟﻤﻠﺤﻖ " ،Hﻟﻮﺍﺉﺢ ﺍﻟﻤﻮﺍﺩ ﺍﻟﺨﻄﺮﺓ "،ﻃﺮﻳﻘﺔ ﺍﺧﺘﺒﺎﺭ ﻗﺎﺑﻠﻴﺔ ﺍﻻﺣﺘﺮﺍﻕ

ﺍﻟﻤﺴﺘﺪﺍﻡ(.ﻭﻣﻊ ﺫﻟﻚ ،ﻳﺘﻢ ﺍﺳﺘﺨﺪﺍﻡ ﻧﻘﻄﺔ ﻭﻣﻴﺾ ﺍﻟﻜﺄﺱ ﺍﻟﻤﻐﻠﻘﺔ ﻟﺘﺼﻨﻴﻒ ﺍﻟﺴﺎﺉﻞ ﻭﺗﺤﺪﻳﺪ ﺧﻄﻮﺭﺗﻪ.

ﻟﻤﺰﻳﺪﻣﻦ ﺍﻟﻤﻌﻠﻮﻣﺎﺕ ،ﺭﺍﺟﻊ ،ASTM E 502ﻃﺮﻳﻘﺔ ﺍﻻﺧﺘﺒﺎﺭ ﺍﻟﻘﻴﺎﺳﻴﺔ ﻻﺧﺘﻴﺎﺭ ﻭﺍﺳﺘﺨﺪﺍﻡ ﻣﻌﺎﻳﻴﺮ

ASTMﻟﺘﺤﺪﻳﺪ ﻧﻘﻄﺔ ﺍﻻﺷﺘﻌﺎﻝ ﻟﻠﻤﻮﺍﺩ ﺍﻟﻜﻴﻤﻴﺎﺉﻴﺔ ﺑﻄﺮﻕ ﺍﻟﻜﻮﺏ ﺍﻟﻤﻐﻠﻖ ،ﻭ ﺍﻝﺩﻟﻴﻞ ASTMﺑﺸﺄﻥ

ﻣﻌﺎﻳﻴﺮﻧﻘﻄﺔ ﺍﻟﻮﻣﻴﺾ ﻭﺍﺳﺘﺨﺪﺍﻣﻬﺎ.

ﺃ3.3.13.ﺿﻐﻂ ﺍﻟﺒﺨﺎﺭ.ﺿﻐﻂ ﺍﻟﺒﺨﺎﺭ ﻫﻮ ﻣﻘﻴﺎﺱ ﻟﻠﻀﻐﻂ ﺍﻟﺬﻱ ﻳﻤﺎﺭﺳﻪ ﺍﻟﺴﺎﺉﻞ ﻋﻠﻰ ﺍﻟﻐﻼﻑ ﺍﻟﺠﻮﻱ

ﻓﻮﻗﻪ.ﻓﺒﻴﻨﻤﺎ ﻳﻀﻐﻂ ﺍﻟﻐﻼﻑ ﺍﻟﺠﻮﻱ ﻋﻠﻰ ﺳﻄﺢ ﺍﻟﺴﺎﺉﻞ ،ﻳﺪﻓﻊ ﺍﻟﺴﺎﺉﻞ ﺇﻟﻰ ﺍﻟﺨﻠﻒ .ﻳﻜﻮﻥ ﺿﻐﻂ ﺍﻟﺒﺨﺎﺭ

ﻋﺎﺩﺓﺃﻗﻞ ﻣﻦ ﺍﻟﻀﻐﻂ ﺍﻟﺠﻮﻱ ﻭﻫﻮ ﻣﻘﻴﺎﺱ ﻟﻤﻴﻞ ﺍﻟﺴﺎﺉﻞ ﺇﻟﻰ ﺍﻟﺘﺒﺨﺮ ﻭﺍﻻﻧﺘﻘﺎﻝ ﻣﻦ ﺍﻟﺤﺎﻟﺔ ﺍﻟﺴﺎﺉﻠﺔ ﺇﻟﻰ

ﺍﻟﺤﺎﻟﺔﺍﻟﻐﺎﺯﻳﺔ .ﻭﻳﺸﺎﺭ ﺇﻟﻰ ﻫﺬﺍ ﺍﻻﺗﺠﺎﻩ ﺃﻳﻀﺎ ﺑﺎﺳﻢ ﺍﻟﺘﻘﻠﺐ ،ﻭﺑﺎﻟﺘﺎﻟﻲ ﺍﺳﺘﺨﺪﺍﻡ ﻫﺬﺍ ﺍﻟﻤﺼﻄﻠﺢﻣﺘﻘﻠﺐ

ﻟﻮﺻﻒﺍﻟﺴﻮﺍﺉﻞ ﺍﻟﺘﻲ ﺗﺘﺒﺨﺮ ﺑﺴﻬﻮﻟﺔ ﺷﺪﻳﺪﺓ .ﻛﻠﻤﺎ ﺯﺍﺩ ﺿﻐﻂ ﺍﻟﺒﺨﺎﺭ ،ﺯﺍﺩ ﻣﻌﺪﻝ ﺍﻟﺘﺒﺨﺮ ﻭﺍﻧﺨﻔﻀﺖ ﻧﻘﻄﺔ

ﺍﻟﻐﻠﻴﺎﻥ.ﺑﺒﺴﺎﻃﺔ ،ﻫﺬﺍ ﻳﻌﻨﻲ ﺍﻟﻤﺰﻳﺪ ﻣﻦ ﺍﻷﺑﺨﺮﺓ ﻭﺯﻳﺎﺩﺓ ﺧﻄﺮ ﺍﻟﺤﺮﺍﺉﻖ.

ﺃ5.1.6.ﻳﺠﺐ ﺃﺧﺬ ﺍﻻﺭﺗﻔﺎﻉ ﺍﻟﻤﺤﺘﻤﻞ ﻓﻲ ﺩﺭﺟﺔ ﺍﻟﺤﺮﺍﺭﺓ ﺃﺛﻨﺎء ﺍﻟﻨﻘﻞ ﺑﺎﻹﺿﺎﻓﺔ ﺇﻟﻰ ﺩﺭﺟﺔ ﺣﺮﺍﺭﺓ ﺍﻟﺘﺤﻤﻴﻞ

ﻭﺍﻻﺭﺗﻔﺎﻉﻓﻲ ﺍﻻﻋﺘﺒﺎﺭ ﻋﻨﺪ ﺗﺤﺪﻳﺪ ﻣﺎ ﺇﺫﺍ ﻛﺎﻥ ﺳﻴﺘﻢ ﻧﻘﻞ ﺍﻟﺴﺎﺉﻞ ﺍﻟﻘﺎﺑﻞ ﻟﻼﺷﺘﻌﺎﻝ ﺃﻭ ﺍﻟﻘﺎﺑﻞ ﻟﻼﺷﺘﻌﺎﻝ

ﻋﻨﺪﻧﻘﻄﺔ ﺍﻟﻐﻠﻴﺎﻥ ﺃﻭ ﺃﻋﻠﻰ ﻣﻨﻬﺎ .ﻓﻲ ﺣﺎﻟﺔ ﻋﺪﻡ ﺗﻮﻓﺮ ﻧﻘﻄﺔ ﻏﻠﻴﺎﻥ ﺩﻗﻴﻘﺔ ﻟﻠﻤﺎﺩﺓ ﺍﻟﻤﻌﻨﻴﺔ ﺃﻭ ﻟﻠﻤﺨﺎﻟﻴﻂ ﺍﻟﺘﻲ

ﻟﻴﺲﻟﻬﺎ ﻧﻘﻄﺔ ﻏﻠﻴﺎﻥ ﺛﺎﺑﺘﺔ ،ﻓﺈﻥ Copyright NFPA 20

ﺷﺮﻛﺔﺃﺑﺎﺩﻏﻮﺳﺘﺎﺭ ﺗﺎﺳﻴﺴﺎﺕ ﺇﻳﺮﺍﻧﻴﻨﺎﻥ ﺍﻟﻤﺤﺪﻭﺩﺓ www.atapars.com

www.atapars.com/NFPA-code/

ﻧﻘﻄﺔﻣﺉﻮﻳﺔ ﻣﻦ ﺍﻟﺘﻘﻄﻴﺮ ﺍﻟﺬﻱ ﺗﻢ ﺇﺟﺮﺍﺅﻩ ﻭﻓﻘﺎً ﻟﻠﻤﻮﺍﺻﻔﺔ ،ASTM D 86ﺍﻟﻄﺮﻳﻘﺔ ﺍﻟﻘﻴﺎﺳﻴﺔ ﻟﻼﺧﺘﺒﺎﺭ

ﻟﺘﻘﻄﻴﺮﺍﻟﻤﻨﺘﺠﺎﺕ ﺍﻟﺒﺘﺮﻭﻟﻴﺔ ،ﻭﻳﻤﻜﻦ ﺍﺳﺘﺨﺪﺍﻣﻪ ﻛﻨﻘﻄﺔ ﻏﻠﻴﺎﻥ ﺍﻟﺴﺎﺉﻞ.

ﺃ5.1.8.ﻓﻲ ﺣﺎﻟﺔ ﺍﻟﺸﻚ ،ﻳﺠﺐ ﺍﺳﺘﺸﺎﺭﺓ ﻣﻮﺭﺩ ﺃﻭ ﻣﻨﺘﺞ ﺍﻟﺴﺎﺉﻞ ﺍﻟﻘﺎﺑﻞ ﻟﻼﺷﺘﻌﺎﻝ ﺃﻭ ﺍﻟﻘﺎﺑﻞ ﻟﻼﺷﺘﻌﺎﻝ ﺃﻭ

ﺃﻱﺳﻠﻄﺔ ﻣﺨﺘﺼﺔ ﺃﺧﺮﻯ ﺑﺸﺄﻥ ﻣﺪﻯ ﻣﻼءﻣﺔ ﻣﻮﺍﺩ ﺍﻟﺒﻨﺎء ﺍﻟﻤﺮﺍﺩ ﺍﺳﺘﺨﺪﺍﻣﻬﺎ.

