Professional Documents

Culture Documents

AM-1220017 en C1 Main 092642 230801 061817

Uploaded by

BagwisOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AM-1220017 en C1 Main 092642 230801 061817

Uploaded by

BagwisCopyright:

Available Formats

KONE Polaris™ Destination Control System

Installation Instruction

K O N E P O L A R I S ™ D E S T I N AT I O N C O N T R O L S Y S T E M

X000022775

© 2017 KONE Corporation 1 (2 06) AM-12.20.017

All rights reserved (C) 2018-04-30

KONE Polaris™ Destination Control System

Installation Instruction

© 2017 KONE Corporation

All rights reserved.

Important Notice

This guidelines and instructions document and its contents (the “Instructions”) are for training

purposes, KONE technician use, and other authorized internal use. The Instructions do not contain

all the relevant information regarding the performance of the maintenance for the equipment in

question and the installation or replacement of associated components (the “Work”). Any person

engaging in the Work must follow all instructions related to the respective equipment and all

applicable KONE safety rules. Further, such persons must be qualified and authorized to perform

the Work, which includes possessing licenses required by law and training provided by KONE for

the specific equipment.

Authorized Use - License

Only technicians who perform the Work and their supervisors, as well as other individuals KONE

may from time to time designate in writing (“Authorized User”), are intended to possess and use the

Instructions. KONE grants the Authorized User a limited, revocable license to possess and use the

Instructions during the Authorized User’s term of employment with KONE to perform the Work

(“License”). Possession or use of the Instructions in a manner inconsistent with the License granted

is strictly prohibited. Under no circumstances is the Authorized User permitted to copy, disclose,

publish, or disseminate the Instructions to anyone, unless prior written consent has been obtained

from the KONE legal function. The Authorized User shall return the Instructions to KONE upon

separation of employment with KONE. Violation of this paragraph may result in disciplinary action,

up to and including termination of employment, and legal action against the Authorized User.

Prohibited Possession or Use by Others

Possession, use, copying, disclosure, publication, or dissemination of the Instructions by an

individual who or entity that is not an Authorized User is strictly prohibited (“Prohibited Use”), unless

prior written consent is obtained from the KONE legal function. KONE disclaims any and all liability

for loss or damage including without limitation, indirect or consequential loss or damage, resulting

from or in connection with Prohibited Use. Prohibited Use shall result in legal or equitable action by

KONE against violators.

P r o p r i e t a r y, C o n f i d e n t i a l , I n t e l l e c t u a l P r o p e r t y

The Instructions are owned by KONE Corporation, its affiliates, and its subsidiaries (“KONE”). The

Instructions are proprietary, confidential, and contain KONE intellectual property and trade secrets.

The Instructions are protected by international and local intellectual property laws, including but not

limited to copyright law. Unless otherwise expressly mentioned, all trademarks and product names

in the Instructions are trademarks or registered trademarks of KONE. Unauthorized possession,

use, copying, disclosure, publication, or dissemination of the Instructions infringes upon KONE’s

legal rights and shall result in legal or equitable action by KONE against violators.

© 2017 KONE Corporation 2 (206) AM-12.20.017

All rights reserved (C) 2018-04-30

KONE Polaris™ Destination Control System

Installation Instruction

TA B L E O F C O N T E N T S

1 ABOUT THIS INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.1 Audience. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.2 Feedback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.3 Translations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.4 Approvals and changes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2 KONE POLARIS DESTINATION CONTROL SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.1 Signalization, KSS800 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.2 Signalization, KSS 900 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.3 Related information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.3.1 Generic safety instructions for elevator installation . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.3.2 Generic instructions for elevator installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

