Professional Documents

Culture Documents

Corbel 3

Uploaded by

Aek JanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Corbel 3

Uploaded by

Aek JanCopyright:

Available Formats

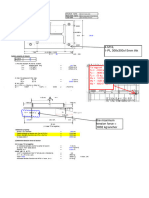

PROJECT Electric Chiller replacement DESIGN IN CASE max shear force

JOINT NAME anchor to existing RC beam JOINT NAME position 3 to 8

( Find Tension forces in Anchorage Re bar/w chemical agent )

fc' 280 ksc

fy of re bar 4000 ksc

fut of re bar 5900 ksc

Mux ( factored load ) 0.878 Ton-m <-- from 6.5 Ton x 0.135 m

Vu ( factored load ) 6.5 Ton 270 mm

Pu ( factored load ) 0.0 Ton * Remark Pu + = compression force, - = tension force

, in case of a < 0, all bolts occur tension force

B= 675

Vu =

T

48

y

N= 450 177

CENTER Base plate

. 402.00 CENTER

x

Mux + 177

a= 201.618

48

Mu=

Pu/(NB)+ 6Mux/(BN^2)

400

( unit ; mm.)

( unit ; mm)

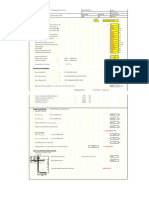

STEP 1 . DESIGN MOMENT AND TENSION

Sum external force

Pu = 0.5*[ Pu/(NB)+ 6Mux/(BN2) ]*B* a - T

0 = 13x a - T

0 = 2621.06 - T

T = 2621.0 kg.

used rebar dia ( Top)-> = 16 mm. total Top bar = 2 Nos T = 14476.46 kg. >2620.96cm^2 OK

used rebar dia ( Top)-> = 16 mm. total bot bar = 4 Nos area = 8.04 cm2

Check sum moment about center line of beam

Mu = -Pu *17.7+ 0.5* [ Pu/(NB)+ 6Mux/(BN^2) ]*B*a* (40.2-0.333a)

87750 = -1.77 + 2621.06 * (40.2-0.3333*20.16 )

87750 = 87749.931

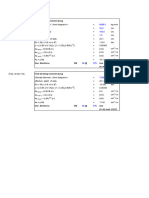

STEP 3 . DESIGN SHEAR

Check for dowel bar

The stud area not used for moment is aviable for shear transfer by friction.

Asv = ( ( 14476.46-2620.96) / (0.9 Fy ) +8.04)

= 11.3 cm2

Vn = µ* Asv* Fy , µ = 0.6

= 27199.66667 kg.

= 27.2 Ton

фVn = 0.75Vn = 20.400 Ton >6.5 Ton. OK

You might also like

- Surgical Instruments, Types of Surgery and Surgical TechniquesDocument12 pagesSurgical Instruments, Types of Surgery and Surgical Techniquessheryl_morales100% (1)

- Paracord Wrist Lanyard Made With The Snake KnotDocument14 pagesParacord Wrist Lanyard Made With The Snake Knotkevinpettit100% (1)

- Design of Doubly Reinforced RC Beam (ACI 318-14) : Particulars Remarks 1 Material Properties Codes and SectionsDocument71 pagesDesign of Doubly Reinforced RC Beam (ACI 318-14) : Particulars Remarks 1 Material Properties Codes and SectionsLavender HoneyNo ratings yet

- Staircase Beam Design - 2Document28 pagesStaircase Beam Design - 2Sai Sushank67% (3)

- Annular Raft Under 1250 Cum OHRDocument1 pageAnnular Raft Under 1250 Cum OHRanirban dasNo ratings yet

- Cold Vent Stack Foundation DesignDocument13 pagesCold Vent Stack Foundation Designdoverman0% (1)

- φ - Vc b f ' c Vu b Tu - P: Design for Torsion and Shear According to ACI-318-99Document2 pagesφ - Vc b f ' c Vu b Tu - P: Design for Torsion and Shear According to ACI-318-99mahmoud IbrahemNo ratings yet