ﺃ5.3.2.ﺍﻟﺤﺪ ﺍﻷﺩﻧﻰ ﻣﻦ ﺍﻟﻤﺘﻄﻠﺒﺎﺕ ﻟﻠﻤﻮﺍﺩ ﺍﻟﻤﺪﺭﺟﺔ ﻓﻲ ﺍﻟﺠﺪﻭﻝ 5.3.2ﻣﻜﺮﺭ ﻣﻦ ،CFR 178.345 49

ﺍﻟﺴﺎﺭﻱﺍﻋﺘﺒﺎﺭﺍً ﻣﻦ 1ﻳﻨﺎﻳﺮ .1974

ﺃ5.3.13.4.ﺗﺘﻮﻓﺮ ﻣﻌﻠﻮﻣﺎﺕ ﺣﻮﻝ ﺍﻟﻄﺮﻕ ﺍﻟﻤﻨﺎﺳﺒﺔ ﻹﺟﺮﺍء ﺍﺧﺘﺒﺎﺭﺍﺕ ﺍﻟﺘﺪﻓﻖ ﻓﻲ ،API 2000ﺻﻬﺎﺭﻳﺞ

ﺗﺨﺰﻳﻦﺍﻟﻬﻮﺍء ﻭﺍﻟﻀﻐﻂ ﺍﻟﻤﻨﺨﻔﺾ :ﻏﻴﺮ ﻣﺒﺮﺩﺓ ﻭﻣﺒﺮﺩﺓ.

ﺃ5.4.1.1.ﻳﺘﻢ ﺗﻀﻤﻴﻦ ﺣﺪ ﺍﻟﻠﺰﻭﺟﺔ ﺍﻟﺒﺎﻟﻎ 45ﺛﺎﻧﻴﺔ ﻷﻏﺮﺍﺽ ﺍﻟﺤﺎﺟﺔ ﺇﻟﻰ ﺻﻤﺎﻣﺎﺕ ﺩﺍﺧﻠﻴﺔ ﻋﻨﺪ ﻧﻘﻞ

ﺍﻟﺰﻳﻮﺕﺍﻟﻤﻘﻄﺮﺓ ﺣﺮﺓ ﺍﻟﺘﺪﻓﻖ ،ﻣﺜﻞ ﺍﻟﻜﻴﺮﻭﺳﻴﻦ ﻭﺯﻳﺖ ﺍﻟﺪﻳﺰﻝ ﻭﺯﻳﺖ ﺍﻟﺘﺪﻓﺉﺔ ﺍﻟﻤﻨﺰﻟﻲ ،ﻭﻻﺳﺘﺜﻨﺎء ﻫﺬﺍ

ﺍﻟﺸﺮﻁﻋﻨﺪ ﻧﻘﻞ ﺍﻟﺰﻳﻮﺕ ﺍﻟﻠﺰﺟﺔ ﻣﺜﻞ ﺯﻳﺖ ﺍﻟﻮﻗﻮﺩ ﺍﻟﻤﺘﺒﻘﻲ ﻭﺯﻳﺖ ﻭﻗﻮﺩ ﺍﻟﺴﻔﻦ ،ﻭﺍﻟﻤﻨﺘﺠﺎﺕ ﺍﻷﺳﻔﻠﺘﻴﺔ

ﺍﻟﺘﻲﻳﻤﻜﻦ ﺃﻥ ﺗﺘﺠﻤﺪ ﻭﺗﺴﺒﺐ ﺧﻠﻼ ًﻓﻲ ﺍﻟﺼﻤﺎﻡ.

ﺃ9.1.7.ﻭﻓﻲ ﺣﺎﻟﺔ ﺍﻟﺸﻚ ،ﻳﻨﺒﻐﻲ ﺍﺳﺘﺸﺎﺭﺓ ﻣﻮﺭﺩ ﺃﻭ ﻣﻨﺘﺞ ﺍﻟﺴﺎﺉﻞ ﺍﻟﻘﺎﺑﻞ ﻟﻼﺷﺘﻌﺎﻝ ﺃﻭ ﺍﻟﻘﺎﺑﻞ ﻟﻼﺷﺘﻌﺎﻝ

ﺃﻭﺃﻱ ﺳﻠﻄﺔ ﻣﺨﺘﺼﺔ ﺃﺧﺮﻯ.

ﺃ9.1.10.ﻟﺘﻘﻠﻴﻞ ﺧﻄﺮ ﺍﻹﺷﻌﺎﻝ ﺍﻟﺴﺎﻛﻦ ﻋﻨﺪ ﺍﻟﺘﻐﻴﻴﺮ ﻣﻦ ﺍﻟﻔﺉﺔ ﺍﻷﻭﻟﻰ ﺇﻟﻰ ﺍﻟﻔﺉﺔ ﺍﻟﺜﺎﻧﻴﺔ ﺃﻭ ﺍﻟﻔﺉﺔ

ﺍﻟﺜﺎﻟﺜﺔ)ﺗﺤﻤﻴﻞ ﺍﻟﻤﻔﺘﺎﺡ( ،ﻗﺪ ﺗﻜﻮﻥ ﻫﻨﺎﻙ ﺍﺣﺘﻴﺎﻃﺎﺕ ﺃﺧﺮﻯ ﺿﺮﻭﺭﻳﺔ).ﺍﻧﻈﺮ ﺍﻟﻤﻠﺤﻖ ﺏ ﻟﻤﺰﻳﺪ ﻣﻦ

ﺍﻟﻤﻌﻠﻮﻣﺎﺕ(.

ﺃ9.2.12.3.ﻳﻤﻜﻦ ﺃﻥ ﺗﻜﻮﻥ ﺃﺳﻼﻙ ﺍﻟﺴﻨﺪﺍﺕ ﻣﻌﺰﻭﻟﺔ ﺃﻭ ﻏﻴﺮ ﻣﻌﺰﻭﻟﺔ .ﻳﺴﻤﺢ ﺍﻟﺴﻠﻚ ﻏﻴﺮ ﺍﻟﻤﻌﺰﻭﻝ ﺑﺈﺟﺮﺍء

ﻓﺤﺺﺑﺼﺮﻱ ﺟﺎﻫﺰ ﻻﺳﺘﻤﺮﺍﺭﻳﺔ ﺍﻟﺮﺍﺑﻄﺔ .ﻳﺠﺐ ﺍﺧﺘﺒﺎﺭ ﺍﻷﻧﻮﺍﻉ ﺍﻟﻤﻌﺰﻭﻟﺔ ﻛﻬﺮﺑﺎﺉﻴﺎً ﺃﻭ ﻓﺤﺼﻬﺎ ﺩﻭﺭﻳﺎً ﻟﻠﺘﺄﻛﺪ

ﻣﻦﺍﺳﺘﻤﺮﺍﺭﻳﺔ ﺩﺍﺉﺮﺓ ﺍﻟﺮﺍﺑﻄﺔ ﺑﺄﻛﻤﻠﻬﺎ ،ﺑﻤﺎ ﻓﻲ ﺫﻟﻚ ﺍﻟﻤﺸﺎﺑﻚ ﻭﺍﻟﻤﻮﺻﻼﺕ.

ﺃ ﺍﻟﻤﻠﺤﻖﺏ ﺍﻻﺣﺘﻴﺎﻃﺎﺕ ﺍﻟﻼﺯﻣﺔ ﺿﺪ ﺍﻻﺷﺘﻌﺎﻝ ﺑﺎﻟﻜﻬﺮﺑﺎء ﺍﻟﺴﺎﻛﻨﺔ

ﻻﻳﻌﺪ ﻫﺬﺍ ﺍﻟﻤﻠﺤﻖ ﺟﺰءﺍً ﻣﻦ ﻣﺘﻄﻠﺒﺎﺕ ﻭﺛﻴﻘﺔ NFPAﻭﻟﻜﻨﻪ ﺗﻢ ﺗﻀﻤﻴﻨﻪ ﻷﻏﺮﺍﺽ ﺇﻋﻼﻣﻴﺔ ﻓﻘﻂ.

ﺏ1.ﻣﻌﻠﻮﻣﺎﺕ ﻋﺎﻣﺔ.

ﺏ1.1.ﻳﺘﻀﻤﻦ ﺍﻟﻔﺼﻞ 9ﻣﻦ ﻫﺬﻩ ﺍﻟﻤﻮﺍﺻﻔﺔ ﺍﻟﻘﻴﺎﺳﻴﺔ ﻣﺘﻄﻠﺒﺎﺕ ﻣﻮﺟﻬﺔ ﻟﻤﻨﻊ ﺣﺪﻭﺙ ﺣﺮﺍﺉﻖ ﺃﻭ

ﺍﻧﻔﺠﺎﺭﺍﺕﻧﺎﺗﺠﺔ ﻋﻦ ﺍﻟﻜﻬﺮﺑﺎء ﺍﻟﺴﺎﻛﻨﺔ ﺃﺛﻨﺎء ﺗﺸﻐﻴﻞ ﻣﺮﻛﺒﺎﺕ ﺍﻟﺼﻬﺎﺭﻳﺞ .ﻳﻮﻓﺮ ﻫﺬﺍ ﺍﻟﻤﻠﺤﻖ ﻣﻌﻠﻮﻣﺎﺕ

ﺃﺳﺎﺳﻴﺔﺑﺸﺄﻥ ﺗﻮﻟﻴﺪ ﻭﺗﺮﺍﻛﻢ ﻭﺇﻃﻼﻕ ﺍﻟﺸﺤﻨﺎﺕ ﺍﻟﺴﺎﻛﻨﺔ )ﺍﻟﺸﺮﺭ( ﻓﻲ ﻣﺜﻞ ﻫﺬﻩ ﺍﻟﻌﻤﻠﻴﺎﺕ ﻭﻳﺸﺮﺡ ﺃﺳﺒﺎﺏ

ﺍﻻﺣﺘﻴﺎﻃﺎﺕﺍﻟﻤﻄﻠﻮﺑﺔ.