2.3.3 Method related instructions for elevator installation . . . . . . . . . . . . . . . . . . . . . . . . .10

2.3.4 KONE Polaris Installation instruction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

3 SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

3.1 General safety precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

3.2 Fall prevention . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

3.3 Electrical safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

3.3.1 Electrical safety in installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

3.3.2 Take 5 - Five steps to ensure electrical safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

3.4 Method related safety instructions for elevator installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

3.4.1 Installation method safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

3.5 Personal safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

3.5.1 Personal protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

3.5.2 Personal protective equipment (PPE) for elevator installation and

commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

3.5.3 Personal protection signs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

3.5.4 Recommended working postures and ergonomic methods. . . . . . . . . . . . . . . . .16

3.6 Warnings and cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

3.7 Warning signs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

4 INSTALLATION QUALITY AND EFFICIENCY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

4.1 5S . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

4.2 Customer experience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

5 SITE REQUIREMENTS AND TOOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

5.1 Site requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

5.2 Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

6 INSTALL IN MACHINE ROOM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

6.1 Machine room general arrangement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

6.2 KONE Polaris™ 500 electrification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

6.2.1 Power supply for segmented shaft network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

6.2.2 Group connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

6.3 KONE Polaris™ 800/900 electrification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

6.3.1 Power supply for segmented shaft network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

6.3.2 Additional power supply for segmented shaft network . . . . . . . . . . . . . . . . . . . . . .26

© 2017 KONE Corporation 3 (2 06) AM-12.20.017

All rights reserved (C) 2018-04-30

KONE Polaris™ Destination Control System

Installation Instruction

6.3.3 Group connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

6.4 Install DOP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

6.4.1 Install surface mounted destination operation panel (KSP 955/KSP

957) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

6.4.2 Install surface mounted destination operation panel (KSP 833 / KSP

853) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

6.4.3 Install touch DOP (KSP 858, Surface mounted). . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

6.4.4 Install touch DOP (KSP 858, Pedestal mounted) . . . . . . . . . . . . . . . . . . . . . . . . . . .55

6.4.5 Install flush mounted destination operation panel (KSP 965 / KSP

967) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

6.4.6 Install pedestal DOP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72

6.4.7 Install touch DOP (KSP 958) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .76

6.5 Install elevator identifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79

6.5.1 Install passive elevator identifier (KST 830 / KST 850) . . . . . . . . . . . . . . . . . . . . .79

6.5.2 Install active elevator identifies (KST 950). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .81

6.5.3 Install active elevator identifier (KST 840 / KST 860 / KST 870) . . . . . . . . . . . .82

6.5.4 Install passive triangle EID (KST 880) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84

6.5.5 Install active triangle EID (KST 890) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

6.6 INSTALL DESTINATION INDICATOR AT LANDING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

6.6.1 Install the back box to concrete/brick wall . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

6.6.2 Adjust fixing brackets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .94

6.6.3 Connect and fix DIN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .95

7 INSTALL COP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .97

7.1 Car operating panel KCS 853 (partial height) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .97

7.2 Car operating panel KSC 843 and KSC 863 (full height) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .99

7.3 Car operating panel KSC 955 and KSC 957 (full height) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

7.4 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

7.4.1 COP KSC 843, KSC 853 and KSC 863 wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

7.4.2 COP KSC 955 and KSC 957 wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

8 INSTALLING JAMB MOUNTED DESTINATION INDICATOR (JM-DIN). . . . . . . . . . . . . . . . . . . . . . . . 106

9 INSTALL DESTINATION GUIDANCE DISPLAY (DGD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

9.1 DGD module KSG 847 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

9.1.1 Wiring diagram (KSG 847) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

9.1.2 Install DGD module (KSG 847) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

9.2 DGD module KSG 857 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .114

9.2.1 Wiring diagram (KSG 857) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .114

9.2.2 Connect cables (KSG 857). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .115

9.2.3 Connect LON cables (KSG 857) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .117

9.2.4 Install DGD module (KSG 857) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .118

10 SETTINGS AND ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

10.1 Settings in the LCD display (colour), KM832339 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

10.2 Settings in the LCD display (color), KM50313880 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

10.3 Color displays DIN, DCS COP and DOP (KSS 900-series). . . . . . . . . . . . . . . . . . . . . . . . . . . 125

10.4 Black and white displays DOP and DCS COP (KSS 900 series) . . . . . . . . . . . . . . . . . . . . . 126

10.5 Elevator identifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

11 COMMISSIONING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

© 2017 KONE Corporation 4 (2 06) AM-12.20.017

All rights reserved (C) 2018-04-30

KONE Polaris™ Destination Control System

Installation Instruction

11.1

KONE Polaris™ 500 commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

11.1.1 LON download . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

11.1.2 LCE parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

11.1.3 Downloading floor markings to COP and DOP . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

11.2 KONE Polaris 800/900 commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

11.2.1 Check LCECPU software version. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

11.2.2 Install or update KGC files. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

11.2.3 Loading DCS roll call files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

11.2.4 Load DCS roll call files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

11.2.5 LON download . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

11.2.6 Setting the LCE parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

11.2.7 PINCODE files with KONE Polaris™ 800/900. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

11.2.8 Visual guidance arrows and walking time parameters . . . . . . . . . . . . . . . . . . . . 136

11.3 Activate keypad COP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

11.4 Configure keypad COP or DOP buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

11.5 Commission LAN Touch DOPs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

11.5.1 Configure LAN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

11.5.2 Verify LAN configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

11.5.3 Reset LAN configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

11.5.4 Changing LAN KSP 858 settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

11.6 Configure touch DOPs (KSP 958) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

11.7 Check touch DOP (KSP 958) LAN connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

11.8 Check double network. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

11.8.1 Checking the doubled network (KONE Polaris™ 500) . . . . . . . . . . . . . . . . . . . . 155

11.8.2 Check the double network (KONE Polaris 800/900) . . . . . . . . . . . . . . . . . . . . . . 155

11.9 Checking ethernet connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

11.10 Commission DGD modules (KSG 847, KSG 857) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

11.10.1 Site requirements for LON based systems (KSG 847, KSG 857) . . . . . . . . 157

11.10.2 Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

11.10.3 Prerequisites for KSG 857 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

11.10.4 Prerequisites for KSG 847 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

11.10.5 Commission DGD (KSG 847, KSG 857) with LON connection . . . . . . . . . . . 163

11.10.6 Remove mouse and return turnstile back to operation (turnstiles with

KSG 857) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

11.10.7 Remove mouse and return turnstile back to operation (turnstiles with

KSG 847) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

11.11 Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

11.11.1 Testing of signalization devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

11.11.2 Test walking time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

11.11.3 Visual guidance for DOP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

11.11.4 Pincodes and features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

APPENDIX A CUTOUT CONFIGURATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

APPENDIX B NETWORK STRUCTURE AND DEVICE WIRING (KONE POLARIS™ 500) . . . . . . . . . . . . 184

APPENDIX C NETWORK STRUCTURE AND DEVICE WIRING (KONE POLARIS™ 800/

900) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

APPENDIX D TOUCH DOP (KSP 958) PIN CODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

© 2017 KONE Corporation 5 (2 06) AM-12.20.017

All rights reserved (C) 2018-04-30

KONE Polaris™ Destination Control System

Installation Instruction

APPENDIX E DCS PARAMETER FILES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

12 ADJUST WALKING TIME AND VISUAL GUIDANCE USING KGC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

12.1 Change TCP/IP address of PC (Windows XP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

12.2 Adjust walking time and visual guidance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

13 OPERATE DESTINATION CAR OPERATING PANEL KEYPAD, KM51008954V004 . . . . . . . . . 203

APPENDIX F OPERATING DESTINATION CAR OPERATING PANEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

© 2017 KONE Corporation 6 (2 06) AM-12.20.017

All rights reserved (C) 2018-04-30

KONE Polaris™ Destination Control System

Installation Instruction

1 A B O U T T H I S I N F O R M AT I O N

1.1 Audience

This information is intended to be used by people who are familiar with elevator installation

and have received proper training on methods and safety as specified by KONE.

1.2 Feedback

Report errors in the information or suggest improvements to ktd@kone.com.

1.3 Tr a n s l a t i o n s

If you need assistance in getting technical information translated, contact ktd@kone.com.

1.4 Approvals and changes

Issue: C

D a t e : 2018–04–30

Reference CR:

Changes:

– First issue from Framemaker

– Added new Chapters

• Install passive triangle EID (KST 880)

• Install active triangle EID (KST 890)

• Install destination guidance display (DGD)

• LAN and LON commissioning for destination guidance display

• Appendix: Opening and closing destination car operating panel keypad cabinet,

KM51214685V004

Compiled by:

– Tiina Halonen, Information Designer

Checked by:

– Tapio Lainela, Global Installation

– Mika Kemppainen, Category manager

Approved by:

– Saku Pitkanen, Global Installation

Tr a n s l a t i o n a p p r o v e d b y :

X0000222505 A.10

© 2017 KONE Corporation 7 (2 06) AM-12.20.017

All rights reserved (C) 2018-04-30

KONE Polaris™ Destination Control System

Installation Instruction

2 K O N E P O L A R I S D E S T I N AT I O N C O N T R O L S Y S T E M

2.1 Signalization, KSS800

1

3 4

X000022776

1. Elevator identifier (EID)

2. Jamb mounted destination indicator (JMDIN)

3. Destination COP

4. Surface mounted KEYPAD DOP

5. Surface mounted Touch DOP

6. Pedestal mounted Touch DOP

7. Destination indicator (DINL)

X0000227546 A.2

© 2017 KONE Corporation 8 (2 06) AM-12.20.017

All rights reserved (C) 2018-04-30

KONE Polaris™ Destination Control System

Installation Instruction

2.2 Signalization, KSS 900

8

4

7 1

5

2

X000022777

1. Surface mounted KEYPAD DOP 6. Elevator identifier (EID)

2. Surface mounted TOUCH DOP 7. Destination COP

3. Flush mounted KEYPAD DOP 8. Destination indicator

4. KEYPAD DOP with pedestal 9. Turnstile DOP

5. TOUCH DOP with pedestal

X0000204208 A.4

2.3 Related information

2.3.1 Generic safety instructions for elevator installation

Following safety instructions should be referred to in conjunction with product and component

specific installation instructions:

– AM-01.03.001 Preventing falls from height when working on elevators, escalators and

building doors

© 2017 KONE Corporation 9 (2 06) AM-12.20.017

All rights reserved (C) 2018-04-30

KONE Polaris™ Destination Control System

Installation Instruction

– AM-01.03.002 Take 5 - Electrical safety when working on elevators, escalators and

autowalks

– AM-01.03.010 Elevator installation — safety manual

– AM-01.03.019 Preventing unauthorized persons from operating elevator/escalator before

completion and handover to public use

2.3.2 Generic instructions for elevator installation

– Shaft vane diagrams, layout drawings, wiring diagrams

– AM-01.03.009 General instructions for material handling, using transportation and lifting

equipment

– AM-01.01.190 Environmental excellence - Installation

– AM-01.01.260 5S guide book - Eliminating unnecessary actions in elevator installation

– AM-01.01.261 5S advanced instructions - Eliminating unnecessary actions in elevator

installation

– AM-01.01.262 5S Advanced instructions - Eliminating unnecessary actions in elevator

modernization and in full replacement business

2.3.3 Method related instructions for elevator installation

– Installation hoist manual

– AM-01.01.257 Visual inspection - quality control of the car interior and landings