- Oriental Yeast India Pvt. Ltd. OPYE Project: Design Calculation For Treated Molasses Tank (11-B-05)Document2 pagesOriental Yeast India Pvt. Ltd. OPYE Project: Design Calculation For Treated Molasses Tank (11-B-05)Tushar MangratiNo ratings yet

- Solution Manual for an Introduction to Equilibrium ThermodynamicsFrom EverandSolution Manual for an Introduction to Equilibrium ThermodynamicsNo ratings yet

- The Splicing Handbook Chapter 1Document17 pagesThe Splicing Handbook Chapter 1Archie AdkinsNo ratings yet

- Cal. Stanchion Pipe 3 In. SCH80 - Lifting Lug 2Document5 pagesCal. Stanchion Pipe 3 In. SCH80 - Lifting Lug 2Anisa Rifqi0% (1)

- Calculations: Beam Design-Ultimate Strength Design: (Aci 318)Document10 pagesCalculations: Beam Design-Ultimate Strength Design: (Aci 318)Anass SoubraNo ratings yet

- Wire Ropes, Elevators & Machine Shop (PSE Module 31.1) SolutionDocument7 pagesWire Ropes, Elevators & Machine Shop (PSE Module 31.1) SolutionChen-chenLaydaPerezMontesNo ratings yet

- AISC Connection-2nd Edition - (2+2) Anchor Rod-FixedDocument16 pagesAISC Connection-2nd Edition - (2+2) Anchor Rod-FixedTuấnThanhNo ratings yet

- Two Way SlabDocument88 pagesTwo Way SlabSushil KumarNo ratings yet

- Air Coolers HeadsDocument30 pagesAir Coolers HeadsSergio PluchinskyNo ratings yet

- Deflection CalculationDocument6 pagesDeflection CalculationSuhas MangaloreNo ratings yet

- Calculation Beam Elastic Foundation: Type SDocument7 pagesCalculation Beam Elastic Foundation: Type Smotiur basumNo ratings yet

- ATC2Document1 pageATC2Aek JanNo ratings yet

- Weld Check: I. Connection Properties Bridge IDDocument3 pagesWeld Check: I. Connection Properties Bridge IDJemicah YumenaNo ratings yet

- Design Of Beam 2 TO4 Floor Beam (Horizontal) : x ρ fy fc'Document10 pagesDesign Of Beam 2 TO4 Floor Beam (Horizontal) : x ρ fy fc'Denice CastroNo ratings yet

- AISC360 Round Filled Composite MemberDocument2 pagesAISC360 Round Filled Composite MemberHattori HanzoNo ratings yet

- Sleeper Retaining Wall - 204905Document9 pagesSleeper Retaining Wall - 204905Lê Hoàng TháiNo ratings yet

- Analysis of Structures (Trusses, Frames and Machines)Document77 pagesAnalysis of Structures (Trusses, Frames and Machines)Tamzidul HoqueNo ratings yet

- Base Design (Blocks) - Commented On 26.09.2017Document4 pagesBase Design (Blocks) - Commented On 26.09.2017tsinghal_19No ratings yet

- Check The Concrete Breakout PedestalDocument7 pagesCheck The Concrete Breakout PedestalEakJhuanNo ratings yet

- 05 ColumnsDocument4 pages05 ColumnsJefreyMatuanMondranoNo ratings yet

- PT Gunanusa Utama Fabricators PT Gunanusa Utama Fabricators PT Gunanusa Utama FabricatorsDocument2 pagesPT Gunanusa Utama Fabricators PT Gunanusa Utama Fabricators PT Gunanusa Utama FabricatorsRiandi HartartoNo ratings yet

- 15-Cold Formed 2021Document35 pages15-Cold Formed 2021karim hassanNo ratings yet