ﺏ1.2.ﻟﻠﺤﺼﻮﻝ ﻋﻠﻰ ﻣﻨﺎﻗﺸﺔ ﺃﻛﺜﺮ ﺗﻔﺼﻴﻼ ًﻟﻠﻜﻬﺮﺑﺎء ﺍﻟﺴﺎﻛﻨﺔ ﻭﻃﺮﻕ ﺍﻟﺘﺤﻜﻢ ﻓﻴﻬﺎ ﺑﻐﺮﺽ ﺍﻟﺘﺨﻠﺺ ﻣﻦ

ﻣﺨﺎﻃﺮﺍﻟﺤﺮﻳﻖ ﺃﻭ ﺍﻟﺘﺨﻔﻴﻒ ﻣﻨﻬﺎ ،ﺭﺍﺟﻊ ،NFPA 77ﺍﻟﻤﻤﺎﺭﺳﺔ ﺍﻟﻤﻮﺻﻰ ﺑﻬﺎ ﻋﻠﻰ ﺍﻟﻜﻬﺮﺑﺎء ﺍﻟﺴﺎﻛﻨﺔ.

ﺏ2.ﺍﻟﻜﻬﺮﺑﺎء ﺍﻟﺴﺎﻛﻨﺔ.

ﺣﻘﻮﻕﺍﻟﻄﺒﻊ ﻭﺍﻟﻨﺸﺮ NFPA

ﺷﺮﻛﺔﺃﺑﺎﺩﻏﻮﺳﺘﺎﺭ ﺗﺎﺳﻴﺴﺎﺕ ﺇﻳﺮﺍﻧﻴﻨﺎﻥ ﺍﻟﻤﺤﺪﻭﺩﺓ www.atapars.com

www.atapars.com/NFPA-code/

ﺏ2.1.ﺍﻟﺠﻴﻞ.ﺗﻨﺘﺞ ﺍﻟﻜﻬﺮﺑﺎء ﺍﻟﺴﺎﻛﻨﺔ ﺩﺍﺉﻤﺎً ﺗﻘﺮﻳﺒﺎً ﻋﻦ ﺍﻻﺗﺼﺎﻝ ﺍﻟﺤﻤﻴﻢ ﻭﺍﻟﻔﺼﻞ ﺍﻟﻼﺣﻖ ﺑﻴﻦ ﻣﺎﺩﺗﻴﻦ،

ﻭﻏﺎﻟﺒﺎًﻣﺎ ﺗﻜﻮﻧﺎ ﻣﺎﺩﺗﻴﻦ ﻣﺨﺘﻠﻔﺘﻴﻦ .ﻓﻲ ﺣﻴﻦ ﺃﻥ ﺍﻟﻤﻈﺎﻫﺮ ﺍﻷﻛﺜﺮ ﺷﻬﺮﺓ ﺗﺸﻤﻞ ﻓﺼﻞ ﺍﻟﻤﻮﺍﺩ ﺍﻟﺼﻠﺒﺔ ،ﻓﺈﻥ

ﻓﺼﻞﺍﻟﻤﻮﺍﺩ ﺍﻟﺼﻠﺒﺔ ﺍﻟﺴﺎﺉﻠﺔ ﻫﻮ ﺃﻳﻀﺎً ﻭﺳﻴﻠﺔ ﺗﻮﻟﻴﺪ ﻭﻫﻲ ﺍﻷﻛﺜﺮ ﺃﻫﻤﻴﺔ ﻓﻲ ﺗﺸﻐﻴﻞ ﻣﺮﻛﺒﺎﺕ ﺍﻟﺼﻬﺎﺭﻳﺞ.

ﻳﺆﺩﻱﺗﺪﻓﻖ ﺃﻱ ﺳﺎﺉﻞ )ﺣﺘﻰ ﺍﻟﻤﺎء( ﻋﺒﺮ ﺳﻄﺢ ﻣﺎ ،ﻣﺜﻞ ﺟﺪﺍﺭ ﺍﻷﻧﺒﻮﺏ ،ﺇﻟﻰ ﻓﺼﻞ ﺍﻟﺸﺤﻨﺎﺕ

ﺍﻟﻜﻬﺮﺑﺎﺉﻴﺔ.ﺇﺫﺍ ﻛﺎﻥ ﺍﻟﺴﺎﺉﻞ ﻣﻮﺻﻼً ﻟﻠﻜﻬﺮﺑﺎء ،ﻣﺜﻞ ﺍﻟﻤﺎء ،ﻓﺈﻥ ﺍﻟﺸﺤﻨﺎﺕ ﺍﻟﻤﻨﻔﺼﻠﺔ ﺗﺘﺤﺪ ﺑﺴﺮﻋﺔ ،ﻭﻻ

ﻳﻮﺟﺪﺩﻟﻴﻞ ﻭﺍﺿﺢ ﻋﻠﻰ ﺣﺪﻭﺙ ﻓﺼﻞ ﺍﻟﺸﺤﻨﺎﺕ ﻋﻠﻰ ﺍﻹﻃﻼﻕ .ﻭﻟﻜﻦ ﺇﺫﺍ ﻛﺎﻥ ﺍﻟﺴﺎﺉﻞ ﻣﻮﺻﻼً ﺭﺩﻳﺉﺎً،

ﻛﻤﺎﻫﻮ ﺍﻟﺤﺎﻝ ﻓﻲ ﺍﻟﻌﺪﻳﺪ ﻣﻦ ﺍﻟﺰﻳﻮﺕ ،ﻓﻘﺪ ﺗﺘﻢ ﺇﻋﺎﻗﺔ ﻋﻤﻠﻴﺔ ﺇﻋﺎﺩﺓ ﺍﻟﺘﺮﻛﻴﺐ ﻫﺬﻩ ،ﻭﻗﺪ ﺗﺘﺮﺍﻛﻢ

ﺍﻟﺸﺤﻨﺎﺕﺍﻟﻤﺴﺘﻤﺮﺓ.

ﺇﺫﺍﺗﻢ ﻣﻞء ﻭﻋﺎء ﻣﻌﺪﻧﻲ ﻣﻌﺰﻭﻝ ﻋﻦ ﻣﺤﻴﻄﻪ ﺑﻬﺬﻩ ﺍﻟﻄﺮﻳﻘﺔ ،ﻓﻴﻤﻜﻦ ﺗﻮﺻﻴﻞ ﺍﻟﺸﺤﻨﺔ ﺍﻟﺘﻲ ﻳﺤﻤﻠﻬﺎ

ﺍﻟﺴﺎﺉﻞﺇﻟﻰ ﺍﻟﻮﻋﺎء .ﻭﺑﻌﺒﺎﺭﺓ ﺃﺧﺮﻯ ،ﻳﻤﻜﻦ ﺃﻥ ﺗﺼﺒﺢ ﺍﻟﺴﻔﻴﻨﺔ "ﻣﺸﺤﻮﻧﺔ" ،ﺃﻭ ﺗﻔﺘﺮﺽ ﺇﻣﻜﺎﻧﺎﺕ ﻛﻬﺮﺑﺎﺉﻴﺔ

ﻣﺨﺘﻠﻔﺔﻋﻦ ﺗﻠﻚ ﺍﻟﻤﺤﻴﻄﺔ ﺑﻬﺎ .ﺇﺫﺍ ﺗﻢ ﺗﻘﺮﻳﺐ ﺳﻠﻚ ﻣﺘﺼﻞ ﺑﺠﺴﻢ ﺁﺧﺮ ﺃﻭ ﺑﺎﻷﺭﺽ ﻣﻦ ﺍﻟﻮﻋﺎء ﺍﻟﺬﻱ ﻳﺘﻢ

ﻣﻠﺆﻩ،ﻓﻴﻤﻜﻦ ﺇﻃﻼﻕ ﻫﺬﻩ ﺍﻟﺸﺤﻨﺔ ﻋﻠﻰ ﺷﻜﻞ ﺷﺮﺍﺭﺓ.

ﺑﻄﺮﻳﻘﺔﻣﺨﺘﻠﻔﺔ ﺇﻟﻰ ﺣﺪ ﻣﺎ ﻭﻟﻜﻦ ﻣﻤﺎﺛﻠﺔ ،ﻗﺪ ﺗﺘﺮﺍﻛﻢ ﺍﻟﺸﺤﻨﺔ ﻋﻠﻰ ﺳﻄﺢ ﺍﻟﺴﺎﺉﻞ ﻓﻲ ﻣﻨﻄﻘﺔ ﺑﻌﻴﺪﺓ ﻋﻦ

ﺟﺪﺭﺍﻥﺍﻟﻮﻋﺎء ،ﻋﻠﻰ ﺍﻟﺮﻏﻢ ﻣﻦ ﺃﻥ ﺍﻟﻮﻋﺎء ﻧﻔﺴﻪ "ﻣﺆﺭﺽ" ،ﻭﻳﻤﻜﻦ ﺇﻃﻼﻕ ﻫﺬﻩ ﺍﻟﺸﺤﻨﺔ ﺍﻟﺴﻄﺤﻴﺔ ،ﻓﻲ ﻇﻞ

ﻇﺮﻭﻑﻣﻌﻴﻨﺔ ،ﻓﻲ ﺷﻜﻞ ﺷﺮﺍﺭﺓ.

ﻛﻞﻣﻦ ﻫﺎﺗﻴﻦ ﺍﻟﻮﺳﻴﻠﺘﻴﻦ ﻹﻧﺘﺎﺝ ﺍﻟﺸﺮﺍﺭﺓ ﻣﻬﻤﺘﺎﻥ ﻭﺳﻴﺘﻢ ﺍﻟﺘﻌﺎﻣﻞ ﻣﻌﻬﻤﺎ ﺑﺸﻜﻞ ﻣﻨﻔﺼﻞ.

