Professional Documents

Culture Documents

Hse 0008 Aapp K

Hse 0008 Aapp K

Uploaded by

Sugeng RiyadiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hse 0008 Aapp K

Hse 0008 Aapp K

Uploaded by

Sugeng RiyadiCopyright:

Available Formats

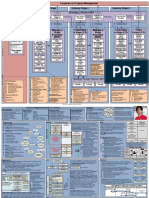

Permit to Work System - Offshore Operations (SWAS Process Improvement Effort) SEPCo - HSE0008A - Appendix K

Permit to Work System Process Maps

Any work to be performed at an SOI Developing Assets location follows the Permit to Work Process. Depending upon the

size and complexity of the job, various levels of permitting, planning, approval and documentation are required. The high-

level process on this page describes the overall process of job planning and execution. Each subsequent page describes in

more detail the sub-processes. These process maps were prepared by the team that developed the Permit to Work document

and are included as an extra tool to be used for PTW System implementation and training.

Job Definition Pre-Job Approval Initiate Work Execute Work Closeout

Planning Work

Approved: February 10, 2000 - (Rev. 1.0) Page 1 of 10

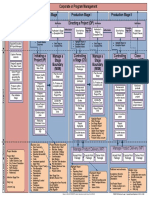

Permit to Work System - Offshore Operations (SWAS Process Improvement Effort) SEPCo - HSE0008A - Appendix K

Job Definition Phase

waiver

Allowable Safe Work Plan

Identify job task to Y Safe Work Plan Process

in Required?

Y

(Sec. 2.0)

be performed SIMOPS? (Sec. 2.2)

(Sec. 4.0)

N

Determine if lockout/

tagout (Sec. 5.2) or

N

confined space entry

(Sec. 6.0) is needed

Safe Work Permit (Sec. 3.0) Safe Work

Y

and preliminary JSA Permit

(Attachment L) reviewed by Required?

PIC (Sec. 3.3)

Conduct Work per Start-Up Start-up Permit

Standard Procedure or Permit Y

JSA or PIC's Needed?

Process

(Attachment L/M) (Sec. 7.3) (Sec. 7.0)

N

Inspect work area

and close out

permit

Approved: February 10, 2000 - (Rev. 1.0) Page 2 of 10

Permit to Work System - Offshore Operations (SWAS Process Improvement Effort) SEPCo - HSE0008A - Appendix K

Safe Work Plan Process

Pre-Job Planning Approval Initiate Work Execute Work Closeout Work

1. Review Applicable HSE 1. Conduct Preliminary 1. Put HSE Controls in 1. Maintain HSE Controls 1. Remove HSE Controls

Guidance as needed Walkdowns with Opns Place:

Team Leaders, OIM, - site access

Construction Focal Point – LO/TO

and Contractor Leads – Confined Space

– Permit Posting

- Other

2. Conduct Planning 2. Review all permits and 2. Establish 2. If work must be stopped 2. Closeout Permits

meetings with site plans for completeness. Communications before completed, make

management, (LO/TO, Confined Space the work site safe,

contractors, and other Entry attached if needed) closeout permits and

involved parties repermit to complete.

3. Conduct POB planning 3. Brief platform staff on 3. Conduct Tailgate safety 3. When shift and crew 3. Critique the job and

considering all ongoing work activities. meeting changes occur follow the provide feedback to

activities requirements for permit

renewal.

4. Assure all personnel 4. Validate readiness of 4. Final walkdown 4. If scope change occurs, 4. Initiate Startup Plan

have adequate training. Shell staff. initiate MOC and return

to Job Definition

5. Conduct job-specific 5. Validate readiness of 5. 5. Conduct daily 5.

orientation/training for Contract staff. communications and

contract and Shell staff permitting process

6. Review SIMOPs 6. Receive final approval 6. 6. 6.

Requirements from site coordinating

committee, construction

supvsr and Asset Leader.