– AM-01.05.014 DT-5 user instructions

– AM-01.05.019 Site trolley KM50032754G01

– AM-01.05.026 DT-6 ride comfort measurements and analyzes

– AS-12.02.001 Electrostatic discharge (ESD) protection for field personnel

X0000112360 B.2

2.3.4 KONE Polaris Installation instruction

– AM-12.20.005 KONE Signalization System (KSS) installation

– AM-13.20.019 KONE LAN

– AM-13.20.022 KONE People Flow System Software Installation

– AM-13.20.023 KONE Remote Call

– AR-12.20.009 Spare parts manual for KONE Polaris™ destination control system (DCS)

devices

– AS-10.22.028 Software upload for LCECPU561 board

– AS-12.20.009 Repair instruction for KONE Polaris™ destination control system (DCS)

– AS-12.20.012 Replacement Instruction for Touch Screen Destination Operating Panel

(DOP) KSP 858

– AS-13.20.005 Repair instruction for KONE E- Link™ release 5.1 elevator and escalator

management system

– AS-13.20.007 KONE LAN Fault finding and repairs

– 1369755 User Interface Menu Instructions for LCECPU561

© 2017 KONE Corporation 10 (206) AM-12.20.017

All rights reserved (C) 2018-04-30

KONE Polaris™ Destination Control System

Installation Instruction

– 813138 Global LCE Fault Codes

X0000222539 A.3

© 2017 KONE Corporation 11 ( 2 0 6 ) AM-12.20.017

All rights reserved (C) 2018-04-30

KONE Polaris™ Destination Control System

Installation Instruction

3 SAFETY

3.1 General safety precautions

– The installation method in KONE installation instructions is designed to ensure that the

installation process is safe. Possible differences between the method and local safety

regulations must be considered. Any local variations to the method must be supported by a

local method statement and risk assessment. Follow the installation method. To prevent

potentially dangerous situations which you have not considered, do not skip any step.

N O T E : Warning signs highlight possible hazards.

– Follow your national lift codes and other safety-related regulations.

N O T E : If there is conflict between the code and this instruction, rely on your national code.

– The local safety codes and rules must be obeyed always.

– Installation work must be carried out only by competent and qualified personnel.

Ensure that you have adequate information to do the work and fully understand all the

p o ss i b l e e ff e c ts of y ou r a ct i on s .

- IF IN DOUBT - ASK.

Talk to your supervisor if you have any doubts about the working method or safety-related

issues.

– Personal protection equipment must be available and used, inspected and certified as

required.

– Use only approved manual handling techniques.

– Do not work at different levels within the same / adjacent elevator shaft enclosures.

– Always position the elevator car to a safe level relative to landing before accessing or

egressing.

– NEVER WORK UNDER A SUSPENDED LOAD! Ensure that the lifting equipment is

correctly rated for the task, in good condition, inspected and certified as required.

– Check the condition of all tools before taking them into use.

N O T E : Take special care of electric cables, plugs and sockets, and ensure that hoisting

equipment is in safe serviceable condition. Follow the requirements of your local

regulations.

– Ensure that waste materials are handled in accordance with your local regulations.

– Safety in open elevator shafts.

For example, duplex elevator: Keep both cars at the same working height.

– Store the materials in zero mechanical energy state.

– When you store materials, for short or long periods, ensure that they are stacked safely

and that they cannot cause injury if they are displaced or drop down. Items such as

counterweight frames must always be stored in a horizontal position.

© 2017 KONE Corporation 12 (206) AM-12.20.017

All rights reserved (C) 2018-04-30

KONE Polaris™ Destination Control System

Installation Instruction

– Do not drill, grind, weld or cut metal near the machine. If grinding or welding is required in

the proximity of the machine, cover the machine from sparks. Because of the magnetic

field, electronic devices may malfunction or stop working in the proximity of the machine.

Keep credit and bank cards and electronic watches away from the working area.

3.2 Fall prevention

1. Identify all possible fall hazards.

2. Remove the fall hazards, if possible.

N O T E : Refer to your local procedures for the type of entrance protection required.

3. If it is not possible to remove a fall hazard, then reduce the risk of fall using fall

prevention methods.

4. If it is not possible to protect against a fall hazard using fall prevention methods, then

use fall arrest equipment. The use of fall arrest equipment must always be verified

through specific risk assessment. Safety harness must be secured to a life-line or other

approved anchorage point. The provision of suitable rescue equipment, instruction and

training must be available to ensure the timely rescue if there is a fall.

5. If applicable, use safety harness in accordance with your national codes.

Safety harnesses with lanyards: When your safety harness is not secured to a life-line or

other approved anchorage point, ensure that the lanyard does not cause a catching or

tripping hazard.

Refer to AM-01.03.001 Preventing falls from height when working on elevators, escalators

and building doors.

X0000054969 B.2

3.3 Electrical safety

3.3.1 Electrical safety in installation

– A locking off system for main electric supplies isolator or other system (for example fuse

removal, or locking and tagging system) must be agreed with main contractor before

installation commences.

– When measuring with multimeter, check the operation of the multimeter before and after

the measurements.

– Do not connect or disconnect any connectors when the power is ON.

– Familiarize yourself with the safety instruction AM-01.03.002 and follow it always. Refer to

AM-01.03.002 Take 5 - Electrical safety when working on elevators, escalators and

autowalks.

X0000111014 B.2

3.3.2 Ta k e 5 - F i v e s t e p s t o e n s u r e e l e c t r i c a l s a f e t y

The following five steps must be taken in the specified order unless there are essential

reasons for doing otherwise.

© 2017 KONE Corporation 13 (206) AM-12.20.017

All rights reserved (C) 2018-04-30

KONE Polaris™ Destination Control System

Installation Instruction

1. Disconnect power supply completely.

2. Secure against reconnection.

3. Verify that the installation is de-energized.

4. Check the requirements for earthing in special circumstances.

5. Provide protection against adjacent live parts.

3.4 Method related safety instructions for elevator installation

– AM-01.03.003 Take 2 - Double security safety practice when using hoists for man riding

purposes

– AM-01.05.016 Installing light entrance protection (LEP)

– AM-01.05.020 Installing KONE heavy entrance protection (HEP) — single door,

KM1360190G02

– AM-01.05.023 Installing Net Holder System (NHS)

X0000112329 C.2

3.4.1 Installation method safety

Follow the safety instructions given in elevator level instructions.

X0000204245 A.2

3.5 Personal safety

3.5.1 Personal protection

Personal Protective Equipment (PPE) are devices, appliances and clothing designed and

used to protect against safety, health or other workplace hazards.

If the risks associated with your work cannot be controlled by other means, your employer

must provide you with personal protective equipment (PPE).

Personal protective equipment are provided for your personal protection. YOU MUST USE

THEM AS REQUIRED.

3.5.2 Personal protective equipment (PPE) for elevator installation and commissioning

All installation work must follow local KONE unit safety rules. You must always have at least

the following personal protective equipment.

Use the following PPE at all times:

– Cut resistant gloves against sharp objects

– Working clothes

– High visibility vest

– Safety shoes with ankle protection

– Safety helmet

© 2017 KONE Corporation 14 (206) AM-12.20.017

All rights reserved (C) 2018-04-30

KONE Polaris™ Destination Control System

Installation Instruction

– Safety glasses (refer to local safety rules)

Use the following PPE as needed to protect against specific hazards:

– Safety goggles

– Protective gloves against chemical hazards, cold and heat (refer to local safety rules)

– Hearing protection

– Dust mask

– Fall restraint or arrest equipment

ASTM ANSI

CUT LEVEL

2 3 Installation

Safety & Method Passport

NAME

PHOTO

X0000085164

For more information on PPE, see AM-01.03.010 Elevator installation — safety manual.