ﺏ2.2.ﺍﺗﺠﺎﻩ ﺍﻟﺸﺤﻦ.ﺍﻟﺸﺮﻭﻁﺍﺗﺠﺎﻩ ﺍﻟﺸﺤﻦﻭﺍﻟﻘﺪﺭﺓ ﻋﻠﻰ ﺗﻮﻟﻴﺪ ﺍﻟﻜﻬﺮﺑﺎء ﺍﻟﺴﺎﻛﻨﺔﻟﻘﺪ ﺩﺧﻠﺖ ﺣﻴﺰ

ﺍﻻﺳﺘﺨﺪﺍﻡﻓﻲ ﻭﺻﻒ ﻗﺪﺭﺓ ﺍﻟﺴﺎﺉﻞ ﻋﻠﻰ ﺗﻮﻟﻴﺪ ﻭﺍﺣﺘﺠﺎﺯ ﺷﺤﻨﺔ ﺧﻄﻴﺮﺓ ﻣﻦ ﺍﻟﻜﻬﺮﺑﺎء ﺍﻟﺴﺎﻛﻨﺔ .ﻭﻓﻲ ﻫﺬﺍ

ﺍﻟﻤﺮﻓﻖﻛﻠﻤﺔﺯﻳﺖﻳﺴﺘﺨﺪﻡ ﻟﺘﺼﻨﻴﻒ ﻣﺜﻞ ﻫﺬﺍ ﺍﻟﺴﺎﺉﻞ ﺑﻐﺾ ﺍﻟﻨﻈﺮ ﻋﻦ ﺍﻟﻤﻨﺸﺄ .ﻓﻲ ﺍﻟﻮﺍﻗﻊ ،ﺗﺘﺮﺍﻭﺡ ﻫﺬﻩ

ﺍﻟﺴﻮﺍﺉﻞﻣﻦ ﻣﻮﺍﺩ ﻛﻴﻤﻴﺎﺉﻴﺔ ﻧﻘﻴﺔ ﺇﻟﻰ ﻣﺨﺎﻟﻴﻂ ﻣﻌﻘﺪﺓ ﻣﺜﻞ ﺍﻟﻜﻴﺮﻭﺳﻴﻦ ﻭﻏﻴﺮﻩ ﻣﻦ ﺍﻟﻤﻨﺘﺠﺎﺕ ﺍﻟﺒﺘﺮﻭﻟﻴﺔ،

ﻭﺑﻌﻀﻬﺎﻟﻪ ﻣﻴﻞ ﻟﻠﺸﺤﻦ ،ﻭﺑﻌﻀﻬﺎ ﻻ.

ﺗﺘﺄﺛﺮﻗﺪﺭﺓ ﺗﻮﻟﻴﺪ ﺍﻟﻜﻬﺮﺑﺎء ﺍﻟﺴﺎﻛﻨﺔ ﻷﻱ ﺯﻳﺖ ﺑﻄﺮﻳﻘﺔ ﻣﻌﻘﺪﺓ ﺑﻮﺟﻮﺩ ﻣﻜﻮﻧﺎﺕ ﻗﺎﺑﻠﺔ ﻟﻠﺘﺄﻳﻦ ﻭﺍﻟﻤﻘﺎﻭﻣﺔ

ﺍﻟﻜﻬﺮﺑﺎﺉﻴﺔﻟﻠﺰﻳﺖ ،ﻛﻤﺎ ﺗﻤﺖ ﻣﻨﺎﻗﺸﺘﻪ ﺑﺎﻟﺘﻔﺼﻴﻞ ﻓﻲ ،NFPA 77ﺍﻟﻤﻤﺎﺭﺳﺔ ﺍﻟﻤﻮﺻﻰ ﺑﻬﺎ ﻋﻠﻰ ﺍﻟﻜﻬﺮﺑﺎء

ﺍﻟﺴﺎﻛﻨﺔ .ﺍﺳﻢ ﺍﻟﻤﻨﺘﺞ ﻟﻴﺲ ﻭﺳﻴﻠﺔ ﻣﻮﺛﻮﻗﺔ ﻟﺘﻤﻴﻴﺰ ﺯﻳﺖ ﻋﻦ ﺁﺧﺮ ﻓﻴﻤﺎ ﻳﺘﻌﻠﻖ ﺑﻘﺪﺭﺓ ﺗﻮﻟﻴﺪ ﺍﻟﻜﻬﺮﺑﺎء

ﺍﻟﺴﺎﻛﻨﺔ.ﻭﻣﻦ ﺛﻢ ،ﻓﺈﻥ ﺍﻻﺣﺘﻴﺎﻃﺎﺕ ﺍﻟﻤﺬﻛﻮﺭﺓ ﻓﻲ ﻫﺬﻩ ﺍﻟﻮﺛﻴﻘﺔ ﺗﺴﺘﻨﺪ ﺇﻟﻰ ﻣﻔﻬﻮﻡ ﺃﻥ ﺟﻤﻴﻊ ﺍﻟﺰﻳﻮﺕ

ﻣﺸﻜﻮﻙﻓﻴﻬﺎ ،ﻣﻊ ﺍﻻﺳﺘﺜﻨﺎء ﺍﻟﻤﻬﻢ ﻭﻫﻮ ﺃﻥ ﺍﻟﻨﻔﻂ ﺍﻟﺨﺎﻡ ﻭﺟﻤﻴﻊ ﺍﻟﻤﻮﺍﺩ ﺍﻟﺘﻲ ﺗﺤﺘﻮﻱ ﻋﻠﻰ ﺃﻛﺜﺮ ﻣﻦ ﻛﻤﻴﺔ

ﺻﻐﻴﺮﺓﺟﺪﺍً ﻣﻦ ﺍﻟﻤﺨﻠﻔﺎﺕ ﺍﻟﺜﻘﻴﻠﺔ ﺍﻟﻨﺎﺗﺠﺔ ﻋﻦ ﺗﻘﻄﻴﺮ ﺍﻟﻨﻔﻂ ﺍﻟﺨﺎﻡ ﻣﻦ ﺍﻟﻤﻌﺮﻭﻑ ﺃﻧﻬﺎ ﻏﻴﺮ ﻣﺮﻛﻤﺔ ﻷﻥ ﻣﻦ

ﺍﻟﻤﻮﺻﻠﻴﺔﺍﻟﻌﺎﻟﻴﺔ ﻧﺴﺒﻴﺎ .ﺗﻘﻊ ﺍﻟﻜﺤﻮﻟﻴﺎﺕ ﺃﻭ ﺍﻟﻤﻮﺍﺩ ﺍﻟﻜﻴﻤﻴﺎﺉﻴﺔ ﺍﻷﺧﺮﻯ ﺍﻟﺘﻲ ﺗﺤﺘﻮﻱ ﻋﻠﻰ ﻛﻤﻴﺎﺕ ﻛﺒﻴﺮﺓ ﻣﻦ

ﺍﻟﻤﺎءﺍﻟﻤﺬﺍﺏ ﻭﺑﻌﺾ ﺍﻟﻤﻮﺍﺩ ﺍﻟﻜﻴﻤﻴﺎﺉﻴﺔ ﺫﺍﺕ ﺍﻟﻤﻘﺎﻭﻣﺔ ﺍﻟﻤﻨﺨﻔﻀﺔ ﻓﻲ ﻧﻔﺲ ﺍﻟﻔﺉﺔ.

ﻧﻈﺮﺍًﻷﻥ ﺟﻤﻴﻊ ﺍﻟﺰﻳﻮﺕ ﺍﻟﺘﻲ ﺗﺨﻀﻊ ﻟﻈﺮﻭﻑ ﺍﻟﻤﻌﺎﻟﺠﺔ ﻟﻬﺎ ﻋﻠﻰ ﺍﻷﻗﻞ ﺑﻌﺾ ﺍﻟﻤﻮﺻﻠﻴﺔ ﺍﻟﺼﻐﻴﺮﺓ ﺑﺤﻴﺚ

ﺗﺘﺴﺮﺏﺍﻟﺸﺤﻨﺔ ﻓﻲ ﺍﻟﻨﻬﺎﻳﺔ ،ﻓﻤﻦ ﺍﻟﻮﺍﺿﺢ ﺃﻥ ﺍﺳﺘﻤﺮﺍﺭ ﺍﻟﺸﺤﻨﺔ ﻳﺠﺐ ﺃﻥ ﻳﻤﺜﻞ ﺗﻮﺍﺯﻧﺎً ﺑﻴﻦ ﻣﻌﺪﻝ ﺍﻟﺘﻮﻟﻴﺪ

ﻭﻣﻌﺪﻝﺍﻟﺘﺴﺮﺏ .ﻳﻌﺘﻤﺪ ﻣﻌﺪﻝ ﺍﻟﺘﻮﻟﻴﺪ ﻋﻠﻰ ﻣﻌﺪﻝ ﺣﺮﻛﺔ ﺍﻟﺴﺎﺉﻞ.

ﻓﻲﺑﻌﺾ ﺍﻟﺤﺎﻻﺕ ،ﺗﻌﺘﺒﺮ ﺍﻟﺴﺮﻋﺔ ﺍﻟﺨﻄﻴﺔ ﻟﻠﺘﺪﻓﻖ ﻓﻲ ﺍﻷﻧﺒﻮﺏ ﻣﻬﻤﺔ ﻣﻦ ﻭﺟﻬﺔ ﻧﻈﺮ ﺍﻟﺘﻮﻟﻴﺪ ﺍﻟﺴﺎﻛﻦ.

ﺗﺘﻀﻤﻦﺣﺎﻟﺔ ﺧﺎﺻﺔ ﺿﺦ ﺍﻟﺰﻳﺖ ﻣﻦ ﺧﻼﻝ ﺍﻟﻤﺮﺷﺤﺎﺕ ،ﺣﻴﺚ ﻣﻦ ﺍﻟﻤﻌﺮﻭﻑ ﺃﻥ ﺍﻻﺗﺼﺎﻝ ﺍﻟﺤﻤﻴﻢ ﺑﻴﻦ

ﺍﻟﺰﻳﺖﻭﻋﻨﺼﺮ ﺍﻟﻤﺮﺷﺢ ﻳﻨﺘﺞ ﻋﻨﻪ ﺩﺭﺟﺔ ﻋﺎﻟﻴﺔ ﻣﻦ ﺍﻟﻜﻬﺮﺑﺔ.