7. Prepare Documentation: 7. Verify POB 7. 7. 7.

- Safe Work Plan

- Applicable Permits

– Communications Plan

– Start-up Plan

8. Inform Platform Staff of 8. 8. 8. 8.

upcoming work

Approved: February 10, 2000 - (Rev. 1.0) Page 3 of 10

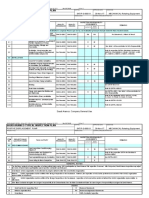

Permit to Work System - Offshore Operations (SWAS Process Improvement Effort) SEPCo - HSE0008A - Appendix K

9. Obtain Regulatory 9. 9. 9. 9.

Approvals

Approved: February 10, 2000 - (Rev. 1.0) Page 4 of 10

Permit to Work System - Offshore Operations (SWAS Process Improvement Effort) SEPCo - HSE0008A - Appendix K

Safe Work Permit Process

Pre-Job Planning Approval Initiate Work Execute Work Closeout Work

1. Employee/Contractor 1. Originator and/or Sponsor 1. Conduct a pre-job safety 1. Do the work. Contractor 1. Finish Work and Assure

group recognizes a non- brings Safe Work Permit meeting and for more supervisor or other work the work area is returned

routine job (See list Sec. to Coordinating complex jobs, the entire supervisor is responsible to it’s original condition.

3.3) that will require a Committee Meeting group walks through the for assuring permit Originator performs final

permit to be done. job prior to beginning requirements are met. work site inspection.

work.

2. Responsible team is 2. Presents the Safe Work 2. If applicable, LO/TO 2. Perform a walk through 2. Sign and date the

contacted and a job Permit to the committee equipment per the and Behavior Based completed section of the

sponsor is assigned. for review and approval. LO/TO process. observation as work is safe work permit.

OIM or Sponsor reads the done. In the event of an

permit to the committee accident, the work permit

and asks for comments, must be completed in the

changes, agreement incident documentation

section and closed and

turned into the control

room

3. Permit Originator 3. Committee screens for 3. Assure that all corrections 3. Sponsor and/or OIM/PIC 3. Turn the completed permit

develops a pre-job safety conflicting work using noted on PICS/JSA and periodically monitor site into the control room for

plan for the work (PICS or SIMOPs matrix. worst events on the safe to assure HSE measures records and remove copy

JSA) work permit are are implemented. from control room board.

addressed.

4. Originator fills out a safe 4. Comments discussed, 4. .Sponsor confirms that all 4. At shift changes, the 4. If a LO/TO accompanies a

work permit. changes made, agreement involved personnel are permit must be renewed safe work permit and

- Describes the job to be by all, each team leader familiar with permit and or reissued. LO/TO has been removed,

done. signs concurring that the job requirements and have remove LO/TO from

- Denotes time and day work can be done, and received Orientation 5. When OIM/PIC crew board and file.

work will begin. then the OIM signs off training. changes occur, the new

- Recognizes the worst giving approval for work OIM/PIC must review all

events associated with the to begin. permitted jobs and sign to

job. indicate concurrence with

- Develops and documents ongoing work.

preventive measures for

the worst events..

- Develops a lock-out tag-

out form if needed.

Approved: February 10, 2000 - (Rev. 1.0) Page 5 of 10

Permit to Work System - Offshore Operations (SWAS Process Improvement Effort) SEPCo - HSE0008A - Appendix K

Safe Work Permit Process (continued)

Pre-Job Planning Approval Initiate Work Execute Work Closeout Work

5. Originator walks through 5. A copy of the permit is Team Leader / Opns

the job site with sponsor, made and hung on a supervisor or Sponsor

work is described, permit board in the control room conducts safety inspection

is discussed, sponsor for communication to all. prior to starting work

agrees/disagrees (if Original is maintained by

disagrees, corrections the person that does the

made), and sponsor signs work.

off that work can be

permitted.

6. Originator provides the 6. In the event of an

safe work permit, LO/TO incident, develop a new

form, and PICS to safe work permit, walk it

Sponsor for presentation to each team leader for

at the Coord. Comm. signature, and obtain

Mtg. Each day at 5 PM. OIM approval

7. If hot work is involved 8. Work permits can be

follow special “Hot extended for three (3)

Work Permit” days if all requirements

requirements Sec. 3.6. for renewal are met. If

Coord. comm. members

all agree, all team leaders

sign and the OIM signs

for approval.