X0000084781 B.4

3.5.3 Personal protection signs

Mandatory Sign Mandatory Sign

Head protection Overall

Dust mask Hearing protection

Safety shoes with ankle Safety gloves / Rubber

protection gloves

© 2017 KONE Corporation 15 (206) AM-12.20.017

All rights reserved (C) 2018-04-30

KONE Polaris™ Destination Control System

Installation Instruction

Mandatory Sign Mandatory Sign

Fall prevention equipment Safety goggles

Fall prevention measures High visibility clothing

3.5.4 Recommended working postures and ergonomic methods

These recommended working postures and ergonomic methods have been identified to

contribute a better workplace and your well-being.

Postures

Working height Working distance

X000008781 X000008782

Adjust height of working to enable your Adjust working distance to enable the object

hands to be within the vertical area of chest to be within length of forearms.

and belt buckle.

N O T E : If work is being carried out by kneeling, with bent back or legs or with hands elevated

above chest, or with object further than length of forearms, ensure to limit time of exposure

and alternate working postures. Ensure that the working area is unobstructed and not

hindering you. Wear knee pads as necessary to protect from knee cut or injury.

© 2017 KONE Corporation 16 (206) AM-12.20.017

All rights reserved (C) 2018-04-30

KONE Polaris™ Destination Control System

Installation Instruction

Small and lightweight objects

Lifting Carrying

X000008783 X000008784

Focus on the lift, even if the lifted object is

1. Keep the lifted object as close to the

light!

body as possible.

1. Go close to the lifted object.

2. Keep your back untwisted and

2. Use your legs.

straight.

3. Keep your back untwisted and straight.

4. Keep both feet on the same lane.

Large or heavy objects

Loading of transport cart Moving heavy objects without a handle

X000008785 X000008786

Slide the component onto the KONE If the object does not contain a handle,

transport cart instead of lifting it. push/slide the object instead of pulling.

WA R N I N G : Use wooden blocks to block the

cart wheels during loading and unloading.

© 2017 KONE Corporation 17 (206) AM-12.20.017

All rights reserved (C) 2018-04-30

KONE Polaris™ Destination Control System

Installation Instruction

3.6 Wa r n i n g s a n d c a u t i o n s

The words WARNING and CAUTION are used in different kinds of hazardous situations to

protect persons or equipment parts in the following way:

WA R N I N G : This is to warn for the most serious hazards where there is a risk to a personal

safety.

C A U T I O N : This is to warn for the risk of an equipment component being damaged, which

may also cause risk to a personal safety.

3.7 Wa r n i n g s i g n s

Sign Message Sign Message

Warning: Unguarded Warning: Slippery

sheave hazard floor

Warning: Automatic Warning: Fumes,

doors Smell, Particles

Warning: Overhead Warning: Mortal

crush hazard in danger

hoistway

Warning: Pit crush Warning: Danger of

hazard explosion

Warning: Danger of Warning: Danger of

falling objects explosion

General warning Warning: Limited

sign: Danger of height

crushing

Warning: No apron Warning: Danger of

on car. Danger of limb crushing

falling in the elevator

shaft.

Warning: Elevator Warning: Danger of

without car door. falling objects

Risk of being

crushed.

© 2017 KONE Corporation 18 (206) AM-12.20.017

All rights reserved (C) 2018-04-30

KONE Polaris™ Destination Control System

Installation Instruction

Sign Message Sign Message

Warning: Danger of Warning: Activated

falling automatically

Warning: Danger of Warning: Suspended

entrapment loads may fall

Warning: Danger of Warning: Danger of

foot crushing splashing (oil under

pressure)

Warning: Escalator Warning: Danger of

crush hazard magnetic field

General warning: Warning: Danger of

Caution, Danger, corrosion or skin

Risk irritation

Warning: Risk of Warning: Heavy

electric shock objects can fall

Warning: Tripping Warning:

hazard Electrostatic

discharge hazard

Warning: Moving Warning: Laser

parts beam

Warning: No nip Caution: Forklift

guards truck

Warning: Danger of Warning: Sharp

burning on hot element

surfaces

General advice to Warning: Clothing

lock and secure the caught in the rotating

relevant device equipment

Warning: Risk of fire Warning: Hand

caught in the rotating

equipment

Warning: Crushing Flying particles or

hazard objects. Risk of eye

or head injury.

Proper eye or face

protection required.

© 2017 KONE Corporation 19 (206) AM-12.20.017

All rights reserved (C) 2018-04-30

KONE Polaris™ Destination Control System

Installation Instruction

Sign Message Sign Message

Warning: Be careful Reduced visibility

in manual handling

of heavy weights

Warning: Danger of

vandalism

© 2017 KONE Corporation 20 (206) AM-12.20.017

All rights reserved (C) 2018-04-30

KONE Polaris™ Destination Control System

Installation Instruction

4 I N S TA L L AT I O N Q U A L I T Y A N D E F F I C I E N C Y

4.1 5S

5S process applies to all phases of the installation, from delivery, rigging & hoisting, assembly,

commissioning to handover. By applying its core elements of Sort, Stabilize, Shine,

Standardize, and Sustain, 5S process contributes significantly to the overall efficiency.

4.2 Customer experience

The focus of your work must always be customer satisfaction. To reach and exceed the

customers’ expectations, be polite, constructive and co-operative, and communicate clearly.

Remember that for customers, you represent KONE, so ensure that you handle or at least

communicate all customer requests and feedback to the correct persons.

For more information on how to deliver best-in-class customer experiences through behavior

and communication, see the KONE Ambassador program in KONE intranet (search for

Ambassador) or contact your supervisor.

© 2017 KONE Corporation 21 (206) AM-12.20.017

All rights reserved (C) 2018-04-30

KONE Polaris™ Destination Control System

Installation Instruction

5 S ITE RE Q UI RE M E N TS A ND TOO L S

5.1 Site requirements

– Shaft wiring installed according to the elevator level installation instructions and delivery

documents

– Cable routings and DCS component locations at landings verified with builder

– Layout drawings and delivery documents reviewed before the installation

– Machine room layout verified

– If the DCS has KSP 958 Touch DOPs, KONE LAN must be installed.

– If installing a pedestal-mounted touch screen DOP, install the floor installation bracket

before finishing of the final floor layer. If the final floor layer is done with a concrete cast or

similar method, protect the threaded bars of the floor installation bracket.

– If the DCS has KSP 858 Touch DOPs (LAN version), KONE People Flow Intelligence (PFI)

server must be installed.

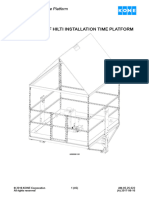

N O T E : This document describes the destination control system component level installation

and commissioning. The elevator platform level installation and commissioning are

documented in elevator platform level AM-documents.