ﺣﻘﻮﻕﺍﻟﻄﺒﻊ ﻭﺍﻟﻨﺸﺮ NFPA

ﺷﺮﻛﺔﺃﺑﺎﺩﻏﻮﺳﺘﺎﺭ ﺗﺎﺳﻴﺴﺎﺕ ﺇﻳﺮﺍﻧﻴﻨﺎﻥ ﺍﻟﻤﺤﺪﻭﺩﺓ www.atapars.com

www.atapars.com/NFPA-code/

ﻭﻓﻲﻛﻠﺘﺎ ﺍﻟﺤﺎﻟﺘﻴﻦ ،ﺇﺫﺍ ﻭﺻﻞ ﺍﻟﺰﻳﺖ ،ﺑﻌﺪ ﻣﻐﺎﺩﺭﺓ ﻣﻜﺎﻥ ﺍﻟﺘﻮﻟﻴﺪ ﺍﻟﻌﺎﻟﻲ ،ﺇﻟﻰ ﻣﻜﺎﻥ ﺑﻪ ﺩﺭﺟﺔ ﺃﻗﻞ ﻣﻦ

ﺍﻻﺿﻄﺮﺍﺏ،ﻓﺈﻥ ﺑﻌﺾ ﺍﻟﺸﺤﻨﺔ ﺳﻮﻑ ﺗﺘﺴﺮﺏ ﺃﻭ "ﺗﺴﺘﺮﺧﻲ" .ﺃﺻﺒﺢ "ﻭﻗﺖ ﺍﻻﺳﺘﺮﺧﺎء" ﺃﺣﺪ ﺍﻻﻋﺘﺒﺎﺭﺍﺕ

ﻓﻲﻛﺜﻴﺮ ﻣﻦ ﺍﻟﺤﺎﻻﺕ.

ﺏ3.ﺧﻄﺮ ﺍﻻﺷﺘﻌﺎﻝ.

ﺇﻥﺗﻄﻮﺭ ﺍﻟﺸﺤﻨﺎﺕ ﺍﻟﻜﻬﺮﺑﺎﺉﻴﺔ ﻻ ﻳﺸﻜﻞ ﻓﻲ ﺣﺪ ﺫﺍﺗﻪ ﺧﻄﺮ ﺍﻟﺤﺮﻳﻖ ﺃﻭ ﺍﻻﻧﻔﺠﺎﺭ .ﻛﻤﺎ ﻳﺠﺐ ﺃﻥ ﺗﻜﻮﻥ ﻫﻨﺎﻙ

ﻭﺳﻴﻠﺔﻟﺘﺠﻤﻴﻊ ﺃﻭ ﺗﺨﺰﻳﻦ ﺍﻟﺸﺤﻨﺔ ﻭﻣﻜﺎﻥ ﻣﺎ )ﻓﺠﻮﺓ ﺷﺮﺍﺭﺓ( ﺣﻴﺚ ﻳﻤﻜﻦ ﺇﻃﻼﻕ ﺍﻟﻄﺎﻗﺔ ﺍﻟﻤﺨﺰﻧﺔ ﻋﻠﻰ ﺷﻜﻞ

ﺷﺮﺍﺭﺓﻓﻲ ﻭﺟﻮﺩ ﺧﻠﻴﻂ ﻗﺎﺑﻞ ﻟﻼﺷﺘﻌﺎﻝ .ﻭﻻ ﻳﻮﺟﺪ ﺧﻄﺮ ﻓﻲ ﺣﺎﻟﺔ ﻏﻴﺎﺏ ﺃﻱ ﻣﻦ ﻫﺬﻩ ﺍﻟﻤﺘﻄﻠﺒﺎﺕ ﺍﻟﺜﻼﺛﺔ –

ﻭﺳﺎﺉﻞﺍﻟﺘﻮﻟﻴﺪ ،ﺃﻭ ﻓﺠﻮﺓ ﺍﻟﺸﺮﺍﺭﺓ ،ﺃﻭ ﺍﻟﺨﻠﻴﻂ ﺍﻟﻘﺎﺑﻞ ﻟﻼﺷﺘﻌﺎﻝ .ﻭﻳﺘﺮﺗﺐ ﻋﻠﻰ ﺫﻟﻚ ﺑﻄﺒﻴﻌﺔ ﺍﻟﺤﺎﻝ ﺃﻧﻪ ﻻ

ﺣﺎﺟﺔﺇﻟﻰ ﺍﺗﺨﺎﺫ ﺃﻱ ﺍﺣﺘﻴﺎﻃﺎﺕ ﺇﺫﺍ ﻛﺎﻥ ﻣﻦ ﺍﻟﻤﻌﺮﻭﻑ ﺃﻥ ﺃﺣﺪ ﺍﻟﻤﺘﻄﻠﺒﺎﺕ ﺍﻟﺜﻼﺛﺔ ﻏﺎﺉﺐ ،ﻭﺃﻧﻪ ﺇﺫﺍ ﻟﻢ ﻳﻜﻦ

ﺫﻟﻚﻣﻀﻤﻮﻧﺎ ،ﻓﻴﺠﺐ ﺗﻮﺟﻴﻪ ﺍﻟﺘﺪﺍﺑﻴﺮ ﺍﻟﺘﺼﺤﻴﺤﻴﺔ ﻧﺤﻮ ﺇﻟﻐﺎء ﺃﺣﺪ ﻫﺬﻩ ﺍﻟﻤﺘﻄﻠﺒﺎﺕ.

ﺏ4.ﺃﻣﺜﻠﺔ.

ﻓﻴﻤﺎﻳﻠﻲ ﺃﻣﺜﻠﺔ ﻋﻠﻰ ﺗﻘﻨﻴﺔ ﺍﻟﺮﺑﻂ ﻭﺍﻟﺘﺄﺭﻳﺾ ﺍﻟﻤﻨﺎﺳﺒﺔ:

) (1ﻓﻲ ﺗﻌﺒﺉﺔ ﻣﺮﻛﺒﺔ ﺍﻟﺼﻬﺮﻳﺞ ﻣﻦ ﺧﻼﻝ ﻓﺘﺤﺔ ﻋﻠﻮﻳﺔ ،ﻳﺘﻢ ﺭﺑﻂ ﺳﻠﻚ ﺑﻴﻦ ﺧﺰﺍﻥ ﺍﻟﺒﻀﺎﺉﻊ ﻭﺳﺎﻕ

ﺍﻟﺘﻌﺒﺉﺔ)ﺍﻧﻈﺮ (.9.2.12ﺳﻴﺤﺎﻓﻆ ﻋﻠﻰ ﺍﻟﺨﺰﺍﻥ ﻭﺃﻧﺒﻮﺏ ﺍﻟﺘﻌﺒﺉﺔ ﺑﻨﻔﺲ ﺍﻹﻣﻜﺎﻧﺎﺕ ﺍﻟﻜﻬﺮﺑﺎﺉﻴﺔ

ﻭﺑﺎﻟﺘﺎﻟﻲﻳﻤﻨﻊ ﺣﺪﻭﺙ ﺷﺮﺍﺭﺓ ﻓﻲ ﻣﻨﻄﻘﺔ ﻳﺸﺘﺒﻪ ﺑﻮﺟﻮﺩ ﺧﻠﻴﻂ ﻗﺎﺑﻞ ﻟﻼﺷﺘﻌﺎﻝ ﻓﻴﻬﺎ]ﺍﻧﻈﺮ

ﺍﻻﺳﺘﺜﻨﺎءﺍﺕﻓﻲ ﺏ .[(2)4.ﻭﻳﻨﺒﻐﻲ ﺍﻟﺘﺄﻛﻴﺪ ﻋﻠﻰ ﺃﻥ ﻫﺬﻩ ﺍﻟﺮﺍﺑﻄﺔ ﻻ ﺗﻤﻨﻊ ﺗﺮﺍﻛﻢ ﺍﻟﺸﺤﻨﺔ ﻋﻠﻰ

ﺳﻄﺢﺍﻟﺴﺎﺉﻞ ،ﻭﻗﺪ ﻳﻜﻮﻥ ﻣﻦ ﺍﻟﻀﺮﻭﺭﻱ ﺍﺗﺨﺎﺫ ﺍﺣﺘﻴﺎﻃﺎﺕ ﺇﺿﺎﻓﻴﺔ)ﺍﻧﻈﺮ ﺍﻟﻘﺴﻢ ﺏ.(5.

) (2ﻻ ﻳﻠﺰﻡ ﻣﺜﻞ ﻫﺬﺍ ﺍﻻﺣﺘﻴﺎﻁ )ﺳﻠﻚ ﺍﻟﺮﺑﻂ( ﻓﻲ ﻇﻞ ﺍﻟﻈﺮﻭﻑ ﺍﻟﺘﻲ ﻳﺘﻢ ﻓﻴﻬﺎ ﺍﻟﺘﺄﻛﺪ ﻣﻦ ﻋﺪﻡ ﻭﺟﻮﺩ ﺧﻠﻴﻂ

ﻗﺎﺑﻞﻟﻼﺷﺘﻌﺎﻝ .ﻣﺜﺎﻝ ﻋﻠﻰ ﻣﺜﻞ ﻫﺬﺍ ﺍﻟﻤﻮﻗﻒ ﻫﻮ ﻋﻨﺪﻣﺎ ﻳﺘﻢ ﺍﺳﺘﺨﺪﺍﻡ ﺍﻟﻤﺮﻛﺒﺎﺕ ﺍﻟﺼﻬﺮﻳﺠﻴﺔ

ﺣﺼﺮﻳﺎًﻟﻨﻘﻞ ﺳﻮﺍﺉﻞ ﺍﻟﻔﺉﺘﻴﻦ ﺍﻟﺜﺎﻧﻴﺔ ﻭﺍﻟﺜﺎﻟﺜﺔ)ﺍﻧﻈﺮ .(9.2.12.2ﻧﻈﺮﺍً ﻷﻥ ﺳﻮﺍﺉﻞ ﺍﻟﻔﺉﺘﻴﻦ

ﺍﻟﺜﺎﻧﻴﺔﻭﺍﻟﺜﺎﻟﺜﺔ ﻻ ﺗﻨﺘﺞ ﻣﺨﺎﻟﻴﻂ ﻗﺎﺑﻠﺔ ﻟﻼﺷﺘﻌﺎﻝ ﻓﻲ ﺩﺭﺟﺎﺕ ﺍﻟﺤﺮﺍﺭﺓ ﺍﻟﻌﺎﺩﻳﺔ ،ﻓﻠﻦ ﻳﻜﻮﻥ ﻫﻨﺎﻙ ﻣﺎ