Approved: February 10, 2000 - (Rev. 1.0) Page 6 of 10

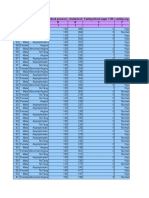

Permit to Work System - Offshore Operations (SWAS Process Improvement Effort) SEPCo - HSE0008A - Appendix K

LockOut / TagOut Process

Pre-Job Planning Approval Initiate Work Execute Work Closeout Work

1. Identify Energy or 1. OIM, TL, review larger 1. LO/TO completed, all 1. All involved review 1. Designated Authorized

hazard type (electrical, jobs requiring Safe Work involved initial, LO/TO insures stored Person or Alternate

hydraulic, gas, etc) Permit/Plan Authorized Person Signs energy released or notifies all involved

@ job site. blocked individuals working on

job reach agreement on

completion

2. Individual or Team 2. Designated Authorized 2. 3 Carbon Copy form 2. Completes work 2. LO/TO removed by

sponsored depending on Person or Alternate utilized, Authorized activities Designated Authorized

job complexity or size insure job is safe Person post Copy Central Person only

Posting area & Control

Room, retains original @

job site

3. Complex or Large jobs 3. All Craft and or Crafts 3. Craft Lock or locks used 3. 3. Closeout and file per

requiring Safe Work required to initial when multiple crafts local procedures (meet

Permits/Plans with condition verification @ working on job, different Shell retention

LO/TO require OIM, TL job site crafts are not keyed same requirements)

involvement (Confined

Space Entry)

4. Locks &Tags required 4. Designated Authorized 4. Individual personal locks 4. 4. Job Task LO/TO not

Craft locks required for Person Communicates to used for jobs performed complete remain on

more than one craft effected work groups and by fewer people of same boards

involvement, color coded area owners craft

5. I.D. resources, drawings, 5. 5. Process Control Locks, 5. 5. If LO/TO active when

manuals, subject experts used for critical process Designated Authorized

controls (relief valve Person leaves TLP

locked open) Alternate is assigned

6. Designated Authorized 6. 6. Only platform operating 6. 6. If LO/TO to remain for

Person (job leader) personnel can reposition extended period an

completes form, ID if process valves / explanation must be

Safe Work Permit/Plan equipment settings. written on posted copies

needed

7. Alternate Authorized 7. 7. Test to get positive 7. 7.

Person assigned if shift assurance that energy

or crew change source is isolated

Approved: February 10, 2000 - (Rev. 1.0) Page 7 of 10

Permit to Work System - Offshore Operations (SWAS Process Improvement Effort) SEPCo - HSE0008A - Appendix K

Confined Space Entry Process

Pre-Job Planning Approval Initiate Work Execute Work Closeout Work

1. All other practical 1. Safe work plan 1. PIC of work site ensure 1. support team stand-by 1. Entry supervisor

alternatives to confined approved? conditions of permit are 2. maintain log performs post entry

space entry considered Safe work permit met and maintained. 3. maintain contact review of procedure and

approved? Maintain a copy of the maintain communication problems encountered

Confined Space Entry permit at the work site. with Control Room

Permit approved

Confined Space Entry

Check List approved

2. Training provided. . . 2. Plan to address H2S 2. Support Team – Establish 4. Support Team – protect 2. Entry supervisor files a

Initial and annual approval if needed log of entries, establish air supply. record of the CSE

refresher & records signals.

available

3. Supervisory Experience 3. Verify qualified and 3. Complete Pre-Entry 5. Support Team monitors 3. Maintain a complete set

and overall work authorized supervision is preparations: work space on a regular of CSE records and any

experience considered in provided - isolate the space basis and after every associated incidents.

assigning “Competent (LO/TO) break or work stoppage.

Person” to supervise – Clean and ventilate

entry. – Test and monitor

– Assemble reqd equip.

– Establish access/egress

4. Entry Supervisor – insure 4. Competent person – 6. Support team is always 4. Ensure that inspection

proper documentation atmosphere tested just ready with rescue and maintenance results

including approved Safe prior to entry, recorded on equipment and plan. are documented.

Work Plan and Permit entry permit and a second

record kept of all results.

Certified “gas free”

5. Entry supervisor verify 5. All hazards safeguarded 7. OIM / PIC postpone all 5. Consider need for a Start

contractor personnel are against. drills and any interfering Up Permit

familiar with Shell’s work while CSE is being

policy and qualified. performed.

