Professional Documents

Culture Documents

Ro-Edi Operation Sop

Uploaded by

Chaouki BouOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ro-Edi Operation Sop

Uploaded by

Chaouki BouCopyright:

Available Formats

Hydrocons

High Purity Water Systems

VALIDATION RECORDS

CLIENT: – M/s BIOTHERA,ALGERIA

SUBJECT: – STANDARD OPERATING PROCEDURE REV: 00

RO-EDI SYSTEM DOCUMENT NO. : – BT/PWG/OSOP/03

Page 1 of 3

STANDARD OPERATING PROCEDURE

RO-EDI

1 OBJECTIVE:

To Establish Standard Operating Procedure for operating RO-EDI System.

2 SCOPE:

This shall be applicable to operate Single pass RO-EDI in Purified Water Generation system.

3 RESPONSIBILITY:

3.1 Doing : Hydrocons Systems Pvt. Ltd.

3.2 Checking : HSPL. / Client

4 PURPOSE:

The purpose of RO-EDI is to generate Purified Water of USP grade.

5 PROCEDURE:

RO System : I

Turn on the two way switch to normal AUTO mode

Press log in to operator and also go to manual mode

First check the level of the Dosing tanks And Soft water storage tank, if level is sufficient then

start the system.

Open Actuated valve AV-06 and also open ADV-01. By pressing in HMI screen.

Name Signature Date

Prepared By Ibrahim Golandaj

Checked By Ramiz Khatib

Start Dosing Pumps and DP03 and DP04 (ANTISCALENT),(SMBS).

Start RO Feed Pump (ROFP01) and let the water go to drain set flow 4.6 m3/hr in RM-02, in this

period check free Chlorine manually using test kit and Inlet Conductivity (<1200 µS/cm), if feed

values are in limit open ADV02 and close ADV01 after 2 minutes start the RO HPP01 also set

reject flow 1.6 m3/hr on RM-03 (RO-I reject)

Check the RO-I outlet conductivity if the conductivity is in limit open the ADV-03 and Starts PH

dosing and close ADV-02 After 2 minutes starts the RO HPP-02

RO System : II

Set the Reject flow 0.8 m3/hr on RM-04 maintain PH 7-8 at RO-II so we will get flow 2.2 m3/hr at

RO-II outlet(On RM-05).

Check the RO-II outlet conductivity is in limit less than 10.

After open valve DV-08, DV-09 and DV-11 ( DV-11 Always open)

Through the valve DV-10 set the flow on Rotameter (RM-06)such manner should be 200 L/Hr

Open the valve BTADV-01 and closed the valve ADV-03

NOTE-All Diaphragm valve operation will be manually.

EDI : I

After 2 minutes start the EDI system by pressing in HMI screen.

Set the voltage at 100 – 160 V & current in range of 1.7 – 2.5 Amps.

Start the UV-01 system.

Low pressure switch is providing before EDI so as to protect EDI from burning due to low flow

rate at EDI inlet. Whenever EDI low pressure switch will give signal then EDI will be trip

immediately.

After EDI system USP Grade water will generate and this will be stored in Purified water storage

tank.

Name Signature Date

Prepared By Ibrahim Golandaj

Checked By Ramiz Khatib

AUTO MODE OPERATION:

Turn on the two way switch to normal AUTO mode

Press log in to operator

First checks for the level of the Dosing tanks if level is sufficient then start the system.

Set the parameters of dosing in HMI screen

and also go to AUTO mode

Press AUTO MODE so the system will run automatically.

Set the flow on flow meters manually through Diaphragm valves.

Monitor the system and maintain the Given operational log sheet.

Note:

If proper flow rate is not maintained in feed line of EDI then EDI will be burn. Hence proper

feed flow rate to be maintained as per above at feed, concentrate & electrolyte chambers.

The high conductivity of the feed water having more than <20 µs/cm then the scaling will

take place in EDI which will damage EDI unit permanently.

All instrument of RO-EDI system should be calibrated stringently every year.