ﻳﻤﻜﻦﺇﺷﻌﺎﻟﻪ ﻓﻲ ﺍﻟﺨﺰﺍﻧﺎﺕ ﺍﻟﺘﻲ ﺗﻨﻘﻞ ﻫﺬﻩ ﺍﻟﺴﻮﺍﺉﻞ .ﺍﻟﻜﻠﻤﺔﺣﺼﺮﻳﺎﺃﻧﻪ ﻣﻬﻢ .ﻫﻨﺎﻙ ﺍﻟﻌﺪﻳﺪ ﻣﻦ

ﺍﻟﻤﺮﻛﺒﺎﺕﺍﻟﺼﻬﺮﻳﺠﻴﺔ ﺍﻟﺘﻲ ﻳﺪﻳﺮﻫﺎ ﺗﺠﺎﺭ ﺯﻳﺖ ﺍﻟﻮﻗﻮﺩ ﻭﺍﻟﺘﻲ ﺗﻨﺪﺭﺝ ﺑﺤﻜﻢ ﻃﺒﻴﻌﺔ ﺍﻟﻌﻤﻠﻴﺔ ﺿﻤﻦ

ﻫﺬﻩﺍﻟﻔﺉﺔ .ﻳﺘﻢ ﺗﻀﻤﻴﻦ ﺍﻻﺳﺘﺜﻨﺎء "ﺣﻴﺚ ﻻ ﺗﺘﻢ ﻣﻌﺎﻟﺠﺔ ﺳﻮﺍﺉﻞ ﻣﻦ ﺍﻟﻔﺉﺔ ﺍﻷﻭﻟﻰ" ﻟﻠﺤﻤﺎﻳﺔ ﻣﻦ

ﺍﻟﺘﻌﺒﺉﺔﻏﻴﺮ ﺍﻟﻤﻘﺼﻮﺩﺓ ﺑﺴﺎﺉﻞ ﻣﻦ ﺍﻟﻔﺉﺔ ﺍﻷﻭﻟﻰ ﻭﻟﻠﺘﻌﺮﻑ ﻋﻠﻰ ﺍﻟﺮﻏﺒﺔ ﻓﻲ ﻭﺟﻮﺩ ﻣﻤﺎﺭﺳﺎﺕ ﺭﺑﻂ

ﻣﻮﺣﺪﺓﻓﻲ ﻣﺤﻄﺔ ﻣﻨﺎﻭﻟﺔ ﺳﻮﺍﺉﻞ ﻣﻦ ﺍﻟﺪﺭﺟﺔ ﺍﻷﻭﻟﻰ ﺑﺎﻹﺿﺎﻓﺔ ﺇﻟﻰ ﺳﻮﺍﺉﻞ ﻣﻦ ﺍﻟﺪﺭﺟﺔ ﺍﻟﺜﺎﻧﻴﺔ ﺃﻭ

ﺍﻟﺜﺎﻟﺜﺔ.

) (3ﻻ ﻳﻮﺟﺪ ﺳﻠﻚ ﺭﺑﻂ ﺿﺮﻭﺭﻱ)ﺍﻧﻈﺮ (9.2.12.1ﺃﺛﻨﺎء ﺗﺤﻤﻴﻞ ﺃﻭ ﺗﻔﺮﻳﻎ ﺍﻷﺳﻔﻠﺖ ﺃﻭ ﺍﻟﺰﻳﺖ ﺍﻟﺨﺎﻡ ﺃﻭ ﺍﻟﻤﻨﺘﺞ

ﺍﻟﺬﻱﻳﺤﺘﻮﻱ ﻋﻠﻰ ﻧﺴﺐ ﻛﺒﻴﺮﺓ ﻣﻦ ﺍﻟﺒﻘﺎﻳﺎ ﺍﻟﺨﺎﻡ ﺃﻭ ﺍﻟﺴﻮﺍﺉﻞ ﺍﻷﺧﺮﻯ ﺍﻟﻤﻌﺮﻭﻓﺔ ﺑﻤﻘﺎﻭﻣﺎﺗﻬﺎ

ﺍﻟﻤﻨﺨﻔﻀﺔ.ﻫﺬﻩ ﺍﻟﺰﻳﻮﺕ ﻟﻴﺴﺖ ﻋﺮﺿﺔ ﻟﺘﺮﺍﻛﻢ ﺷﺤﻨﺎﺕ ﺛﺎﺑﺘﺔ ﺧﻄﻴﺮﺓ ﻋﻠﻰ ﺳﻄﺢ ﺍﻟﺴﺎﺉﻞ ،ﻛﻤﺎ

ﺃﻧﻬﺎﻻ ﺗﻨﺘﺞ ﺷﺤﻨﺎﺕ ﺧﻄﻴﺮﺓ ﻋﻠﻰ ﺍﻟﺤﺎﻭﻳﺔ ،ﻷﻥ ﻣﻮﺻﻠﻴﺔ ﺍﻟﺴﺎﺉﻞ ﻋﺎﻟﻴﺔ ﺑﻤﺎ ﻳﻜﻔﻲ ﻟﻠﺴﻤﺎﺡ

ﺑﺎﻟﺘﺤﻴﻴﺪﺍﻟﺴﺮﻳﻊ ﻷﻱ ﺷﺤﻨﺎﺕ ﻣﻨﻔﺼﻠﺔ ﺃﺛﻨﺎء ﺍﻟﻨﻘﻞ.

) (4ﻟﻴﺴﺖ ﻫﻨﺎﻙ ﺣﺎﺟﺔ ﺇﻟﻰ ﻣﻤﺎﺭﺳﺎﺕ ﻭﻗﺎﺉﻴﺔ ﺛﺎﺑﺘﺔ ،ﺑﻐﺾ ﺍﻟﻨﻈﺮ ﻋﻦ ﺍﻟﺴﺎﺉﻞ ﺍﻟﺬﻱ ﻳﺘﻢ ﺍﻟﺘﻌﺎﻣﻞ ﻣﻌﻪ،

ﺣﻴﺚﻳﻜﻮﻥ ﺍﻟﺘﺮﺗﻴﺐ ﺍﻟﻔﻴﺰﻳﺎﺉﻲ ﺑﺤﻴﺚ ﻻ ﺗﻮﺟﺪ ﻓﺮﺻﺔ ﻟﺤﺪﻭﺙ ﺷﺮﺍﺭﺓ ﻓﻲ ﻭﺟﻮﺩ ﺧﻠﻴﻂ ﻗﺎﺑﻞ

ﻟﻼﺷﺘﻌﺎﻝ.ﺗﺴﺮﺩ ﺍﻟﻔﻘﺮﺓ 9.2.13ﺍﻟﻌﺪﻳﺪ ﻣﻦ ﻫﺬﻩ ﺍﻟﻤﻮﺍﻗﻒ.

ﺣﻘﻮﻕﺍﻟﻄﺒﻊ ﻭﺍﻟﻨﺸﺮ NFPA

ﺷﺮﻛﺔﺃﺑﺎﺩﻏﻮﺳﺘﺎﺭ ﺗﺎﺳﻴﺴﺎﺕ ﺇﻳﺮﺍﻧﻴﻨﺎﻥ ﺍﻟﻤﺤﺪﻭﺩﺓ www.atapars.com

www.atapars.com/NFPA-code/

ﻓﻴﻤﺎﻳﻠﻲ ﺃﻣﺜﻠﺔ ﺇﺿﺎﻓﻴﺔ:

)ﺃ( ﺗﻌﺒﺉﺔ ﺍﻟﺨﺰﺍﻧﺎﺕ ﺍﻷﺭﺿﻴﺔ .ﺗﻜﻮﻥ ﻓﻮﻫﺔ ﺍﻟﺘﻌﺒﺉﺔ ﻋﻠﻰ ﺍﺗﺼﺎﻝ ﺩﺍﺉﻤﺎً ﺑﻔﺘﺤﺔ ﺍﻟﺘﻌﺒﺉﺔ .ﻓﻲ ﻫﺬﻩ

ﺍﻟﺤﺎﻻﺕ،ﺗﻜﻮﻥ ﺍﻟﻔﻮﻫﺔ ﻭﺍﻟﺨﺰﺍﻥ ﻟﻬﻤﺎ ﻧﻔﺲ ﺍﻟﺠﻬﺪ ﺍﻟﻜﻬﺮﺑﺎﺉﻲ ﺑﺴﺒﺐ ﺗﻼﻣﺴﻬﻤﺎ .ﻋﻼﻭﺓ

ﻋﻠﻰﺫﻟﻚ ،ﻻ ﺗﻮﺟﺪ ﻓﺠﻮﺓ ﺷﺮﺍﺭﺓ.

)ﺏ( ﺍﻟﺘﺤﻤﻴﻞ ﺃﻭ ﺍﻟﺘﻔﺮﻳﻎ ﻣﻦ ﺧﻼﻝ ﻭﺻﻼﺕ ﻣﺤﻜﻤﺔ .ﻗﺒﻞ ﺇﺟﺮﺍء ﺍﻻﺗﺼﺎﻝ ،ﻻ ﻳﻮﺟﺪ ﺗﺪﻓﻖ ﻭﻻ

ﺗﻮﺟﺪﺁﻟﻴﺔ ﺗﻮﻟﻴﺪ .ﺃﺛﻨﺎء ﺍﻟﻨﻘﻞ ،ﻗﺪ ﻳﻜﻮﻥ ﻫﻨﺎﻙ ﺗﻮﻟﻴﺪ ﺍﺳﺘﺎﺗﻴﻜﻲ ﺩﺍﺧﻞ ﻧﻈﺎﻡ ﺍﻟﺘﺪﻓﻖ ،ﻭﻟﻜﻦ ﻻ

ﻳﻮﺟﺪﻣﻜﺎﻥ ﻟﺤﺪﻭﺙ ﺷﺮﺍﺭﺓ ﻓﻲ ﻭﺟﻮﺩ ﺧﻠﻴﻂ ﻗﺎﺑﻞ ﻟﻼﺷﺘﻌﺎﻝ .ﻳﻨﻘﻄﻊ ﺍﻟﺘﺪﻓﻖ ﻗﺒﻞ ﺍﻧﻘﻄﺎﻉ

ﺍﻻﺗﺼﺎﻝ،ﻭﻻ ﻳﻤﻜﻦ ﺃﻥ ﻳﻜﻮﻥ ﻫﻨﺎﻙ ﻓﺮﻕ ﺟﻬﺪ ﻹﺣﺪﺍﺙ ﺷﺮﺍﺭﺓ ﻷﻥ ﺍﻟﺠﺰءﻳﻦ ﺍﻟﻤﻄﻠﻮﺏ

ﻓﺼﻠﻬﻤﺎﻣﺘﻼﻣﺴﺎﻥ ﻭﻋﻠﻰ ﻧﻔﺲ ﺍﻹﻣﻜﺎﻧﻴﺔ ﺣﺘﻰ ﻟﺤﻈﺔ ﺍﻻﻧﻔﺼﺎﻝ .ﺍﻟﺤﺸﻮ ﺍﻟﺴﻔﻠﻲ ﻫﻮ ﺣﺎﻟﺔ

ﺧﺎﺻﺔﻣﻦ ﺍﻻﺗﺼﺎﻝ ﺍﻟﻤﻐﻠﻖ ،ﻭﻻ ﺣﺎﺟﺔ ﺇﻟﻰ ﺭﺑﻂ.