Approved: February 10, 2000 - (Rev. 1.0) Page 8 of 10

Permit to Work System - Offshore Operations (SWAS Process Improvement Effort) SEPCo - HSE0008A - Appendix K

Confined Space Entry Process (continued)

Pre-Job Planning Approval Initiate Work Execute Work Closeout Work

6. ID Support Team 8. In the event of a

members and include in temporary work

the CSE safe work plan. stoppage, take

precautions to prevent

unauthorized entry.

7. Complete CSE Checklist.

Analyze all hazards,

check MSDS sheets.

Contact HS&E if

conditions of entry

uncertain.

8. Leadership team and

CSE entry team assure

job-specific safeguards

are determined and

established.

Approved: February 10, 2000 - (Rev. 1.0) Page 9 of 10

Permit to Work System - Offshore Operations (SWAS Process Improvement Effort) SEPCo - HSE0008A - Appendix K

Start-up Permit Process

Pre-Job Planning Approval Initiate Work Execute Work Closeout Work

1. ID a need to start-up 1. Team Leader / Opns 1. Team Leader / Opns 1. Originator places permit 1. Originator closes permit

Large Complex Supvr - Inspect Supvr – check equipment on activity board with

equipment equipment condition for and condition the appropriate work

start-up permit

2. ID a need for special 2. OIM/PIC - Approve SU 2. Tail gate meeting to 2. Copy provided to the 2. Safe work permit not

procedures for start-up permit discuss specific control room or central closed until start-up

procedures and posting area. permit is complete

precautions

3. ID where 2 or more 3. Do the work

contractors are involved

in a start-up of

equipment

4. Originator – can be any

employee that is in

charge of the equipment

5. OIM / PIC or Team

Leader / Opns Supvr is

responsible to determine

if SU permit is necessary

6. Check SIMOPs Matrix,

Determine Influences on

other systems

7. Originator meets with

contractor or other

affected personnel

8. Inspect / review work

site and equipment

9. Check outstanding

permits. Hot work not

permited during start up

without OIM/PIC

approval.

Approved: February 10, 2000 - (Rev. 1.0) Page 10 of 10

You might also like

- q11017 0100d Lps Sta Pk2 Qms Itp 00003 c2 MV LV, MCC, SMDB & VFD PanelDocument4 pagesq11017 0100d Lps Sta Pk2 Qms Itp 00003 c2 MV LV, MCC, SMDB & VFD PanelKarthick Natrajan0% (1)

- 4 IP-OPS-014 Gas Operations Permit To Work SystemDocument38 pages4 IP-OPS-014 Gas Operations Permit To Work SystemNagarajNo ratings yet

- DESCON HSE Report FormatDocument66 pagesDESCON HSE Report FormatMustafa Ricky Pramana Se100% (1)

- MOV Calc. Samples.Document53 pagesMOV Calc. Samples.Shiju Kp.No ratings yet

- Manage Product Delivery (MP) Manage Product Delivery (MP) : & Benefit Review PlanDocument2 pagesManage Product Delivery (MP) Manage Product Delivery (MP) : & Benefit Review PlanAnonymous SmYjg7gNo ratings yet

- JSA Building WorksDocument9 pagesJSA Building WorksMon Trang Nguyễn100% (1)

- Inter-Departmental Procedure - Mesaieed Operations Permit To Work System IP-OPS-014 Pageiofiv Document Change HistoryDocument53 pagesInter-Departmental Procedure - Mesaieed Operations Permit To Work System IP-OPS-014 Pageiofiv Document Change HistorygetrajaNo ratings yet

- HSE Report FromatDocument66 pagesHSE Report Fromatabdulfro100% (1)

- DESCON HSE Report FromatDocument64 pagesDESCON HSE Report FromatCesar ReyesNo ratings yet

- TWJO-ITP-PRC-0005 Reva2 ITP For PC BoxCul in LBDPTDocument6 pagesTWJO-ITP-PRC-0005 Reva2 ITP For PC BoxCul in LBDPTBangkit SamosirNo ratings yet