X0000222583 A.3

Related information

– Install touch DOP (KSP 858, Pedestal mounted) (55)

– AM-13.20.023: KONE RemoteCall

© 2017 KONE Corporation 22 (206) AM-12.20.017

All rights reserved (C) 2018-04-30

KONE Polaris™ Destination Control System

Installation Instruction

5.2 To o l s

Table 1: KONE Polaris™ tools

Draw wire for routing cables through COP opening hook (675110H01), delivered

electrical conduits to landings (DOP located with COP

in the lobby)

X0000093753

Normal hand tools KSS configuration kit with laptop or

configuration switch (804250G10)

X0000060443

Torx (T20) for securing Touch DOP (KSP CF card reader

858) to mounting bracket

Level Impact wrench, 16 mm socket

X000011561

Tape measure Hammer-drill with suction fan (KM269093)

X000011555

X000079964

© 2017 KONE Corporation 23 (206) AM-12.20.017

All rights reserved (C) 2018-04-30

KONE Polaris™ Destination Control System

Installation Instruction

Table 1 KONE Polaris™ tools (continued)

File 8 mm drill bit

X0000056088

KSS configuration kit (829080) Reciprocating saw or hacksaw

X0000082536

Short UTP cable for installations with KGC Multimeter (CAT III compliant), Fluke 179 (or

cabinets equivalent) with insulated test probes (min. L

= 100 mm) specified to 1000 VDC voltage.

X000014440

Insulation resistance and earth continuity

meter with fault loop impedance

measurement capabilities, Metrel MI 3125

SMARTEC or equivalent, EN 61557

compliant device

X0000072685

N O T E : Required measurement capabilities:

Earth continuity, insulation resistance and

fault loop impedance

X000073665 A.6

© 2017 KONE Corporation 24 (206) AM-12.20.017

All rights reserved (C) 2018-04-30

KONE Polaris™ Destination Control System

Installation Instruction

6 I N S TA L L I N M A C H I N E R O O M

6.1 Machine room general arrangement

WA R N I N G : Ensure that the elevator main switches, segmented network main switches and

other machine room equipment are identified properly. Refer to elevator level AM for

markings.

Machine room rack cabinet:

Depending on delivery, UPS, KGC and LON adapter module can be located in a pre-

assembled machine room rack cabinet or delivered separately for wall installation.

1

2

A 3

B 4

C 5

D

X000073667

1. Main switch for segmented network 4. Control cabinet

2. Elevator main switch 5. Drive cabinet

3. KGC cabinets (KGC+UPS+LON) only with

KONE Polaris™ 800/900

X000073668 A.2

© 2017 KONE Corporation 25 (206) AM-12.20.017

All rights reserved (C) 2018-04-30

KONE Polaris™ Destination Control System

Installation Instruction

6.2 KONE Polaris™ 500 electrification

6.2.1 Power supply for segmented shaft network

The number of connected devices in one segment depends on the shaft configuration. The

general rules are:

– Maximum 4 lift group

– Maximum 16 floors

– Maximum 34 DOP / group

– 1 DOP location (DOP ID) / riser

– Maximum 4 pcs DOP / floor, 1 DOP / riser

– Maximum 4 pcs DOP / riser without segmented shaft power supply

– Maximum 4 pcs DOP / segment

Refer to delivery documents for the connections.

X0000222750 A.3

6.2.2 Group connections

KONE Polaris™ 500 DCS requires a duplicated group control network (LON), including:

– LCECPU561 board

– Two LCEGTWO boards

– 251 power supply

– Duplicated cables for LON

Refer to delivery documents for the connections.

X0000222775 A.5

Related information

– Network structure and device wiring (KONE Polaris™ 500) (184)

6.3 KONE Polaris™ 800/900 electrification

6.3.1 Power supply for segmented shaft network

The number of connected devices in one segment depends on the shaft configuration. Refer

to delivery documents for the connections.

X0000226898 A.2

6.3.2 Additional power supply for segmented shaft network

N O T E : If there are more than six segments in the elevator, an additional power supply is

needed for the segmented shaft network.

© 2017 KONE Corporation 26 (206) AM-12.20.017

All rights reserved (C) 2018-04-30

KONE Polaris™ Destination Control System

Installation Instruction

X000017269

1. Connect the supply cables for segmented shaft network to the control panel power

module (390).

Connect the additional supply cable to 15, N/15 and PE for segments 7 – 12.

N O T E : Segmented shaft network power supply cable lengths and diameters can be different.

See the delivery documents for more details.

X0000223169 A.5

6.3.3 Group connections

KONE Polaris™ 800/900 DCS requires a duplicated group control network (LON and CAN),

including:

– LCECPU561 board

– Two LCEGTWO boards

– Two KGCs

– UPS for each Group Computer

– Two LON adapter modules between the group control computers and the LCECPU561

board

– Duplicated cables for LON and CAN

X000017269

1. Route and connect the wiring for group connections.

If the delivery includes a machine room rack cabinet or KGC cabinet, the connections

inside the cabinet are prewired.

Refer to delivery documents for the connections.

X0000223170 A.4

Related information

– Network structure and device wiring (KONE Polaris™ 500) (184)

6.3.3.1 Install KGC

© 2017 KONE Corporation 27 (206) AM-12.20.017

All rights reserved (C) 2018-04-30

KONE Polaris™ Destination Control System

Installation Instruction

6m m

4x25m m

120mm

0 mm

25

X000022782

X0000223229 A.3

© 2017 KONE Corporation 28 (206) AM-12.20.017

All rights reserved (C) 2018-04-30

KONE Polaris™ Destination Control System

Installation Instruction

6.3.3.2 Wiring between KGC, LON adapter module and UPS

4 5 12 11

1 9 12 1 11

9

B A

3 2 3 2

KGC:2 KGC:1

10

10

3 3

2 2

8 6 7 13 8 6 7 13

UPS UPS

10 1 10 1

13 13

X000022783

© 2017 KONE Corporation 29 (206) AM-12.20.017

All rights reserved (C) 2018-04-30

KONE Polaris™ Destination Control System

Installation Instruction

Wire From To

1 UPS: L, N, PE LON adapter module A/B: L, N, PE

2 KGC: COM1 LON adapter module A/B: 732:1

3 KGC: COM2 LON adapter module A/B: 732:2

4 KGC:1, X1A LCECPU561 (375), XG4A on elevator X. Refer to

delivery documents.

5 KGC:1, X1B LCECPU561 (375), XG4A on elevator X. Refer to

delivery documents.

6 KGC:1, X2 KGC:2, X2

7 KGC:1, X1B KGC:2, X1B

8 KGC:1, X1A KGC:2, X1A

9 LON adapter module A, LON adapter module B, XG5

XG5

10 KGC: L, N, PE UPS: L, N, PE

11 LON adapter module A, LCEGTWO board (731:1): XG1B.

XG1:1 Refer to delivery documents.

12 LON adapter module A, LCEGTWO board (731:2): XG1B.

XG1:2 Refer to delivery documents.

13 UPS 230 VAC

N O T E : Both LON adapter modules and both KGC modules are identical.

X0000223230 A.5

6.3.3.3 Install KGC cabinets KM1346008G01 (master) and -G02 (backup)

© 2017 KONE Corporation 30 (206) AM-12.20.017

All rights reserved (C) 2018-04-30

KONE Polaris™ Destination Control System

Installation Instruction

430

550 mm

550

43

0m

m

X000022784

X0000223231 A.4

6.3.3.4 K G C c a b i n e t s c o n n e c t i o n t o p o w e r s u p p l y, e l e v a t o r c o n t r o l l e r a n d e a c h o t h e r s

X000017269

© 2017 KONE Corporation 31 (206) AM-12.20.017

All rights reserved (C) 2018-04-30

KONE Polaris™ Destination Control System

Installation Instruction

45 32

1 1346008G02 1 1346008G01

8 1 3 2

4 5

6 6

7 7

X000017740

Wire From To

1 1 phase power supply (10 KGC cabinet / L, N, PE

A)

2 LON network adapter LCEGTWO board (731:1): XG1B. Refer to delivery

module A, XG1:1 documents.