ﺏ5.ﺗﺤﻤﻴﻞ ﺍﻟﺘﺒﺪﻳﻞ.

ﻋﻠﻰﺍﻟﻤﺪﻯﺗﺤﻤﻴﻞ ﺍﻟﺘﺒﺪﻳﻞ )ﺍﻧﻈﺮ ﺃ(9.1.10.ﺗﻢ ﺍﺳﺘﺨﺪﺍﻣﻪ ﻟﻮﺻﻒ ﻣﻮﻗﻒ ﻳﺘﻄﻠﺐ ﺍﻫﺘﻤﺎﻣﺎً ﺧﺎﺻﺎً.

ﻋﻨﺪﻣﺎﻳﺘﻢ ﺇﻓﺮﺍﻍ ﺍﻟﺨﺰﺍﻥ ﻣﻦ ﺣﻤﻮﻟﺔ ﺳﺎﺉﻞ ﻣﻦ ﺍﻟﺪﺭﺟﺔ ﺍﻷﻭﻟﻰ ،ﻳﺘﺒﻘﻰ ﺧﻠﻴﻂ ﻣﻦ ﺍﻟﺒﺨﺎﺭ ﻭﺍﻟﻬﻮﺍء ،ﻭﺍﻟﺬﻱ

ﻳﻤﻜﻦﺃﻥ ﻳﻜﻮﻥ ،ﻭﻏﺎﻟﺒﺎً ﻣﺎ ﻳﻜﻮﻥ ،ﺿﻤﻦ ﺍﻟﻨﻄﺎﻕ ﺍﻟﻘﺎﺑﻞ ﻟﻼﺷﺘﻌﺎﻝ .ﻋﻨﺪ ﺇﻋﺎﺩﺓ ﻣﻞء ﻫﺬﺍ ﺍﻟﺨﺰﺍﻥ ﺑﺴﺎﺉﻞ ﻣﻦ

ﺍﻟﺪﺭﺟﺔﺍﻷﻭﻟﻰ ،ﻳﺘﻢ ﺍﻟﺘﺨﻠﺺ ﻣﻦ ﺃﻱ ﺷﺤﻨﺔ ﺗﺼﻞ ﺇﻟﻰ ﻫﻴﻜﻞ ﺍﻟﺨﺰﺍﻥ ﺑﻮﺍﺳﻄﺔ ﺳﻠﻚ ﺍﻟﺮﺑﻂ ﺍﻟﻤﻄﻠﻮﺏ)ﺍﻧﻈﺮ

.(9.2.12ﻛﻤﺎ ﺃﻧﻪ ﻻ ﻳﻮﺟﺪ ﺧﻠﻴﻂ ﻗﺎﺑﻞ ﻟﻼﺷﺘﻌﺎﻝ ﻋﻠﻰ ﺳﻄﺢ ﺍﺭﺗﻔﺎﻉ ﻣﺴﺘﻮﻯ ﺍﻟﺰﻳﺖ ﻷﻥ ﺳﺎﺉﻞ ﺍﻟﻔﺉﺔ

ﺍﻷﻭﻟﻰﻳﻨﺘﺞ ﻋﻠﻰ ﺳﻄﺤﻪ ﺧﻠﻴﻄﺎً ﻏﻨﻴﺎً ﺟﺪﺍً ﺑﺤﻴﺚ ﻻ ﻳﻤﻜﻦ ﺍﻻﺷﺘﻌﺎﻝ .ﻫﺬﺍ ﻫﻮ ﺍﻟﻮﺿﻊ ﺍﻟﺸﺎﺉﻊ ﻓﻲ ﺍﻟﻤﺮﻛﺒﺎﺕ

ﺍﻟﺼﻬﺮﻳﺠﻴﺔﺍﻟﺘﻲ ﺗﻌﻤﻞ ﺑﺎﻟﺒﻨﺰﻳﻦ .ﺇﺫﺍ ﺗﺮﺍﻛﻤﺖ ﺷﺤﻨﺔ ﺛﺎﺑﺘﺔ ﻋﻠﻰ ﺍﻟﺴﻄﺢ ،ﻛﻤﺎ ﻳﺤﺪﺙ ﺃﺣﻴﺎﻧﺎً ،ﺑﺪﺭﺟﺔ ﻛﺎﻓﻴﺔ

ﻹﻧﺘﺎﺝﺷﺮﺍﺭﺓ ،ﻓﺈﻧﻬﺎ ﺗﺤﺪﺙ ﻓﻲ ﺟﻮ ﻏﻨﻲ ﺟﺪﺍً ﻭﻏﻴﺮ ﻗﺎﺑﻞ ﻟﻼﺷﺘﻌﺎﻝ ،ﻭﺑﺎﻟﺘﺎﻟﻲ ﻻ ﺗﺴﺒﺐ ﺃﻱ ﺿﺮﺭ.

ﻳﻨﺸﺄﻣﻮﻗﻒ ﻣﺨﺘﻠﻒ ﺗﻤﺎﻣﺎً ﺇﺫﺍ ﻛﺎﻥ ﺍﻟﺴﺎﺉﻞ ﻣﻮﺟﻮﺩﺍًﺗﻢ ﺗﺤﻤﻴﻞ ﺍﻟﺘﺒﺪﻳﻞﺃﻱ ﺃﻧﻪ ﻳﺘﻢ ﺗﺤﻤﻴﻞ ﺳﺎﺉﻞ ﻣﻦ

ﺍﻟﺪﺭﺟﺔﺍﻟﺜﺎﻧﻴﺔ ﺃﻭ ﺍﻟﻔﺉﺔ ﺍﻟﺜﺎﻟﺜﺔ ﻓﻲ ﻣﺮﻛﺒﺔ ﺻﻬﺮﻳﺠﻴﺔ ﻛﺎﻧﺖ ﺗﺤﺘﻮﻱ ﻓﻲ ﺍﻟﺴﺎﺑﻖ ﻋﻠﻰ ﺳﺎﺉﻞ ﻣﻦ ﺍﻟﺪﺭﺟﺔ

ﺍﻷﻭﻟﻰ.ﻟﻴﺴﺖ ﺳﻮﺍﺉﻞ ﺍﻟﻔﺉﺔ IIﺃﻭ ﺍﻟﻔﺉﺔ IIIﺑﺎﻟﻀﺮﻭﺭﺓ ﻣﻮﻟﺪﺍﺕ ﺛﺎﺑﺘﺔ ﺃﻛﺜﺮ ﻓﻌﺎﻟﻴﺔ ﻣﻦ ﺳﻮﺍﺉﻞ ﺍﻟﻔﺉﺔ

ﺍﻷﻭﻟﻰﺍﻟﺘﻲ ﺗﻢ ﺗﺤﻤﻴﻠﻬﺎ ﻣﺴﺒﻘﺎً ،ﻭﻟﻜﻦ ﺍﻟﻐﻼﻑ ﺍﻟﺠﻮﻱ ﺍﻟﻤﻼﻣﺲ ﻟﺴﻄﺢ ﺍﻟﻨﻔﻂ ﺍﻟﻤﺮﺗﻔﻊ ﻻ ﻳﺘﻢ ﺇﺛﺮﺍﺅﻩ

ﻹﺧﺮﺍﺟﻪﻣﻦ ﺍﻟﻨﻄﺎﻕ ﺍﻟﻘﺎﺑﻞ ﻟﻼﺷﺘﻌﺎﻝ .ﺇﺫﺍ ﻛﺎﻧﺖ ﺍﻟﻈﺮﻭﻑ ﺗﺆﺩﻱ ﺇﻟﻰ ﺣﺪﻭﺙ ﺷﺮﺍﺭﺓ ﺇﻣﺎ ﻋﺒﺮ ﺳﻄﺢ ﺍﻟﺰﻳﺖ ﺃﻭ

ﻣﻦﺳﻄﺢ ﺍﻟﺰﻳﺖ ﺇﻟﻰ ﺟﺴﻢ ﺁﺧﺮ ،ﻓﺈﻧﻬﺎ ﺗﻜﻮﻥ ﻓﻲ ﺧﻠﻴﻂ ﻳﻤﻜﻦ ﺃﻥ ﻳﻜﻮﻥ ﺿﻤﻦ ﺍﻟﻨﻄﺎﻕ ﺍﻟﻘﺎﺑﻞ ﻟﻼﺷﺘﻌﺎﻝ،

ﻭﻳﻤﻜﻦﺃﻥ ﻳﺤﺪﺙ ﺍﻧﻔﺠﺎﺭ.