Name Signature Date

Prepared By Ibrahim Golandaj

Checked By Ramiz Khatib

You might also like

- Sop For Ro and Edi SystemDocument5 pagesSop For Ro and Edi SystemPramod PatilNo ratings yet

- Diesel Exhaust Fluid Plant For Automotive Er800Document3 pagesDiesel Exhaust Fluid Plant For Automotive Er800indianepal420No ratings yet

- Modulo de Control de Osmosis PDFDocument15 pagesModulo de Control de Osmosis PDFrafaelNo ratings yet

- NEOPRSP001 - Rev. 01 - Pages 12 - Plant Operation Control ProcedureDocument11 pagesNEOPRSP001 - Rev. 01 - Pages 12 - Plant Operation Control Procedurealialharbi021No ratings yet

- Feed Water System: Chanar Energy Limited Tandlianwala FaisalabadDocument11 pagesFeed Water System: Chanar Energy Limited Tandlianwala FaisalabadMuhammadTayyabNo ratings yet

- Quotation of RO Plant From AQUARO WATER SOUTIONS PDFDocument11 pagesQuotation of RO Plant From AQUARO WATER SOUTIONS PDFAlexander DoraisamyNo ratings yet

- 573 2012 - Appendix - C Process NarativeDocument14 pages573 2012 - Appendix - C Process NarativeamilasriNo ratings yet

- ROS-2210 RO Controller Operation ManualDocument8 pagesROS-2210 RO Controller Operation ManualEndra100% (2)

- NHT Amine Degrease Procedure Rev2Document29 pagesNHT Amine Degrease Procedure Rev2raj kumarNo ratings yet

- SCADA PresentationDocument6 pagesSCADA PresentationGigih PramonoNo ratings yet

- Sop For PWG SystemDocument6 pagesSop For PWG SystemShyam QCNo ratings yet

- Produced Water Skimming ProcedureDocument7 pagesProduced Water Skimming Procedurehai dang maiNo ratings yet

- SOP For PW Generation System, New - 25-11-10Document15 pagesSOP For PW Generation System, New - 25-11-10markandey gupta100% (3)

- Process Description: Venezuela Jose Mixing Plant Wastewater Treatment Package Equipment (PK-1330330)Document20 pagesProcess Description: Venezuela Jose Mixing Plant Wastewater Treatment Package Equipment (PK-1330330)Erick 27 LibreNo ratings yet

- Edi Sop: Procedure To Turning "ON" RO-EDI System in Auto ModeDocument2 pagesEdi Sop: Procedure To Turning "ON" RO-EDI System in Auto ModePramod PatilNo ratings yet

- Operation and Maintenance Manual: Effluent Treatment PlantDocument49 pagesOperation and Maintenance Manual: Effluent Treatment PlantOmkar BharankarNo ratings yet

- Agar API Oil Skimmer ApplDocument2 pagesAgar API Oil Skimmer Appljdiosbernal10No ratings yet

- Agar API Oil Skimmer Appl 2Document2 pagesAgar API Oil Skimmer Appl 2JADNo ratings yet

- 2000 LPDDocument5 pages2000 LPDACTS TECHNO SOLUTIONSNo ratings yet

- Operation & Maintenance Manual: Vishwasri-Oak Park CoimbatoreDocument17 pagesOperation & Maintenance Manual: Vishwasri-Oak Park CoimbatoreSathishkumar DhamodaranNo ratings yet

- R0 - 149 - Offer - Preparation Processing Equipments For 3000 LPH RTS PlantDocument50 pagesR0 - 149 - Offer - Preparation Processing Equipments For 3000 LPH RTS PlantSai Kiran PalikaNo ratings yet

- Reverse Osmosis R14-SERIES Installation InstructionsDocument44 pagesReverse Osmosis R14-SERIES Installation InstructionsWattsNo ratings yet

- Reverse Osmosis R24-SERIES Installation InstructionsDocument44 pagesReverse Osmosis R24-SERIES Installation InstructionsWattsNo ratings yet

- Project Execution PlanDocument20 pagesProject Execution Planprabhu rajendranNo ratings yet

- PFD FileDocument11 pagesPFD FileNaveen MahawarNo ratings yet

- Ultra Clear RO-EDI & LaboStarDocument8 pagesUltra Clear RO-EDI & LaboStarcristi5cNo ratings yet

- (EZ SDI) Automatic SDI Monitoring SystemDocument2 pages(EZ SDI) Automatic SDI Monitoring SystemLely Zikri ZulhidayahNo ratings yet

- Ablandador Manual-Hankscraft-Runxin PDFDocument37 pagesAblandador Manual-Hankscraft-Runxin PDFgonzaloagustin84No ratings yet

- Automation & Controls in Water & Waste Water Treatment Plants Y.v.satyanarayana, Head - Technology, Ion Exchange (India) Ltd.Document5 pagesAutomation & Controls in Water & Waste Water Treatment Plants Y.v.satyanarayana, Head - Technology, Ion Exchange (India) Ltd.Abhishek VijayanNo ratings yet

- User's Manual: Oil Content Meter Model GQS-206Document19 pagesUser's Manual: Oil Content Meter Model GQS-206Bhayu alfianNo ratings yet