3 LON network adapter LCEGTWO board (731:2): XG1B. Refer to delivery

module A, XG1:2 documents.

4 KGC:1, X1A LCECPU561 (375), XG4A on elevator X. Refer to

delivery documents.

5 KGC:1, X1B LCECPU561 (375), XG4A on elevator X. Refer to

delivery documents.

6 KGC:1, X1B KGC:2, X1B

7 KGC:1, X1A KGC:2, X1A

8 LON network adapter LON network adapter module B, XG5

module A, XG5

Refer to related commissioning and safety inspection, AM-11.65.XXX, when measuring

measure between control cabinet PE terminal and KGC cabinet PE terminal.

© 2017 KONE Corporation 32 (206) AM-12.20.017

All rights reserved (C) 2018-04-30

KONE Polaris™ Destination Control System

Installation Instruction

LD FUNCTION

01 LIFT 1

02 LIFT 2

03 LIFT 3

04 LIFT 4

05 LIFT 5

06 LIFT 6

07 LIFT 7

08 LIFT 8

09 CALLS

10 M ON W S

11 WATCHDOG

12 M ASTER

13 ALLOCATION

14 ECONOM Y

15 TF

16 FAULT 1

O LED-TEST

O LED-INVERT

X000022785

N O T E : Both KGC cabinets are identical, except that the KGC modules must have different

node IDs. You can check the KGC node IDs by pressing the LED-TEST and LED-INVERT

buttons on the KGC simultaneously. The G01 and G02 KGC must switch on different LEDs

(LEDs 01 – 03) to indicate that their node IDs are different. If the node IDs are same, you can

change the node IDs with DIP switches.

– Power supply cables (1) are supplied locally.

– LON cables (2, 3) between KGC cabinets and elevator controller come with elevator

electrification delivery.

– CAN cables (4, 5) between KGC cabinets and elevator controller are delivered one with

each cabinet.

– Cables (6, 7, 8) between KGC cabinets are delivered with the backup cabinet.

X0000223232 A.6

Related information

– AM-13.20.016 KONE group control system KM1343771Gxx

6.4 Install DOP

6.4.1 Install surface mounted destination operation panel (KSP 955/KSP 957)

N O T E : Route all DOP cables such that the cables have approximately 200 mm slack for easy

installation.

© 2017 KONE Corporation 33 (206) AM-12.20.017

All rights reserved (C) 2018-04-30

KONE Polaris™ Destination Control System

Installation Instruction

1. Detach the DOP from the back plate.

X000073726

2. Fit the back plate to the wall.

Fill the hole around the cable with fire protection foam.

Usage of required PPE according to producer’s safety data sheet.

X000073727

3. Check the display settings.

© 2017 KONE Corporation 34 (206) AM-12.20.017

All rights reserved (C) 2018-04-30

KONE Polaris™ Destination Control System

Installation Instruction

4. Connect the cables to XS1 and XS2 on the DOPMUL board.

XS1

XS2

X000073728

1 2

XS1

XS1 XS1

XS2

X000022791

1. DOP at topmost floor

2. Latest DOP from the control panel

© 2017 KONE Corporation 35 (206) AM-12.20.017

All rights reserved (C) 2018-04-30

KONE Polaris™ Destination Control System

Installation Instruction

5. Attach the DOP to the claws on top of the back plate.

Snap the DOP in position and secure with screws.

X000022792

X000104197

X0000223234 A.5

Related information

– Cutout configurations (176)

– Settings and Adjustment (121)

6.4.2 Install surface mounted destination operation panel (KSP 833 / KSP 853)

© 2017 KONE Corporation 36 (206) AM-12.20.017

All rights reserved (C) 2018-04-30

KONE Polaris™ Destination Control System

Installation Instruction

N O T E : Route all DOP cables such that the cables have approximately 200 mm slack for easy

installation.

X000022794

1. Remove the plastic piece from the through hole using screw driver or knife.

X000022797

© 2017 KONE Corporation 37 (206) AM-12.20.017

All rights reserved (C) 2018-04-30

KONE Polaris™ Destination Control System

Installation Instruction

2. Drill hole for the cable (25 mm) to the wall, if needed.

1026

X0000228186

N O T E : Incase of NA, guide the grounding cable through cut-out of back plate.

3. Mark and drill fixing holes (6 mm) for the back plate.

Fix the back plate.

X000022799

© 2017 KONE Corporation 38 (206) AM-12.20.017

All rights reserved (C) 2018-04-30

KONE Polaris™ Destination Control System

Installation Instruction

4. Route and connect the cables.

Fill the hole around the cable with fire protection foam.

Usage of required PPE according to producer’s safety data sheet.

X000022800

© 2017 KONE Corporation 39 (206) AM-12.20.017

All rights reserved (C) 2018-04-30

KONE Polaris™ Destination Control System

Installation Instruction

5. Fix the front plate.

X000022801

X000022802

X0000223235 A.6

Related information

– Cutout configurations (176)

© 2017 KONE Corporation 40 (206) AM-12.20.017

All rights reserved (C) 2018-04-30

KONE Polaris™ Destination Control System

Installation Instruction

6.4.2.1 Install card reader (Optional)

1. Fix the card reader to the back plate using cable tie.

X0000228188

2. Route and connect the cables.

X0000223196 A.3

6.4.3 Install touch DOP (KSP 858, Surface mounted)

© 2017 KONE Corporation 41 (206) AM-12.20.017

All rights reserved (C) 2018-04-30

KONE Polaris™ Destination Control System

Installation Instruction

Figure 1: Delivery content (DOP weight = 4 kg, 4.6 kg with packet)

X000022804

Normal hand tool includes

– Torx (T20) for securing Touch DOP (KSP 858) to mounting bracket

– Spirit level (500 mm)

– Tape measure

© 2017 KONE Corporation 42 (206) AM-12.20.017

All rights reserved (C) 2018-04-30

KONE Polaris™ Destination Control System

Installation Instruction

1. Remove the mounting bracket from the DOP by opening the torx (T20) screws (*).

X000022805

*

N O T E : Store the screws (*). They are needed for fixing the DOP back to the mounting

bracket.

© 2017 KONE Corporation 43 (206) AM-12.20.017

All rights reserved (C) 2018-04-30

KONE Polaris™ Destination Control System

Installation Instruction

2. Mark the installation height (X = 944 mm) with spirit level.

X000022806

3. Mark all fixing holes on the wall using the mounting bracket.

X000022807

N O T E : Leave 70 mm free space (Y) around the mounting bracket. The DOP is wider

than the bracket.

© 2017 KONE Corporation 44 (206) AM-12.20.017

All rights reserved (C) 2018-04-30

KONE Polaris™ Destination Control System

Installation Instruction

4. Mark and remove the cable hole cover on the mounting bracket, which matches the

cable hole in the wall.

X000022808

5. Drill the fixing holes on the wall with 6 mm drill bit.

X000022809

6. Remove the protective film from the mounting bracket.

© 2017 KONE Corporation 45 (206) AM-12.20.017

All rights reserved (C) 2018-04-30

KONE Polaris™ Destination Control System

Installation Instruction

7. Fix the mounting bracket on the wall with torx (T20) screws (*).

X000022810

*

N O T E : Do not tighten the screws (*) fully.

8. Check the mounting bracket alignment with spirit level.

X000022811

Adjust it if needed.