- Bolt HTB (L.100.7)Document3 pagesBolt HTB (L.100.7)ronaldyyahyaNo ratings yet

- Rectangular Beam Design - 2010 NSCPDocument2 pagesRectangular Beam Design - 2010 NSCPrenzo1221No ratings yet

- Perencanaan Kolom Bulat: Data: 2Document7 pagesPerencanaan Kolom Bulat: Data: 2Silviano Da Coneicicao AparicoNo ratings yet

- Design of Rectangular RC Beams With Known DimensionsDocument6 pagesDesign of Rectangular RC Beams With Known DimensionsEleazar MendozaNo ratings yet

- Design Criteria: fs fc' L β Try h: Design of Columns: 2C3Document1 pageDesign Criteria: fs fc' L β Try h: Design of Columns: 2C3Rowen Rae AgupitanNo ratings yet

- Example 2 To Start ExplainationDocument8 pagesExample 2 To Start ExplainationsamehNo ratings yet

- Design of Stairs and Landing: Page NoDocument6 pagesDesign of Stairs and Landing: Page NoJun Dela PeñaNo ratings yet

- Design of Member : Strut (Layer 1)Document8 pagesDesign of Member : Strut (Layer 1)freddyNo ratings yet

- Connections 1 - Ch.7 Welded Shear Connections - Exercise Solutions (2 of 2) (265-268)Document4 pagesConnections 1 - Ch.7 Welded Shear Connections - Exercise Solutions (2 of 2) (265-268)travis8zimmermannNo ratings yet

- Type 2Document1 pageType 2EakJhuanNo ratings yet

- Corbel 4Document1 pageCorbel 4Aek JanNo ratings yet

- Project Beam No. B4 Client Floor 2 FL Title Date: Addition Ptho-31 Kyowa Hakko ThailandDocument1 pageProject Beam No. B4 Client Floor 2 FL Title Date: Addition Ptho-31 Kyowa Hakko ThailandEakJhuanNo ratings yet

- Project Beam No. B9 Client Floor 2 FL Title Date: Addition Ptho-31 Kyowa Hakko ThailandDocument1 pageProject Beam No. B9 Client Floor 2 FL Title Date: Addition Ptho-31 Kyowa Hakko ThailandEakJhuanNo ratings yet

- Design of Platform Pedestal: 1. Design Data:: I. Load From BM - 3: (See Separate Sheet) 43.120 KNDocument1 pageDesign of Platform Pedestal: 1. Design Data:: I. Load From BM - 3: (See Separate Sheet) 43.120 KNp_ignatiusNo ratings yet

- Attachment 1 - Bi-Axial Bending CheckDocument2 pagesAttachment 1 - Bi-Axial Bending CheckYang W OngNo ratings yet

- Walk Way CalculationsDocument71 pagesWalk Way CalculationszakariaalbashiriNo ratings yet

- XX2 PDFDocument3 pagesXX2 PDFgarysootetNo ratings yet

- InputsDocument6 pagesInputskeerthivasan_mrvNo ratings yet

- Statics and Mechanics I. Statics: Cable in Tension Is Cable BEDocument4 pagesStatics and Mechanics I. Statics: Cable in Tension Is Cable BEPaul Adriane TornerosNo ratings yet

- Design of Water Tank Structural Design CalculationsDocument3 pagesDesign of Water Tank Structural Design CalculationsUzziel Abib GabiolaNo ratings yet

- ATC3Document1 pageATC3Aek JanNo ratings yet

- Calculation Sheet: Test Job Member Design For SB2Document2 pagesCalculation Sheet: Test Job Member Design For SB2bungykitNo ratings yet

- SSE Shear Design - EC2v1 - 07 - G1 - 20211027 - 2234 - 32Document1 pageSSE Shear Design - EC2v1 - 07 - G1 - 20211027 - 2234 - 32SES DESIGNNo ratings yet

- Type 1Document1 pageType 1EakJhuanNo ratings yet

- Tann Designs & Engineers: PadeyeDocument3 pagesTann Designs & Engineers: PadeyejasekanNo ratings yet