- Reverse Osmosis Model R4X40 Installation InstructionsDocument16 pagesReverse Osmosis Model R4X40 Installation InstructionsWattsNo ratings yet

- SOP-EG-009 HSRO Operating ProcedureDocument3 pagesSOP-EG-009 HSRO Operating ProcedureJayDwarkadhish.15No ratings yet

- System ManualDocument14 pagesSystem ManualCareers SSPNo ratings yet

- Water Treatment Plant Spesification PDFDocument8 pagesWater Treatment Plant Spesification PDFrando85100% (1)

- Service Manual For Closed Circuit: FramoDocument1 pageService Manual For Closed Circuit: FramoДмитрий МещерскихNo ratings yet

- Spec Excav Pc200Document3 pagesSpec Excav Pc200Soni100% (2)

- Effluent & Sewage Treatment Plant 110 KLD: Operation ManualDocument10 pagesEffluent & Sewage Treatment Plant 110 KLD: Operation ManualBinod DavisNo ratings yet

- Fmea PW System-1Document17 pagesFmea PW System-1Atul Sharma100% (5)

- Smart Bilge DatasheetDocument2 pagesSmart Bilge DatasheetWildan oktapianNo ratings yet

- 100 KLD STP New-1Document13 pages100 KLD STP New-1Anjita KumariNo ratings yet

- Hydraulic System Inspection SOPDocument6 pagesHydraulic System Inspection SOPGovinda RaiNo ratings yet

- Hydraulic System Inspection SOPDocument6 pagesHydraulic System Inspection SOPZev ZekNo ratings yet

- Handling of Water SamplingDocument12 pagesHandling of Water Samplingsaptaksamadder4No ratings yet

- CIP Automatic Manual 1200NETDocument24 pagesCIP Automatic Manual 1200NETDuc Hung NguyenNo ratings yet

- Users Manual GQS-206 En1Document19 pagesUsers Manual GQS-206 En1abuzer1981100% (1)

- HEI-IMS-CHEM-SOP10 Sodium Hypochlorite Plant OperationDocument8 pagesHEI-IMS-CHEM-SOP10 Sodium Hypochlorite Plant Operationrizwan chNo ratings yet

- Millenium Ro System Specifications: A Ge Osmonics Portable Reverse Osmosis SystemDocument7 pagesMillenium Ro System Specifications: A Ge Osmonics Portable Reverse Osmosis SystemgimenNo ratings yet

- Project 12Document7 pagesProject 12Rohan lallNo ratings yet

- User Manual Water Level ControllerDocument4 pagesUser Manual Water Level ControllerRaison MukkathNo ratings yet

- Algae AnalyzersDocument136 pagesAlgae Analyzerskallinganishanth3786No ratings yet

- Agar OW201 and Coriolis Meter Appl 12Document2 pagesAgar OW201 and Coriolis Meter Appl 12JADNo ratings yet

- Reverse Osmosis R12-Wall Mount Installation InstructionsDocument15 pagesReverse Osmosis R12-Wall Mount Installation InstructionsWattsNo ratings yet

- Dig Cont ChecklistDocument2 pagesDig Cont ChecklistMainak ChatterjeeNo ratings yet

- Reverse Osmosis Model #R44 Installation InstructionsDocument40 pagesReverse Osmosis Model #R44 Installation InstructionsWatts100% (1)

- Operation Manual: For Intelligent Dispensing Peristaltic Pump WT300F, WT600FDocument48 pagesOperation Manual: For Intelligent Dispensing Peristaltic Pump WT300F, WT600FWilliams RobinsonNo ratings yet

- Icomta - Ows KapalDocument7 pagesIcomta - Ows Kapalzulkifliarik77No ratings yet

- GHV Booster Sets Series - 2017-05-16Document31 pagesGHV Booster Sets Series - 2017-05-16J BiuNo ratings yet

- SOP For PSG, NewDocument8 pagesSOP For PSG, Newmarkandey guptaNo ratings yet

- Automotive Actuators and EVAP System TestingFrom EverandAutomotive Actuators and EVAP System TestingRating: 4.5 out of 5 stars4.5/5 (4)

- Grasso - Oil SeparatorDocument4 pagesGrasso - Oil Separatoranon_568840501No ratings yet

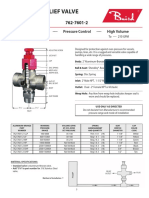

- 2" Liquid Relief Valve: High Pressure - Pressure Control - High VolumeDocument1 page2" Liquid Relief Valve: High Pressure - Pressure Control - High VolumeCESAR MORANo ratings yet