© 2017 KONE Corporation 46 (206) AM-12.20.017

All rights reserved (C) 2018-04-30

KONE Polaris™ Destination Control System

Installation Instruction

9. Mark the riser ID on the mounting bracket sticker.

X0000186313

N O T E : The marking helps the maintenance persons to identify the respective elevator

that is connected to the DOP.

10. Make the strain relief for the cables.

m

m

0

20

X000022813

– Insert a cable tie to the mounting bracket strain relief hole.

– Route the cables through the cable tie.

– Tighten the cable tie such that the cables have approximately 200 mm slack for easy

DOP removal during maintenance.

© 2017 KONE Corporation 47 (206) AM-12.20.017

All rights reserved (C) 2018-04-30

KONE Polaris™ Destination Control System

Installation Instruction

11. Connect all the provided cables to the DOP.

The following cabling configurations are possible:

– LON only

– LAN only

– LON and LAN

– ACS reader cable (optional)

–

Connect the cables according to the markings on the cables and on DOP. The cabling

configuration is site-dependent. The ACS reader is optional and can be installed inside

the DOP later. If provided, push the ACS reader cable inside the DOP and leave it loose.

Leave enough slack for the ACS reader installation later on.

LON Connection (XS1, XS2)

XS2

XS1

X0000186310

1 2

XS1

XS1 XS1

XS2

X000022791

© 2017 KONE Corporation 48 (206) AM-12.20.017

All rights reserved (C) 2018-04-30

KONE Polaris™ Destination Control System

Installation Instruction

1. DOP at topmost floor

2. Latest DOP from the control panel

N O T E : XS1 cable powers the DOP. When you connect the cable XS1, the LAN socket

LEDs (A) flash once to indicate that the DOP is powered. The cable XS2 does not flash

the LAN socket LEDs. To avoid errors in DCS operation, ensure that the cable XS1 is

connected to the socket XS1.

To ensure that XS1 and XS2 are correctly connected (requires that the riser power is

on):

1. Connect the cable XS2 to socket XS2 and ensure that the LEDs in the LAN socket do

not flash.

If the LAN socket LEDs flash when connecting XS2, the XS2 marked cable is actually

the XS1 cable. In this case, connect the other LON cable to XS2.

2. Connect the cable XS1 to socket XS1 and ensure that the LEDs in the LAN socket

flash.

LAN Connection

LAN

X0000186311

ACS reader cable (Optional)

© 2017 KONE Corporation 49 (206) AM-12.20.017

All rights reserved (C) 2018-04-30

KONE Polaris™ Destination Control System

Installation Instruction

ACS

X0000186312

12. If a fire rated installation is needed, fill the hole in the wall around the cable with fire

protection foam.

Usage of required PPE according to producer’s safety data sheet.

13. Attach the DOP to the claws of the mounting bracket.

X0000186315

© 2017 KONE Corporation 50 (206) AM-12.20.017

All rights reserved (C) 2018-04-30

KONE Polaris™ Destination Control System

Installation Instruction

14. Recheck the DOP alignment with the spirit level.

Adjust the mounting bracket if needed.

15. Secure the DOP to the mounting bracket with torx (T20) screws (*).

X0000186308

16. If in the delivery, install the optional card reader inside the DOP.

© 2017 KONE Corporation 51 (206) AM-12.20.017

All rights reserved (C) 2018-04-30

KONE Polaris™ Destination Control System

Installation Instruction

17. Cover the DOP with the plastic bag to protect it from dust and damage until

commissioning.

X000022819

Before commissioning, remove the protection.

Before handover, also remove the protective film from the display.

18. Perform commissioning after all DCS devices are installed.

X0000223197 A.6

Related information

– Cutout configurations (176)

– Install ACS card reader (53)

– Commissioning (128)

© 2017 KONE Corporation 52 (206) AM-12.20.017

All rights reserved (C) 2018-04-30

KONE Polaris™ Destination Control System

Installation Instruction

6.4.3.1 Install ACS card reader

a)

c)

b)

A

X0000227655

N O T E : Ensure that the rubber caps (*) on the switches do not fall.

C A U T I O N : To avoid scratches to the backplate or damage to the opening mechanism, do not

bend and twist or use force with the screwdriver.

1. Connect the ACS reader cable to the DOP.

X0000186319

© 2017 KONE Corporation 53 (206) AM-12.20.017

All rights reserved (C) 2018-04-30

KONE Polaris™ Destination Control System

Installation Instruction

2. 1. Fix the plastic locking clips (B) of the ACS reader into the slots in the DOP.

2. Push the ACS reader in place such that the plastic locking clips (C) get locked into the

slot in the DOP.

N O T E : Clicking sound is heard while pushing the ACS reader.

1 2

X0000186320

© 2017 KONE Corporation 54 (206) AM-12.20.017

All rights reserved (C) 2018-04-30

KONE Polaris™ Destination Control System

Installation Instruction

3. Close the ACS cover.

X000022823

X0000223324 A.4

6.4.4 Install touch DOP (KSP 858, Pedestal mounted)

© 2017 KONE Corporation 55 (206) AM-12.20.017

All rights reserved (C) 2018-04-30

KONE Polaris™ Destination Control System

Installation Instruction

1 5

X000073703

1. KSP 858, pedestal mounted (front and back view)

2. Floor installation bracket

3. Fixing bag

4. Cover

5. LAN adapter for connecting DOP prewiring to floor wiring

6. Delivery box

N O T E : DOP weight = 22 kg with delivery box.

X0000223329 A.2

Related information

– Site requirements (22)

6.4.4.1 Cutting installation bracket bolts to FFL + 32 mm

The installation bracket bolts need to fit under the pedestal cover. As the finished floor level

(FFL) thickness varies per site, cut the bolts to FFL + 32 mm.

N O T E : Only unpack the installation bracket and the fixing bag. Keep the Touch DOP in the

delivery box to protect it from dust and damage.

© 2017 KONE Corporation 56 (206) AM-12.20.017

All rights reserved (C) 2018-04-30

KONE Polaris™ Destination Control System

Installation Instruction

1. Place the installation bracket on the unfinished floor level.

X000073704

2. Place the lower nuts (4 pcs) on the Finished Floor Level (FFL).

X000073705

3. Align the lower nuts with the 2 ft. level.

FFL

FFL

X000073706

© 2017 KONE Corporation 57 (206) AM-12.20.017

All rights reserved (C) 2018-04-30

KONE Polaris™ Destination Control System

Installation Instruction

4. Mark the dimension of FFL + 32 mm (max. FFL + 35 mm) on the threads with a

permanent marker.

32 mm

(1-1/4 in.)

32 mm

(1-1/4 in.)

X000073707

5. Remove the lower nuts.

X000073708

© 2017 KONE Corporation 58 (206) AM-12.20.017

All rights reserved (C) 2018-04-30

KONE Polaris™ Destination Control System

Installation Instruction

6. Cut the installation bracket bolts at the marked points.

X000073709

N O T E : Cut the bolts with a reciprocating saw or hacksaw to avoid hot work. Round off

the bolt ends with a file.

Round off the bolt ends with a file.

X0000223333 A.2

6.4.4.2 Install touch DOP

1. Mark the fixing holes (4 pcs) on the unfinished floor level with the floor installation

bracket.

X000073710

N O T E : Horizontal holes (1) must face towards DOP front side.

© 2017 KONE Corporation 59 (206) AM-12.20.017

All rights reserved (C) 2018-04-30

KONE Polaris™ Destination Control System

Installation Instruction

2. Drill the holes with 8 mm drill bit.

1089197.pdf

X000022937

3. Fix the bracket on the unfinished floor level with 10 mm bolts (4 pcs.).

1089198.pdf

X000022938

N O T E : To secure the fixing, use an impact wrench and the 10 mm bolts included in the

delivery.