- 3RD FloorDocument33 pages3RD FloorengineersparkconstructioncleanNo ratings yet

- 1PB 15Document1 page1PB 15Aek JanNo ratings yet

- Footing DesignDocument48 pagesFooting DesignmonishNo ratings yet

- Slab DesignDocument12 pagesSlab DesignPAOLO AGORILLANo ratings yet

- Check Beam 7: Nding Moment Diagram Shear Force DiagramDocument2 pagesCheck Beam 7: Nding Moment Diagram Shear Force DiagramtfvnjyNo ratings yet

- Tutorial 1Document3 pagesTutorial 1Trevor LingNo ratings yet

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionFrom EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNo ratings yet

- Trial and Error Eccentric Distance Find Balance Section .: Use Re Bar (DB/RB) CB 11.611Document3 pagesTrial and Error Eccentric Distance Find Balance Section .: Use Re Bar (DB/RB) CB 11.611Aek JanNo ratings yet

- Electric Chiller Replacement 8000 RT Step Down Building: Project Name Design by Building Name Floor/ LevelDocument2 pagesElectric Chiller Replacement 8000 RT Step Down Building: Project Name Design by Building Name Floor/ LevelAek JanNo ratings yet

- TrenchDocument1 pageTrenchAek JanNo ratings yet

- RoofDocument1 pageRoofAek JanNo ratings yet

- Roof 1Document1 pageRoof 1Aek JanNo ratings yet

- Slab Transfor1Document1 pageSlab Transfor1Aek JanNo ratings yet

- PunchingDocument1 pagePunchingAek JanNo ratings yet

- Piling 2Document3 pagesPiling 2Aek JanNo ratings yet

- StairDocument1 pageStairAek JanNo ratings yet

- Roof 2Document1 pageRoof 2Aek JanNo ratings yet

- Mat350 1Document2 pagesMat350 1Aek JanNo ratings yet

- Beam End Force Summary: S1 Shear Joint of Sub Truss (Service Load)Document1 pageBeam End Force Summary: S1 Shear Joint of Sub Truss (Service Load)Aek JanNo ratings yet

- Trial and Error Eccentric Distance Find Balance Section .: Use Re Bar (DB/RB) CB 11.611Document3 pagesTrial and Error Eccentric Distance Find Balance Section .: Use Re Bar (DB/RB) CB 11.611Aek JanNo ratings yet

- Mat 250Document1 pageMat 250Aek JanNo ratings yet

- BP H175.3Document1 pageBP H175.3Aek JanNo ratings yet

- 1PS 01Document1 page1PS 01Aek JanNo ratings yet

- Project Beam No. Client Struc 12 KV Switchgear Building Title Date 25 FEB 2023Document1 pageProject Beam No. Client Struc 12 KV Switchgear Building Title Date 25 FEB 2023Aek JanNo ratings yet

- Steel Columnh150x150.1Document1 pageSteel Columnh150x150.1Aek JanNo ratings yet

- Pedestal Design and Fixed Anchor To RC BeamDocument1 pagePedestal Design and Fixed Anchor To RC BeamAek JanNo ratings yet

- Result 1Document1 pageResult 1Aek JanNo ratings yet

- Steel Columnh150x150.2Document3 pagesSteel Columnh150x150.2Aek JanNo ratings yet

- Column Base Plate Design (ASD) : 12 KV Switchgear BLDG Maximum Bending MomentDocument2 pagesColumn Base Plate Design (ASD) : 12 KV Switchgear BLDG Maximum Bending MomentAek JanNo ratings yet

- 02-Apr-22 14-Mar-2023 10:12 24KV - Switchgear - 12 - MA: Job No Sheet No RevDocument2 pages02-Apr-22 14-Mar-2023 10:12 24KV - Switchgear - 12 - MA: Job No Sheet No RevAek JanNo ratings yet

- Attachment B Machine Load DataDocument1 pageAttachment B Machine Load DataAek JanNo ratings yet