- DESCON HSE Report FromatDocument66 pagesDESCON HSE Report FromatMarvin BerrensteinNo ratings yet

- HSE Report Fromat369852Document65 pagesHSE Report Fromat369852Mohammed Amer PashaNo ratings yet

- Answers To Comments of ITP-0004 Rev.03Document1 pageAnswers To Comments of ITP-0004 Rev.03yangshileiNo ratings yet

- L2 Risk Assessment Leakage HVAC Ducting Rectification - PlanDocument5 pagesL2 Risk Assessment Leakage HVAC Ducting Rectification - PlanHaris Risdiana100% (2)

- Permit To Work Procedure: TitleDocument31 pagesPermit To Work Procedure: TitleWale OyeludeNo ratings yet

- TESDA-OP-IAS-02-F05 Action Catalogue (For ACs) - OLARTE (SMAW NCI)Document18 pagesTESDA-OP-IAS-02-F05 Action Catalogue (For ACs) - OLARTE (SMAW NCI)Mark Anthony Arenas GioketoNo ratings yet

- Insulation WorksDocument8 pagesInsulation WorksBangkit SamosirNo ratings yet

- Itp Transfer Tower - Xls (Bvi Comment)Document52 pagesItp Transfer Tower - Xls (Bvi Comment)Alif Rahmat FebriantoNo ratings yet

- Mohamad FadliDocument6 pagesMohamad Fadlishamierrul shahliNo ratings yet

- Manage Product Delivery (MP) Manage Product Delivery (MP) : Project MandateDocument3 pagesManage Product Delivery (MP) Manage Product Delivery (MP) : Project Mandate007 009No ratings yet

- Daily HSE Report01Document69 pagesDaily HSE Report01jap marcellenNo ratings yet

- 04 IP-OPS-014 - Permit To Work SystemDocument53 pages04 IP-OPS-014 - Permit To Work SystemAlfred JohnNo ratings yet

- QB0025-F-MST-CIV-030-0016 - Block Works - R0Document31 pagesQB0025-F-MST-CIV-030-0016 - Block Works - R0moin uddinNo ratings yet

- TWJO-ITP-GEN-0009 Reva0 ITP For Precast Box Culvert in L B Depot AreaDocument5 pagesTWJO-ITP-GEN-0009 Reva0 ITP For Precast Box Culvert in L B Depot AreaBangkit SamosirNo ratings yet

- ADP-220533-006 R2 Gully,Roof Trench,Snow Melting. System (a)Document26 pagesADP-220533-006 R2 Gully,Roof Trench,Snow Melting. System (a)saithu09janNo ratings yet

- MOP ATM Hydra site Data Center NetEco restart to active adapter softwar...Document3 pagesMOP ATM Hydra site Data Center NetEco restart to active adapter softwar...bilel oukilNo ratings yet

- Hazard Identification (Hazid) : XXX ProjectDocument15 pagesHazard Identification (Hazid) : XXX ProjectariesyihaNo ratings yet

- Factory Acceptance Test Procedure For DCS - Page 1Document2 pagesFactory Acceptance Test Procedure For DCS - Page 1kapsarcNo ratings yet

- PTW Procedure (Rev.01)Document20 pagesPTW Procedure (Rev.01)waheedNo ratings yet

- Receiving Inspection ProcedureDocument12 pagesReceiving Inspection ProcedureDindo QuintanNo ratings yet

- Permit To Work - Lifting OperationsDocument2 pagesPermit To Work - Lifting OperationsAadarshNo ratings yet

- DVFA Scorecard For German Corporate GovernanceDocument7 pagesDVFA Scorecard For German Corporate GovernanceVinayNo ratings yet

- PETA-7.6 Step DescriptionDocument41 pagesPETA-7.6 Step DescriptionNack Abd RauofNo ratings yet

- Class 1 Minor Work Standard ProcedureDocument2 pagesClass 1 Minor Work Standard ProcedureWong WesleykitNo ratings yet

- ZCR 19372 v0.4Document10 pagesZCR 19372 v0.4John LeungNo ratings yet

- Control System Integration Project: CONTRACT NO.: EDC 13-228/GC113-036Document7 pagesControl System Integration Project: CONTRACT NO.: EDC 13-228/GC113-036Jayson Escamillan100% (1)