ﺗﻢﺍﻟﺘﺄﻛﻴﺪ ﻋﻠﻰ ﺃﻥ ﺭﺑﻂ ﺍﻟﺨﺰﺍﻥ ﺑﺴﺎﻕ ﺍﻟﺘﻌﺒﺉﺔ ﻟﻴﺲ ﻛﺎﻓﻴﺎً؛ ﻓﻘﺪ ﺣﺪﺛﺖ ﻏﺎﻟﺒﻴﺔ ﺍﻻﻧﻔﺠﺎﺭﺍﺕ ﺍﻟﻤﺴﺠﻠﺔ

ﻋﻨﺪﻣﺎﻛﺎﻥ ﻳﻌُﺘﻘﺪ ﺃﻥ ﺍﻟﺨﺰﺍﻥ ﻗﺪ ﺗﻢ ﺭﺑﻄﻪ ﺑﺸﻜﻞ ﻛﺎﻑ ٍ.ﺇﻥ ﺍﻟﺠﻬﺪ ﺍﻟﻜﻬﺮﻭﺳﺘﺎﺗﻴﻜﻲ ﺍﻟﻤﺴﺆﻭﻝ ﻋﻦ ﺍﻟﺸﺮﺍﺭﺓ

ﻣﻮﺟﻮﺩﺩﺍﺧﻞ ﺍﻟﺨﺰﺍﻥ ﻋﻠﻰ ﺳﻄﺢ ﺍﻟﺴﺎﺉﻞ ﻭﻻ ﻳﻤﻜﻦ ﺇﺯﺍﻟﺘﻪ ﺑﺎﻟﺮﺑﻂ .ﺗﺸﻤﻞ ﺍﻟﺘﺪﺍﺑﻴﺮ ﺍﻟﺮﺍﻣﻴﺔ ﺇﻟﻰ ﺗﻘﻠﻴﻞ

ﻓﺮﺻﺔﺣﺪﻭﺙ ﻣﺜﻞ ﻫﺬﺍ ﺍﻻﺷﺘﻌﺎﻝ ﺍﻟﺴﺎﻛﻦ ﺍﻟﺪﺍﺧﻠﻲ ﻣﺎ ﻳﻠﻲ:

) (1ﺗﺠﻨﺐ ﻣﺮﻭﺟﻲ ﺍﻟﺸﺮﺍﺭﺓ .ﺗﺰﻳﺪ ﺍﻷﺟﺴﺎﻡ ﺍﻟﻤﻮﺻﻠﺔ ﺍﻟﺘﻲ ﺗﻄﻔﻮ ﻋﻠﻰ ﺳﻄﺢ ﺍﻟﺰﻳﺖ ﻣﻦ ﻓﺮﺻﺔ ﺣﺪﻭﺙ

ﺷﺮﺍﺭﺓﻓﻲ ﺟﺪﺍﺭ ﺍﻟﺨﺰﺍﻥ .ﻳﻤﻜﻦ ﻟﻘﻀﺒﺎﻥ ﺍﻟﻘﻴﺎﺱ ﺍﻟﻤﻌﺪﻧﻴﺔ ﺃﻭ ﻏﻴﺮﻫﺎ ﻣﻦ ﺍﻷﺷﻴﺎء ﺍﻟﺘﻲ ﺗﺒﺮﺯ ﻓﻲ

ﻣﺴﺎﺣﺔﺍﻟﺒﺨﺎﺭ ﺃﻥ ﺗﺨﻠﻖ ﻓﺠﻮﺓ ﺷﺮﺍﺭﺓ ﻋﻨﺪﻣﺎ ﻳﻘﺘﺮﺏ ﻣﺴﺘﻮﻯ ﺍﻟﺴﺎﺉﻞ ﺍﻟﻤﺮﺗﻔﻊ ﻣﻦ ﺍﻹﺳﻘﺎﻁ .ﺃﺣﺪ

ﺍﻻﺣﺘﻴﺎﻃﺎﺕﺍﻟﺸﺎﺉﻌﺔ ﻫﻮ ﺍﺷﺘﺮﺍﻁ ﻭﺻﻮﻝ ﺃﻧﺎﺑﻴﺐ ﺍﻟﺘﻌﺒﺉﺔ )ﻣﺎﺳﻮﺭﺓ ﺍﻟﺘﺼﺮﻳﻒ( ﺇﻟﻰ ﺃﻗﺮﺏ ﻣﻜﺎﻥ

ﻣﻤﻜﻦﻣﻦ ﻗﺎﻉ ﺍﻟﺨﺰﺍﻥ .ﺃﻱ ﻋﻤﻠﻴﺔ ﻣﺜﻞ ﺃﺧﺬ ﺍﻟﻌﻴﻨﺎﺕ ،ﺃﻭ ﻗﻴﺎﺱ ﺩﺭﺟﺔ ﺣﺮﺍﺭﺓ ﺍﻟﺰﻳﺖ ،ﺃﻭ ﺍﻟﻘﻴﺎﺱ

ﺍﻟﺬﻱﻳﺘﻀﻤﻦ ﺧﻔﺾ ﺟﺴﻢ ﻣﻮﺻﻞ ﻣﻦ ﺧﻼﻝ

ﺣﻘﻮﻕﺍﻟﻄﺒﻊ ﻭﺍﻟﻨﺸﺮ NFPA

ﺷﺮﻛﺔﺃﺑﺎﺩﻏﻮﺳﺘﺎﺭ ﺗﺎﺳﻴﺴﺎﺕ ﺇﻳﺮﺍﻧﻴﻨﺎﻥ ﺍﻟﻤﺤﺪﻭﺩﺓ www.atapars.com

www.atapars.com/NFPA-code/

ﻳﺠﺐﺗﺄﺟﻴﻞ ﺍﻟﻔﺘﺢ ﻓﻲ ﻣﺴﺎﺣﺔ ﺍﻟﺒﺨﺎﺭ ﺑﺎﻟﺰﻳﺖ ﺣﺘﻰ ﺩﻗﻴﻘﺔ ﻭﺍﺣﺪﺓ ﻋﻠﻰ ﺍﻷﻗﻞ ﺑﻌﺪ ﺗﻮﻗﻒ ﺍﻟﺘﺪﻓﻖ.

ﻳﺆﺩﻱﺍﻟﻘﻴﺎﻡ ﺑﺬﻟﻚ ﺇﻟﻰ ﺍﻟﺴﻤﺎﺡ ﻷﻱ ﺷﺤﻨﺔ ﺳﻄﺤﻴﺔ ﺑﺎﻻﺳﺘﺮﺧﺎء.

) (2ﺗﻘﻠﻴﻞ ﺗﻮﻟﻴﺪ ﺍﻟﻜﻬﺮﺑﺎء ﺍﻟﺴﺎﻛﻨﺔ ﺑﻮﺍﺣﺪ ﺃﻭ ﺃﻛﺜﺮ ﻣﻤﺎ ﻳﻠﻲ:

)ﺃ( ﺗﺠﻨﺐ ﻣﻞء ﺭﺫﺍﺫ ﺍﻟﺰﻳﺖ ﻭﺭﺷﻪ ﻷﻋﻠﻰ ﺣﻴﺚ ﻳﺘﻢ ﺍﺳﺘﺨﺪﺍﻡ ﺍﻟﺤﺸﻮ ﺍﻟﺴﻔﻠﻲ.

)ﺏ( ﺍﺳﺘﺨﺪﻡ ﻣﻌﺪﻻﺕ ﺗﻌﺒﺉﺔ ﻣﻨﺨﻔﻀﺔ ﻋﻨﺪ ﺑﺪﺍﻳﺔ ﺍﻟﻤﻞء ﻣﻦ ﺧﻼﻝ ﻣﺎﺳﻮﺭﺓ ﺍﻟﺘﺼﺮﻳﻒ ،ﺣﺘﻰ ﻳﺘﻢ

ﻏﻤﺮﻧﻬﺎﻳﺔ ﺍﻟﻔﻮﻫﺔ .ﻳﻌﺘﺒﺮ ﺍﻟﺒﻌﺾ ﺃﻥ 3ﻗﺪﻡ /ﺛﺎﻧﻴﺔ ) 0.9ﻡ /ﺛﺎﻧﻴﺔ( ﺇﺟﺮﺍء ﺍﺣﺘﺮﺍﺯﻱ ﻣﻨﺎﺳﺐ.

)ﺝ( ﻋﻨﺪ ﺍﺳﺘﺨﺪﺍﻡ ﺍﻟﻤﺮﺷﺤﺎﺕ ،ﻗﻢ ﺑﺘﻮﻓﻴﺮ ﻭﻗﺖ ﺍﺳﺘﺮﺧﺎء ﻓﻲ ﺍﻷﻧﺎﺑﻴﺐ ﺃﺳﻔﻞ ﺍﻟﻤﺮﺷﺤﺎﺕ.

ﻳﻌﺘﺒﺮﺍﻟﺒﻌﺾ ﺃﻥ ﻭﻗﺖ ﺍﻻﺳﺘﺮﺧﺎء ﻟﻤﺪﺓ 30ﺛﺎﻧﻴﺔ ﻫﻮ ﺇﺟﺮﺍء ﺍﺣﺘﺮﺍﺯﻱ ﻣﻨﺎﺳﺐ.

) (3ﻗﻢ ﺑﺈﺯﺍﻟﺔ ﺍﻟﺨﻠﻴﻂ ﺍﻟﻘﺎﺑﻞ ﻟﻼﺷﺘﻌﺎﻝ ﻋﻦ ﻃﺮﻳﻖ ﺗﺤﺮﻳﺮ ﺍﻟﻐﺎﺯ ﺃﻭ ﺧﻤﻮﻟﻪ ﻗﺒﻞ ﺗﺒﺪﻳﻞ ﺍﻷﺣﻤﺎﻝ.

ﺃ ﺍﻟﻤﻠﺤﻖﺝ ﺍﻟﻤﺮﺍﺟﻊ ﺍﻹﻋﻼﻣﻴﺔ

ﺝ1.ﺍﻟﻤﻨﺸﻮﺭﺍﺕ ﺍﻟﻤﺮﺟﻌﻴﺔ.

ﺗﺘﻢﺍﻹﺷﺎﺭﺓ ﺇﻟﻰ ﺍﻟﻤﺴﺘﻨﺪﺍﺕ ﺃﻭ ﺃﺟﺰﺍء ﻣﻨﻬﺎ ﺍﻟﻤﺪﺭﺟﺔ ﻓﻲ ﻫﺬﺍ ﺍﻟﻤﻠﺤﻖ ﺿﻤﻦ ﺍﻷﻗﺴﺎﻡ ﺍﻟﻤﻌﻠﻮﻣﺎﺗﻴﺔ ﻟﻬﺬﺍ

ﺍﻟﻤﻌﻴﺎﺭﻭﻻ ﺗﺸﻜﻞ ﺟﺰءﺍً ﻣﻦ ﻣﺘﻄﻠﺒﺎﺕ ﻫﺬﻩ ﺍﻟﻮﺛﻴﻘﺔ ﻣﺎ ﻟﻢ ﻳﺘﻢ ﺇﺩﺭﺍﺟﻬﺎ ﺃﻳﻀﺎً ﻓﻲ ﺍﻟﻔﺼﻞ 2ﻷﺳﺒﺎﺏ ﺃﺧﺮﻯ.