- SeismcDocument1 pageSeismcAek JanNo ratings yet

- La2-Measures of Position - Grouped DataDocument2 pagesLa2-Measures of Position - Grouped Dataaika tiffany esguerraNo ratings yet

- Dolphs Varnishs Resin ChartDocument3 pagesDolphs Varnishs Resin ChartFernando Rodriguez100% (1)

- TNCTDocument2 pagesTNCTjeffrey c. aguilarNo ratings yet

- Calcium and Magnesium in Water: Standard Test Methods ForDocument6 pagesCalcium and Magnesium in Water: Standard Test Methods Fort.mohammedNo ratings yet

- 18OBDG03A Engine Diagnostics PDFDocument1,589 pages18OBDG03A Engine Diagnostics PDFLuis Alberto Choque RamosNo ratings yet

- KaranthDocument9 pagesKaranthRakesh KhannaNo ratings yet

- Brochure Isolation Valves Product Overview en en 5253576Document36 pagesBrochure Isolation Valves Product Overview en en 5253576Muthu Kumar RNo ratings yet

- Battery Charger Series: PowerbaseDocument1 pageBattery Charger Series: PowerbaseCristopher Jason Lopez CansinoNo ratings yet

- KAMP Syllabus Nova FinalDocument4 pagesKAMP Syllabus Nova FinalShailendra100% (1)

- Assignment - DBB1103 - BBA 1 - Set-1 - May - 2021Document8 pagesAssignment - DBB1103 - BBA 1 - Set-1 - May - 2021NISHANTNo ratings yet

- Lymph Node Removal (Lymphadenectomy) - Health Information - Bupa UKDocument10 pagesLymph Node Removal (Lymphadenectomy) - Health Information - Bupa UKFanti Aldesia HafildNo ratings yet

- Product Catalogue 01Document11 pagesProduct Catalogue 01Sanja TinaNo ratings yet

- 000 A Ee 0230028 513 R0Document13 pages000 A Ee 0230028 513 R0onur gunesNo ratings yet

- Com. Medicine Scheme of Exam 08-11-22Document39 pagesCom. Medicine Scheme of Exam 08-11-2260-K NileshNo ratings yet

- Diamer Bhasha DamDocument14 pagesDiamer Bhasha DamJunaidahmadNo ratings yet

- Entanglement-Based Secure Quantum Cryptography Over 1,120 KilometresDocument18 pagesEntanglement-Based Secure Quantum Cryptography Over 1,120 KilometresFredy OrjuelaNo ratings yet

- Head Office 14, Gudeok-Ro 232beon-Gil, Seo-Gu, Busan 49223, KoreaDocument28 pagesHead Office 14, Gudeok-Ro 232beon-Gil, Seo-Gu, Busan 49223, KoreaRoi HbbNo ratings yet

- Revised ListDocument10 pagesRevised List5paisaNo ratings yet

- RAC Risk Management Guide 19.06Document6 pagesRAC Risk Management Guide 19.06bookslover1No ratings yet

- 化熱chapt3Document5 pages化熱chapt3卓冠妤No ratings yet

- 2004cwl Infrequent Pp52-103Document52 pages2004cwl Infrequent Pp52-103Henry LanguisanNo ratings yet

- Geological Society of America Citation StyleDocument4 pagesGeological Society of America Citation Style146256No ratings yet

- Types of Juicers - EditedDocument17 pagesTypes of Juicers - EditedAbdulrehmanNo ratings yet

- Oikos Cases 2005 Mountain InstituteDocument22 pagesOikos Cases 2005 Mountain InstituteabdelNo ratings yet

- Chrysanthemum Cinerariifolium PDFDocument3 pagesChrysanthemum Cinerariifolium PDFUmmuNo ratings yet

- Transportation and Highway Engineering PDFDocument3 pagesTransportation and Highway Engineering PDFReymark AbatayoNo ratings yet

- Thought Translation DeviceDocument2 pagesThought Translation DeviceArun SudanNo ratings yet