- SP 07 Sop Customer PropertyDocument13 pagesSP 07 Sop Customer PropertyLoemban S Jody100% (1)

- JSA-014 Comments Action FormDocument1 pageJSA-014 Comments Action FormHaleemUrRashidBangashNo ratings yet

- MS For EPPI New Land, Construction of New Bus Terminal - Mechanical Work - Rev.01-MinDocument59 pagesMS For EPPI New Land, Construction of New Bus Terminal - Mechanical Work - Rev.01-MinToasted MamonNo ratings yet

- Work at HeightDocument22 pagesWork at HeightSayed Darwish75% (4)

- Satip D 001 01Document11 pagesSatip D 001 01Rijwan Mohammad0% (1)

- Moc Procedure Flow ChartDocument8 pagesMoc Procedure Flow Chartadewunmi olufemiNo ratings yet

- Nonconformance Control ProcedureDocument16 pagesNonconformance Control ProcedureDindo QuintanNo ratings yet

- Procedure For Permit To Work - Dukhan FieldsDocument60 pagesProcedure For Permit To Work - Dukhan FieldsGokul QC100% (1)

- GT-1065 - Disconnection and Removal, #2 Bearing Area Probes and TCPLsDocument14 pagesGT-1065 - Disconnection and Removal, #2 Bearing Area Probes and TCPLsMadih ElghannamNo ratings yet

- GEN 2 SWP ManualDocument95 pagesGEN 2 SWP Manualcarlos Nascimento RicoNo ratings yet

- Skid Mounted Unit InstallationDocument2 pagesSkid Mounted Unit Installationric leonisoNo ratings yet

- PTWS Process Flow1Document1 pagePTWS Process Flow1Denis JacutinNo ratings yet

- Confined Space Emergency Rescue Plan: Document No - RevDocument17 pagesConfined Space Emergency Rescue Plan: Document No - RevIdris AdeniranNo ratings yet

- Punch List ProcedureDocument18 pagesPunch List ProcedureAnu Jose50% (2)

- QT2109958 - ITP For 1T-1201 Buffer Water Tank Itp PDFDocument3 pagesQT2109958 - ITP For 1T-1201 Buffer Water Tank Itp PDFGanesh EswaranNo ratings yet

- SL-S008 Environment: Completed QuestionsDocument5 pagesSL-S008 Environment: Completed QuestionsfdolarosaNo ratings yet

- Confined Space Entry ProcedureDocument37 pagesConfined Space Entry ProcedureJamal Shah100% (1)

- Satip G 006 0122Document10 pagesSatip G 006 0122Rijwan MohammadNo ratings yet

- Do - 070 - S 2017 DOTS For InfraDocument87 pagesDo - 070 - S 2017 DOTS For InfrarubydelacruzNo ratings yet

- GT-1033-Speed Pickups & #1 Bearing Seismic Probes, Disconnection and RemovalDocument11 pagesGT-1033-Speed Pickups & #1 Bearing Seismic Probes, Disconnection and RemovalMadih Elghannam100% (1)

- GroutingDocument1 pageGroutingAlif Rahmat FebriantoNo ratings yet

- Managing Software Deliverables: A Software Development Management MethodologyFrom EverandManaging Software Deliverables: A Software Development Management MethodologyNo ratings yet

- Distributed Process Control ReportFrom EverandDistributed Process Control ReportNo ratings yet

- CSC248 Test Prep 7Document4 pagesCSC248 Test Prep 7Josh OscarNo ratings yet

- Lenmed Health BrochureDocument7 pagesLenmed Health Brochuremaputohospital100% (13)

- Final Minutes 320 RBDocument1,866 pagesFinal Minutes 320 RByasserNo ratings yet

- The Ego and Analysis of Defense-Jason Aronson, Inc. (2005) Paul GrayDocument356 pagesThe Ego and Analysis of Defense-Jason Aronson, Inc. (2005) Paul GrayClinica MonserratNo ratings yet

- ACE Personal Trainer Practice Exam Kit - 2018Document447 pagesACE Personal Trainer Practice Exam Kit - 2018vishal pundir92% (13)