© 2017 KONE Corporation 60 (206) AM-12.20.017

All rights reserved (C) 2018-04-30

KONE Polaris™ Destination Control System

Installation Instruction

4. Place the lower nuts (4 pcs) on the FFL.

X000073713

5. Check the alignment of lower nuts with the 2 ft. level.

FFL

FFL

X000073706

N O T E : Depending on the site, aim to install the touch DOP on the floor installation

bracket after the builder has completed the Finished Floor Level (FFL). Keep the touch

DOP safely inside the delivery box till the FFL is finished.

N O T E : If the FFL is done with the concrete cast or similar method, protect the threaded

bars of the floor installation bracket.

© 2017 KONE Corporation 61 (206) AM-12.20.017

All rights reserved (C) 2018-04-30

KONE Polaris™ Destination Control System

Installation Instruction

6. Place the touch DOP on the lower nuts.

X000073714

7. Install the upper nuts (4 pieces).

X000073715

© 2017 KONE Corporation 62 (206) AM-12.20.017

All rights reserved (C) 2018-04-30

KONE Polaris™ Destination Control System

Installation Instruction

8. Check the vertical alignment of touch DOP with the 2 ft. level and tighten all nuts.

FFL

1089203.pdf

X000022942

© 2017 KONE Corporation 63 (206) AM-12.20.017

All rights reserved (C) 2018-04-30

KONE Polaris™ Destination Control System

Installation Instruction

9. Connect the wiring.

X000073717

X000073718

© 2017 KONE Corporation 64 (206) AM-12.20.017

All rights reserved (C) 2018-04-30

KONE Polaris™ Destination Control System

Installation Instruction

X000073719

1. Route the wires through a hose.

2. Install the cable ties for strain relief.

3. Connect the cable:

– LON XS1, LON XS2

– LAN (optional)

10. Mark the riser ID on the bottom cover sticker (2).

X000073720

N O T E : The marking helps the maintenance persons to identify the respective elevator

that is connected to the DOP.

© 2017 KONE Corporation 65 (206) AM-12.20.017

All rights reserved (C) 2018-04-30

KONE Polaris™ Destination Control System

Installation Instruction

11. Install the cover with torx (T20) screws (2 pcs).

X000073721

12. Cover the touch DOP with the delivery box to protect it from dust and damage until

commissioning.

Cut and remove the other end of the box to slide it over the touch DOP.

13. Perform commissioning after all DCS devices are installed.

X0000223334 A.4

Related information

– Commissioning (128)

6.4.5 Install flush mounted destination operation panel (KSP 965 / KSP 967)

6.4.5.1 Install back box to concrete/brick wall

© 2017 KONE Corporation 66 (206) AM-12.20.017

All rights reserved (C) 2018-04-30

KONE Polaris™ Destination Control System

Installation Instruction

1. Install a 3/4 inch conduit box connector to the knockout in the back box. The conduit will

run from the back box to the hoistway duct.

X000022824

2. Fit the back box into the hole in the wall.

X000022825

© 2017 KONE Corporation 67 (206) AM-12.20.017

All rights reserved (C) 2018-04-30

KONE Polaris™ Destination Control System

Installation Instruction

3. Fasten the back box in the hole using the fixing screws inside the box.

Push the back box at least 2 mm inside the finished wall surface.

Ensure that the back box is correctly aligned.

Have the builder fill in the space around the back box.

Fill the hole around the flex conduit with fire caulking.

X000073722

The adjustment range of the face plate is 0 – 20 mm in depth and ± 3 mm in horizontal

direction.

© 2017 KONE Corporation 68 (206) AM-12.20.017

All rights reserved (C) 2018-04-30

KONE Polaris™ Destination Control System

Installation Instruction

X000073723

X0000223346 A.5

Related information

– Cutout configurations (176)

6.4.5.2 Adjust fixing brackets

1. Tension the fixing brackets slightly using the fixing screws.

© 2017 KONE Corporation 69 (206) AM-12.20.017

All rights reserved (C) 2018-04-30

KONE Polaris™ Destination Control System

Installation Instruction

2. Adjust the brackets to the finished wall level.

X000073724

3. Tighten the bracket fixing screws.

X000022829

© 2017 KONE Corporation 70 (206) AM-12.20.017

All rights reserved (C) 2018-04-30

KONE Polaris™ Destination Control System

Installation Instruction

4. Adjust the sideways and tighten the screws.

X000022830

X0000223349 A.3

6.4.5.3 Fix and connect flush mounted DOP

1. Check the display settings.

2. Connect the cables to XS1 and XS2 on the DOPMUL board at back of the DOP.

XS1

XS2

X000073725

© 2017 KONE Corporation 71 (206) AM-12.20.017

All rights reserved (C) 2018-04-30

KONE Polaris™ Destination Control System

Installation Instruction

3. Fit the DOP in place.

X000022832

X0000223305 A.4

Related information

– Settings and Adjustment (121)

6.4.6 Install pedestal DOP

© 2017 KONE Corporation 72 (206) AM-12.20.017

All rights reserved (C) 2018-04-30

KONE Polaris™ Destination Control System

Installation Instruction

X000022833

© 2017 KONE Corporation 73 (206) AM-12.20.017

All rights reserved (C) 2018-04-30

KONE Polaris™ Destination Control System

Installation Instruction

1. Ensure that the destination operation panel wiring is installed from the elevator shaft to

the stand.

N O T E : The cable must measure 59 in. (1.5 meters) from the floor level.

X000022834

2. Fix the pedestal base to the floor:

1. Mark the places of the fixing anchors to the floor.

2. Remove the pedestal base and drill holes for the fixing anchors.

3. Attach the fixing anchors.

4. Fit the pedestal base in place and secure with bolts.

Expander bolts 4 x M8 are delivered with the pedestal base.

N O T E : Mark the pedestal with warning tape if the installation is interrupted at this stage.

© 2017 KONE Corporation 74 (206) AM-12.20.017

All rights reserved (C) 2018-04-30

KONE Polaris™ Destination Control System

Installation Instruction

3. Fix the pedestal back frame to the base. Adjust the back frame according to the finished

floor surface.

X000022835

Route the wires through the frame.

4. Fix the pedestal front frame in place.

X000022836

5. Check the display settings.

6. Connect the cables to XS1 and XS2 on the DOPMUL board of the unit.

© 2017 KONE Corporation 75 (206) AM-12.20.017

All rights reserved (C) 2018-04-30

KONE Polaris™ Destination Control System

Installation Instruction

7. Fix the DOP in place.

X000022838

Slide the plate at the bottom of the DOP inside the pedestal and attach the DOP to the

claws at the top of the pedestal.

Secure with screws.

XS1

XS2

X000022837

X0000223350 A.3

Related information

– Cutout configurations (176)

– Settings and Adjustment (121)

6.4.7 Install touch DOP (KSP 958)

© 2017 KONE Corporation 76 (206) AM-12.20.017

All rights reserved (C) 2018-04-30

KONE Polaris™ Destination Control System

Installation Instruction

1

X000022839

1. Touch DOP

2. Memory card

3. Power 100 – 240 VAC / 12 VDC + cable

Figure 2: Touch DOP delivery

N O T E : Handle LAN Cat cables with extreme care:

– Never bend them beyond the radius of:

• 50 mm (when handling during installation)

• 30 mm (static installed state)

– Do not pull, twist or crush them. Always use hand winding if cable is on reel. The maximum

pull-out force is only 90 Nm (approximately 10 kg).

X000021463