- Valve Sizing and SelectionDocument7 pagesValve Sizing and SelectionDevendra BangarNo ratings yet

- Cyl Lift 580SNDocument3 pagesCyl Lift 580SNhandokoNo ratings yet

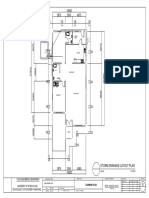

- Storm Drainage Layout Plan Allen-RafaelDocument1 pageStorm Drainage Layout Plan Allen-RafaelVios, Allen Rafael M.No ratings yet

- 1995 Sarawak Water Supply RegulationDocument69 pages1995 Sarawak Water Supply RegulationCheng Siaw HueiNo ratings yet

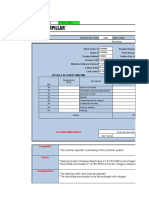

- Request Form KH08588Document4 pagesRequest Form KH08588nelsonNo ratings yet

- Hydraulic Systems VI Handout PDFDocument39 pagesHydraulic Systems VI Handout PDFMalik ForbesNo ratings yet

- Specialty PumpsDocument9 pagesSpecialty PumpsLorino BaldezamoNo ratings yet

- Bomba de Diafragma Samoa DF50 PDFDocument54 pagesBomba de Diafragma Samoa DF50 PDFArnulfo Diaz CuellarNo ratings yet

- Hitachi ZX200-5G Breaker Installation-1Document93 pagesHitachi ZX200-5G Breaker Installation-1Aung Ko ThantNo ratings yet

- CDL4 123ph50hzci22kwDocument2 pagesCDL4 123ph50hzci22kwthreephase electricNo ratings yet

- Valvula de Cuchilla NEWCON de 42 Pulg. Con Accionamiento HidraulicoDocument1 pageValvula de Cuchilla NEWCON de 42 Pulg. Con Accionamiento HidraulicoAlejandro Pupunovich RodriguezNo ratings yet

- MPLEDocument33 pagesMPLEDominic Vincent VerNo ratings yet

- Bombas Pvp16Document10 pagesBombas Pvp16Gustavo HuertasNo ratings yet

- Materials For HSN Codes (Sales)Document6 pagesMaterials For HSN Codes (Sales)Sachin SinghNo ratings yet

- Husco PDFDocument70 pagesHusco PDFhamdaNo ratings yet

- 43 - Southern Cross - Iso Pump - 125 X 100 - 400 - 1470 RPMDocument1 page43 - Southern Cross - Iso Pump - 125 X 100 - 400 - 1470 RPMBayuNo ratings yet

- SM-Kobelco SK300LC-6E Szervíz (YC07U0623 )Document1,184 pagesSM-Kobelco SK300LC-6E Szervíz (YC07U0623 )Károly Vigh100% (2)

- Pneumatic Fittings Quote - Shift Air Pneumatics 2018Document11 pagesPneumatic Fittings Quote - Shift Air Pneumatics 2018Yogeshwar AgrawalNo ratings yet

- Hydraulic MachinesDocument11 pagesHydraulic MachinesShubhamNo ratings yet

- Main Cooling Water Circulation Pump / Lines Pipe Line Pump Discharge Pump SuctionDocument7 pagesMain Cooling Water Circulation Pump / Lines Pipe Line Pump Discharge Pump SuctionRamdas TaloleNo ratings yet

- BBA Pumps North America - Troubleshooting BADocument2 pagesBBA Pumps North America - Troubleshooting BAMarcosNo ratings yet

- Sanyi Gate Valve Spare PartsDocument18 pagesSanyi Gate Valve Spare PartsAnonymous MxwCc4No ratings yet

- Midterm Exam Engineering Utilities 2Document54 pagesMidterm Exam Engineering Utilities 2DebbieNo ratings yet

- Training Tail Lift Technology Mod 4 Signs & Symbols enDocument19 pagesTraining Tail Lift Technology Mod 4 Signs & Symbols enArmin PatelNo ratings yet

- A. Load Values, in Water Supply Fixture Units (Wsfu) For All AreasDocument4 pagesA. Load Values, in Water Supply Fixture Units (Wsfu) For All AreasIbrahim A. HameedNo ratings yet

- 390 Hydraulics PDFDocument9 pages390 Hydraulics PDFJacques Van NiekerkNo ratings yet

- Procedure For Hydrostatic Test & Load Test of Pump ColumnDocument13 pagesProcedure For Hydrostatic Test & Load Test of Pump ColumnHà HuệNo ratings yet

- Master Plumber Review Material 1Document224 pagesMaster Plumber Review Material 1Marvin Kalngan100% (1)