- Health Dissertation TopicsDocument6 pagesHealth Dissertation TopicsUK100% (1)

- Beta Alanine Supplementation PresentationDocument11 pagesBeta Alanine Supplementation Presentationapi-576308167No ratings yet

- Domestic CUSA UG (945102217ILS-B)Document181 pagesDomestic CUSA UG (945102217ILS-B)Luis SiviraNo ratings yet

- The Effects of Jealousy and Favoritism in AcademicDocument8 pagesThe Effects of Jealousy and Favoritism in AcademicRosebel RedubladoNo ratings yet

- Integumentary SystemDocument61 pagesIntegumentary SystemNicole EncinaresNo ratings yet

- Workplace Resilience Scale Winwood2013 PDFDocument8 pagesWorkplace Resilience Scale Winwood2013 PDFAmy BCNo ratings yet

- Method Statement For Installation of CCTV Camera System: Join For Latest ArticlesDocument1 pageMethod Statement For Installation of CCTV Camera System: Join For Latest Articleshaytham65No ratings yet

- Periodontal PocketsDocument51 pagesPeriodontal PocketsShawqi ANo ratings yet

- 7 Tips To Reduce Risk of CancerDocument2 pages7 Tips To Reduce Risk of Cancerjubilla mondanoNo ratings yet

- Heitz-Mayfield Iti TG 13 en LeseprobeDocument44 pagesHeitz-Mayfield Iti TG 13 en LeseprobeS. BenzaquenNo ratings yet

- The 7 Biggest Mistakes Made by Singers..Document17 pagesThe 7 Biggest Mistakes Made by Singers..César De La Cruz OlivaNo ratings yet

- Media and Information Literacy The Influence of Media and Information To Communication Learning Activity Sheet No. 1Document41 pagesMedia and Information Literacy The Influence of Media and Information To Communication Learning Activity Sheet No. 1amaya dxeuNo ratings yet

- A Regional Approach To Foot and Ankle MRIDocument17 pagesA Regional Approach To Foot and Ankle MRInior100% (1)

- Over Not Out: The Housing and Homelessness Issues Specifc To Lesbian, Gay, Bisexual and Transgender Asylum SeekersDocument28 pagesOver Not Out: The Housing and Homelessness Issues Specifc To Lesbian, Gay, Bisexual and Transgender Asylum SeekersLGBT Asylum NewsNo ratings yet

- Martha Alemayehus Resume LeadersipDocument3 pagesMartha Alemayehus Resume Leadersipapi-316750582No ratings yet

- Good Health - Pre Auth FormDocument4 pagesGood Health - Pre Auth FormBOOKREADER_NOWNo ratings yet

- Intranasal Breast Milk For Premature Infants With Severe Intraventricular Hemorrhage-An ObservationDocument8 pagesIntranasal Breast Milk For Premature Infants With Severe Intraventricular Hemorrhage-An ObservationLuis GuioNo ratings yet

- Prevention of Disease & Health PromotionDocument2 pagesPrevention of Disease & Health PromotionGhith WhiuNo ratings yet

- 2023 BDRRMC EoDocument5 pages2023 BDRRMC EoAnilyn CelisNo ratings yet

- Age Sex Chest Pain Type Blood Pressure Cholesterol Fasting Blood Sugar 120 Resting Ecg R C C R R C C I I I I I I IDocument14 pagesAge Sex Chest Pain Type Blood Pressure Cholesterol Fasting Blood Sugar 120 Resting Ecg R C C R R C C I I I I I I Isantu4_1111No ratings yet

- Republic of The Philippines Province of North Cotabato City of Kidapawan Barangay SingaoDocument2 pagesRepublic of The Philippines Province of North Cotabato City of Kidapawan Barangay SingaoIvy PacateNo ratings yet

- Microbes in Ferment@3Document13 pagesMicrobes in Ferment@3T Vinit ReddyNo ratings yet

- Bi Support Groups1Document6 pagesBi Support Groups1api-301357752No ratings yet

- APA-Ethical Principles of Psychologists and Code of ConductDocument27 pagesAPA-Ethical Principles of Psychologists and Code of ConductJoshua MendezNo ratings yet

- Hope 1Document3 pagesHope 1Novy MoranNo ratings yet